Patents

Literature

52results about How to "Realize all-round spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

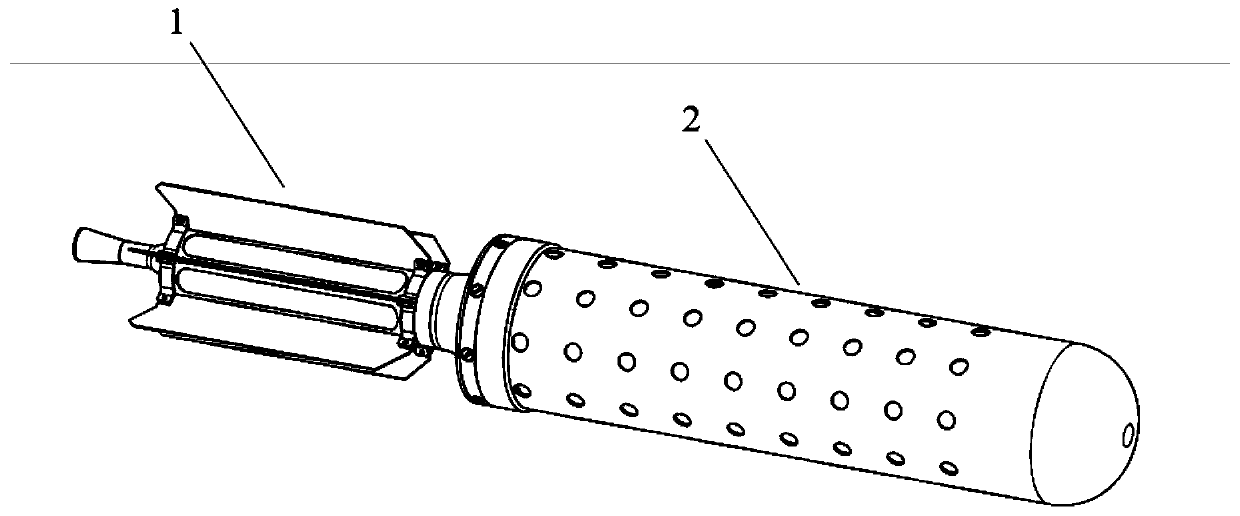

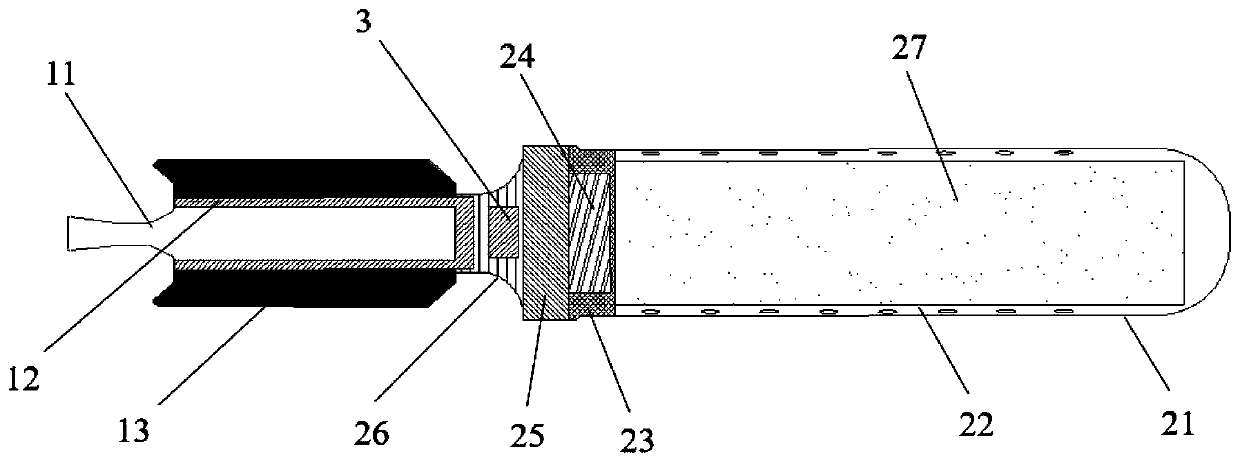

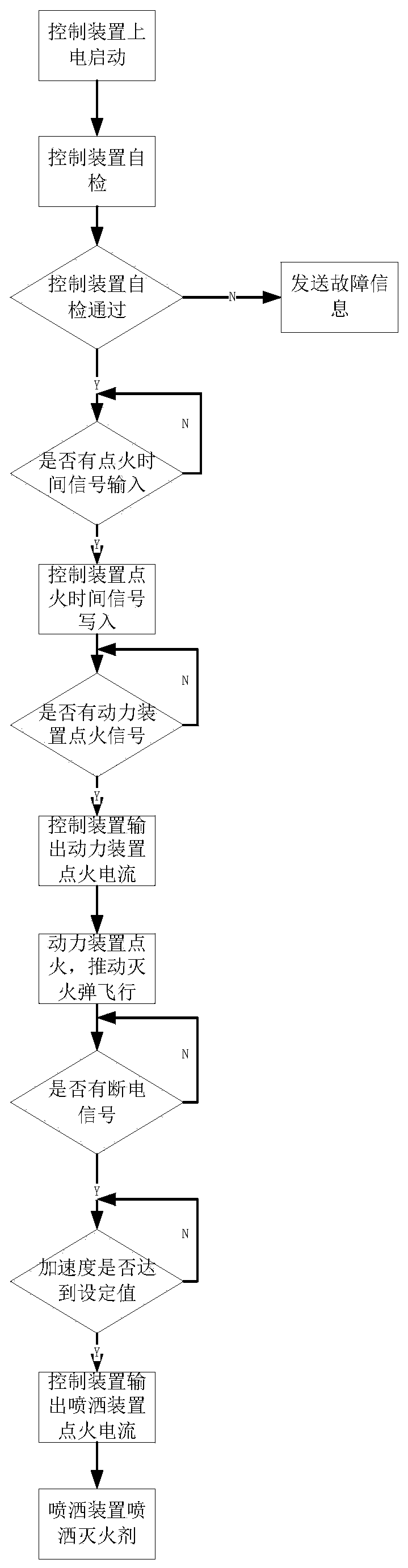

Onboard fire extinguishing bomb and fire extinguishing method

ActiveCN110694207ASimple structurePrecise control of spraying timeAircraft componentsAmmunition projectilesProcess engineeringPower apparatus

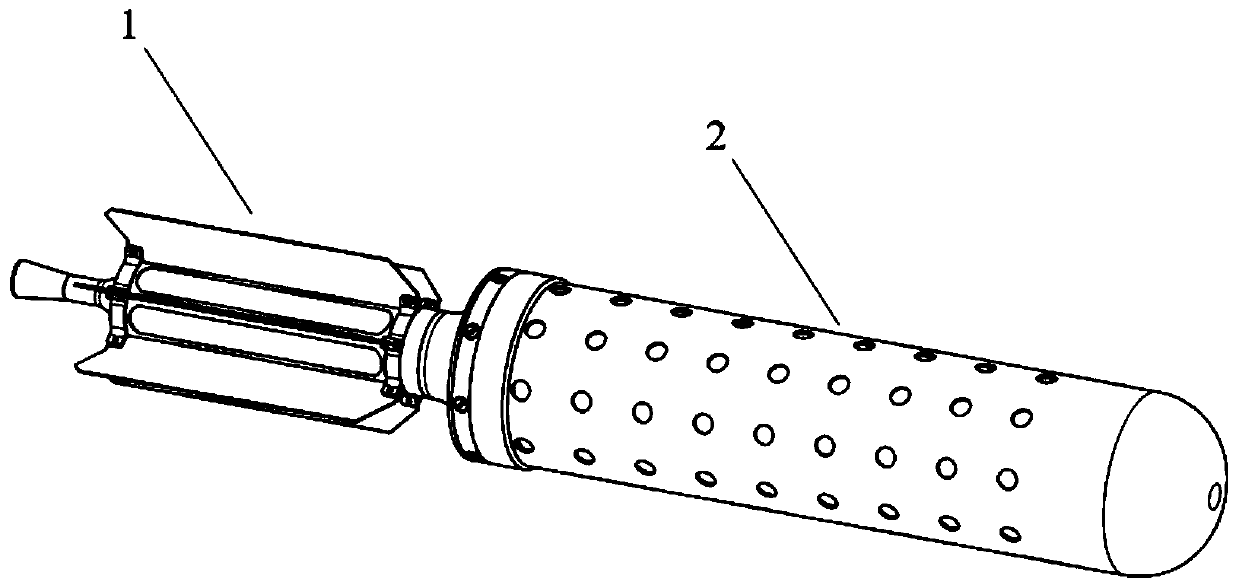

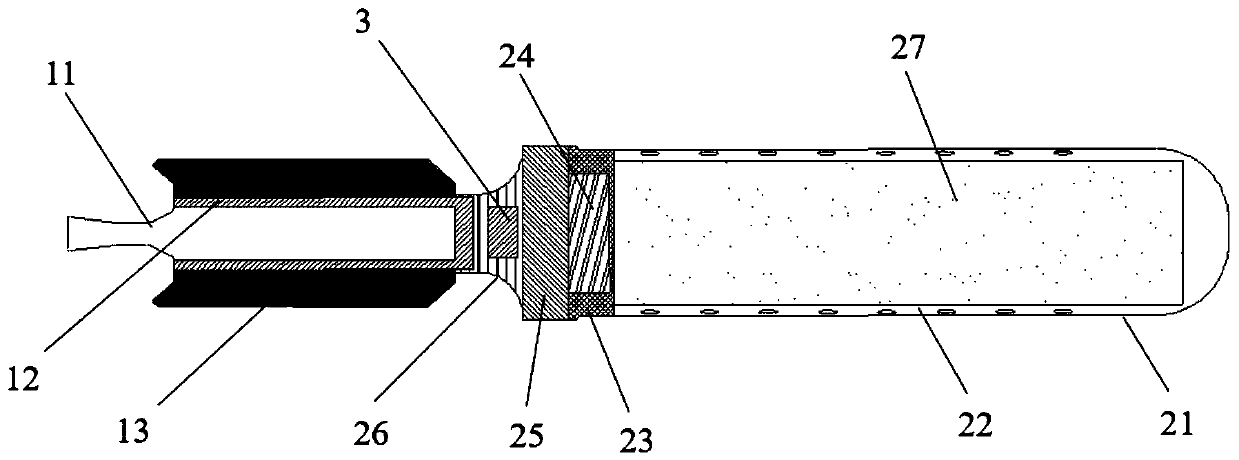

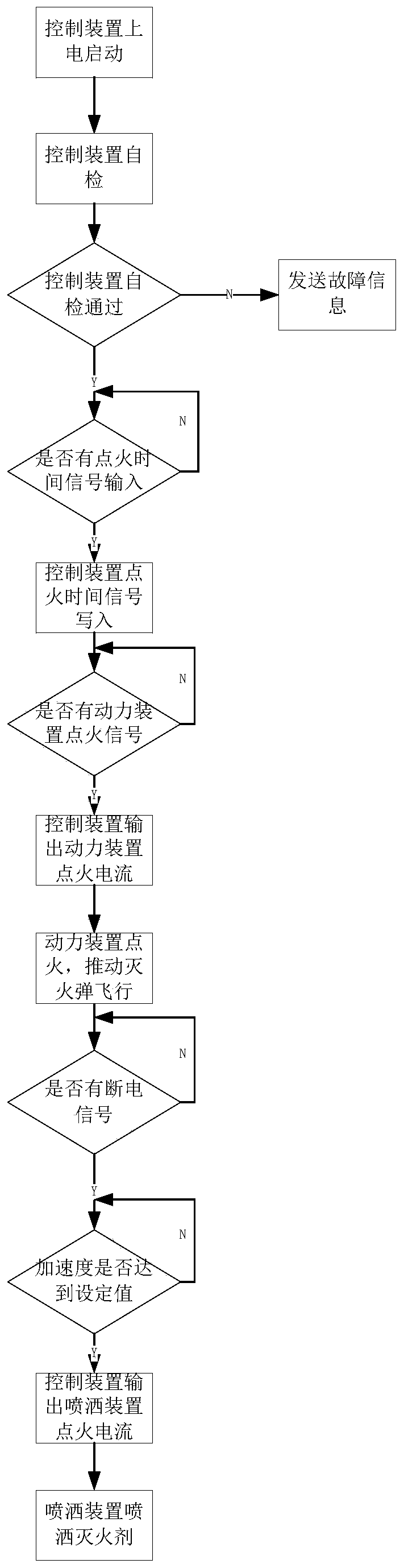

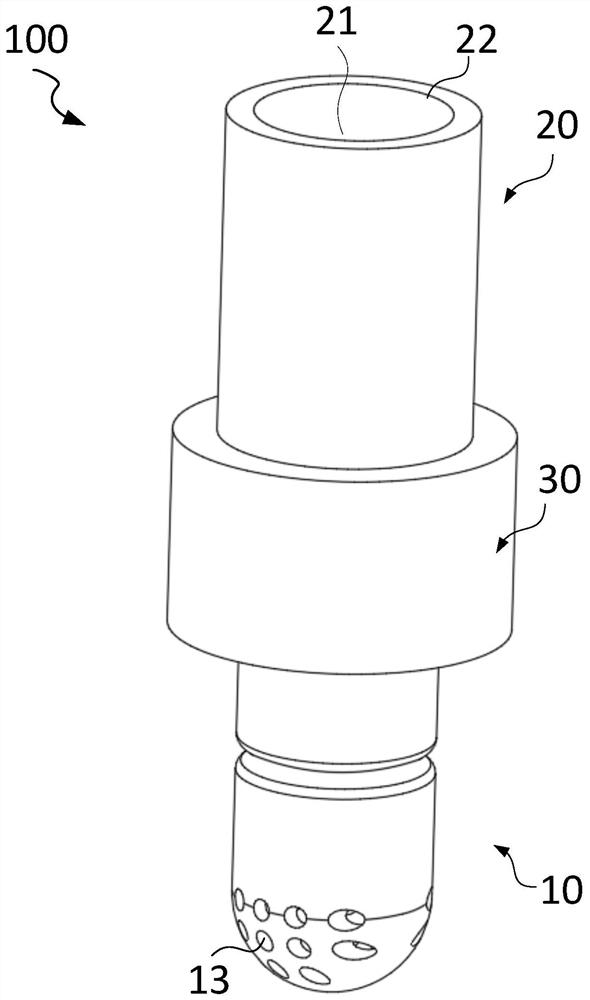

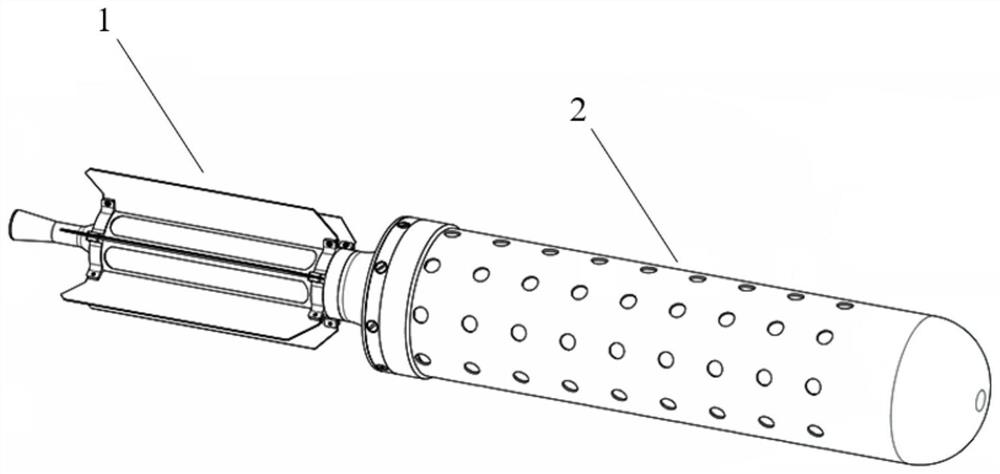

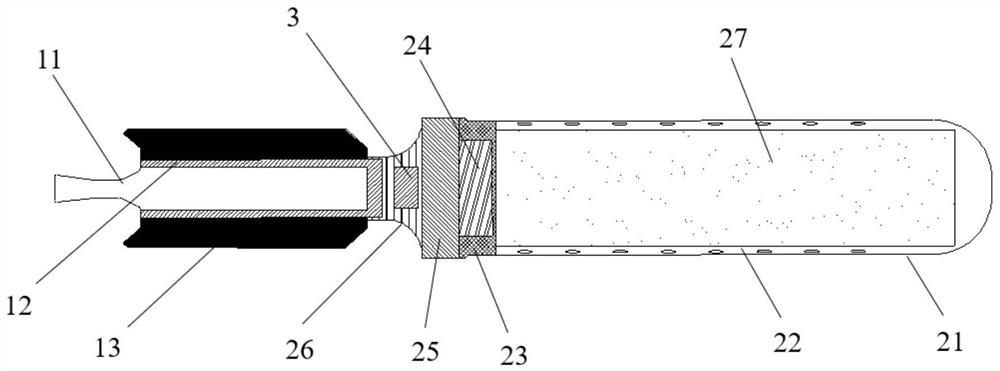

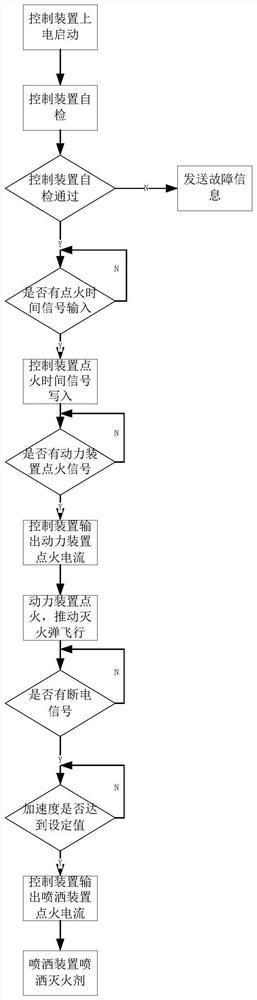

The invention relates to an onboard fire extinguishing bomb and a fire extinguishing method, belongs to the technical field of fire extinguishing bombs, and solves the problems of poor product safety,low control precision, high cost and high residual rate of a fire extinguishing agent of an existing fire extinguishing bomb. The airborne fire extinguishing bomb comprises a power device, a sprayingdevice and a control device, wherein the power device is used for pushing the fire extinguishing bomb to fly, the spraying device is used for spraying a fire extinguishing agent, and the control device is used for controlling ignition of the power device and controlling the spraying device to spray the fire extinguishing agent; the spraying device comprises a spraying shell, an inner container and a grain, the inner container and the grain are arranged inside the spraying shell, and the inner container is used for filling the fire extinguishing agent; the spraying shell is provided with a spraying hole for spraying the fire extinguishing agent, and the spraying hole forms a spraying channel for the fire extinguishing agent; and the high-temperature and high-pressure gas generated after the grain is ignited acts on the fire extinguishing agent, and the fire extinguishing agent can puncture the inner container and be sprayed out through the spraying hole. According to the onboard fire extinguishing bomb and the fire extinguishing method, no toxic fragment is generated in the fire extinguishing and spraying process, the product safety is high, and the caking rate and the residual rate of the fire extinguishing agent are obviously reduced.

