PCB spraying device used for electronic products

A technology for PCB boards and electronic products, applied in the field of PCB board spraying devices for electronic products, can solve the problems of poor spraying effect of PCB boards, waste of resources, unfavorable recycling of coatings, etc., to achieve good spraying effect, saving resources, guaranteeing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

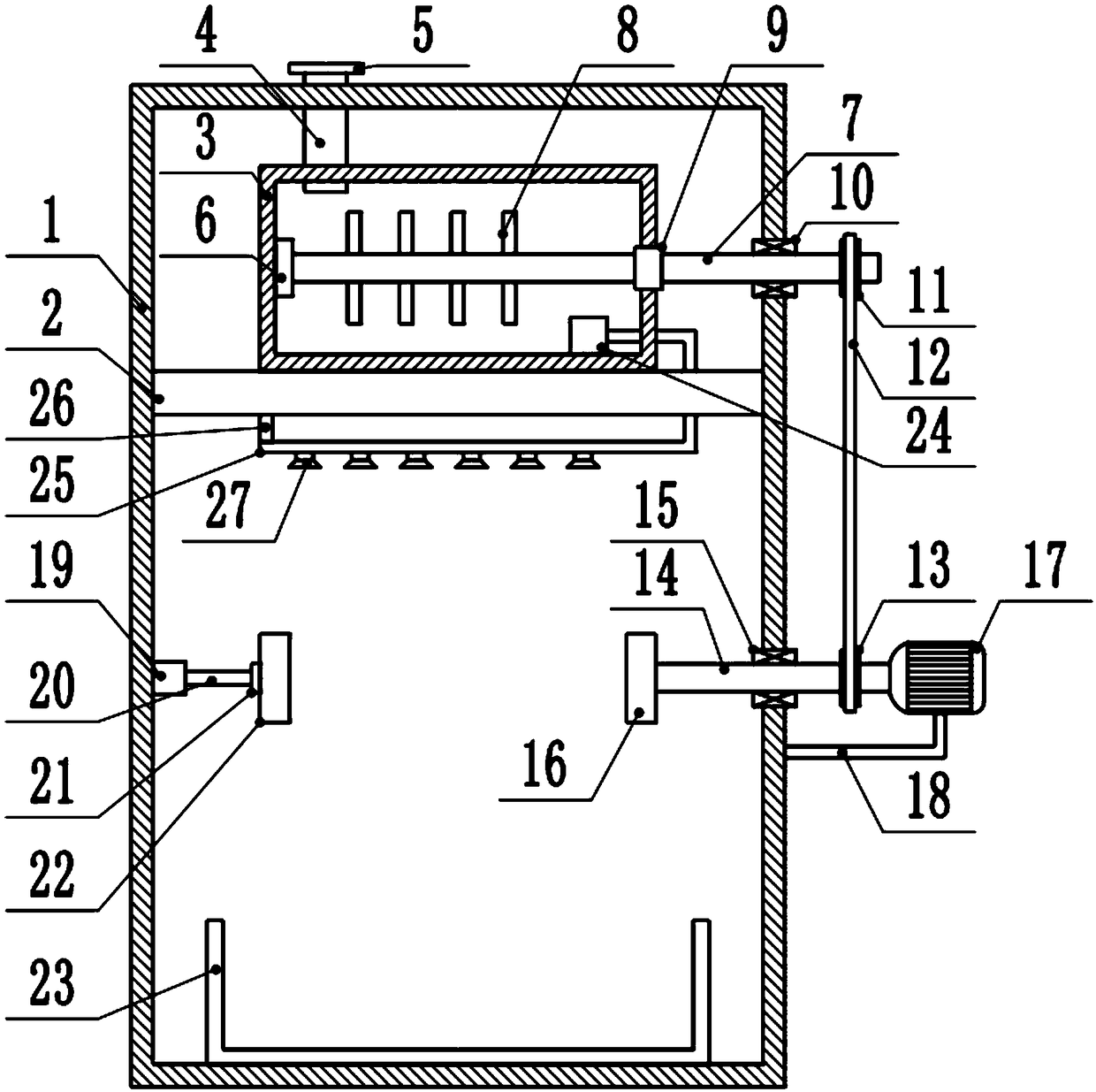

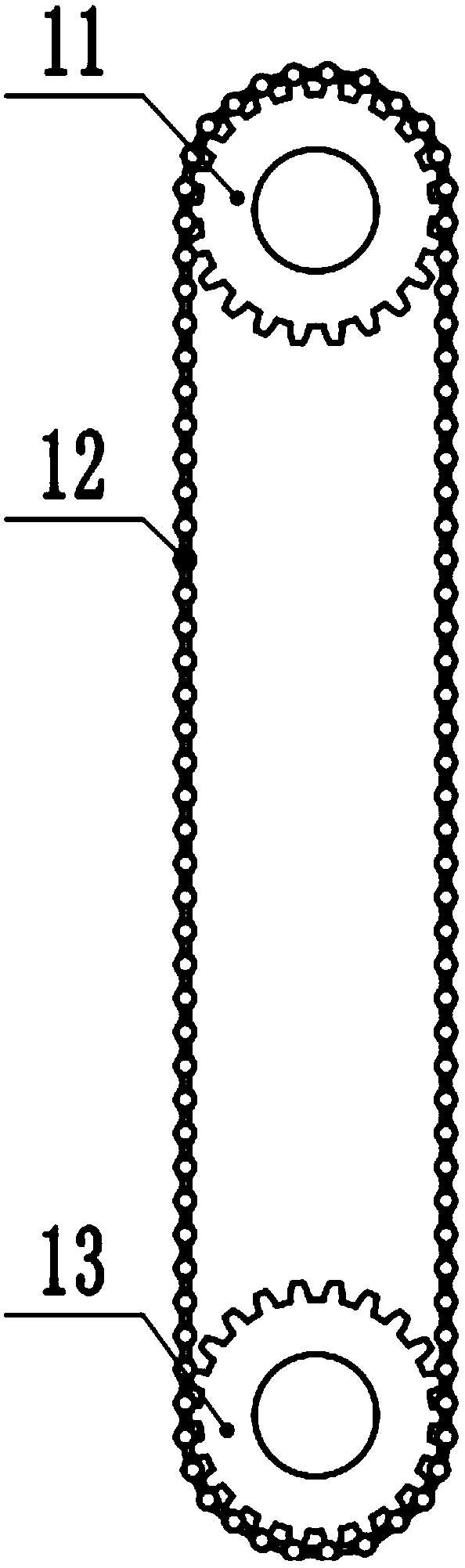

[0021] see Figure 1-2 , a PCB board spraying device for electronic products, including a spraying box 1, a fixed plate 2 is fixedly connected to the top of the box body on the left and right sides inside the spraying box 1, and a mixing box 3 is fixedly installed in the middle of the upper surface of the fixing plate 2, and the mixing box 3. A feed pipe 4 is fixedly connected to the middle of the left side of the upper box to realize feeding the mixing box 3. The upper end of the feed pipe 4 passes through the middle of the left side of the upper box of the spraying box 1. The feed pipe 4 The upper end is equipped with a sealing cover 5, the middle part of the inner wall on the left side of the mixing box 3 is fixedly connected with the first bushing 6, and the middle part of the right side of the first bushing 6 is slidingly connected with the driven rotating rod 7 inside, and the right end of the driven rotating rod 7 passes through The inside of the middle of the box on th...

