Delayed coking device and counterflow steam pressure testing method for coke tower

A technology of delayed coking and coke tower, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc. It can solve problems such as easy water hammer, large steam consumption, and small temperature rise of coke tower, so as to achieve reduced operation and avoid Aggregation, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

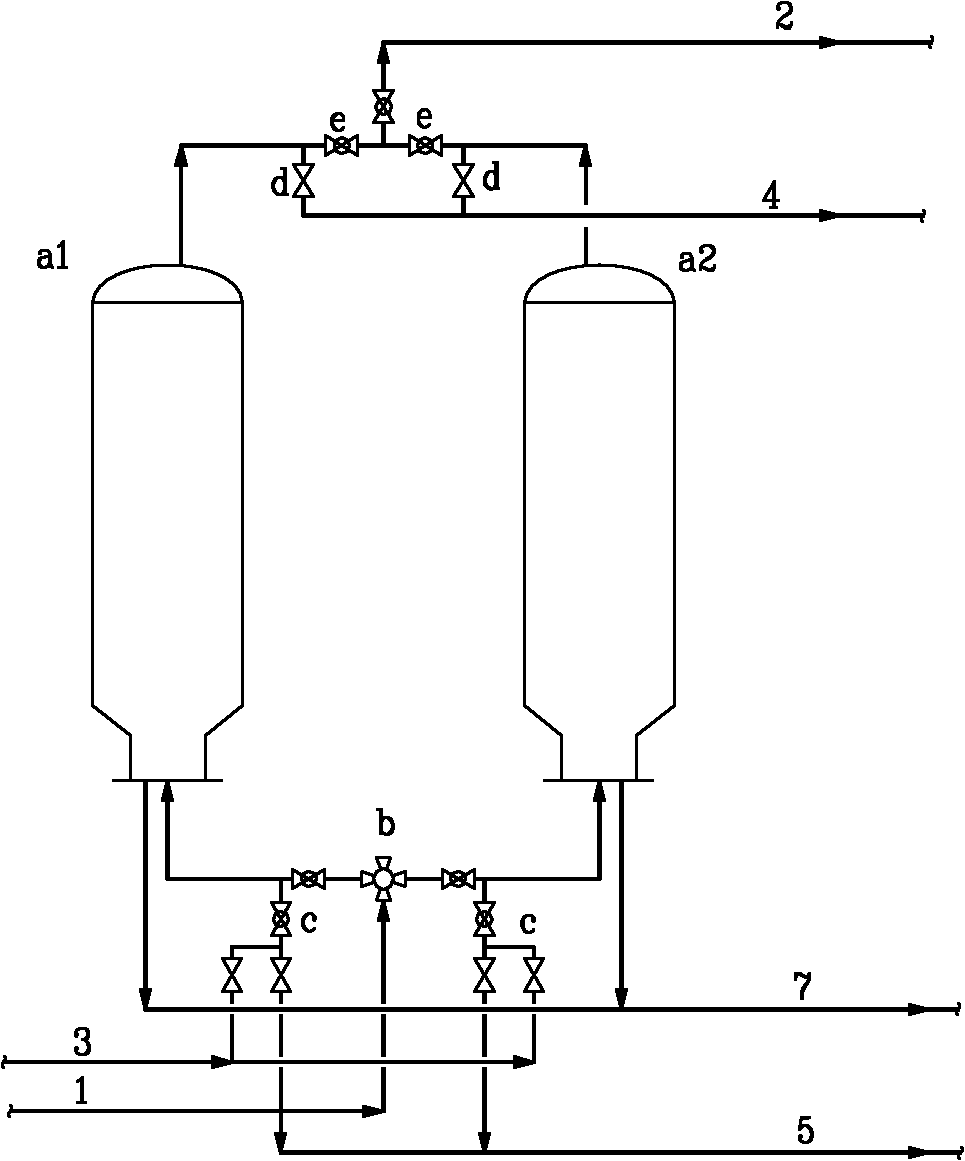

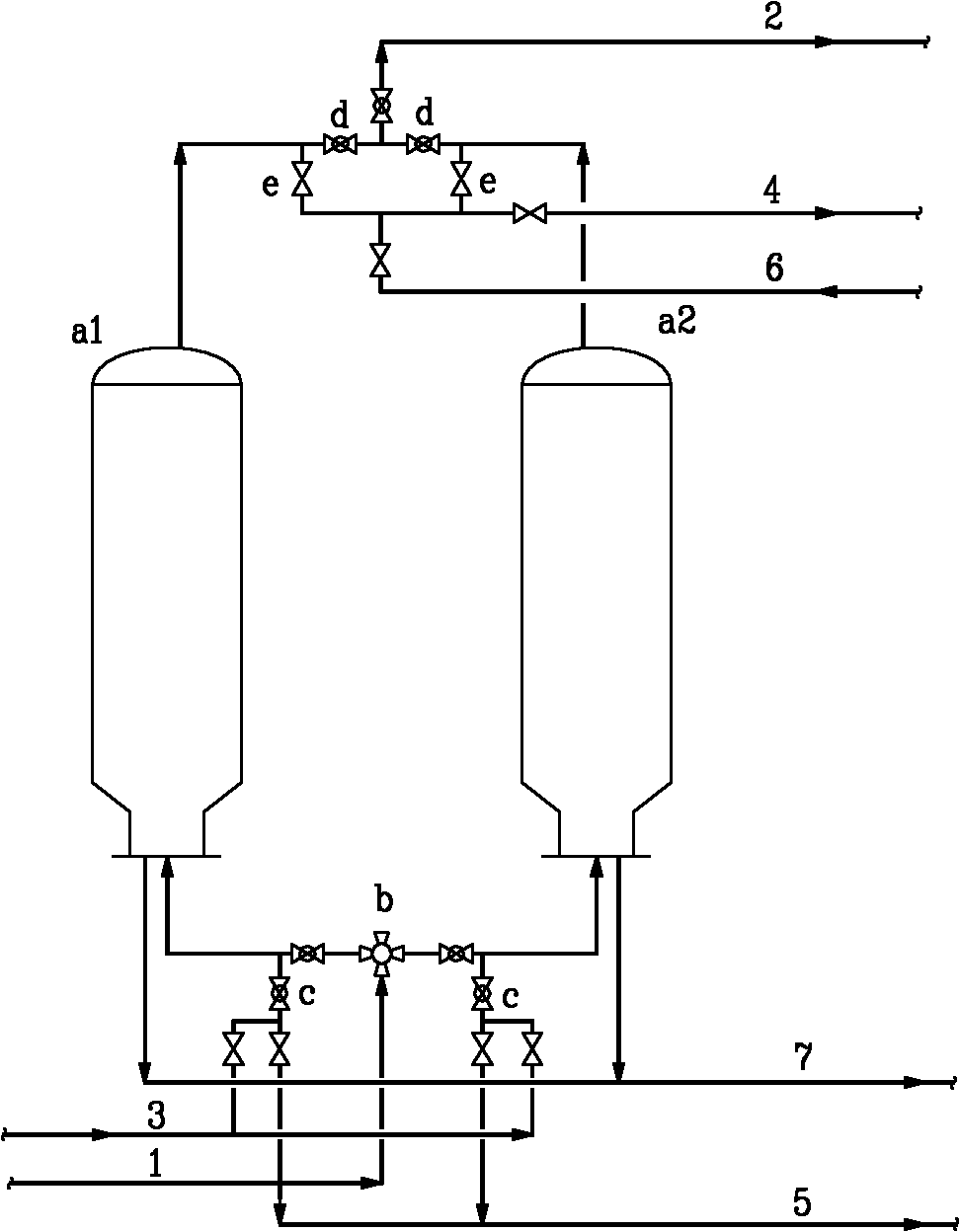

[0030] Such as figure 2 As shown, a delayed coking unit includes coke tower one a1 and coke tower two a2, and the four-way valve b, oil rejection valve c, breathing valve d, large oil and gas line ball valve e and related pipelines connected thereto. The purging and pressure test steam pipeline is set on the top of the coke tower a1 and the coke tower two a2, respectively connected to the coke tower a1 and the coke tower two a2, and the bottom of the coke tower a1 and the coke tower two a2 is provided with a vent to the coke Pool plumbing.

[0031] During defocusing operation,

[0032] The coke oil 1 from the outlet of the heating furnace enters the coke tower a1 after being switched by the four-way valve b, and the high-temperature oil gas 2 after the reaction enters the downstream fractionation system from the top of the tower. As shown in the figure, a coke tower a1 and a2, when the first coke tower a1 is in coke operation, the second coke tower a2 is in the decoking ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com