Owner:BEIJING MECHANICAL EQUIP INST

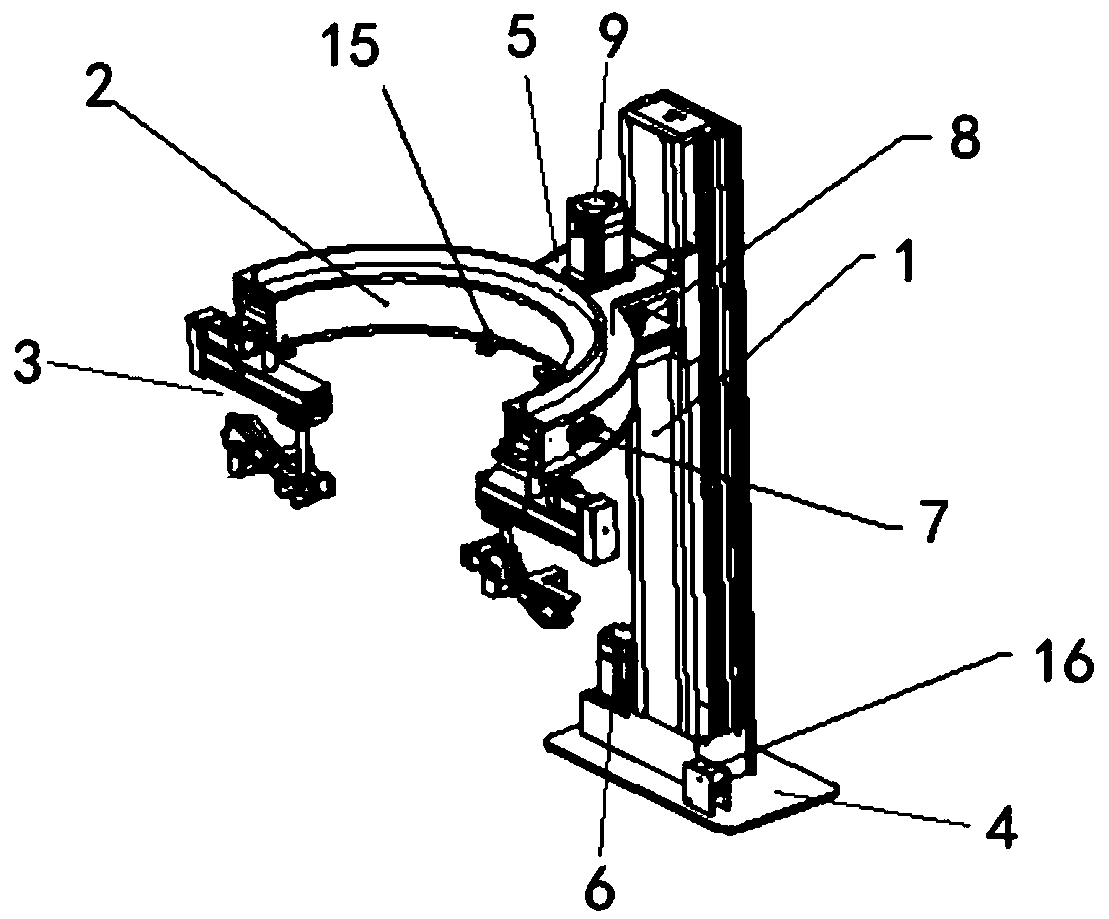

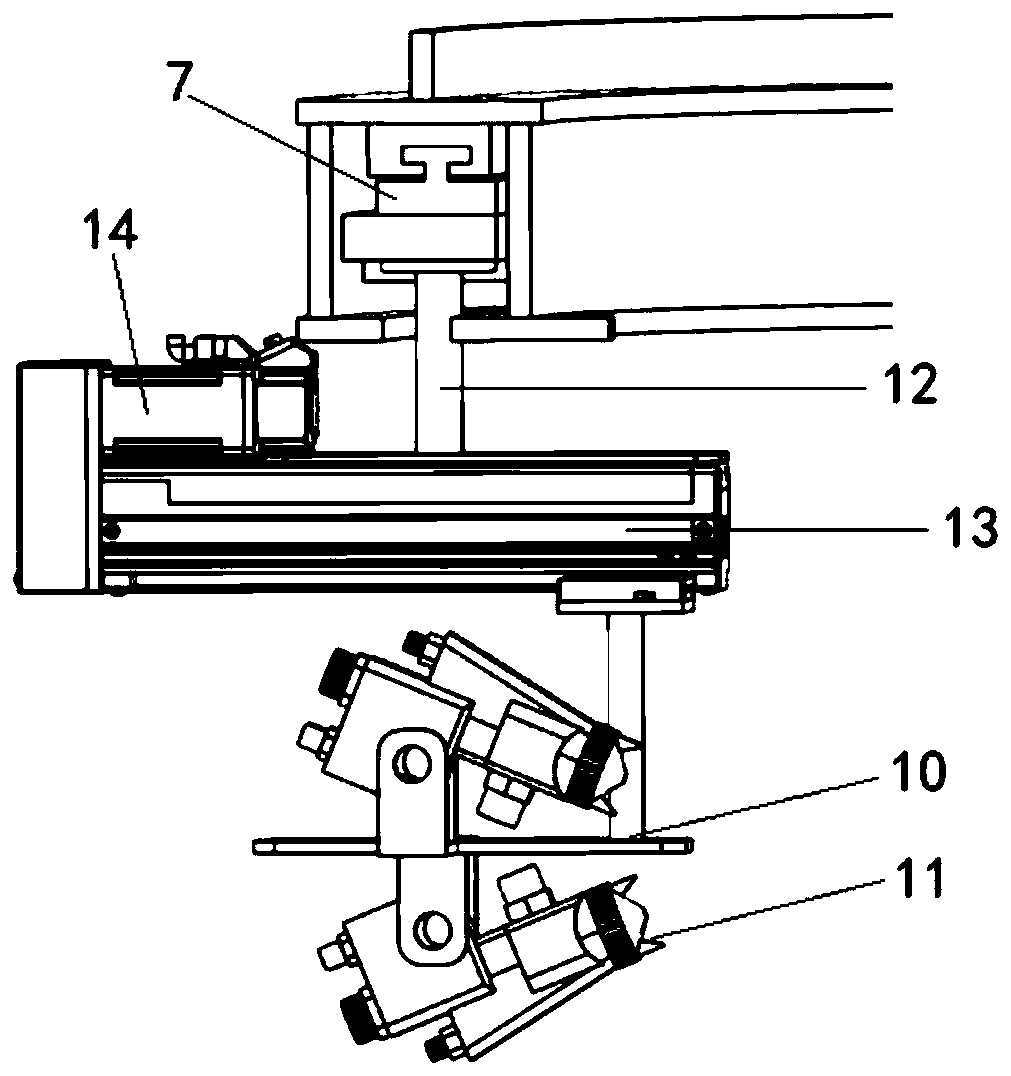

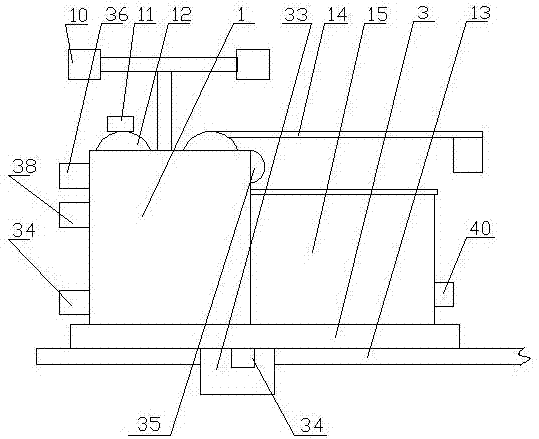

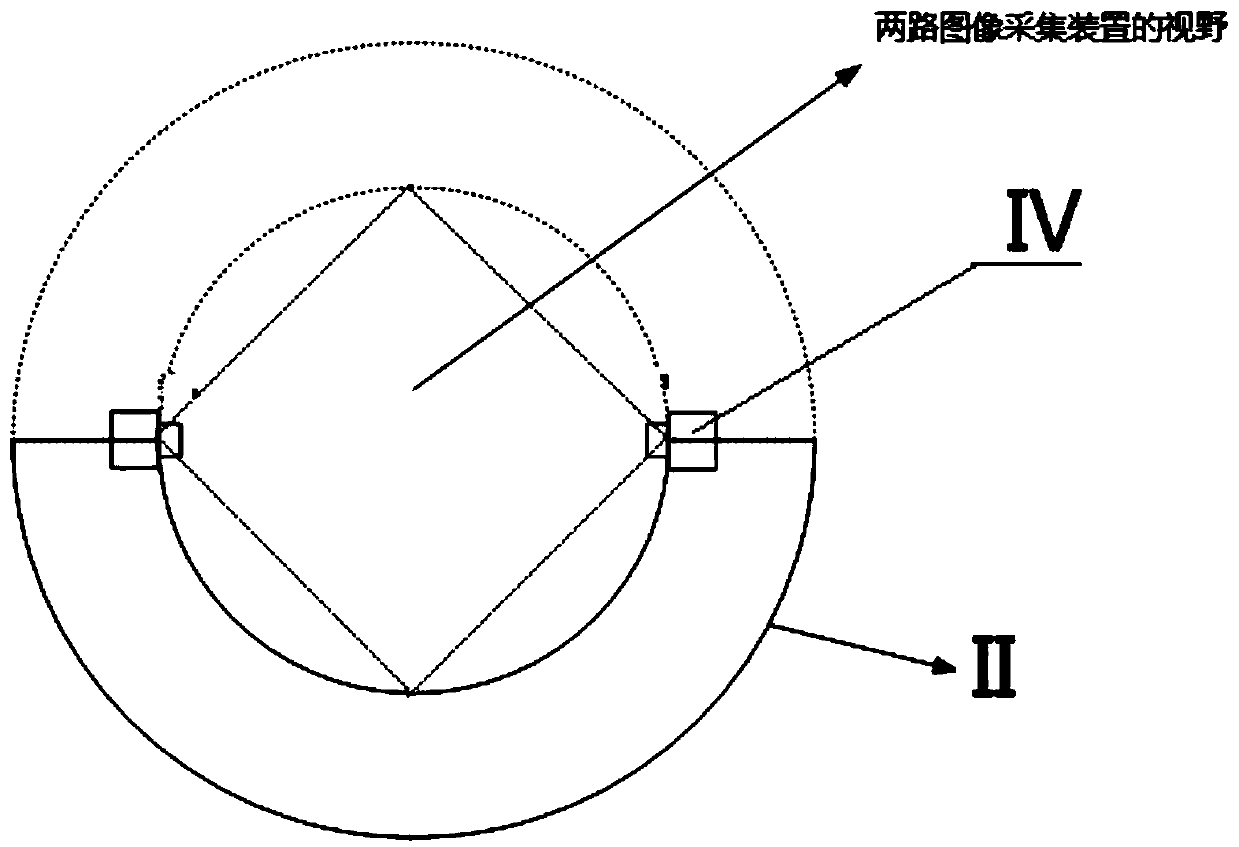

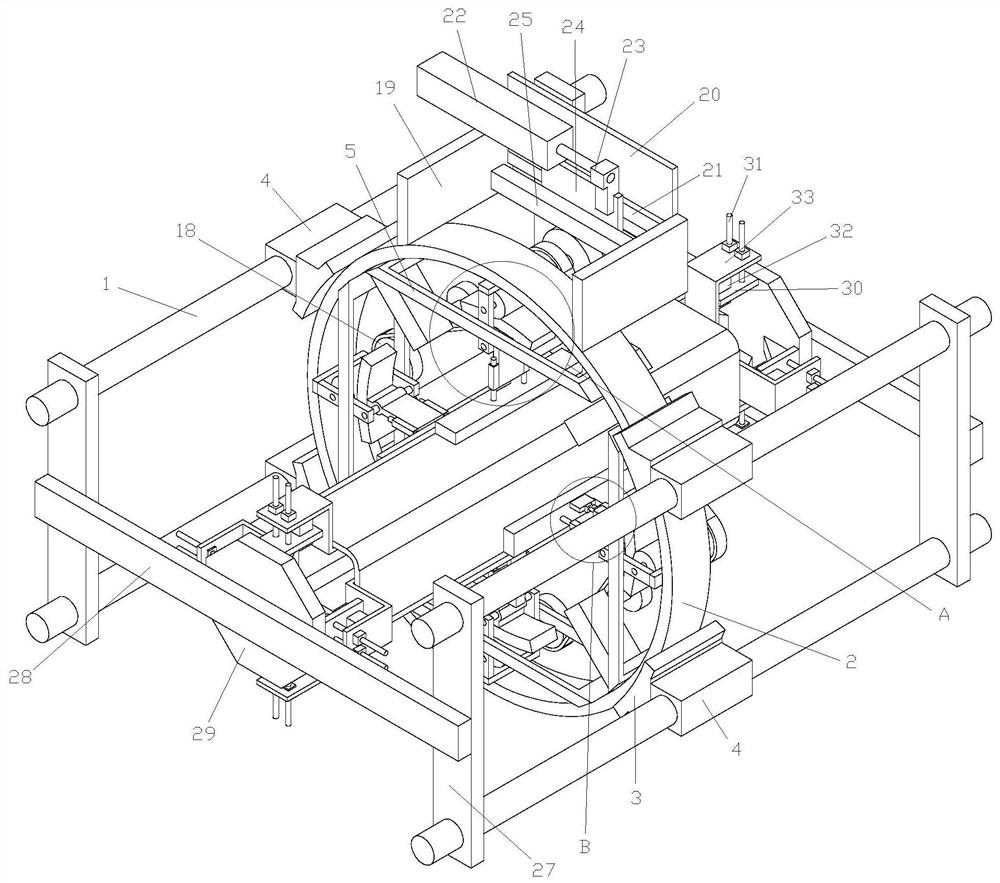

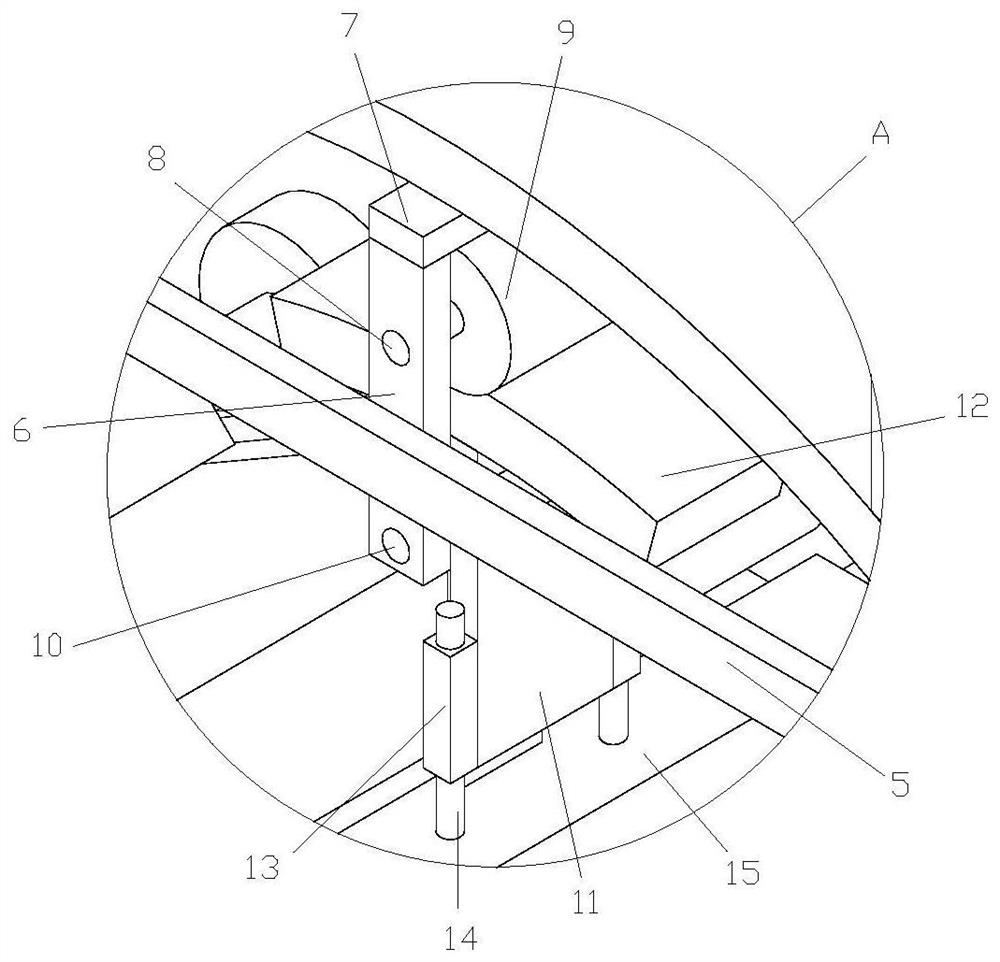

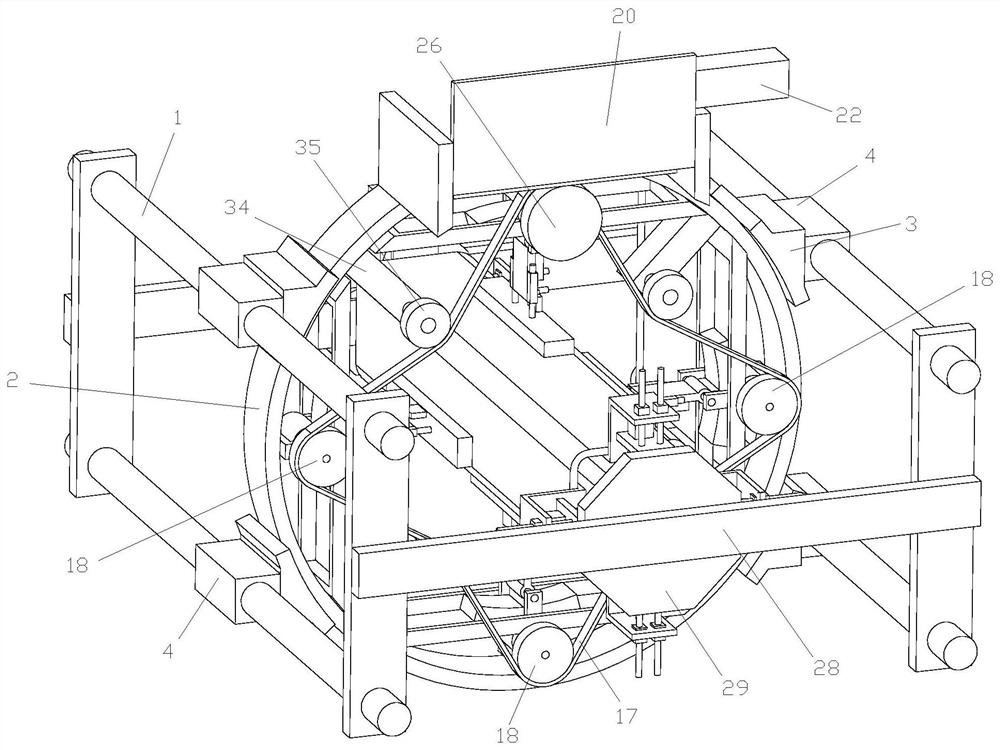

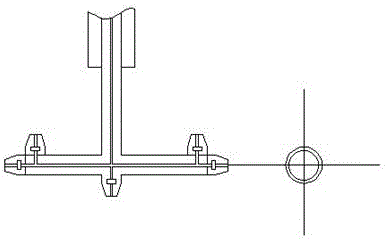

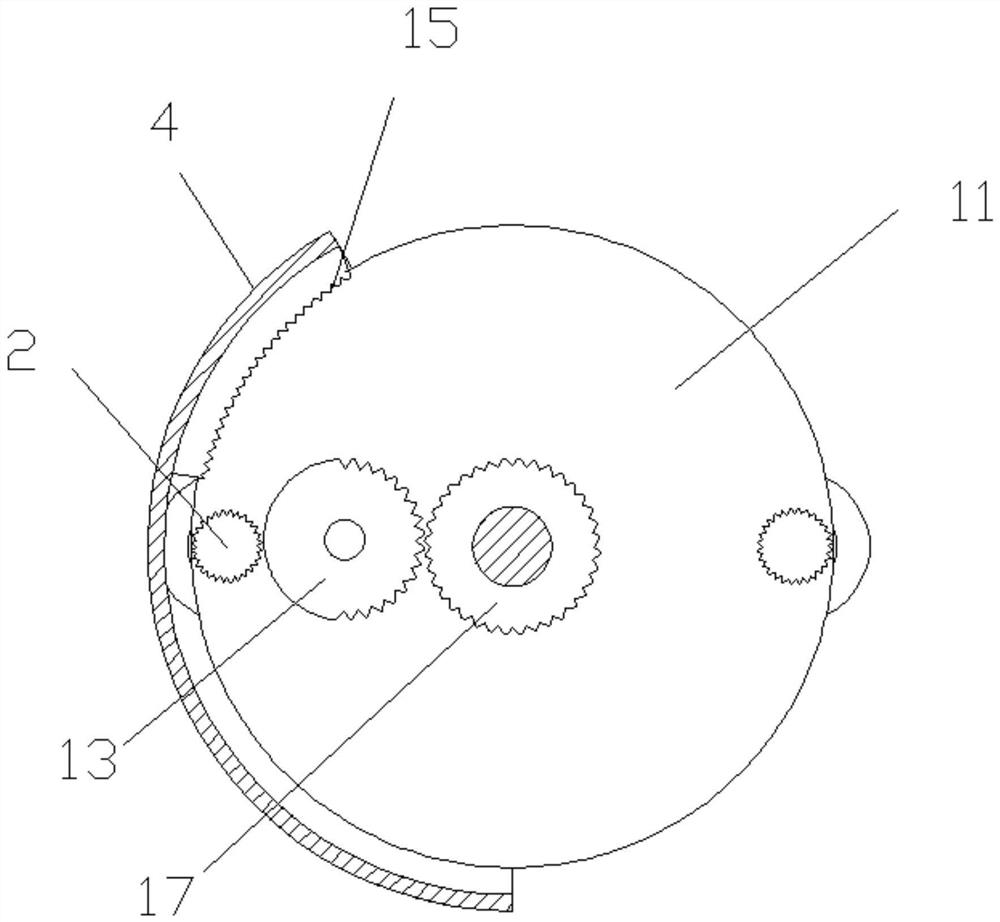

Transformer substation insulator RTV uniform spraying system and control method

PendingCN110787935ARealize all-round sprayingFull Coverage GuaranteedSpraying apparatusReciprocating motionTransformer

The invention discloses a transformer substation insulator RTV uniform spraying system. The transformer substation insulator RTV uniform spraying system comprises a holding mechanism and at least onespraying mechanism. The holding mechanism is in a fan ring or ring shape, the at least one spraying mechanism is arranged on the holding mechanism, and the spraying mechanisms can do circumferential reciprocating motion along the holding mechanism. Each spraying mechanism comprises a spraying gun rack for allowing a spraying gun to be mounted. The spraying gun racks can do radial reciprocating motion in the diameter direction of the holding mechanism. According to the transformer substation insulator RTV uniform spraying system, automatic RTV spraying of insulators is achieved, and spraying isuniform.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

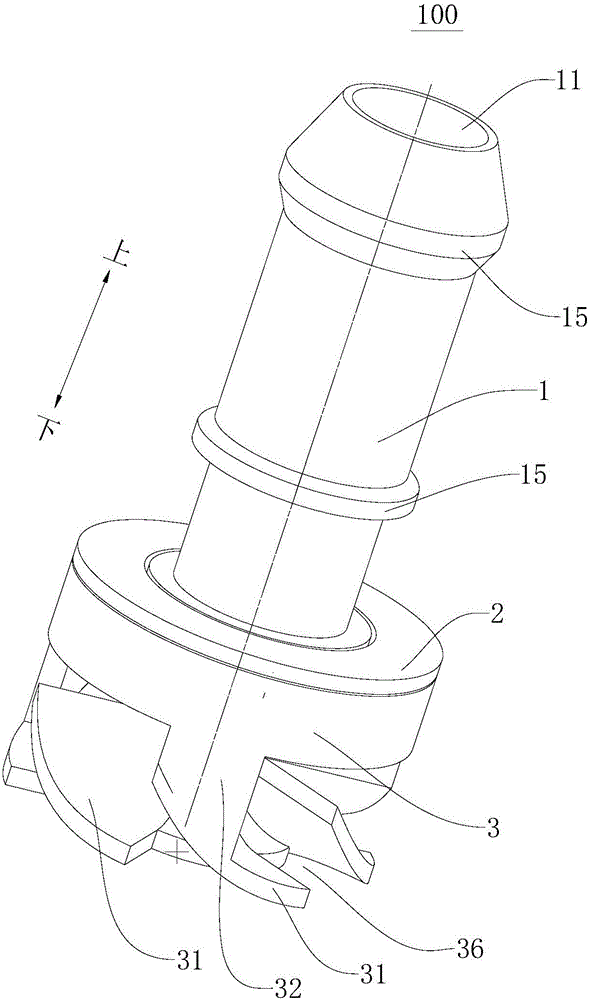

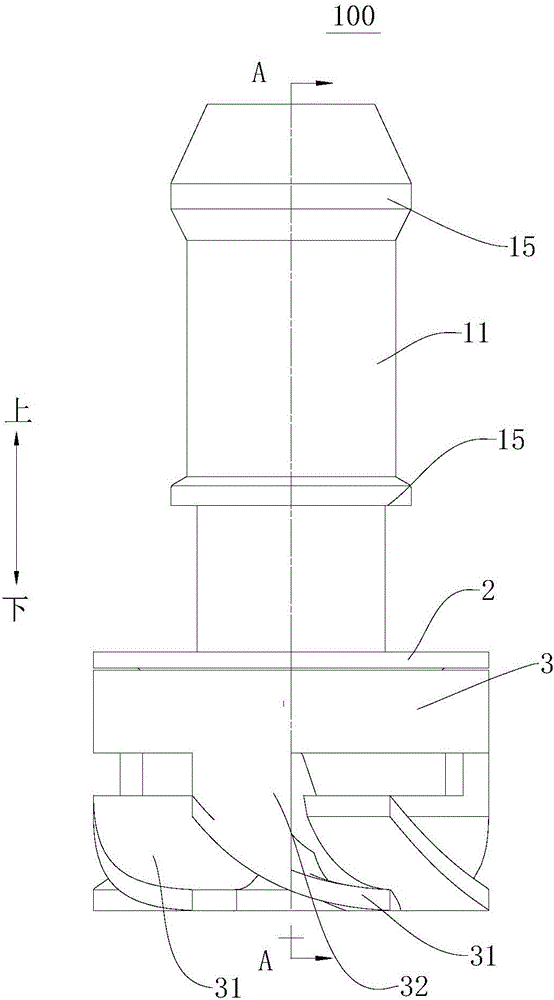

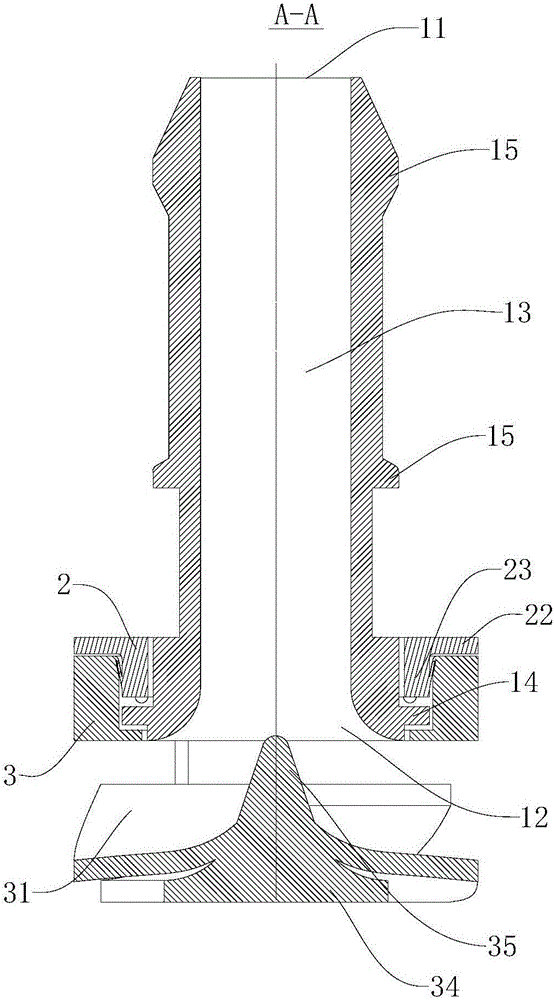

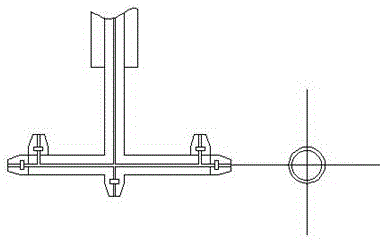

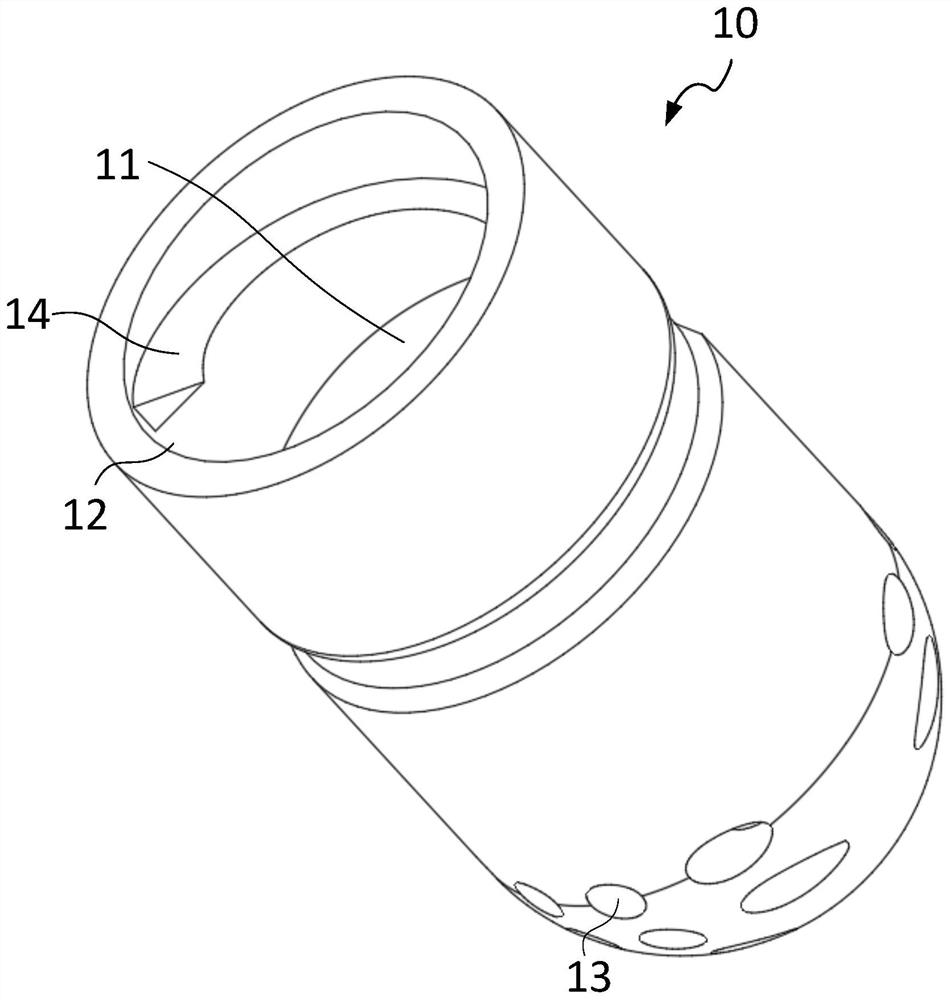

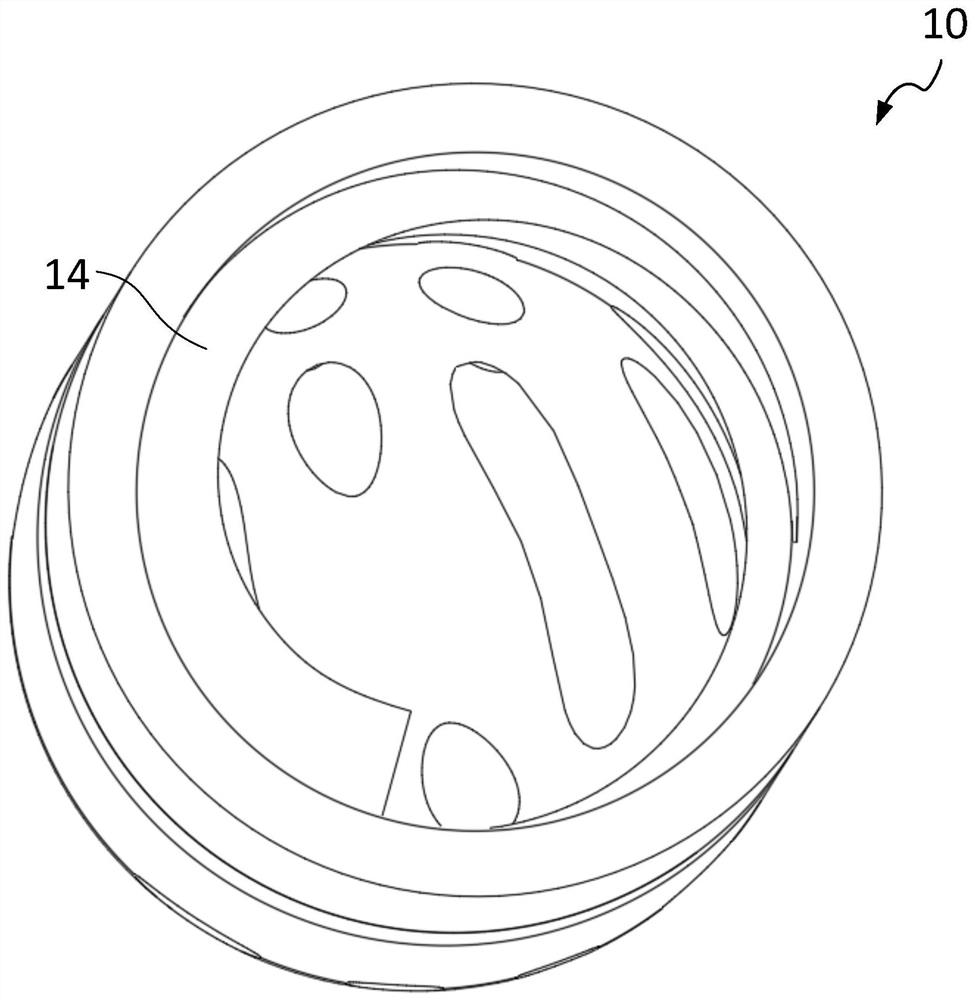

Spraying device for washing machine and washing machine with same

ActiveCN105970539AImprove aestheticsSimple structureMovable spraying apparatusWashing machine with receptaclesInlet channelWater spray

