Anti-abrasion nano luggage and manufacturing process thereof

A manufacturing process and anti-wear technology, applied in luggage, clothing, accessories, etc., can solve the problems of high cost, insignificant effect of nanomaterials, large amount of nanomaterials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

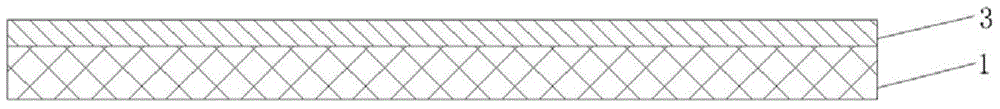

[0022] Such as figure 1 and 2 A kind of anti-abrasion nano box and bag shown, comprises the case shell 1 that is molded by ABS, PC, PP or other etc. plastics. The outside of the box shell is sprayed with a layer of nano coating 3 . Nano-coating 3 is mainly composed of inorganic nano-materials, acrylate, polyurethane and various additives, among which the inorganic nano-materials are SiO 2 or CaCO 3 nanomaterials. Nano-coating 3 is a transparent coating, which is easy to adhere to the surface of the box and will not fall off. After the coating is formed on the surface of the box, it will not cover the inherent appearance color of the box and retain the appearance of the box. .

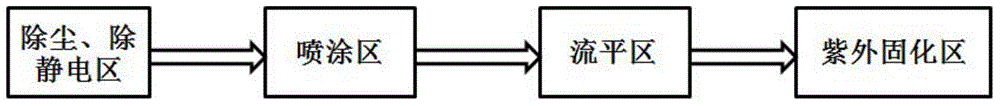

[0023] Such as image 3 and 4 Shown is the technological process of the present invention:

[0024] Dust removal and static removal area: to ensure the cleanliness of the surface of the box shell d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com