Embodiment 2

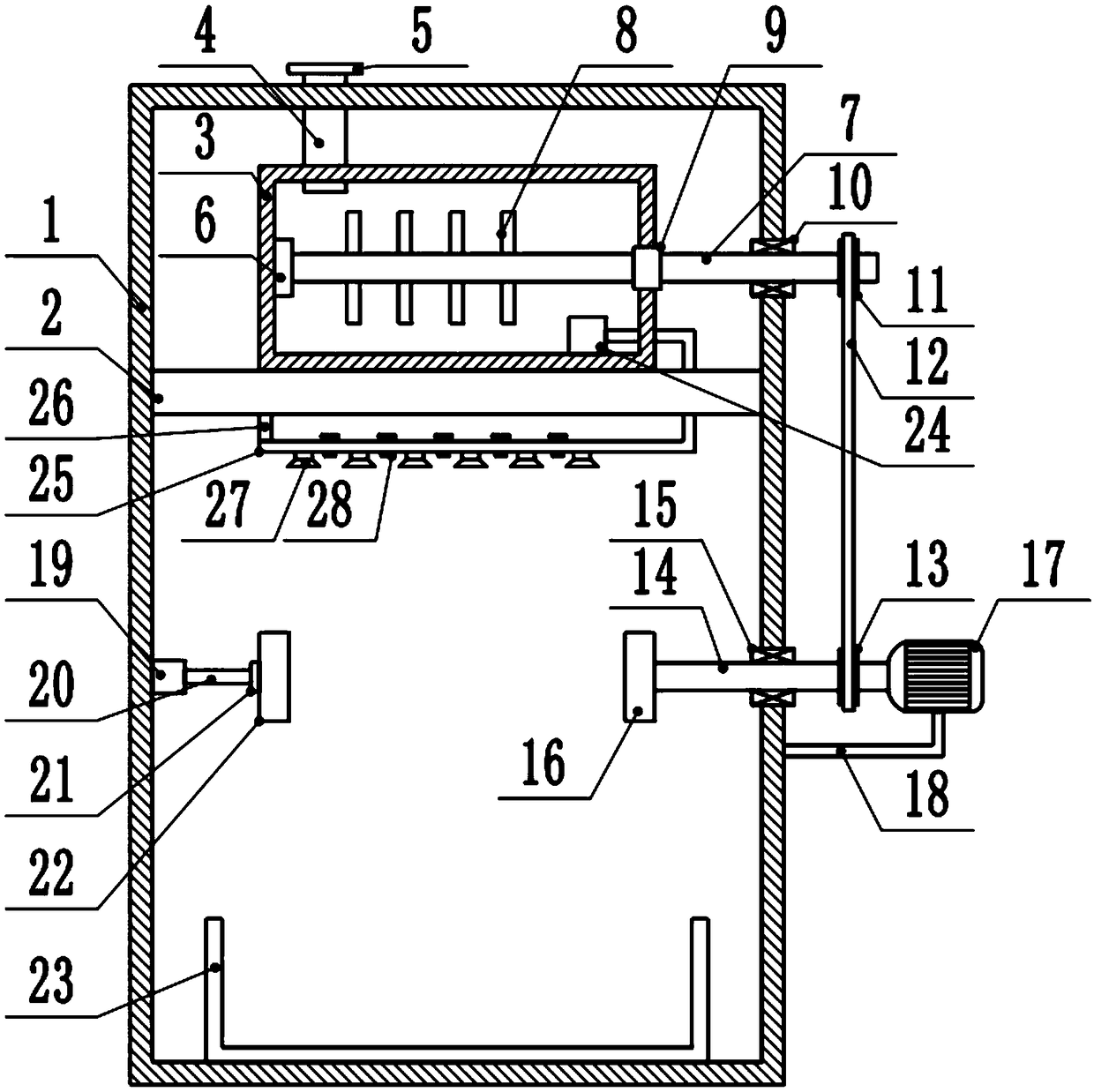

[0024] see image 3 The difference between the second embodiment and the first embodiment is that a control valve 28 is installed in the middle of the left side of the connecting pipe 25, and the control valves 28 are respectively located between the two nozzles 27, and the nozzles are controlled by the control valve 28 for spraying. paint, and control the number of nozzles 27 for spraying according to the length of the PCB board, avoiding simultaneous spraying of all nozzles 27, causing unnecessary waste and saving resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com