The invention discloses a spraying device for a washing machine and the washing machine with the same. The spraying device for the washing machine comprises a water inlet pipe, a buckle and a spraying head. A water inlet and outlet channel is defined in the water inlet pipe, a water inlet is formed in one end of the water inlet pipe, and a water outlet is formed in the other end of the water inlet pipe. The buckle is arranged at the other end of the water inlet pipe in the mode of rotating around the axis of the water inlet pipe. The spraying head is connected with the buckle, a plurality of blades are arranged on the spraying head and distributed at intervals in the circumferential direction of the spraying head, at least part of each blade extends obliquely relative to the axial direction of the spraying head, and a water spraying opening is defined between every two adjacent blades and communicated with the water inlet channel. According to the spraying device for the washing machine, the spraying head can carry out 360-degree omnidirectional rotating spraying; besides, it is not needed to arrange multiple spraying heads, so that the structure is simple, the size is small, and installation is convenient; dynamic rotating spraying can be achieved, so that the visual effect of spraying is good, and the aesthetic perception of the washing machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

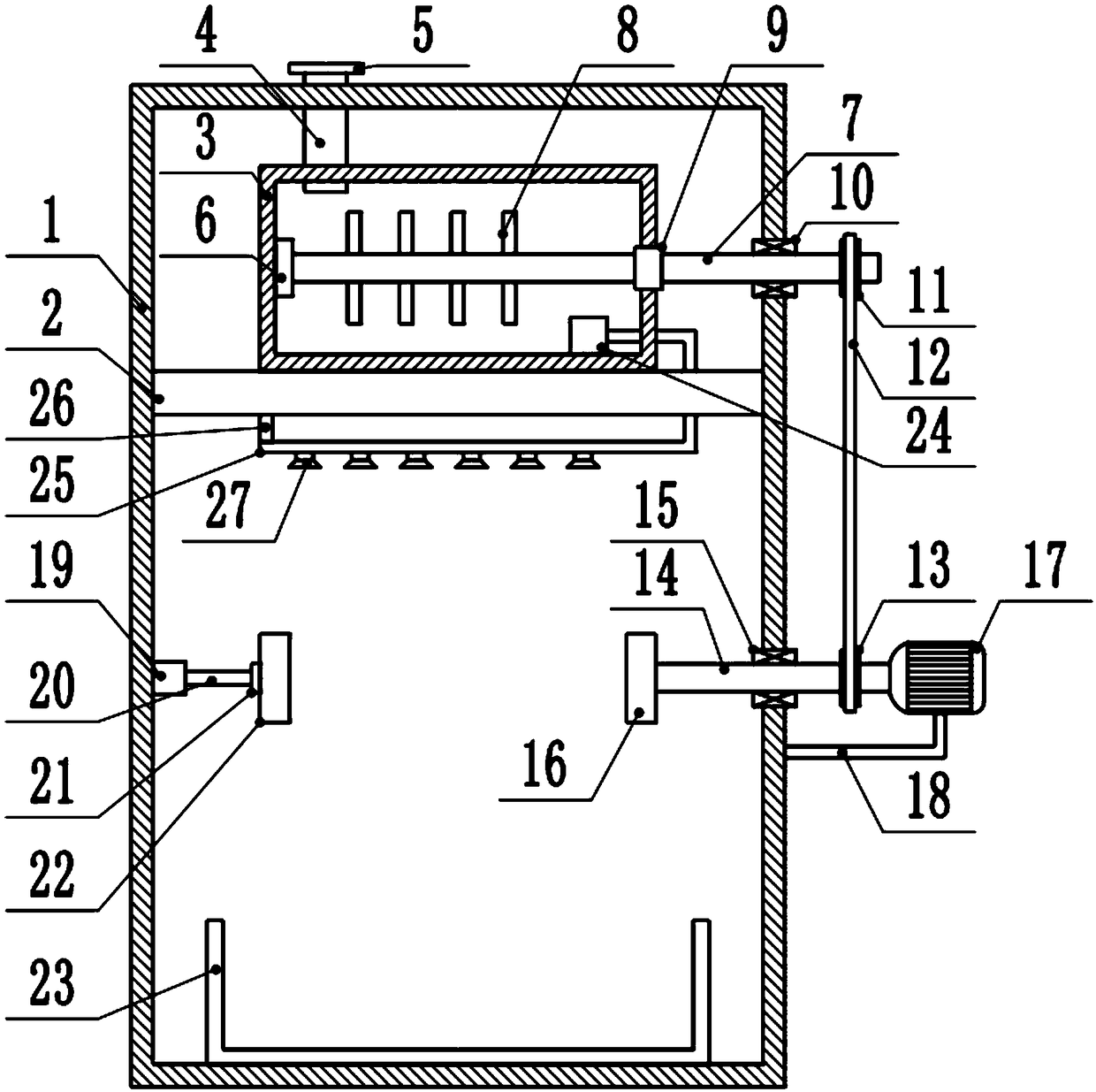

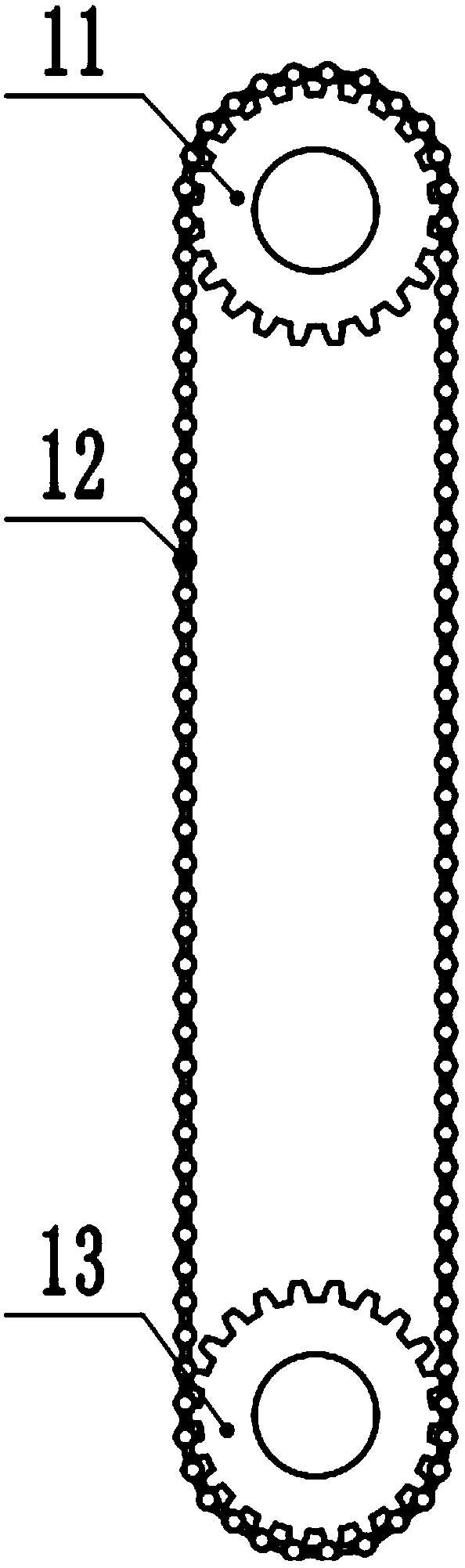

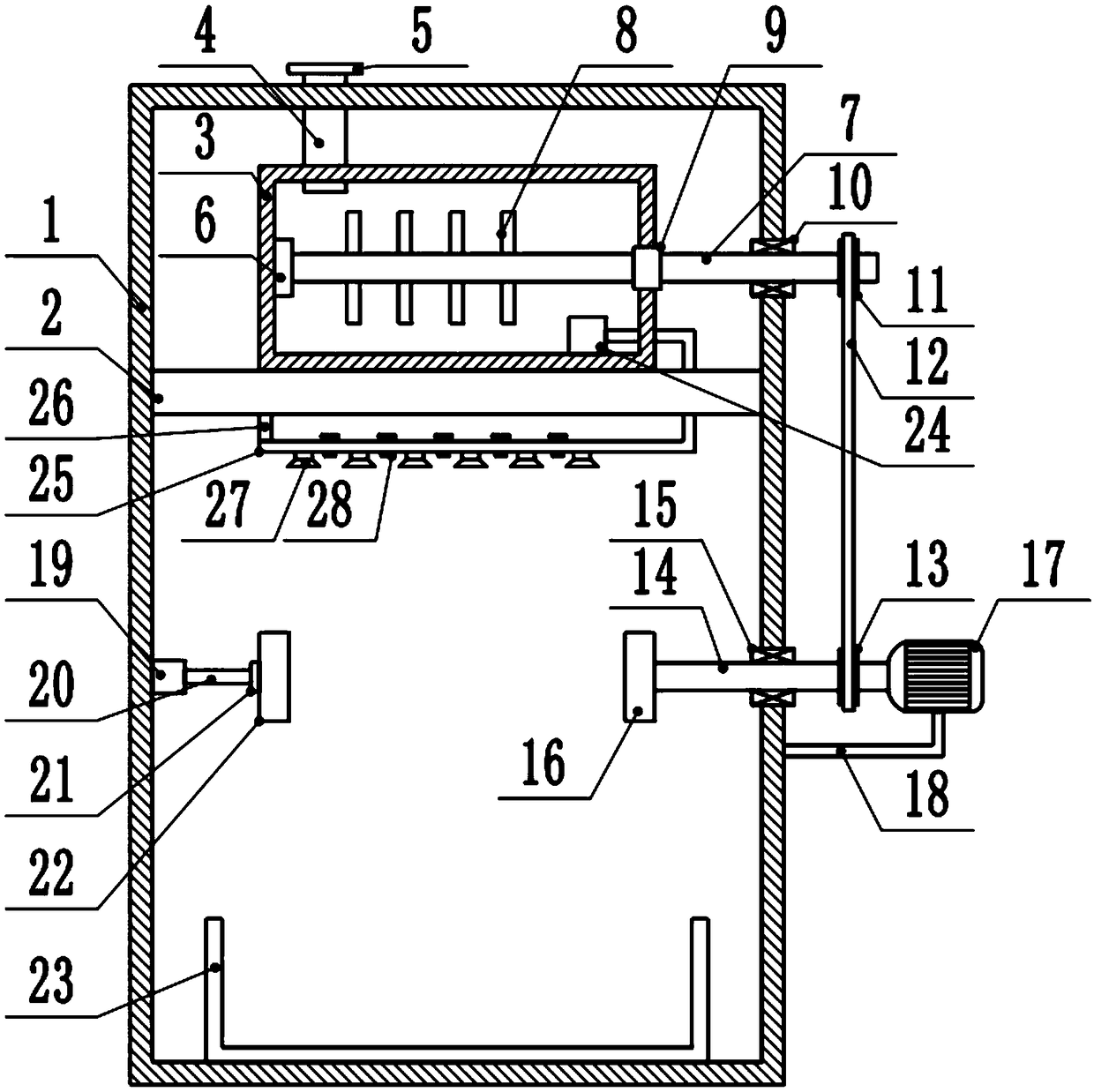

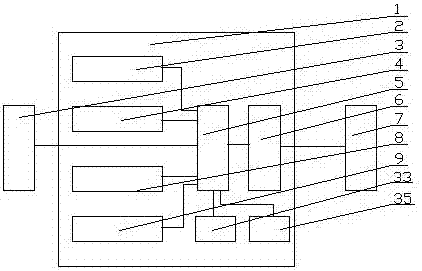

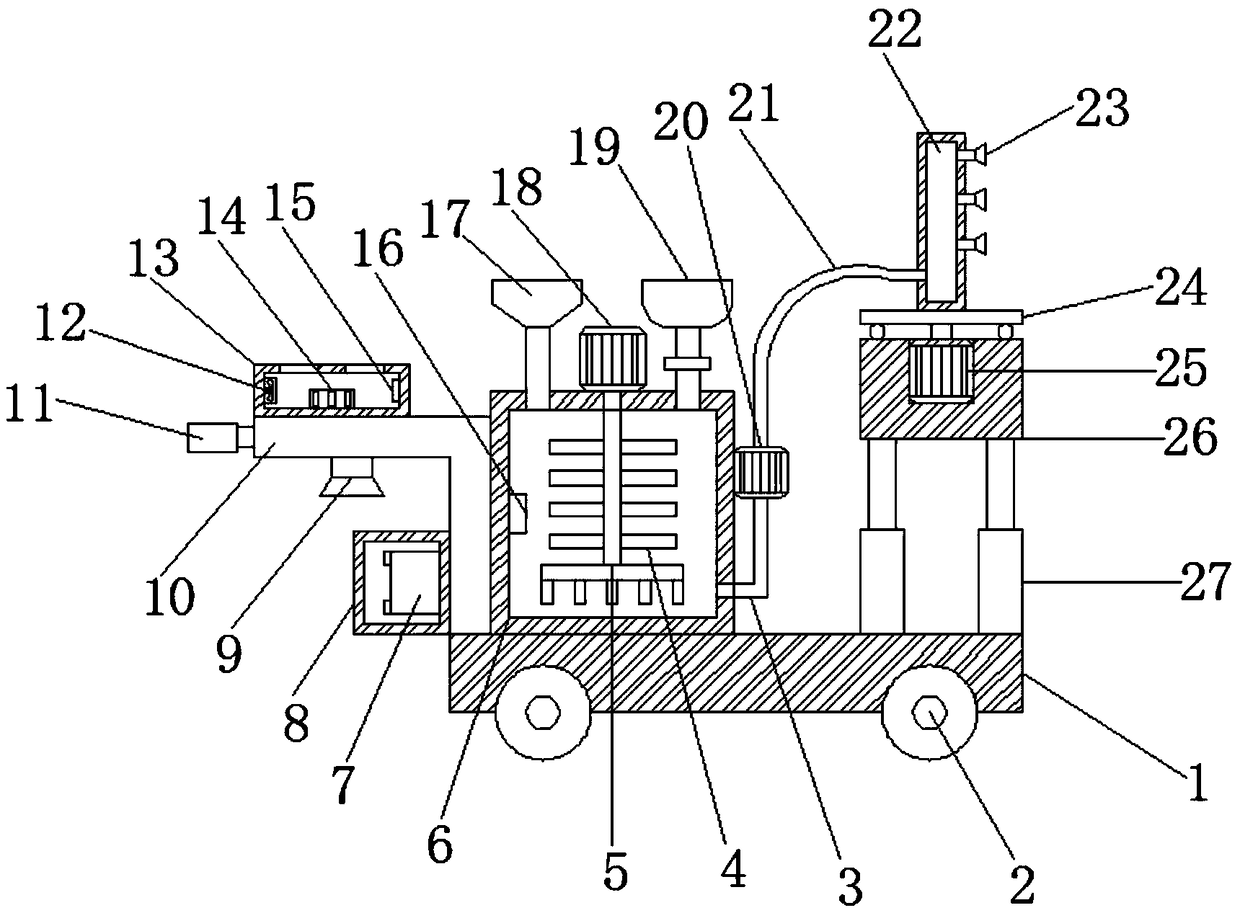

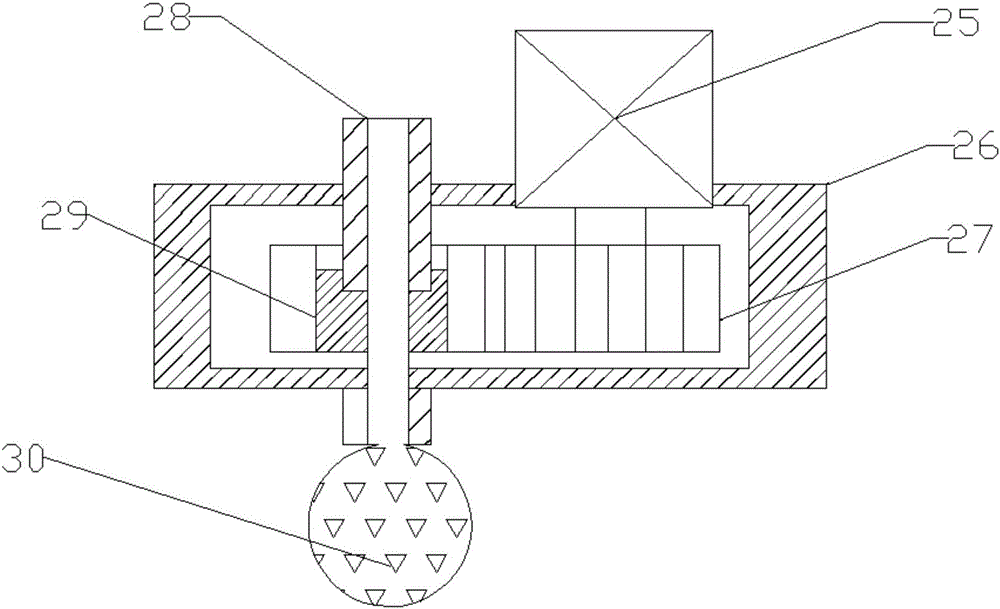

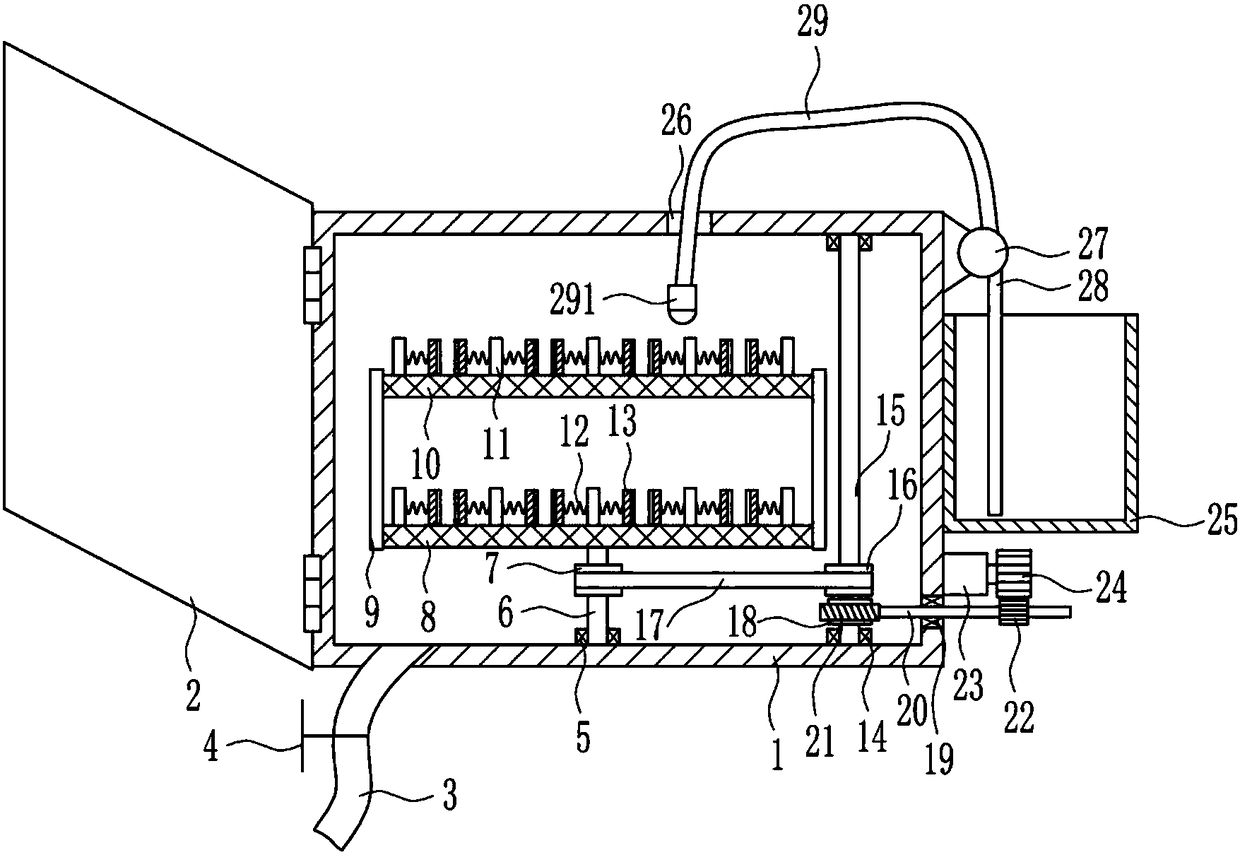

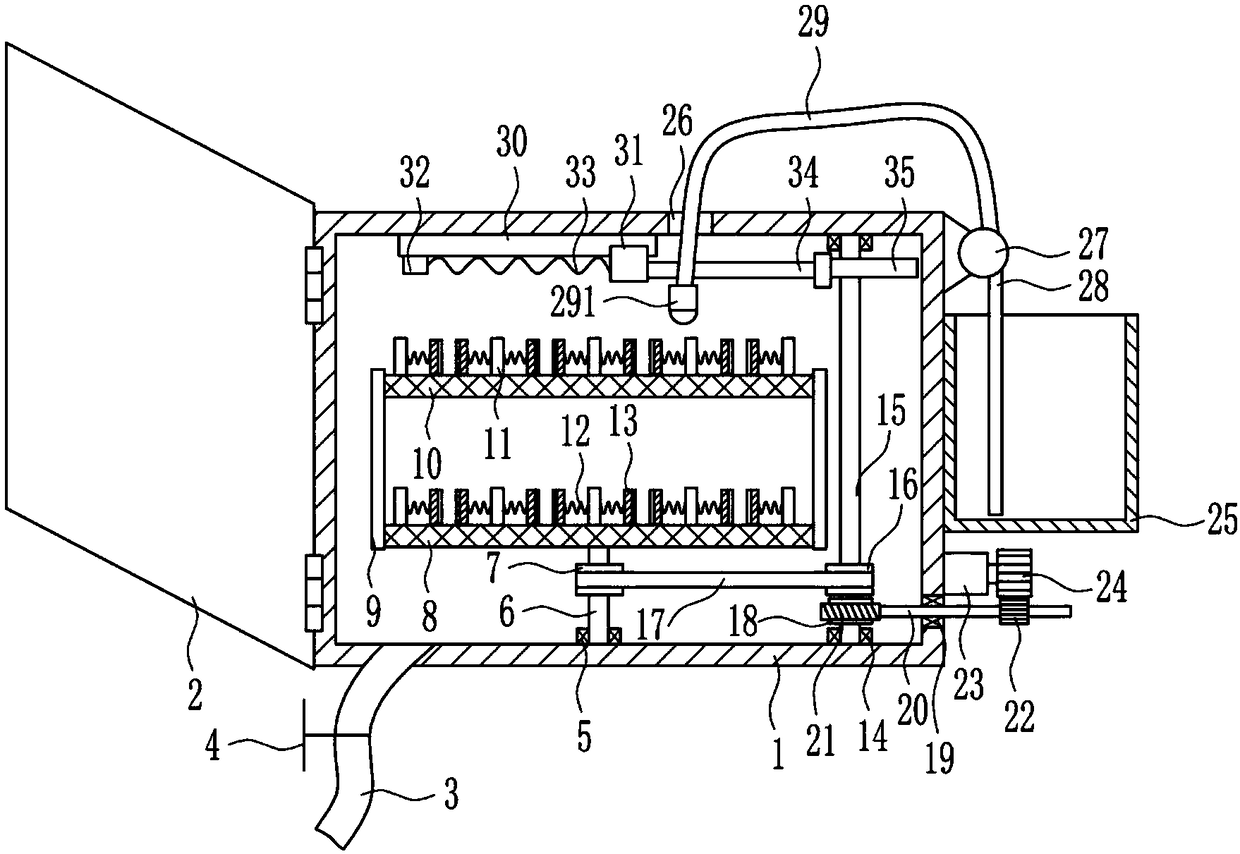

