Industrial kiln co-processing method and equipment for hazardous wastes

A hazardous waste, co-processing technology, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of low combustion efficiency, secondary treatment, low moisture content, etc., to achieve high drying efficiency, high drying effect, The effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

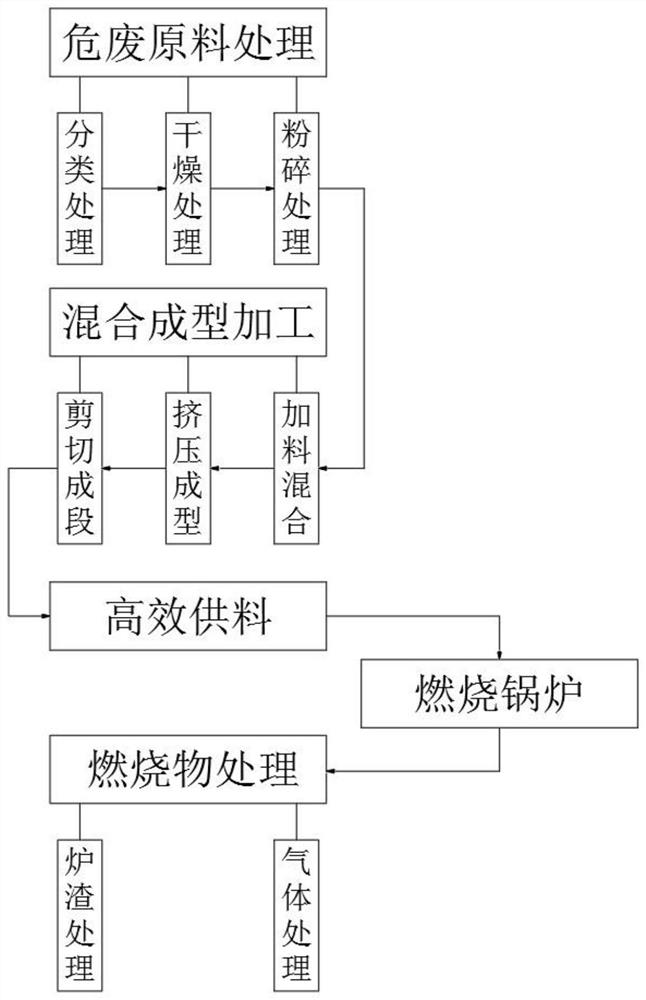

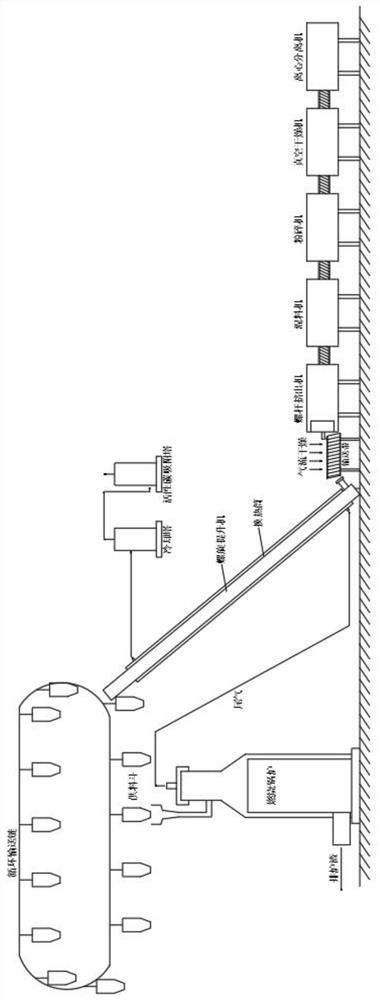

[0052] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a method for co-processing hazardous waste in industrial kilns, including the following disposal steps:

[0053] S1. Hazardous waste raw material treatment;

[0054] S2, hybrid molding processing;

[0055] S3, efficient feeding;

[0056] S4. Combustion treatment.

[0057] Based on the above technical solution, in S1, the treatment of hazardous waste raw materials specifically includes the following treatment steps:

[0058] A. Classification processing;

[0059] B. Drying treatment;

[0060] C. Crushing treatment;

[0061] In processing step A, classified treatment refers to the classification of hazardous waste materials to be disposed of. The classification standard is mainly based on the moisture content of hazardous waste materials. Specifically, hazardous waste materials are divided into low Hazardous waste materials and hazardous waste materials with high moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com