Blowout type spraying device

A technology of spraying device and transmission belt, which is applied in spraying device, device for coating liquid on the surface, coating and other directions to achieve the effect of uniform spraying, improved efficiency, and avoiding dead spots of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation, structure, features and effects of the blowout spraying device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

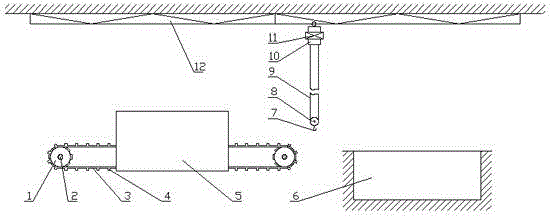

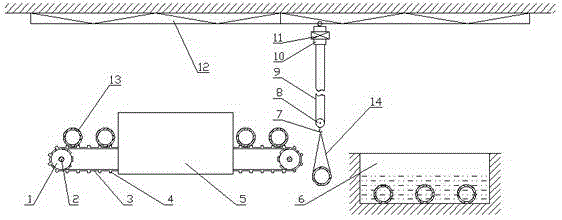

[0017] see figure 1 , the blowout spraying device of the present invention comprises transmission wheel 1, transmission belt 3, preheating storehouse 5, spraying well 6, wherein: transmission wheel 1 is contained on the driving shaft 2, transmission wheel 1 and transmission belt 3 match, and transmission belt 3 wears Over the preheating chamber 5, the output side of the transmission belt 3 is provided with a spraying well 6, and the top of the transmission belt 3 and the spraying well 6 is provided with a lifting assembly 11. The lifting assembly 11 includes a fixed tower 12, a connector 10, a rope 9, and a hook 7. The connector 10 is movably installed on the fixed tower 12, and the lower end of the connector 10 is equipped with a rope 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com