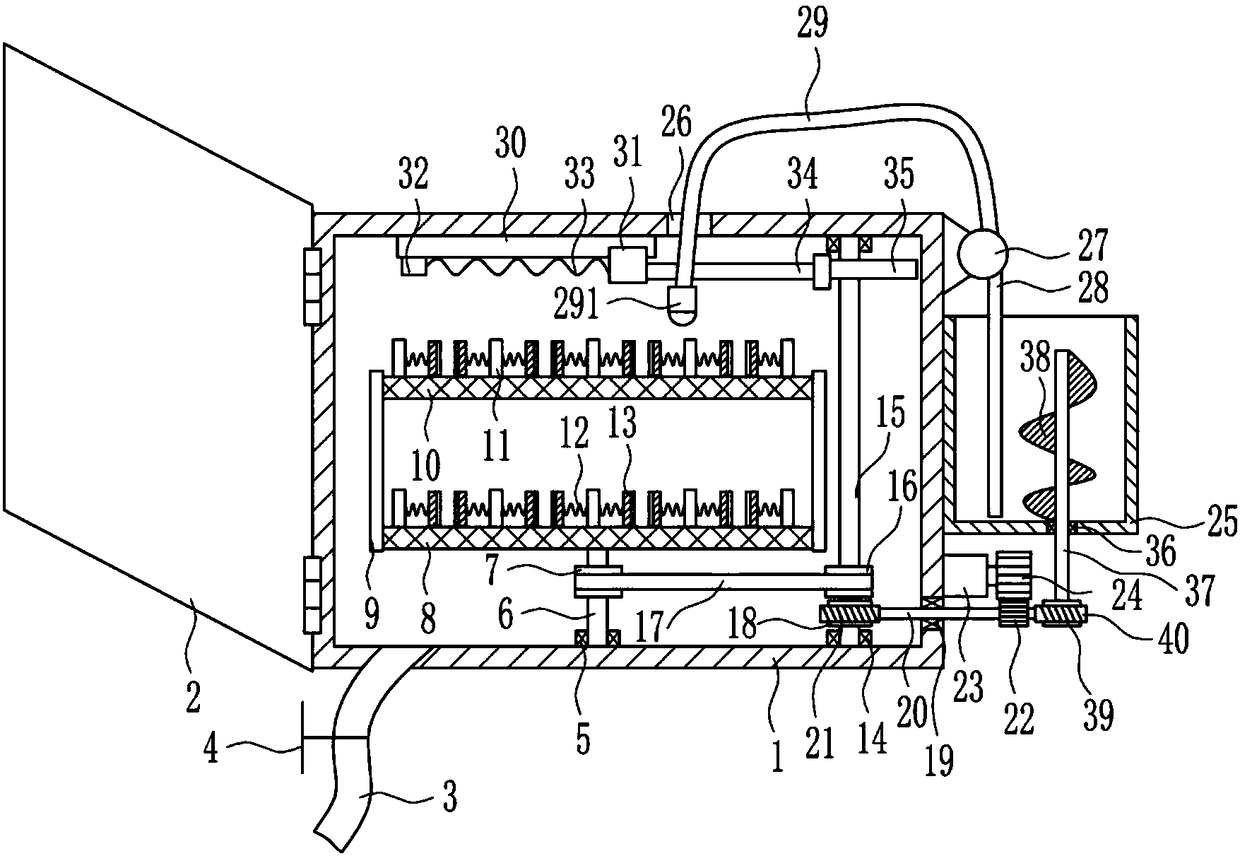

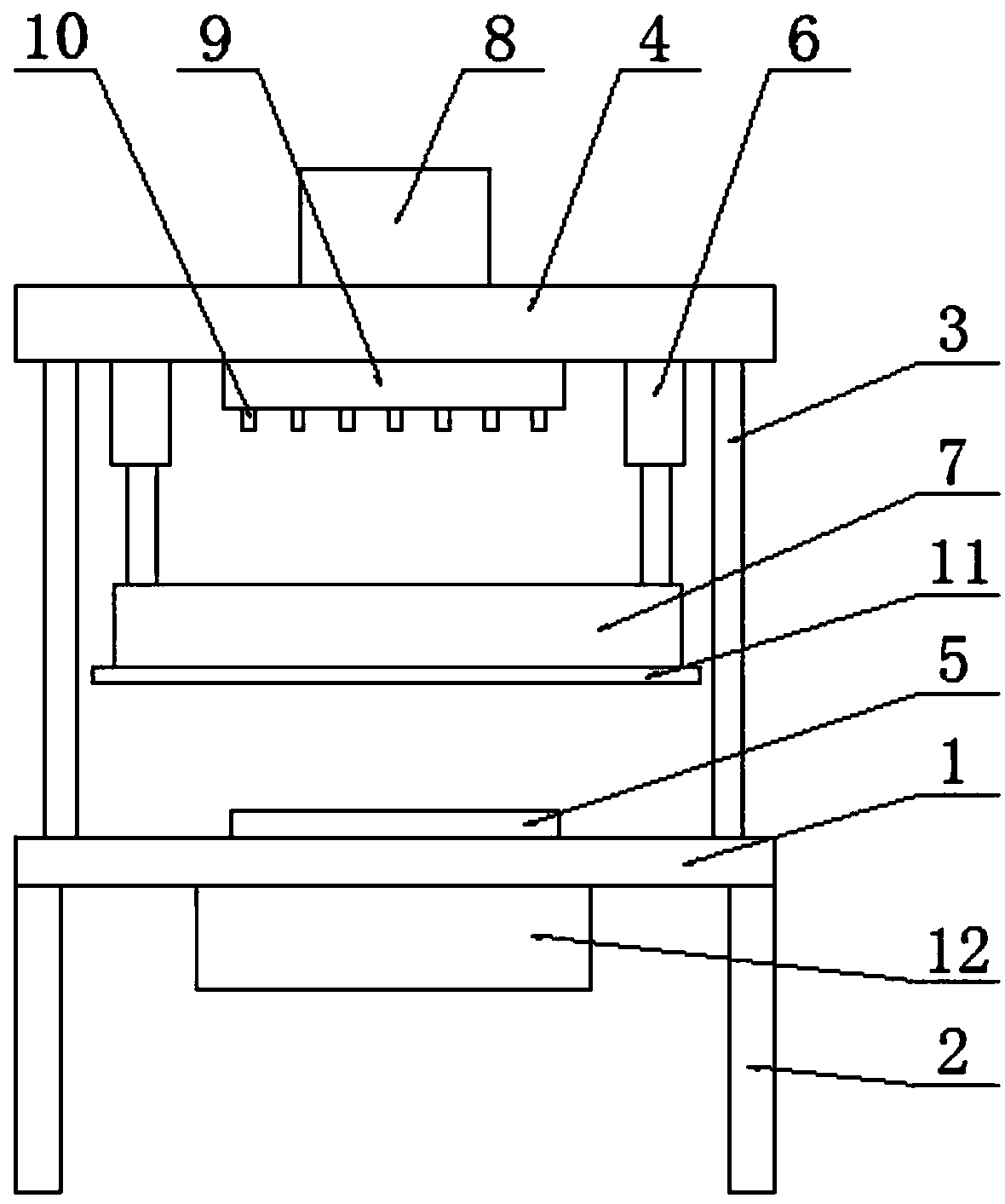

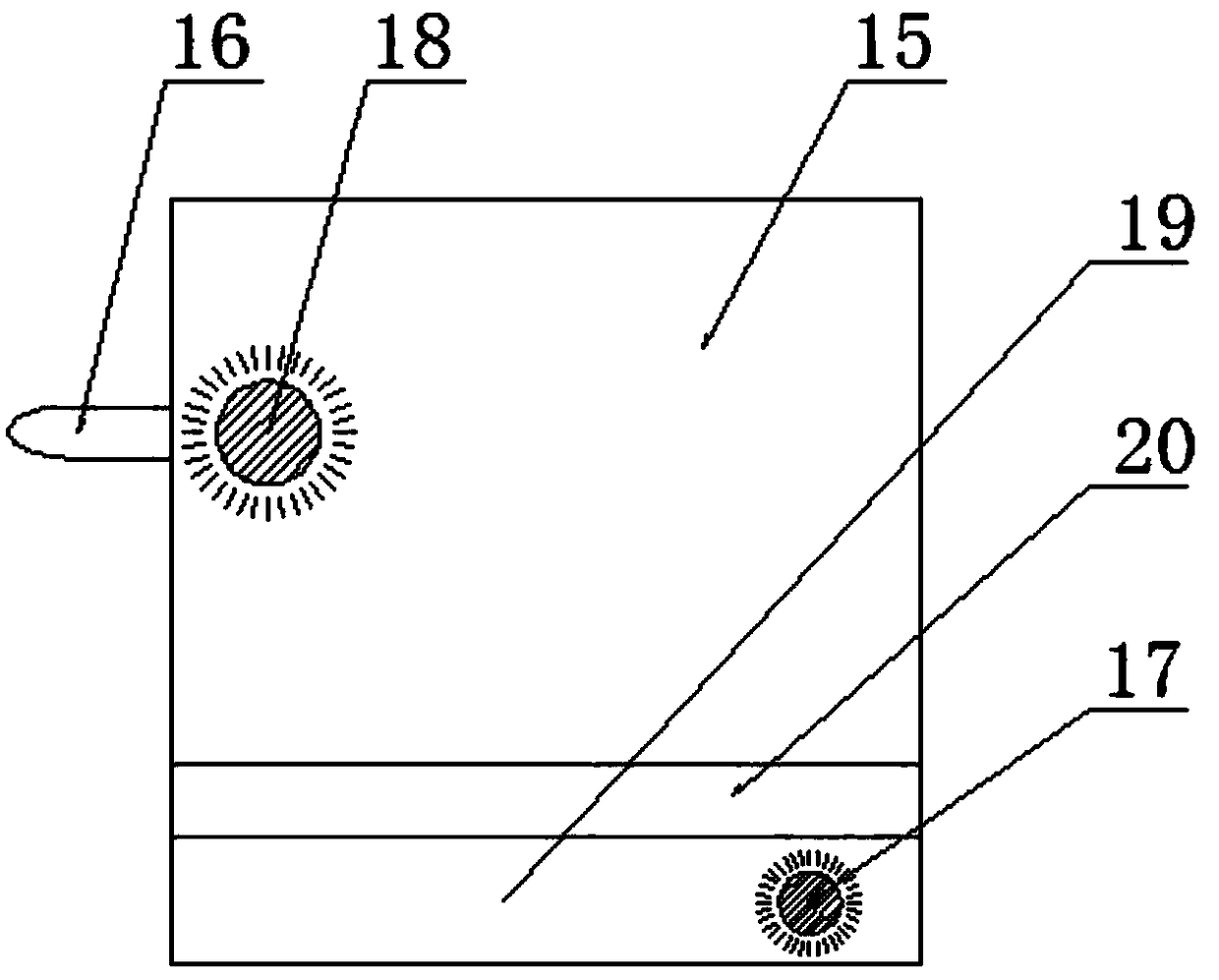

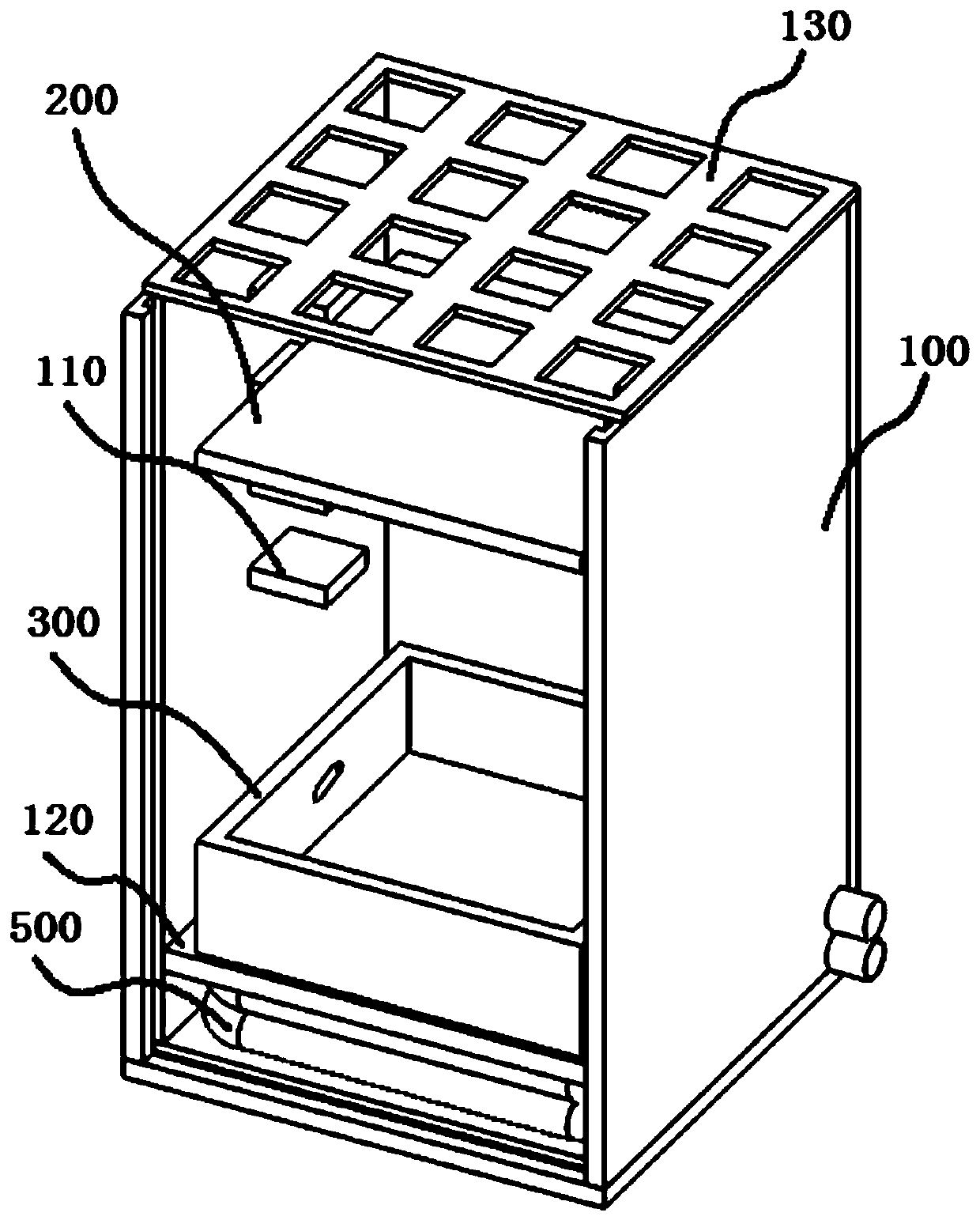

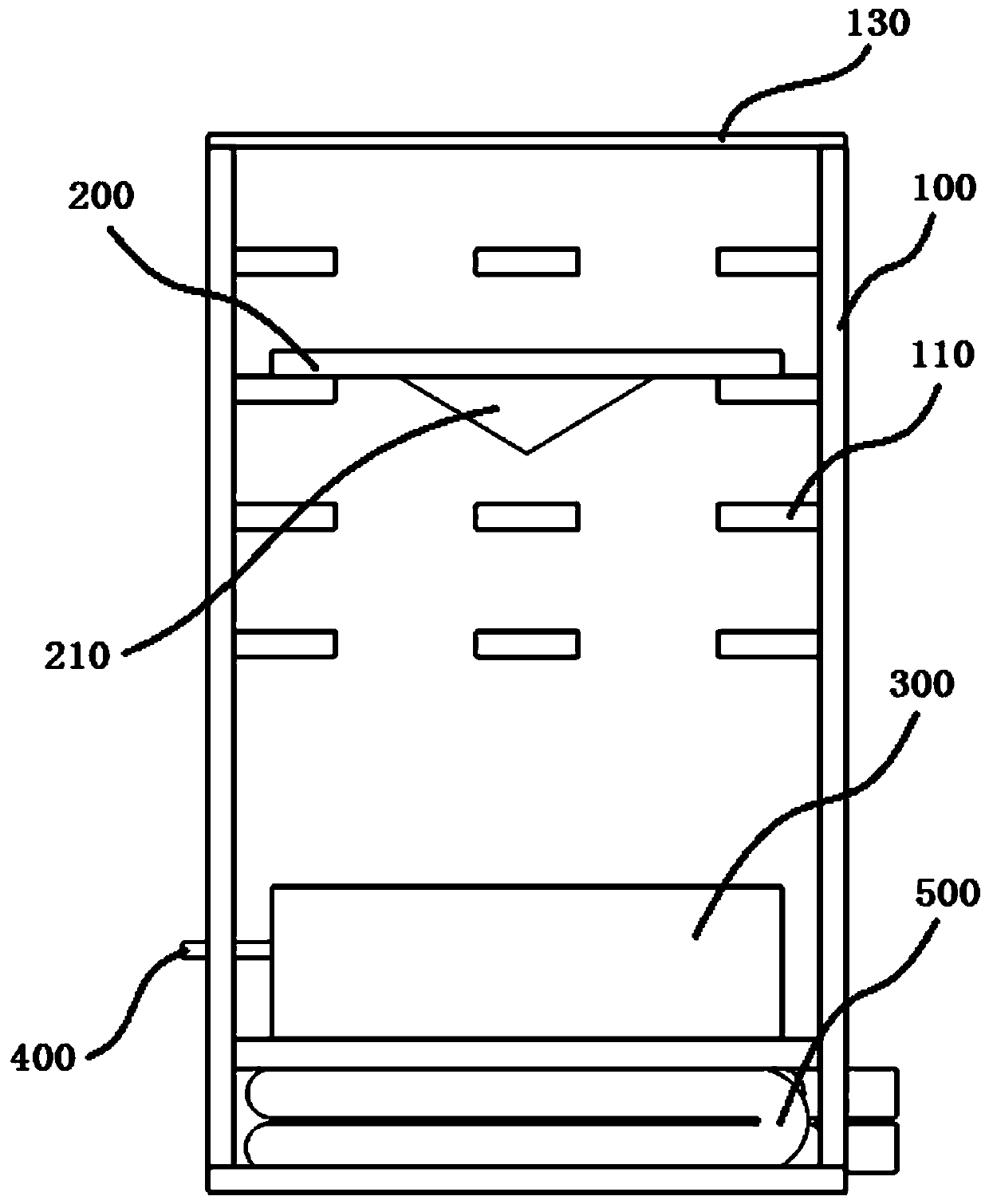

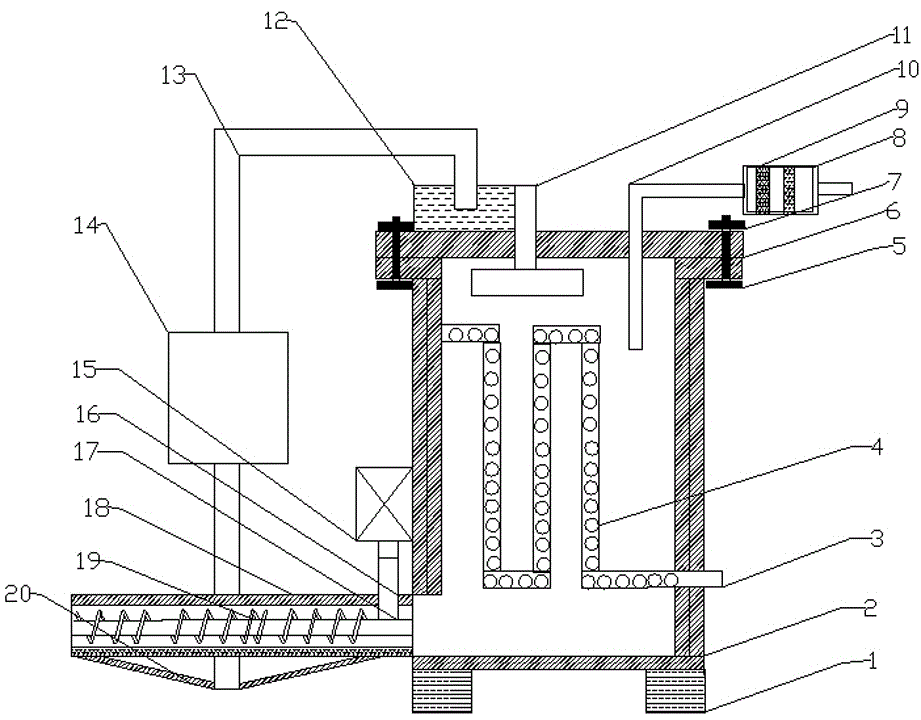

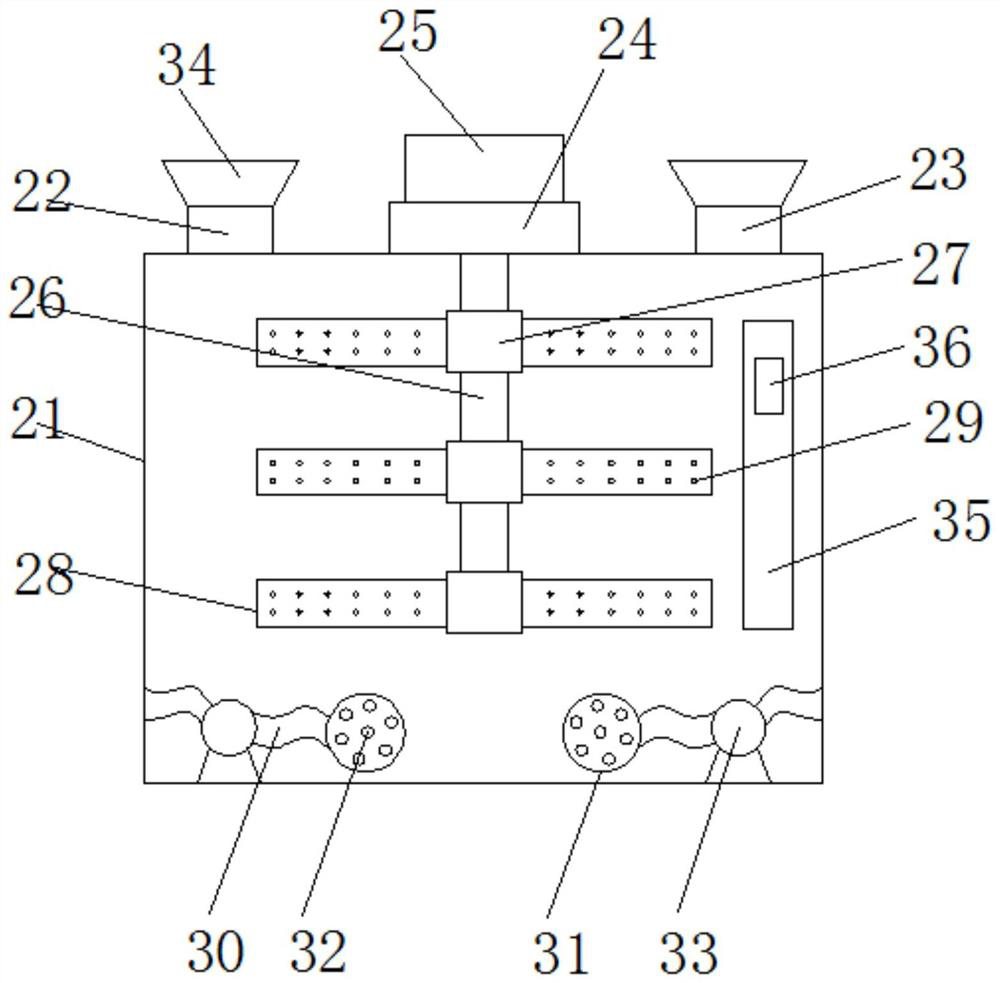

PCB spraying device used for electronic products

InactiveCN109290108AQuality assuranceQuality improvementPrinted circuit liquid treatmentSpraying apparatusContact modeMechanical engineering

The invention discloses a PCB spraying device used for electronic products, and relates to the field of electronic products. The PCB spraying device comprises a spraying box. A fixing plate is fixedlyconnected to the upper portions of the left side and the right side of the interior of the spraying box. A mixing box is fixedly mounted in the middle of the upper surface of the fixing plate. A first shaft sleeve is fixedly connected to the middle of the inner wall of the left side of the spraying box. A driven rotary rod is slidably connected to the interior of the middle of the right side of the first shaft sleeve. The right end of the driven rotary rod penetrates through the interior of the middle of the right side of the mixing box and the interior of the middle of the upper portion of the right side of the spraying box, and an anti-wear sealing rubber pad is connected to the joint of the driven rotary rod and the mixing box in a contact mode. A first bearing is mounted at the jointof the driven rotary rod and the spraying box. By adoption of the PCB spraying device, omnibearing spraying of PCBs can be achieved, and the spraying effect is very good; and in the spraying process,residual paint is collected through a collection box, so that paint is recycled, and resources are saved.

Owner:郑州莱兹电子科技有限公司

Power transmission line repairing and bird repelling device

ActiveCN107134739AGuaranteed stabilityHigh sensitivityAnimal repellantsApparatus for overhead lines/cablesEngineeringTower

The invention discloses a power transmission line repairing and bird repelling device comprising an overhead track which is arranged along a power transmission line, a moving trolley which is arranged on the overhead track, a balance mechanism which is arranged on the bottom surface of the moving trolley, an inspection robot which is arranged on the moving trolley, a control center which is arranged on the moving trolley and connected with the inspection robot, and a cleaning mechanism which is arranged on the moving trolley and used for cleaning the power transmission line. The inspection robot is enabled to move along the power transmission line through cooperation of the overhead track and the moving trolley, the situation of the birds on the power transmission line and the tower can be monitored, the bird nest can be cleaned through a bird nest removing mechanism, and the device is ensured not to tilt in capturing the bird nest through combination of the balance mechanism on the bottom part of the moving trolley so that safe operation of the power transmission line can be protected; and the phenomenon that the birds do not build the bird nest at the original location again in a period of time can be realized by using the natural bird repelling agent.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

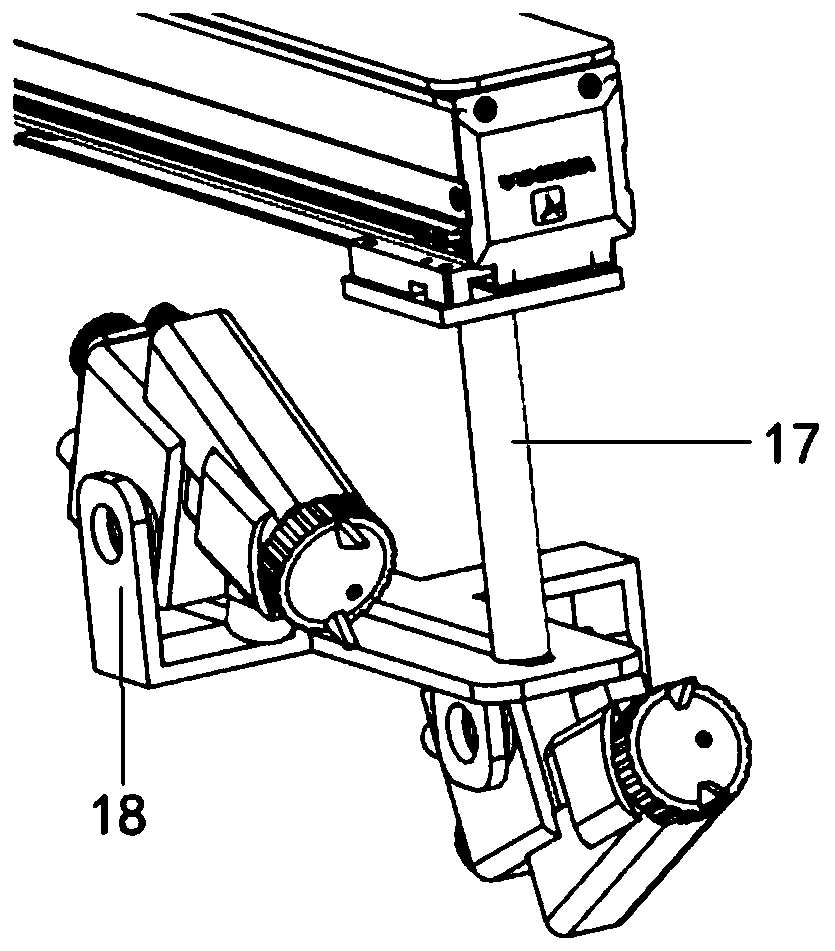

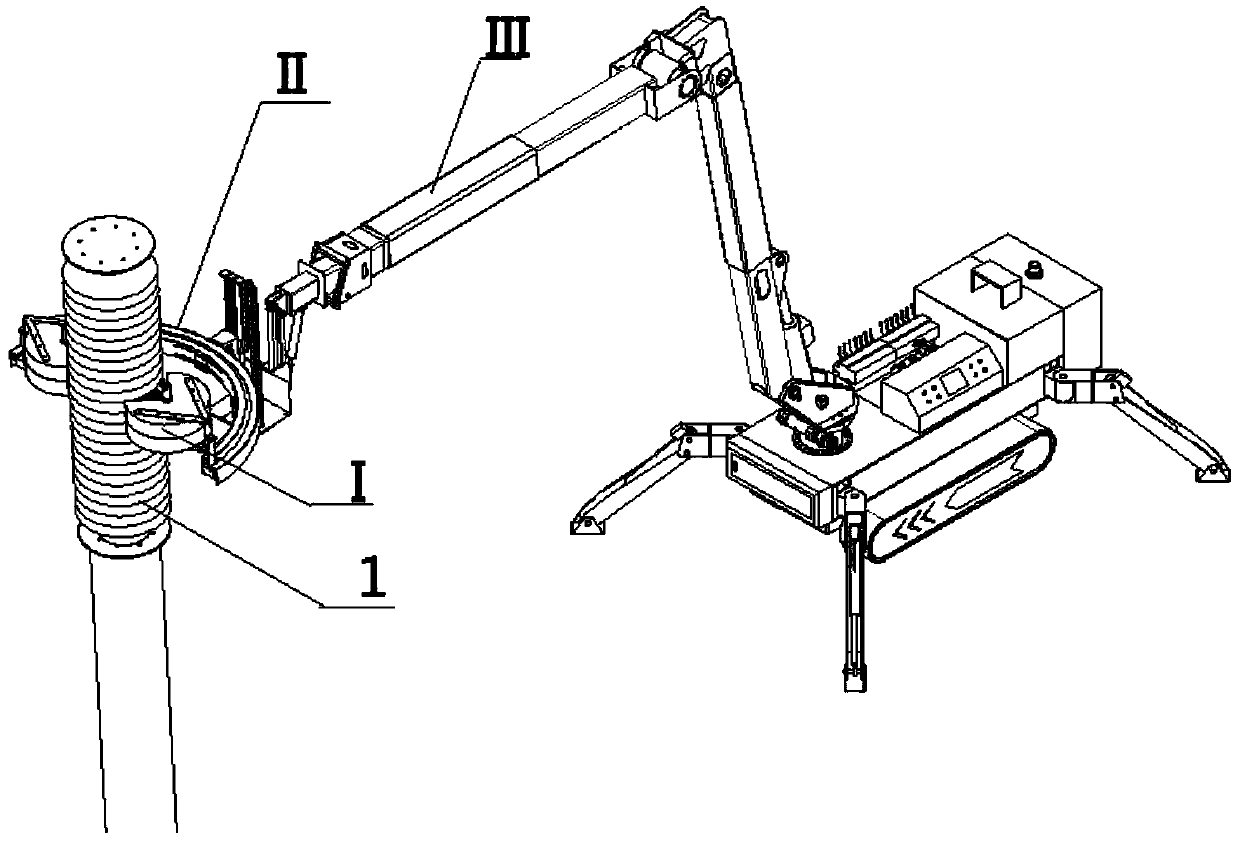

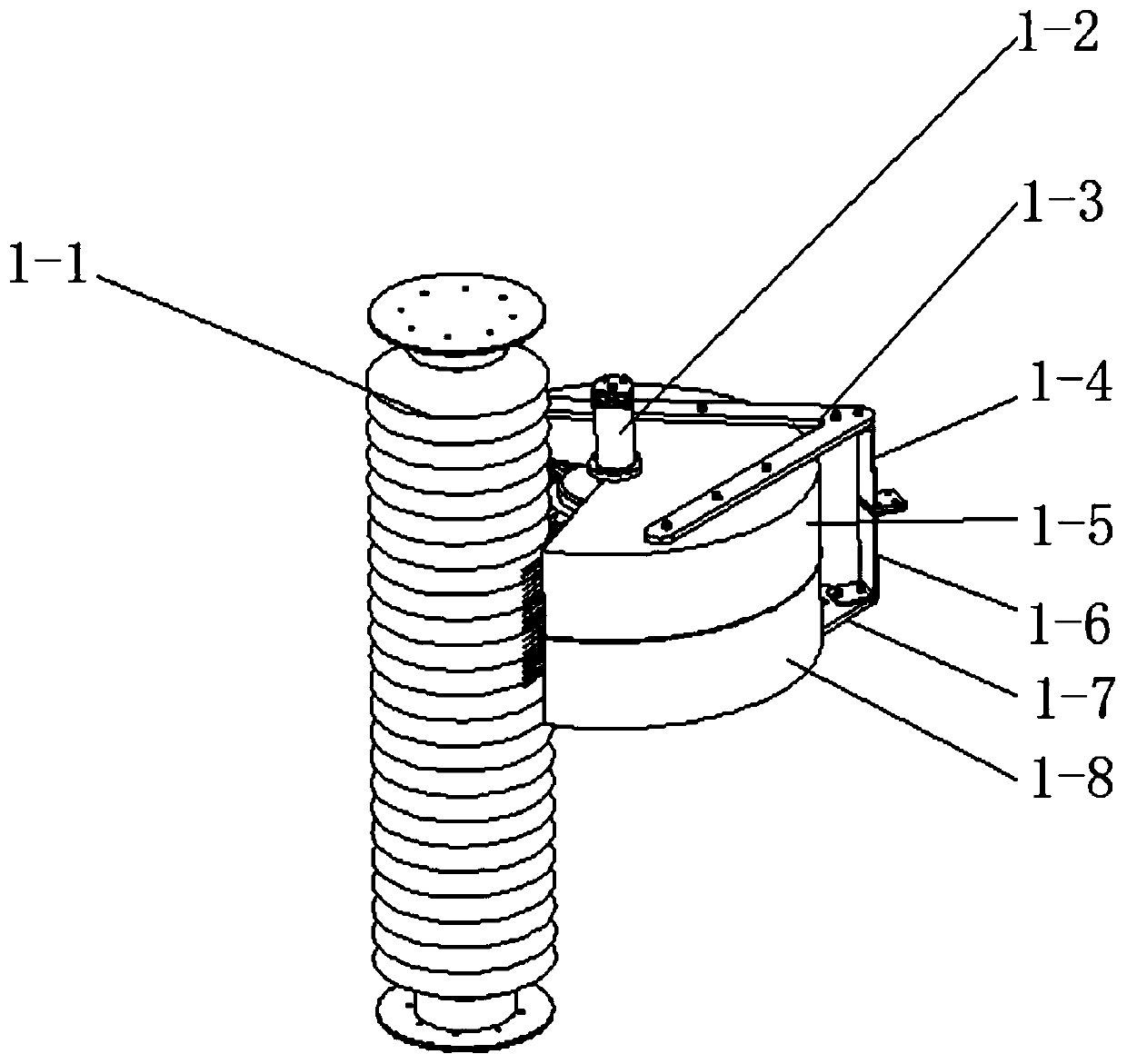

Transformer substation insulator hot-line work robot system and method

ActiveCN110883764ASolve positioningSolving the Alignment DilemmaProgramme-controlled manipulatorGripping headsRobotic systemsTransformer

The invention discloses a transformer substation insulator hot-line work robot system and method. The system comprises a robot body, a control module arranged in the robot body and an insulating lifting mechanism arranged on the robot body. The tail end of the insulating lifting mechanism is connected with a live-line work tool through a quick connecting part; the live-line work tool comprises a live-line cleaning device or an RTV spraying device. The invention has the beneficial effects that the system can be quickly switched to the RTV spraying device after an insulator sweeping operation iscompleted, so the continuous operation of sweeping-spraying of the insulators of a transformer substation can be achieved.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

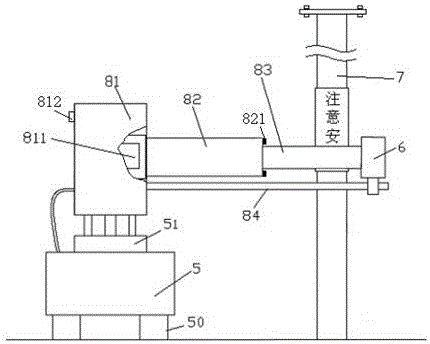

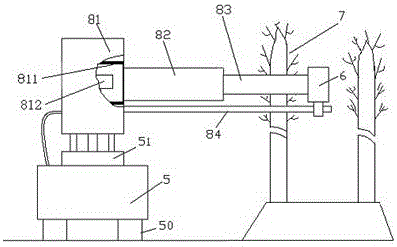

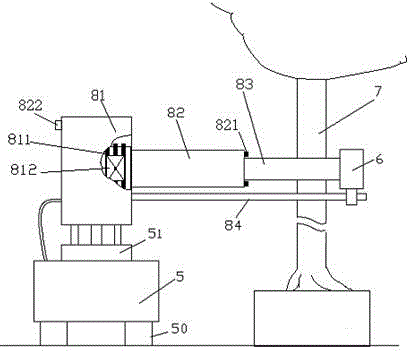

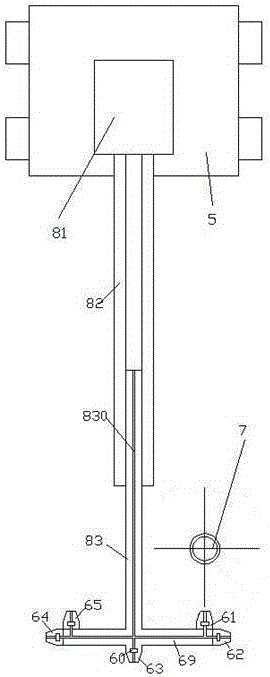

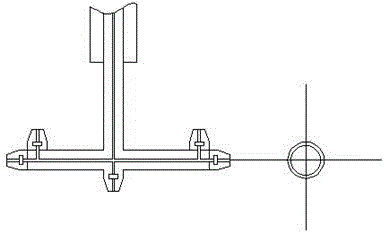

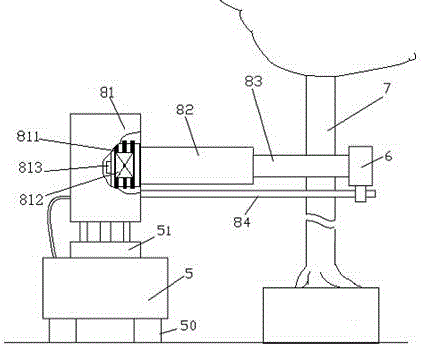

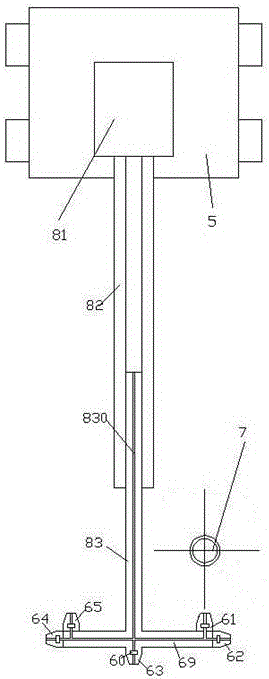

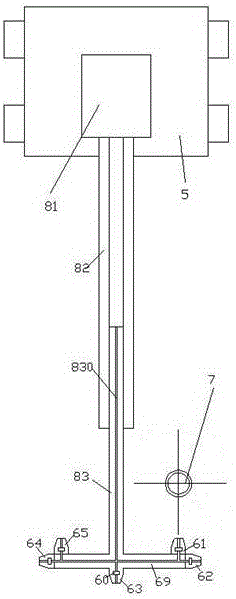

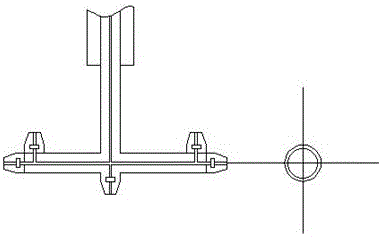

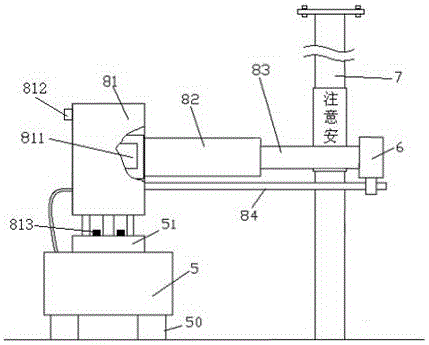

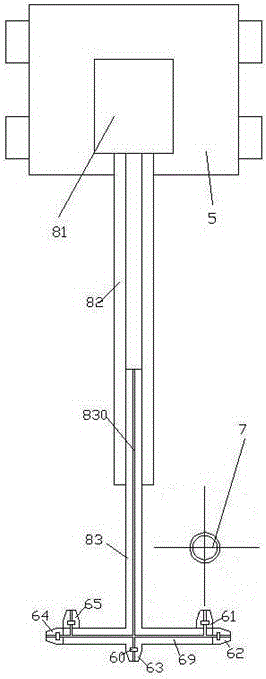

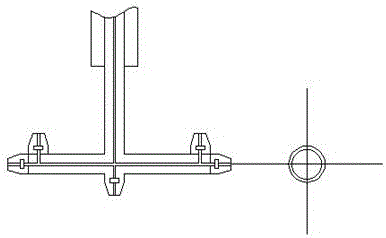

Efficient telegraph pole character spraying device

ActiveCN106393997ARealize all-round sprayingTypewritersPower drive mechanismsVehicle frameElectric machine

Provided is an efficient telegraph pole (7) character spraying device. The efficient telegraph pole (7) character spraying device comprises a character spraying template mounted on a telegraph pole (7), a traveling vehicle frame part (5) provided with traveling wheels (50), a lifting unit (51) located on the traveling vehicle frame part (5), and spraying equipment (81) driven by the lifting unit (51) in a lifting mode. The spraying equipment (81) comprises a body part connected with the lifting unit (51), a threaded sleeve (82) driven by a motor in the body part and a telescopic screw (83) driven by the threaded sleeve (82) in a threaded mode. A through hole (830) extending in the axial direction is formed in the telescopic screw (83) and used for conveying sprayed liquid, and the through hole (830) is in fluid connection with a spraying execution assembly (6) located at the tail end of the telescopic screw (83).

Owner:常州中科绿塑环保科技有限公司

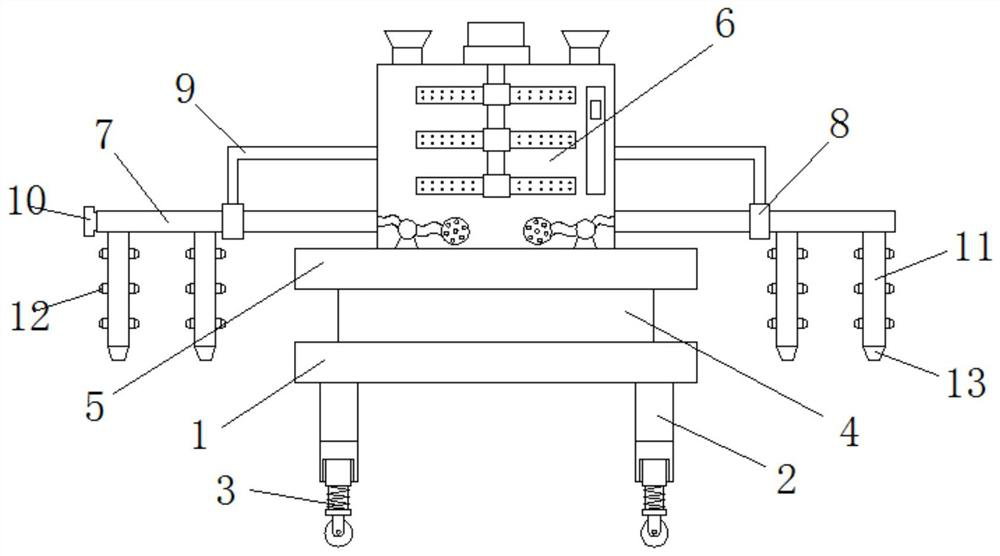

Steel structure surface paint spraying device

InactiveCN113019775AAchieve vertical movementRealize all-round sprayingSpraying apparatusTransmission beltGear wheel

The invention discloses a steel structure surface paint spraying device, and belongs to the technical field of steel structure equipment. By arranging a first telescopic electric cylinder, extension and retraction of the first telescopic electric cylinder is controlled, the spacing distance between a paint spraying plate and steel in each group of paint spraying assemblies is adjusted, the uniformity of the paint spraying plates during paint spraying is realized, non-uniform paint spraying is prevented, by arranging a second telescopic electric cylinder, extension and retraction of the second telescopic electric cylinder is controlled, a straight rack is driven to transversely move, the transverse movement of the straight rack drives a second rotating gear which is engaged with the straight rack to rotate, due to the fact that the second rotating gear is coaxially connected with a transmission belt wheel, the second rotating gear rotates to drive a first shaft in each paint spraying assembly to rotate through a transmission belt, rotation of a first rotating gear is achieved, rotation of an arc-shaped rack is achieved through rotation of a first rotating gear, so that the paint spraying plates rotate around second shafts, comprehensive paint spraying of the steel is achieved, and spraying dead angles are reduced.

Owner:绍兴三雄钢结构有限公司

Portable device for spraying pesticides for garden seedling trees and using method thereof

InactiveCN106259273ARealize all-round sprayingInsect catchers and killersElectric machineryEngineering

The invention discloses a portable device for spraying pesticides for garden seedling trees and a using method thereof. The portable device comprises a travelling frame part (5), elevating equipment (51) and a spraying assembly (81), wherein mobile wheels (50) are mounted on the travelling frame part (5), the elevating equipment (51) is located on the travelling frame part (5), the spraying assembly (81) is driven by the elevating equipment (51) in an elevatable manner, and comprises a main body portion, a threaded sleeve (82) and a telescopic screw rod (83), the main body portion is connected with the elevating equipment (51), the threaded sleeve (82) is driven by an electric motor in the main body portion, the telescopic screw rod (83) is driven by the threaded sleeve (82) in a threaded manner, an axially extended through hole (830) is arranged in the telescopic screw rod (83) to transfer spraying liquid, the through hole (830) is in liquid connection with a spraying executing assembly (6) located at a tail end of the telescopic screw rod (83).

Owner:枣庄市园林工程公司

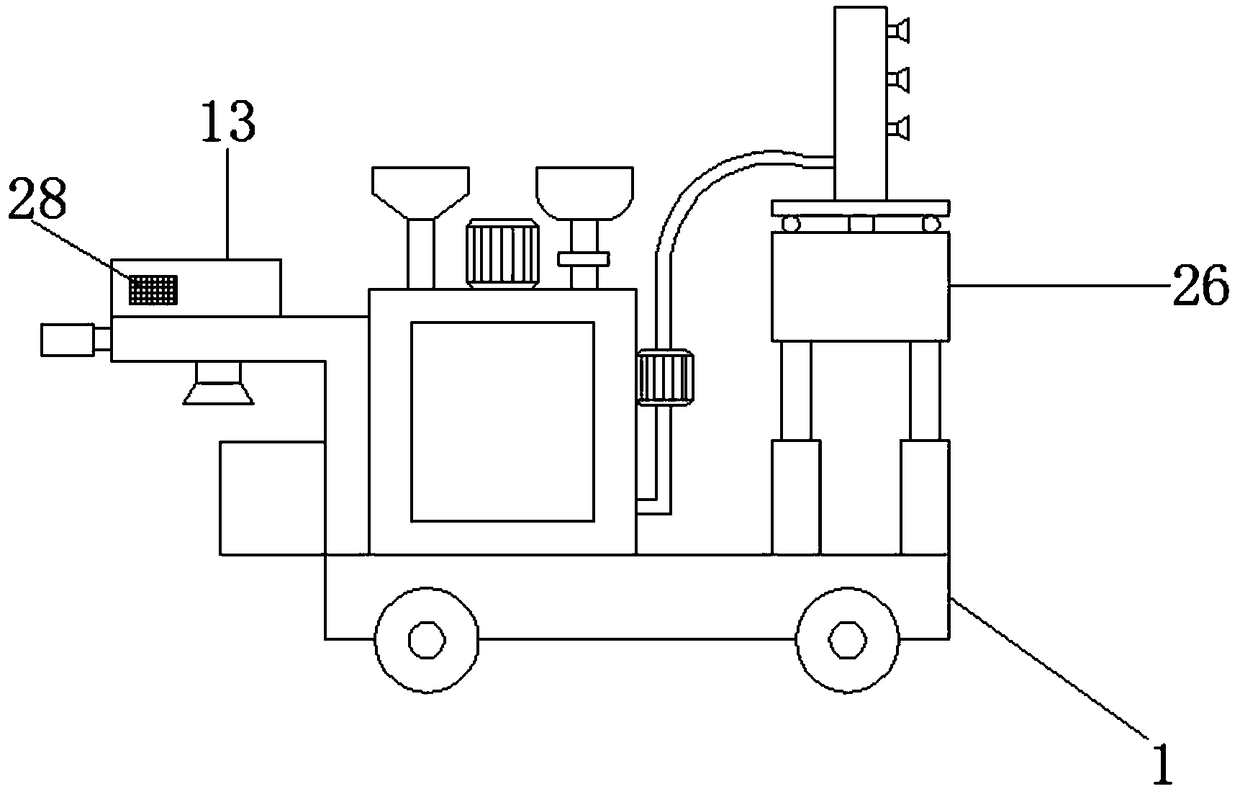

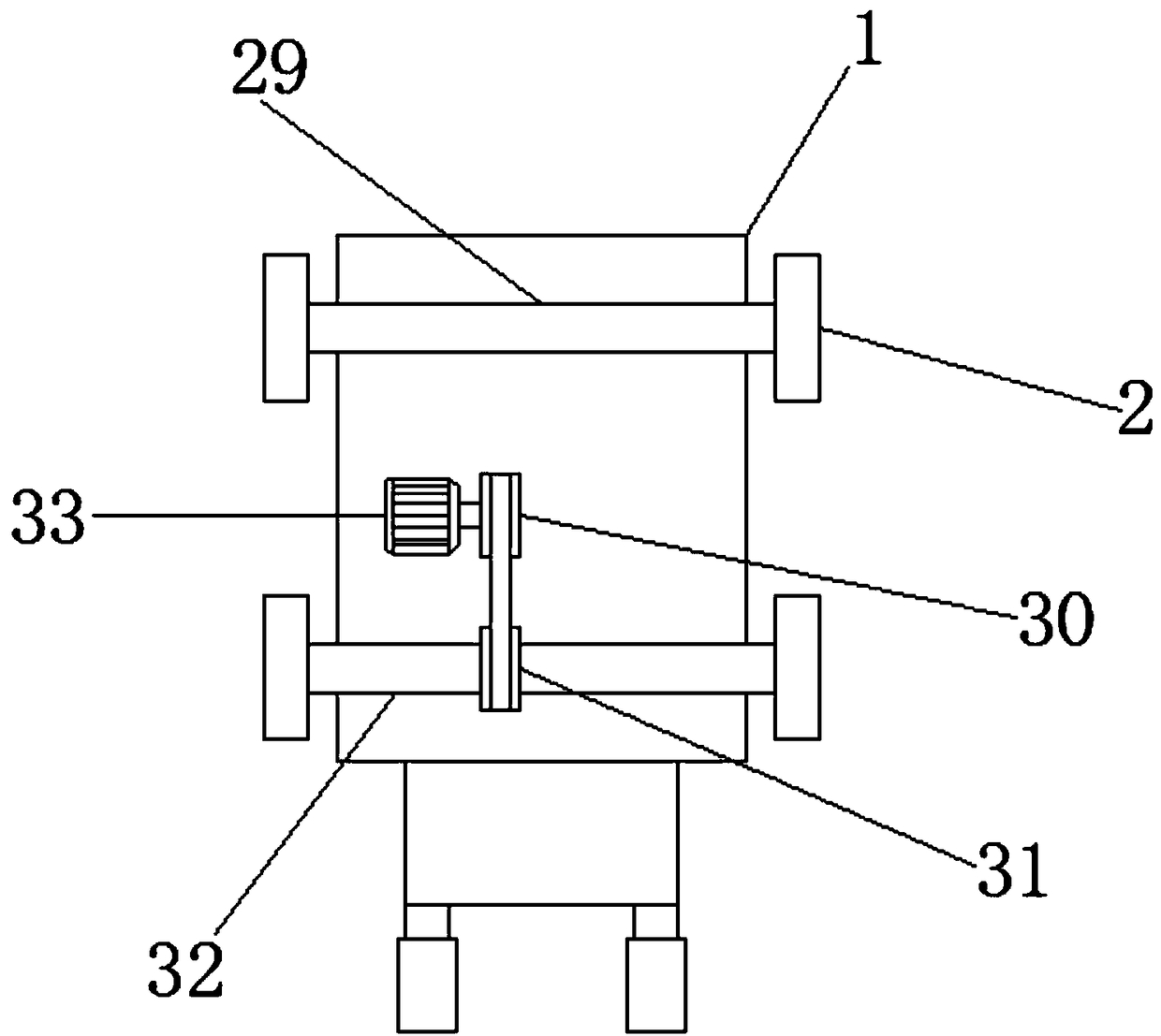

Pasture spraying device capable of rotating in all directions for animal husbandry

InactiveCN108812609AEasy to sprayImprove spraying efficiencyRotary stirring mixersTransportation and packagingCouplingEngineering

The invention belongs to the technical field of spraying devices, particularly relates to a pasture spraying device capable of rotating in all directions for animal husbandry, and aims at solving theproblems of simple structural design, single function and poor spraying effect of a spraying device. In order to solve the above problems, the invention provides the pasture spraying device. The pasture spraying device comprises a base, a mixing tank is fixed to the outer wall of the top of the base through screws, a motor is fixed to the outer wall of the top of the mixing box through screws, theoutput shaft of the motor is connected with a stirring rod through a coupler, stirring blades are welded to the outer wall of the stirring rod, a water inlet hole is formed in the outer wall of the top of the side, close to the motor, of the mixing box, a water inlet hopper is inserted in the inner wall of the water inlet hole, and a drug inlet hole is formed in the outer wall of the top of the side, close to the other side of the motor, of the mixing tank. The pasture spraying device has the advantages of wide spraying range and convenient use, the spraying efficiency of pastures is improved, automatic moving of the device is achieved, the moving is convenient, the device is time-saving and labor-saving, the working efficiency of people is improved, and it is ensured that the device canbe operated for a long time.

Owner:位素华

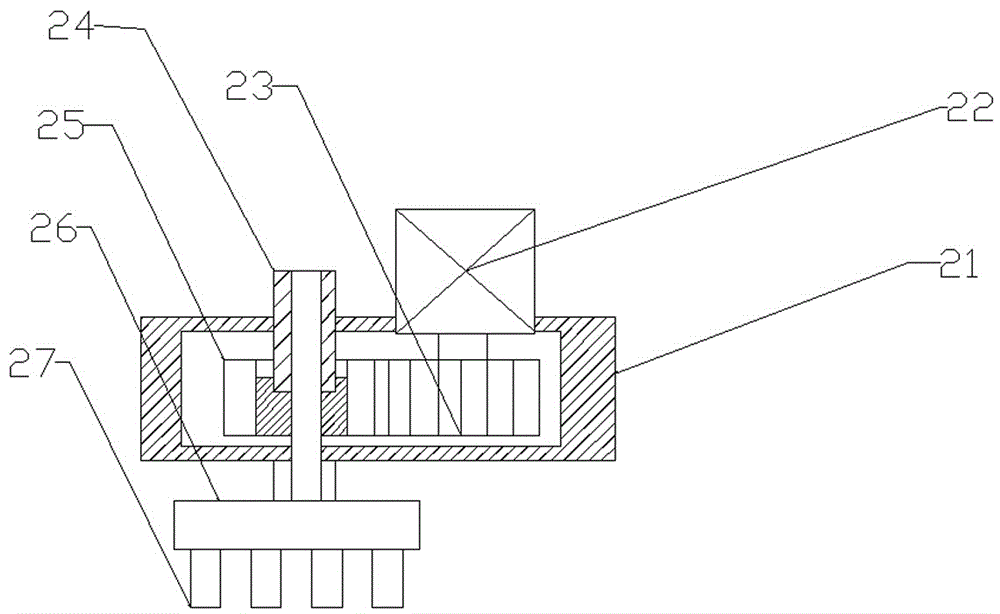

Self-washing type crossed worm wheel and worm chemical stirring device

InactiveCN106492675AReasonable structural designRealize all-round sprayingRotary stirring mixersTransportation and packagingGear driveMotor drive

The invention provides a self-washing type crossed worm wheel and worm chemical stirring shaft device which comprises a stirring barrel, a motor bracket, stirring devices, an upper end cover, a spraying device, a worm wheel, a material conveying pipe, a transverse type rotating shaft and a housing, wherein the worm wheel is arranged at the lower end of a worm; the worm wheel is fixedly connected to a longitudinal rotating shaft in a sleeving manner; transverse type stirring shafts are uniformly arranged on the longitudinal type rotating shaft; stirring branch shafts are fixedly arranged at the tail ends of the transverse type stirring shafts; a fourth gear is fixedly connected to a water pipe in a sleeving manner; the lower end of the water pipe is fixedly connected with a spherical spraying head. The self-washing type crossed worm wheel and worm chemical stirring shaft device is reasonable in structural design; the rotation of a first servo motor drives a second gear to rotate so as to drive the stirring devices to stir chemical materials; the worm and the worm wheel are in meshed transmission to drive the stirring branch shafts to uniformly mix and stir the chemical materials; rotation of a second servo motor drives a third gear to rotate so as to drive the fourth gear to rotate; the fourth gear drives the water pipe to rotate so as to drive the spherical spraying head to rotate to realize all-round spraying.

Owner:河南微服网络科技有限公司

Fire extinguishing bomb and fire extinguishing method

ActiveCN110575636AImprove securitySafe and efficient sprayingAmmunition projectilesFire rescueEngineeringHigh pressure

The invention relates to a fire extinguishing bomb and a fire extinguishing method and belongs to the technical field of fire extinguishing bombs. The problems of poor safety, low control precision, high cost and high fire extinguishing agent surplus ratio of an existing fire extinguishing bomb product are solved. The fire extinguishing bomb comprises a power device, a spraying device and a control device, the power device is used for pushing flight of the fire extinguishing bomb, and the control device is used for controlling ignition of the power device and controlling the spraying device tospray a fire extinguishing agent; the spraying device comprises a spraying shell, a liner and a propellant grain, the liner and the propellant grain are arranged in the spraying shell, and the lineris used for being filled with the fire extinguishing agent; the spraying shell is provided with spraying holes for the fire extinguishing agent to be sprayed out of, and the spraying holes form a spray channel of the fire extinguishing agent; after the propellant grain is ignited, generated high-temperature and high-pressure gas is applied to the fire extinguishing agent so that the fire extinguishing agent can break through the liner and be released out of the fire extinguishing bomb from the spraying holes. According to the fire extinguishing bomb, in the spraying process, no harmful fragments are generated, the product safety is high, and the caking rate and surplus ratio of the fire extinguishing agent are obviously lowered.

Owner:BEIJING MECHANICAL EQUIP INST

Blowout type spraying device

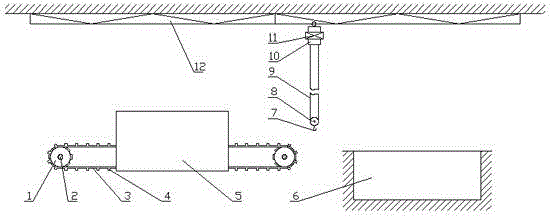

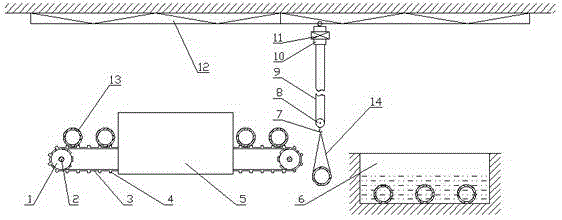

InactiveCN104307705AEasy to transportEasy to installLiquid surface applicatorsCoatingsDrive wheelTower

The invention discloses a blowout type spraying device. The device comprises a driving wheel (1), a driving belt (3), a pre-heating storeroom (5) and a spraying well (6), and is characterized in that the driving wheel (1) is arranged on an actuating shaft (2), the driving wheel (1) is matched with the driving belt (3), the driving belt (3) penetrates through the pre-heating storeroom (5), and the output side of the driving belt (3) is provided with the spraying well (6), and a hoisting component (11) is arranged above the driving belt (3) and the spraying well (6); the hoisting component (11) comprises a fixed tower (12), a connecting piece (10), a rope (9) and a hook (7); the connecting piece is movably mounted on the fixed tower (12), the lower end of the connecting piece (10) is provided with the rope (9), the rope (9) is connected with a pulley (8), and the hook (7) is arranged on the pulley (8). The spraying device disclosed by the invention is uniform in spraying, efficient and convenient, economical and environment-friendly.

Owner:六枝特区华兴管业制品有限公司

Spraying head of washing machine, spraying device and washing machine

PendingCN113152036AImprove cleanlinessIncrease cleaning speedOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention provides a spraying head of a washing machine. The spraying head comprises a spraying head body; a flow guide cavity and a rotation driving assembly are arranged in the spraying head body; one end of the spraying head body is provided with an opening end, and the other end of the spraying head body is provided with a plurality of spraying openings; the two ends of the flow guide cavity communicate with the opening end and the spraying openings; the rotation driving assembly is fixed to the inner wall of the flow guide cavity; the opening end is used for being coaxially and rotationally arranged in a water outlet of a water inlet piece; and water flow enters the spraying head body from the water inlet piece and impacts the rotation driving assembly to drive the spraying head body to rotate, so that the spraying openings spray water in a rotating mode. The invention further provides a spraying device of the washing machine and the washing machine. The spraying head of the washing machine provided by the invention can realize 360-degree all-dimensional spraying, has a good defoaming effect, can improve the washing cleanliness and the cleaning speed, and can also clean parts such as door glass, an inner barrel and a door seal of the washing machine.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

Airborne fire extinguishing bomb and fire extinguishing method

ActiveCN110694207BSimple structurePrecise control of spraying timeAmmunition projectilesAircraft componentsProcess engineeringPower apparatus

Owner:BEIJING MECHANICAL EQUIP INST

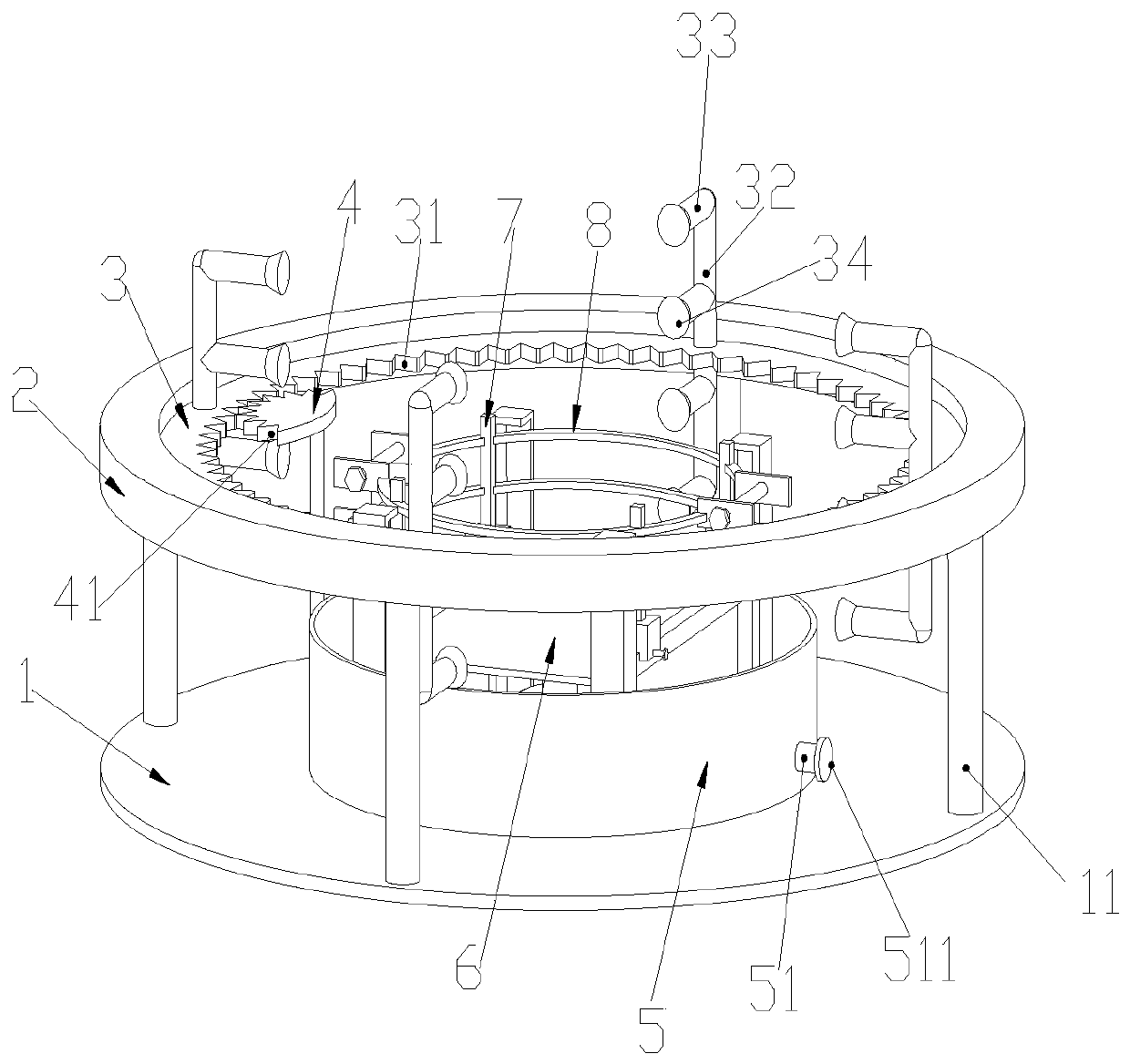

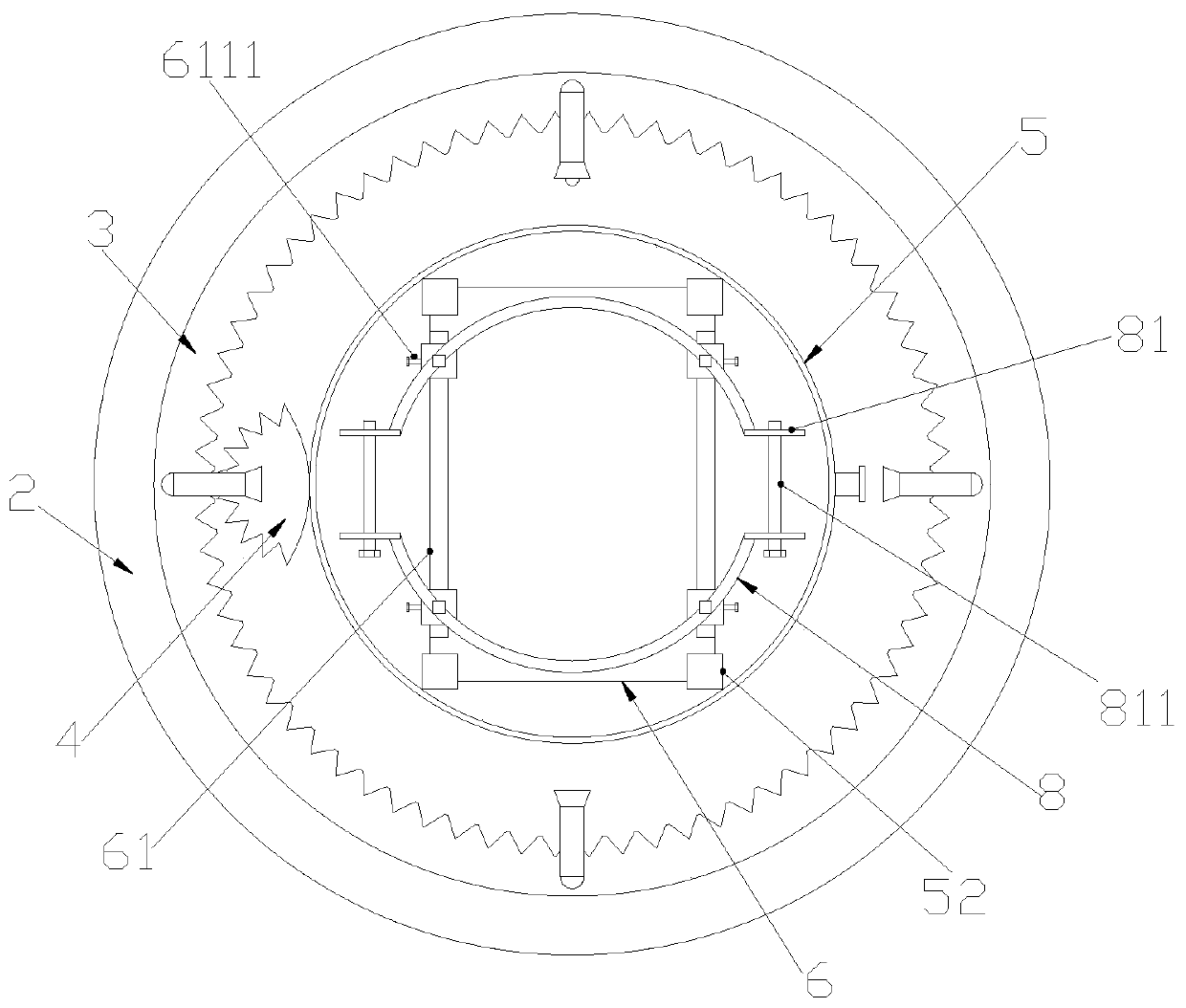

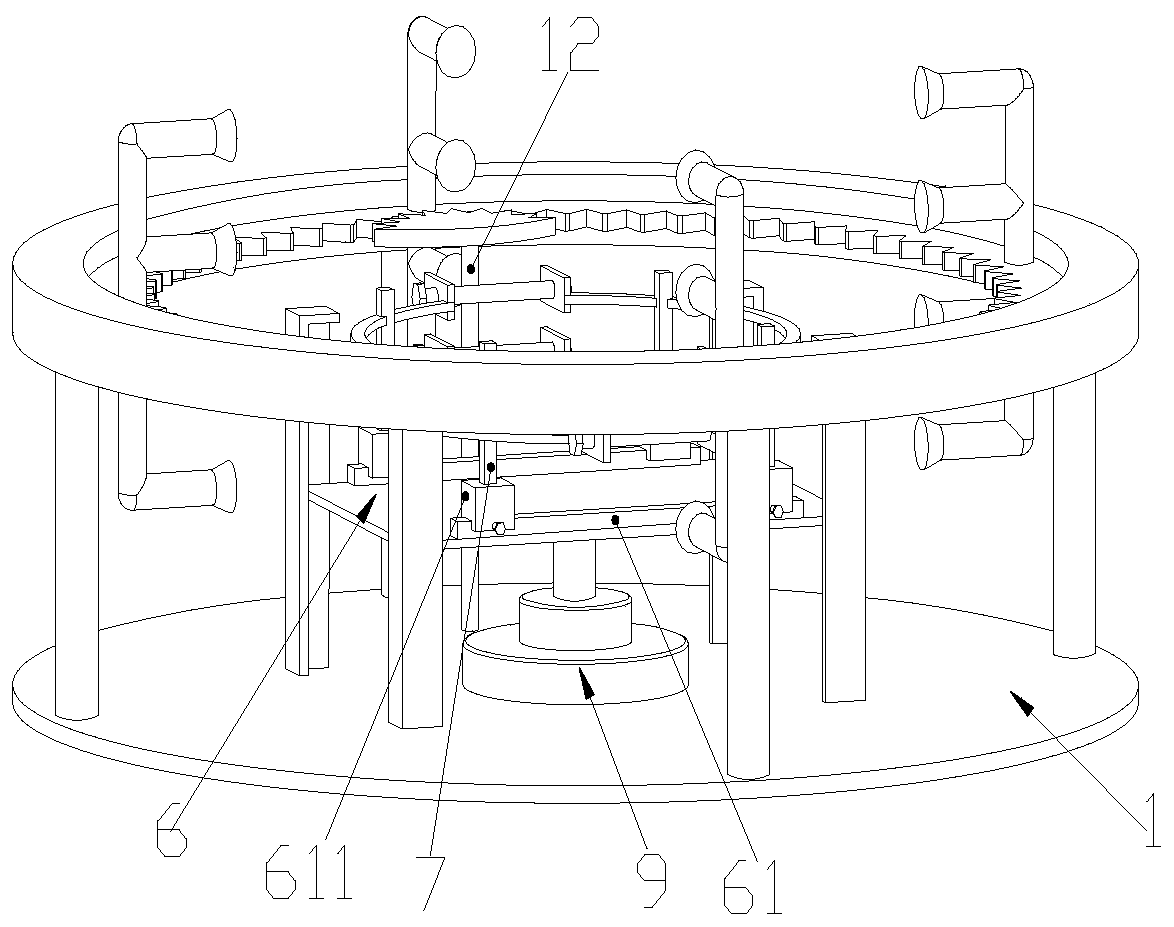

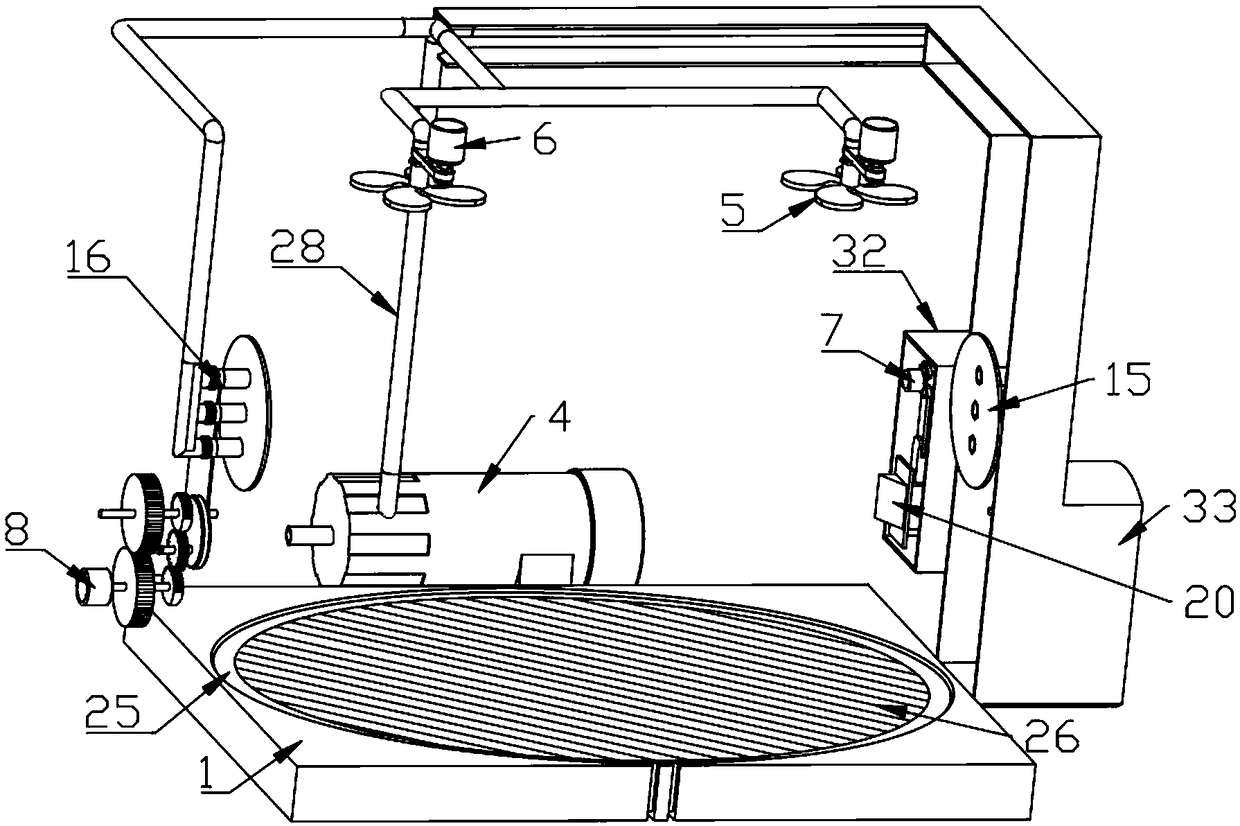

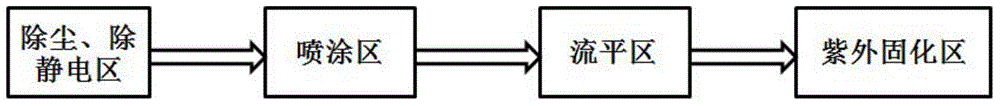

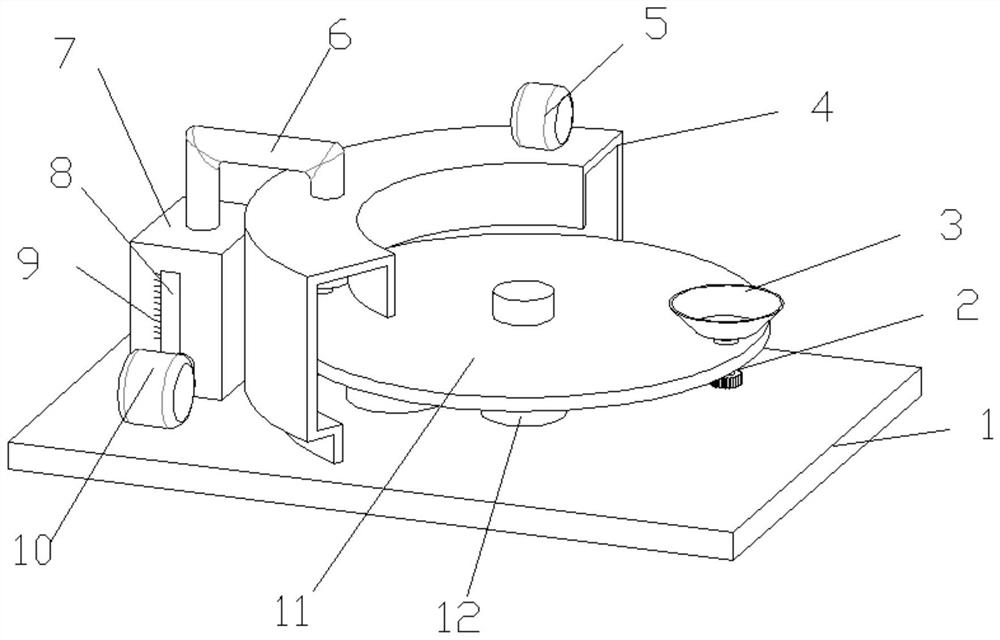

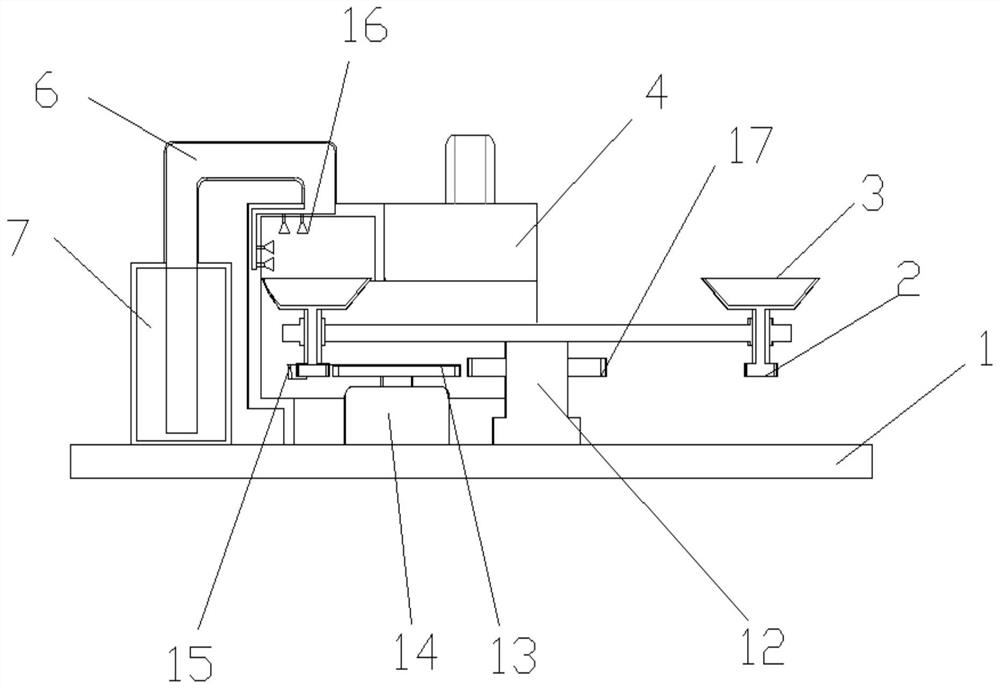

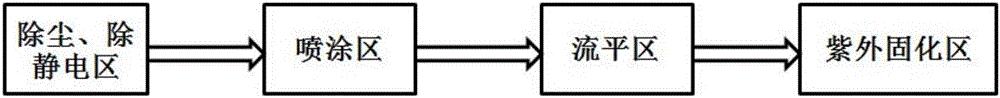

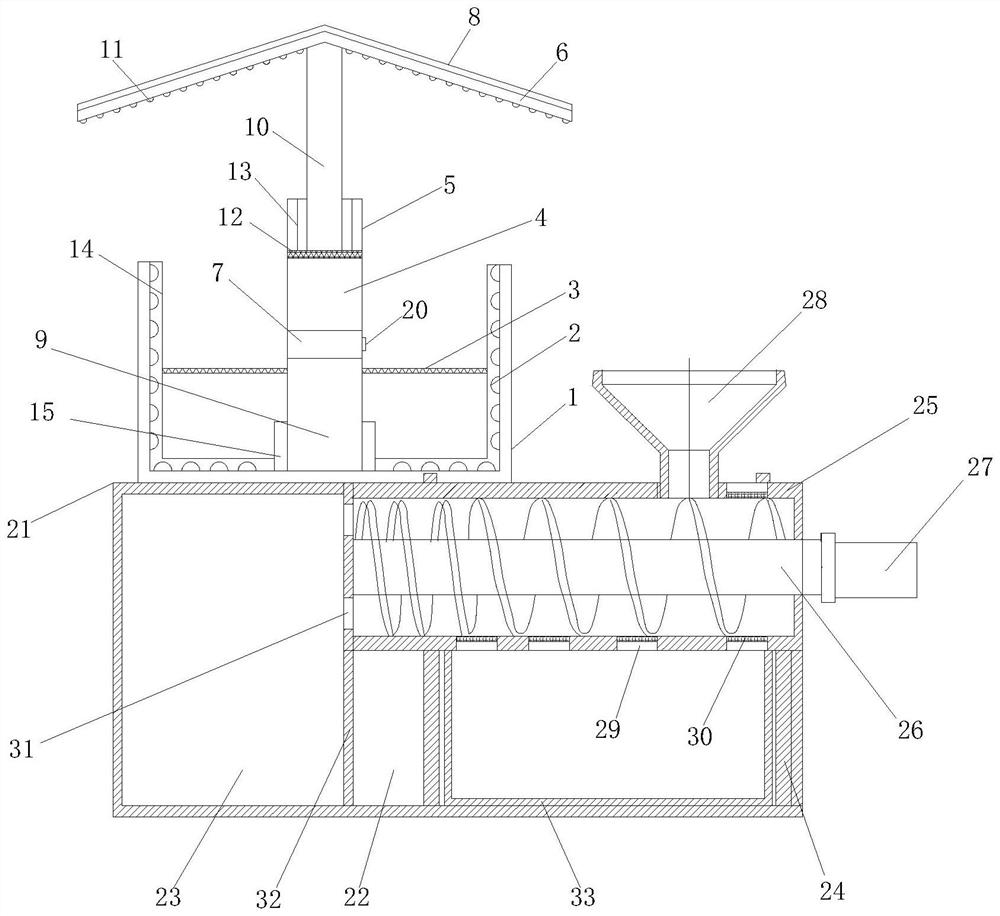

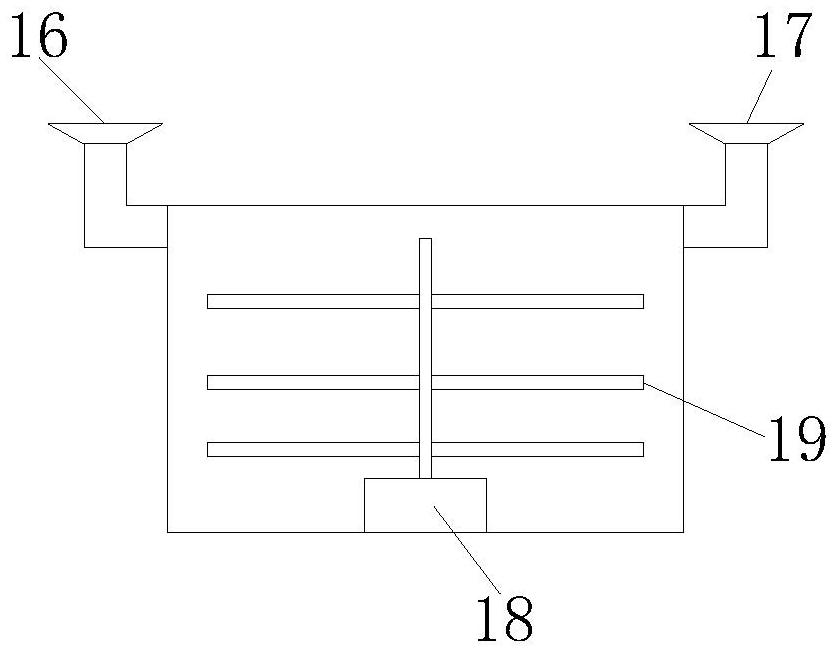

A spraying equipment and spraying process for cylindrical parts

ActiveCN109453921BFully automatedAvoid direct contactSpraying apparatusPretreated surfacesEngineeringAutomation

The invention discloses spraying equipment for cylindrical parts. The spraying equipment comprises a round base and is characterized in that supporting columns are arranged at the upper end of the base, and an annular fixing table is arranged at the upper ends of the supporting columns; a first sliding groove is formed in the inner side of the circumference of the annular fixing table, and a rotating table is installed in the first sliding groove; a rotating shaft is arranged at the upper end of the base, and a driving mechanism is fixed at the upper end of the rotating shaft; a collecting groove is formed in the upper end of the base; a fixing column is arranged at the bottom end of the collecting groove, and a second sliding groove is formed in the fixing column; a supporting table is arranged in the second sliding groove; sliding rails which are symmetrically distributed are arranged at the upper end of the supporting table, and sliding blocks are arranged on the sliding rails; fixing columns are arranged at the upper ends of the sliding blocks, and clamping grooves are formed in the fixing columns; and arc-shaped fixing rings are fixed in the clamping grooves. The invention aims to provide the spraying equipment for the cylindrical parts and the spraying process of the spraying equipment. A spraying pipe capable of rotating intermittently and a lifting clamping device are arranged on the device, so that full automation of spraying equipment is realized.

Owner:山东惠元新材料科技发展有限公司

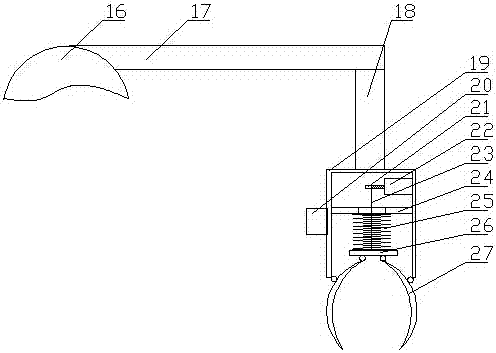

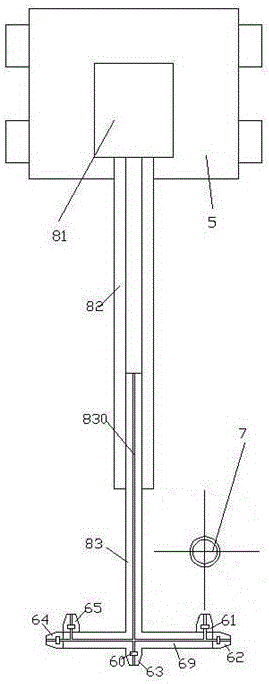

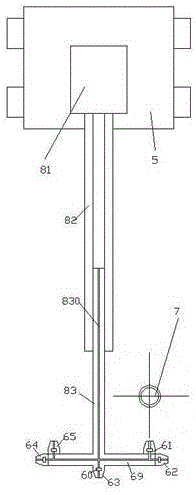

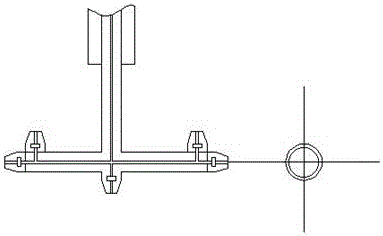

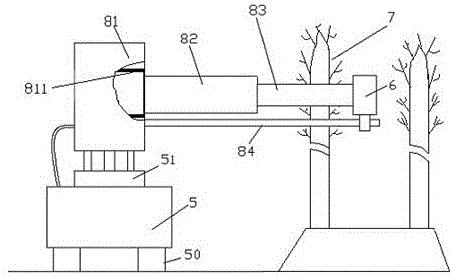

Whitewashing mechanism for whitewashing tree trunk and use method of whitewashing mechanism

InactiveCN106345642ARealize all-round sprayingSpraying apparatusPlant protectionEngineeringTree trunk

The invention discloses a whitewashing mechanism for whitewashing a tree trunk (7) and a use method of the whitewashing mechanism. The whitewashing mechanism comprises a walking frame portion (5), a lifting device (51) and a spraying device (81), the walking frame portion (5) is provided with walking rollers (50), the lifting device (51) is positioned on the walking frame portion (5), the lifting device (51) drives the spraying device (81) in a lifting manner, the spraying device (81) comprises a body, a threaded sleeve (82) and a telescopic screw (83), the body is connected with the lifting device (51), the threaded sleeve (82) is driven by a motor in the body, the threaded sleeve (82) drives the telescopic screw (83) in a threaded manner, and an axially extending through hole (830) is formed in the telescopic screw (83), used for conveying spraying liquid and connected with a spraying execution component (6) at the tail end of the telescopic screw (83) by the aid of fluid.

Owner:孙露

Whitewashing device for whitewashing tree trunk and use method of whitewashing device

InactiveCN106345643ARealize all-round sprayingSpraying apparatusPlant protectionEngineeringTree trunk

The invention discloses a whitewashing device for whitewashing a tree trunk (7) and a use method of the whitewashing device. The whitewashing device comprises a walking frame portion (5), a lifting device (51) and a spraying device (81), the walking frame portion (5) is provided with walking rollers (50), the lifting device (51) is positioned on the walking frame portion (5), the lifting device (51) drives the spraying device (81) in a lifting manner, the spraying device (81) comprises a body, a threaded sleeve (82) and a telescopic screw (83), the body is connected with the lifting device (51), the threaded sleeve (82) is driven by a motor in the body, the threaded sleeve (82) drives the telescopic screw (83) in a threaded manner, and an axially extending through hole (830) is formed in the telescopic screw (83), used for conveying spraying liquid and connected with a spraying execution component (6) at the tail end of the telescopic screw (83) by the aid of fluid.

Owner:孙露

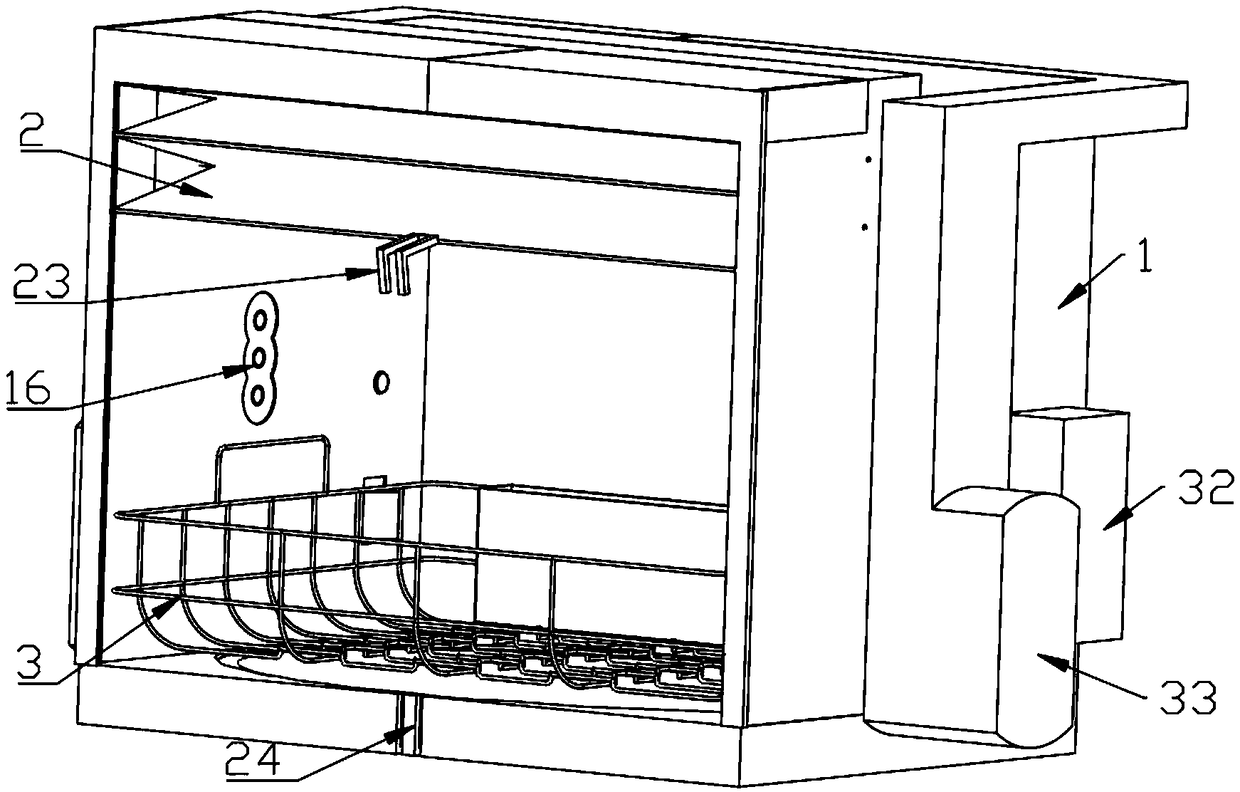

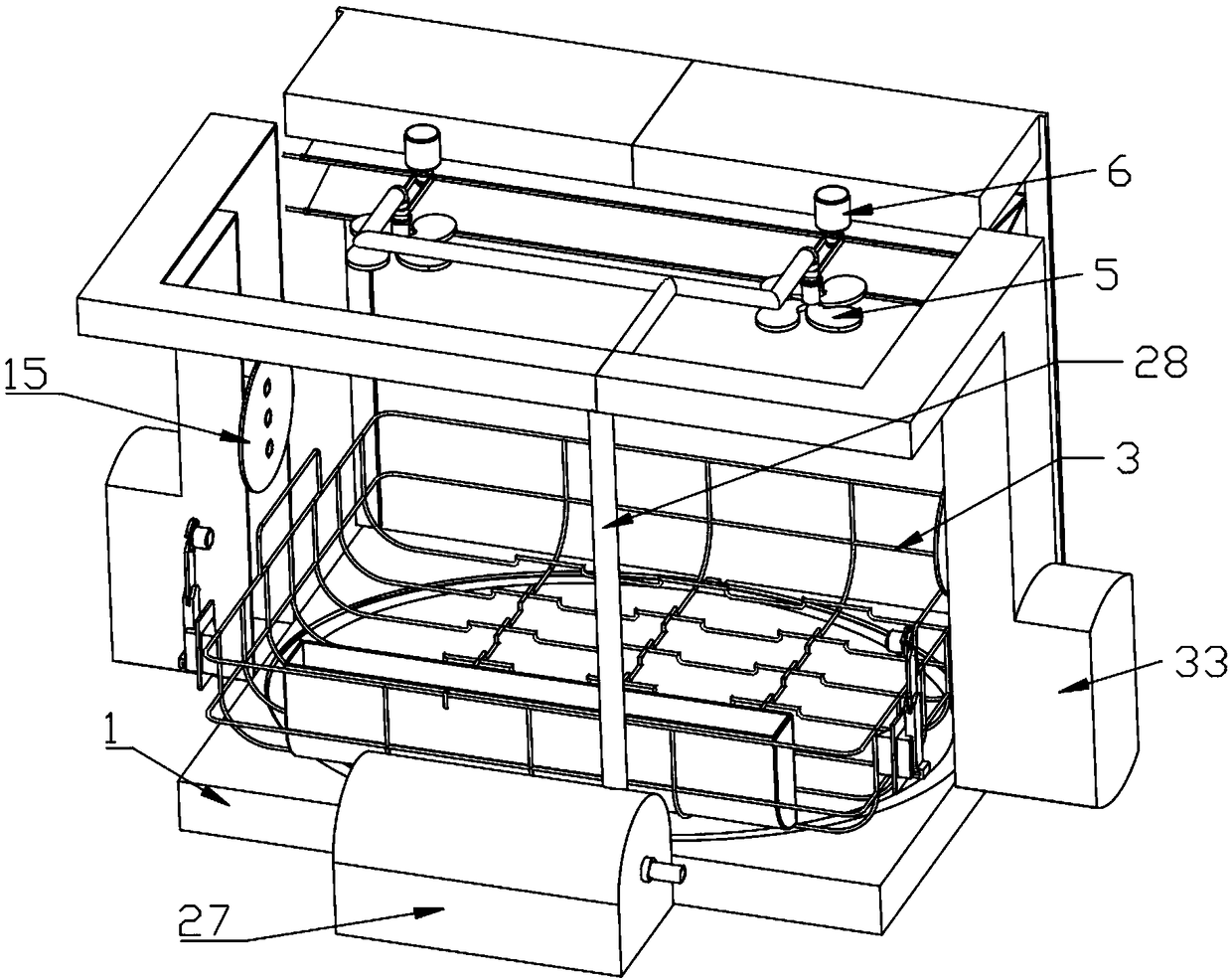

Household dish washing machine

InactiveCN108514391ARealize all-round sprayingExpand the spraying areaTableware washing/rinsing machine detailsMotor drivePulley

The invention relates to a dish washing machine, in particular to a household dish washing machine. The to-be-solved technical problem is to provide the household dish washing machine which has the advantages that the time and labor are reduced, the working efficiency is high, and the operation is simple and convenient. The provided household dish washing machine comprises a box body, a first cover plate, a water outlet pipe, a valve, a first bearing seat, a first rotating shaft, a first belt pulley, a first net plate, a supporting plate, a second net plate, a first fixing block and the like;the left side of the front side face of the box body is connected with the first cover plate through a hinge, the left side of the bottom of the box body is connected with the water outlet pipe, the water outlet pipe is internally provided with the valve, the first bearing seat is arranged in the middle of the bottom in the box body, the first bearing seat is connected with the first rotating shaft, and the upper portion of the first rotating shaft is connected with the first belt pulley. The household dish washing machine has the advantages that a motor drives agitating vanes and the net plates to rotate, so that the cleaning efficiency is improved, a cleaning solution is laterally sprayed through a shower nozzle, the dirt removing ability is improved, thereby achieving the effects that the time and labor are reduced, the cleaning efficiency is high, and the operation is simple and convenient.

Owner:谢峰

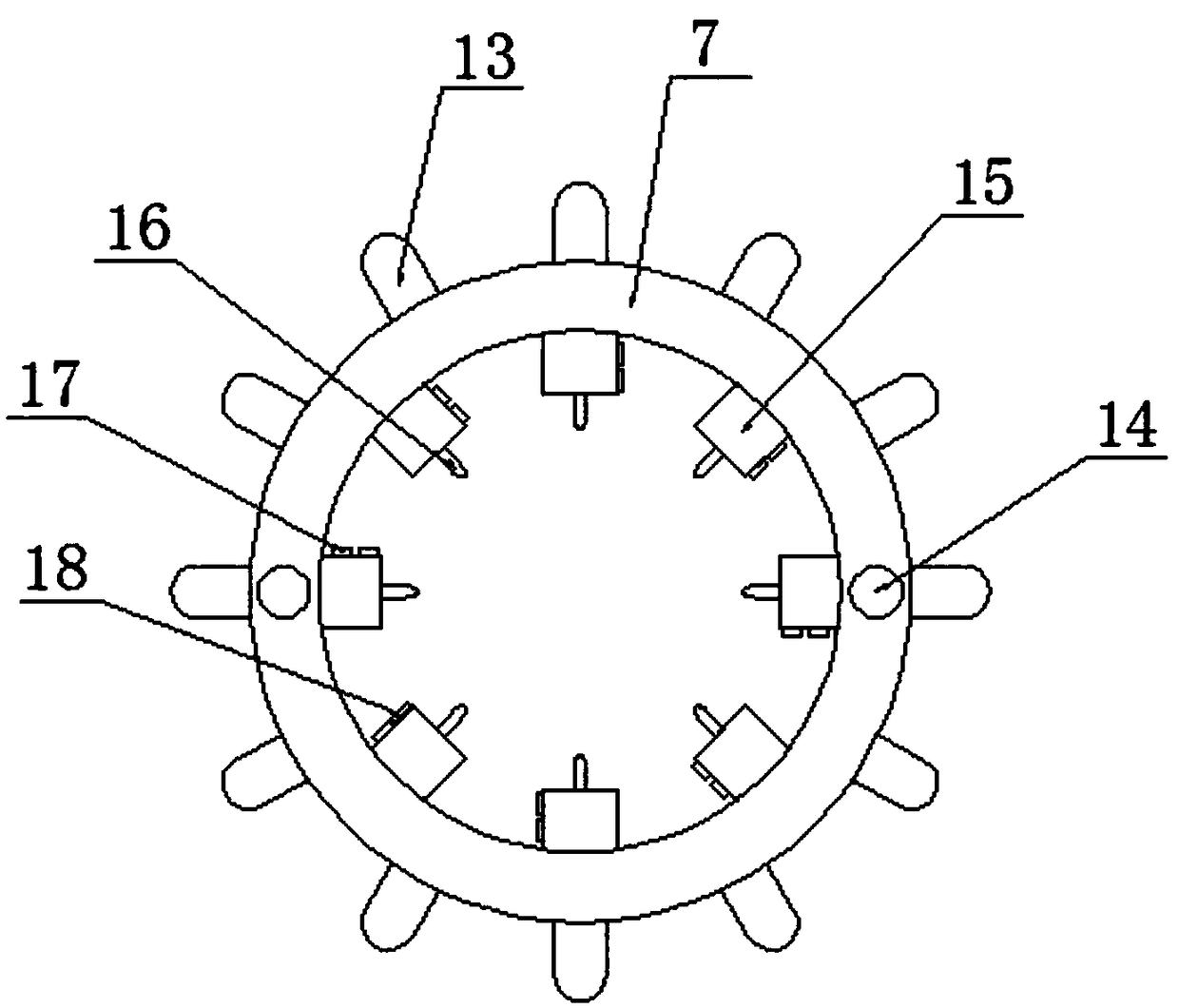

Spraying mechanism for ceramic processing

InactiveCN108787236AImprove work efficiencyShorten processing timeSpraying apparatusPretreated surfacesAir heaterEngineering

The invention discloses a spraying mechanism for ceramic processing. The spraying mechanism comprises a workbench. Supporting legs are fixedly connected to the four corners of the bottom face of the workbench. The four corners of the top face of the workbench are fixedly connected with supporting columns. A top plate is fixedly connected to the top ends of the supporting columns. A containing table is fixedly arranged at the center of the upper surface of the workbench. The lower surface of the top plate is fixedly connected with electric telescopic rods. A horizontal fixing ring is arranged below the top plate and fixedly connected with the electric telescopic rods. A rotation ring is fixedly arranged on the inner side of the fixing ring. The inner side of the rotation ring is fixedly connected with a first supporting base. A second supporting base is arranged above the first supporting base. The upper surface of the second supporting base is fixedly connected with spraying devices. The multiple spraying devices are arranged on the rotation ring, and all-direction spraying of a ceramic blank is achieved. Meanwhile, the top plate is provided with an air heater, the sprayed ceramicsurface coating can be rapidly dried and congealed, the work efficiency is improved, and the machining time is saved.

Owner:JIANGSU TIANBAO CERAMICS CO LTD

Pesticide-spraying device for garden nursery stocks and use method thereof

InactiveCN106359347ARealize all-round sprayingInsect catchers and killersElectric machineryPesticide

The invention relates to a pesticide-spraying device (7) for garden nursery stocks and a use method thereof. The device comprises a walking frame part (5), a lifting device (51) and a spraying component (81), wherein moving wheels (50) are arranged on the walking frame part (5); the lifting device (51) is located on the walking frame part (5); the spraying component (81) is driven by the lifting device (51) which is lifted; the spraying component (81) comprises a main body, a threaded sleeve (82) and a stretchable screw rod (83), wherein the main body is connected with the lifting device (51), the threaded sleeve (82) is driven by a motor in the main body, and the stretchable screw rod (83) is driven by the threaded sleeve (82) through a thread; an axial extending middle through hole (830) is formed in the stretchable screw rod (83) and is used for transmitting and spraying the liquid; and the middle through hole (830) is connected with the liquid of a spraying executing component (6) which is located at the tail end of the stretchable screw rod (83).

Owner:李常明

Dish washing machine

ActiveCN108903873ARealize all-round sprayingImprove cleaning efficiencyTableware washing/rinsing machine detailsDrive motorEngineering

The invention discloses a dish washing machine. The dish washing machine comprises a machine body, a folding hand-sliding door, a dish rack, a water pump, water spraying fan blades, rotating motors, adriving motor, a servo motor, a driving gear, a driven gear, half gears, a connecting gear, a first eccentric wheel, a twisting connecting rod, a twisting water pipe, a second eccentric wheel, a linking rod, a rear abutting block, a shape cutting block, inner and outer connecting plates, springs, a water leaking groove, a water guiding pipe, driving belt pulleys, belts, driven belt pulleys, a fixing box and a mounting box. The water leaking groove is formed in the bottom end in the machine body, and the inner and outer connecting plates are symmetrically arranged on the two side walls of themachine body. The shape cutting block slidably penetrates through the side wall of the machine body and the inner and outer connecting plates to be placed in the machine body. The dish washing machinedrives the water spraying fan blades to rotate and spray through the rotating motors, and is matched with the servo motor to drive the twisting water pipe to twist, thereby realizing all-round spraying and improving the cleaning efficiency; and at the same time, the dish washing machine drives the dish rack to shake smoothly through the driving motor, so that the cleaning angle is enlarged, the cleaning area is increased, and the cleanliness is improved.

Owner:台州舒倍康医疗科技有限公司

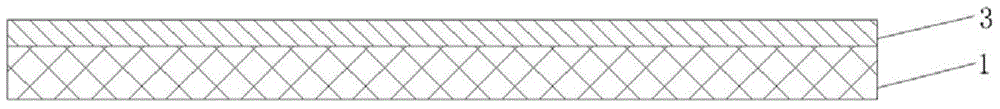

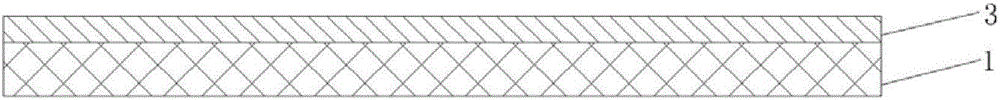

Anti-abrasion nano luggage and manufacturing process thereof

The invention relates to an anti-abrasion nano luggage. When a common hard draw-bar luggage is collided or abraded, scratches are easily formed on the surface so that the service life and the appearance beauty of the draw-bar luggage are seriously influenced. The anti-abrasion nano luggage comprises a luggage shell, and is characterized in that one nano coating is arranged on the outer part of the luggage shell. The nano coating is made of SiO2 or CaCO3 nano materials. The nano coating is sprayed on the surface of the luggage shell and is a transparent coating. According to the anti-abrasion nano luggage, the anti-abrasion durability of a luggage box is improved, the manufacturing is relatively simple and the cost is relatively low.

Owner:NEWCOMER GRP

Convenient word spraying device for telegraph pole

InactiveCN106345631ARealize all-round sprayingMovable spraying apparatusEngineeringMechanical engineering

The invention discloses a convenient word spraying device for a telegraph pole (7). The device comprises a word spraying template, a walking frame portion (5), a lifting device (51) and a spraying device (81), the word spraying template is mounted on the telegraph pole (7), the walking frame portion (5) is provided with walking rollers (50), the lifting device (51) is positioned on the walking frame portion (5), the lifting device (51) drives the spraying device (81) in a lifting manner, the spraying device (81) comprises a body, a threaded sleeve (82) and a telescopic screw (83), the body is connected with the lifting device (51), the threaded sleeve (82) is driven by a motor in the body, the threaded sleeve (82) drives the telescopic screw (83) in a threaded manner, and an axially extending through hole (830) is formed in the telescopic screw (83), used for conveying spraying liquid and connected with a spraying execution component (6) at the tail end of the telescopic screw (83) by the aid of fluid.

Owner:卢晗

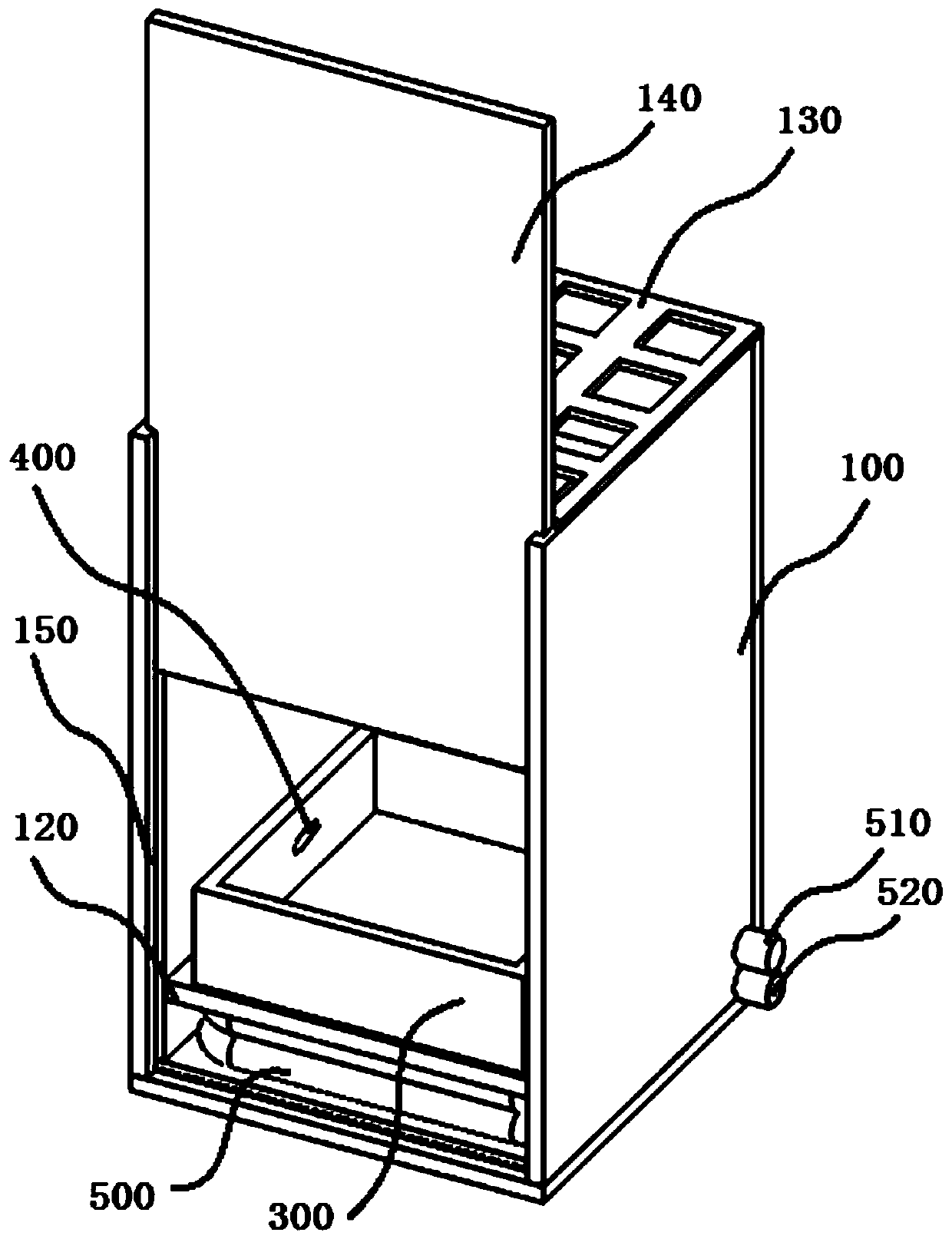

Experimental device and experimental method for rice seedlings

ActiveCN110915496AEasy to control experimental variablesSimplify the experimental stepsClimate change adaptationAgriculture gas emission reductionAgricultural engineeringMechanical engineering

The invention discloses an experimental device for rice seedlings. The device comprises a box body, a movable plate, a planting chassis, a liquid spraying pipe and a cooling pipe, wherein the movableplate and the planting chassis are arranged in the box body; at least one liquid collecting part is arranged below the movable plate, the liquid collecting part is conical, the bottom surface of the liquid collecting part is fixed with the movable plate, and the vertex of the liquid collecting part points to the planting chassis; the planting chassis is used for containing a culture medium and isarranged below the liquid collecting part; one end of the liquid spraying pipe extends out of the box body, and the other end of the liquid spraying pipe is positioned in the planting chassis and extends out of the culture medium; the cooling pipe is used for communicating cold water to cool the interior of the box body and is arranged below the planting chassis. According to the device, two stepsof pesticide spraying and low-temperature control are combined in the same device, so that excessive movement of the rice seedlings is not required, the experimental variables are conveniently controlled, the experimental steps are simplified, and the operation is simple.

Owner:HUNAN RICE RES INST

Anti-corrosion spraying device for production of environmental protection equipment

PendingCN113385345ASpray evenlyRealize all-round sprayingPretreated surfacesCoatingsElectric machineryCorrosion prevention

The invention relates to the technical field of spraying equipment, in particular to an anti-corrosion spraying device for environmental protection equipment production. The anti-corrosion spraying device comprises a bottom plate, a shell and a rotating disc; a vertical rotating shaft is rotatably arranged on the bottom plate; a driven gear and the rotating disc are coaxially and fixedly connected to the rotating shaft; a motor is fixedly mounted on the bottom plate on the side edge of the rotating shaft; an output shaft of the motor is coaxially and fixedly connected with a half gear; the half gear is meshed with the driven gear; two containing discs are evenly and rotatably arranged at the radial position of the rotating disc; the bottoms of the containing discs are coaxially and fixedly connected with connecting pipes; rotating gears are coaxially and fixedly connected to the bottoms of the connecting pipes below the rotating disc; the shell is fixedly arranged on the bottom plate on the side edge of the rotating disc; a paint spraying row is fixedly arranged in the shell; and a raw material box communicates with the paint spraying row through a liquid conveying pipe. The device has the advantages of being simple in structure, convenient to operate, good in synchronism, low in production cost, high in production efficiency, good in continuity and convenient to popularize and implement.

Owner:棽泽(浙江)环保工程有限公司

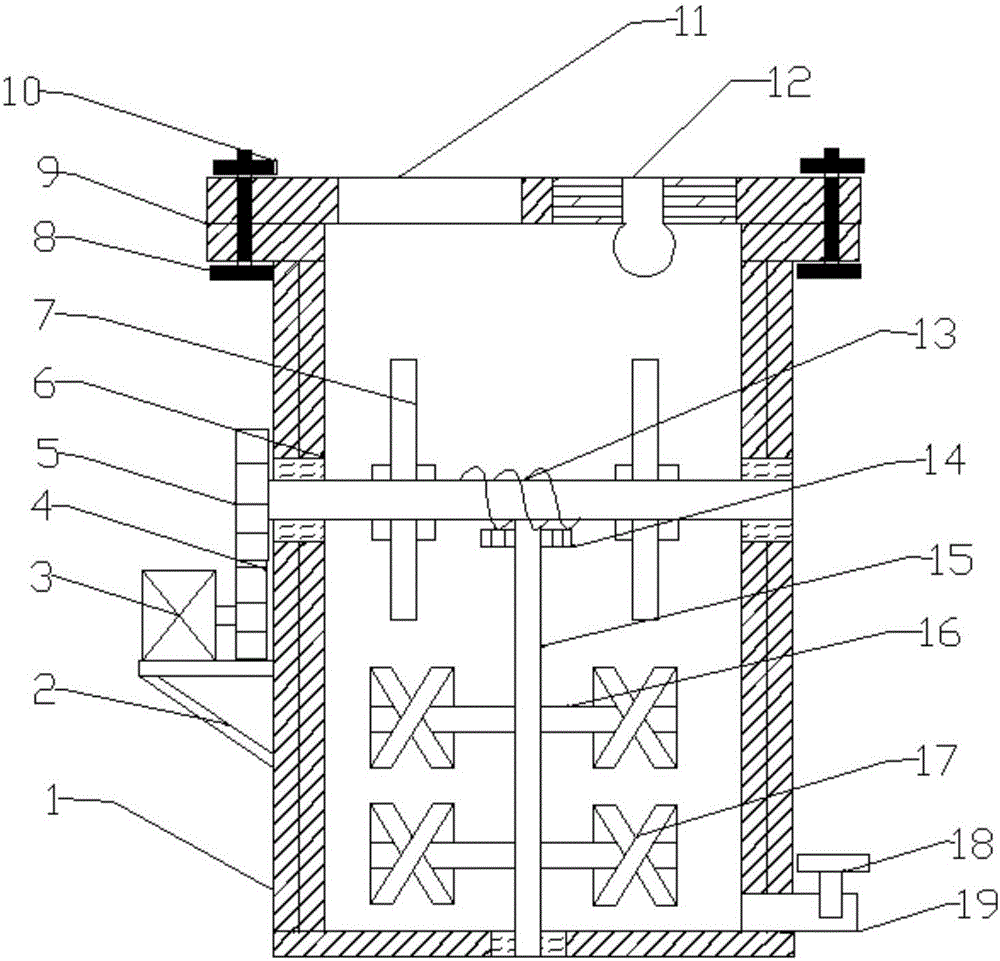

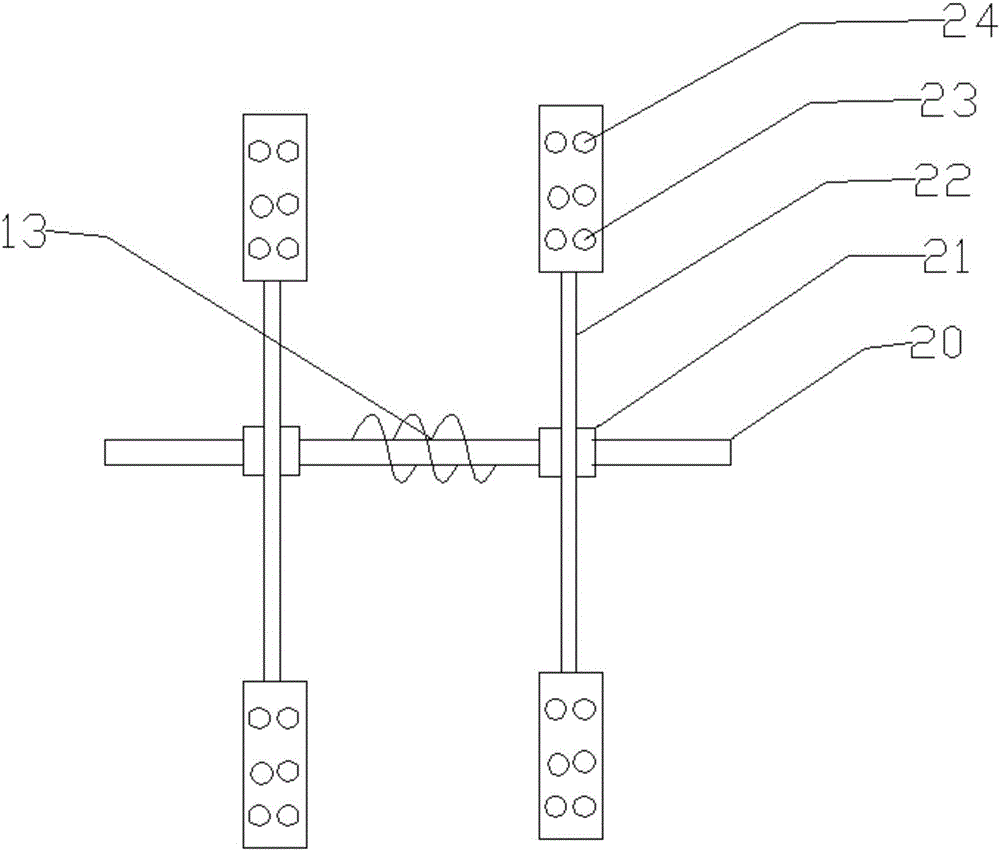

Water circulating dusty gas filtering tank

InactiveCN106693574AImprove filtering effectEasy to disassemble and cleanCombination devicesTreatment involving filtrationHelical bladeWater cycling

The invention provides a water circulating dusty gas filtering tank. The water circulating dusty gas filtering tank comprises a buffer base, a filtering tank, an upper end cover, a spraying device, a first servo motor, a spiral conveyer, a casing, a second servo motor and a bearing, wherein a dusty gas inlet pipe is arranged at one end of the filtering tank; the first servo motor and the spiral conveyer are arranged at the other end of the filtering tank; a gas filtering layer is arranged inside of a tail gas absorption tank; the spiral conveyer is fixedly connected with the filtering tank; helical blades are uniformly arranged inside the spiral conveyer; a hole is formed in the bottom end of the spiral conveyer through hollowing; the bearing is fixedly mounted on the casing and fixedly connected with a water pipe. The water circulating dusty gas filtering tank is reasonable in structure, and is convenient to dismount and clean because the upper end cover is movably connected with the filtering tank; the gas filtering layer is convenient for filtering residual dusty gas; the spraying device can realize omnibearing spraying in the filtering; the spiral conveyer can squeeze and separate dust water slurry and meanwhile can realize water circulation use.

Owner:梅新星

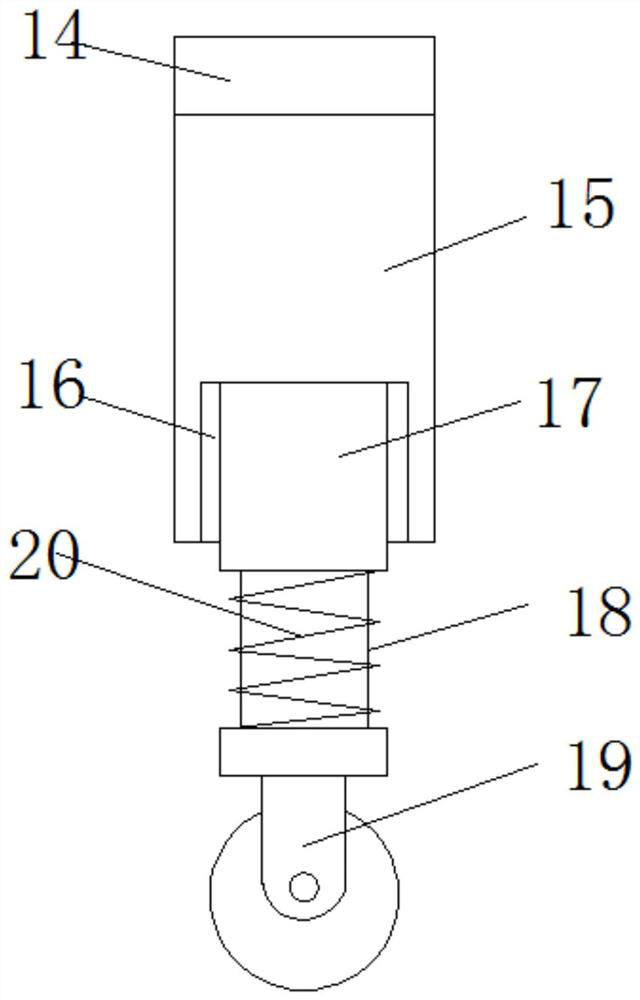

A height-adjustable industrial dust removal device

ActiveCN109432920BEasy to moveEasy to useUsing liquid separation agentHydraulic cylinderDust control

The invention discloses a height-adjustable industrial dust removal device, comprising a bottom plate, a plurality of groups of hydraulic cylinders are arranged at the bottom of the bottom plate, and a moving device is arranged at the bottom of the hydraulic cylinder, and the moving device includes a connecting block, and The top of the connecting block is fixedly connected with the bottom of the hydraulic cylinder, the bottom of the connecting block is provided with a fixing rod, the bottom of the fixing rod is provided with a groove, the inner part of the groove supports the sleeve rod, the support The bottom of the sleeve rod is provided with a supporting rod matched with it, the bottom of the supporting rod is provided with a universal wheel, in addition, the outer side of the supporting rod is provided with a compression spring, and the top of the bottom plate is provided with a rotating device, so The top of the rotating device is provided with a support plate. Beneficial effects: the design is reasonable, the use is convenient, not only the spraying range is effectively improved, but also the spraying height can be adjusted according to the use requirements, thereby effectively improving the dust removal effect.

Owner:TS INVESTMENT CASTING

A kind of wear-resistant nano bag and its manufacturing process

The invention relates to an anti-abrasion nano luggage. When a common hard draw-bar luggage is collided or abraded, scratches are easily formed on the surface so that the service life and the appearance beauty of the draw-bar luggage are seriously influenced. The anti-abrasion nano luggage comprises a luggage shell, and is characterized in that one nano coating is arranged on the outer part of the luggage shell. The nano coating is made of SiO2 or CaCO3 nano materials. The nano coating is sprayed on the surface of the luggage shell and is a transparent coating. According to the anti-abrasion nano luggage, the anti-abrasion durability of a luggage box is improved, the manufacturing is relatively simple and the cost is relatively low.

Owner:NEWCOMER GRP

Sanitation type insect trap

InactiveCN114304098AEasy to useEffective in controlling mosquitoesSpraying apparatusWaste collection and transferRefuse collectionHusk

The environmental sanitation type insect trap comprises an insect trap body and a garbage can arranged at the bottom of the insect trap body, and the insect trap body comprises an outer shell, a trap lamp, an electric wire net, a liquid medicine box, a pheromone storage barrel, a spraying plate, a power supply box and a solar panel; a plurality of trap lamps are distributed on the inner side wall of the outer shell, the electric wire net is arranged in the outer shell, a supporting column is arranged on a bottom plate of the outer shell, and a power supply box, a liquid medicine box and a pheromone storage barrel are sequentially arranged at the top of the supporting column; a pesticide is put into the pesticide liquid box, a spraying head connected with the pesticide liquid box is arranged on the spraying plate, multiple sets of pheromone storage grids are installed in an inner cavity of the pheromone storage barrel, and pheromones of different pests are injected into the pheromone storage grids; the interior of a dustbin body of the dustbin is divided into a solid-liquid separation bin and a garbage collection bin through a partition plate, and a solid-liquid separation device is arranged in the solid-liquid separation bin. According to the environmental sanitation type insect trap, the problem of pollution of mosquitoes and flies near the dustbin can be effectively solved, and the environmental protection effect is improved.

Owner:湖南天长农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com