Water circulating dusty gas filtering tank

A filter tank and circulating technology, which is applied in the field of water circulation type dust gas filter tank, can solve the problems of wasting water resources, reducing product quality, and insufficient dust absorption, achieving the effect of reasonable structure design and improving absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

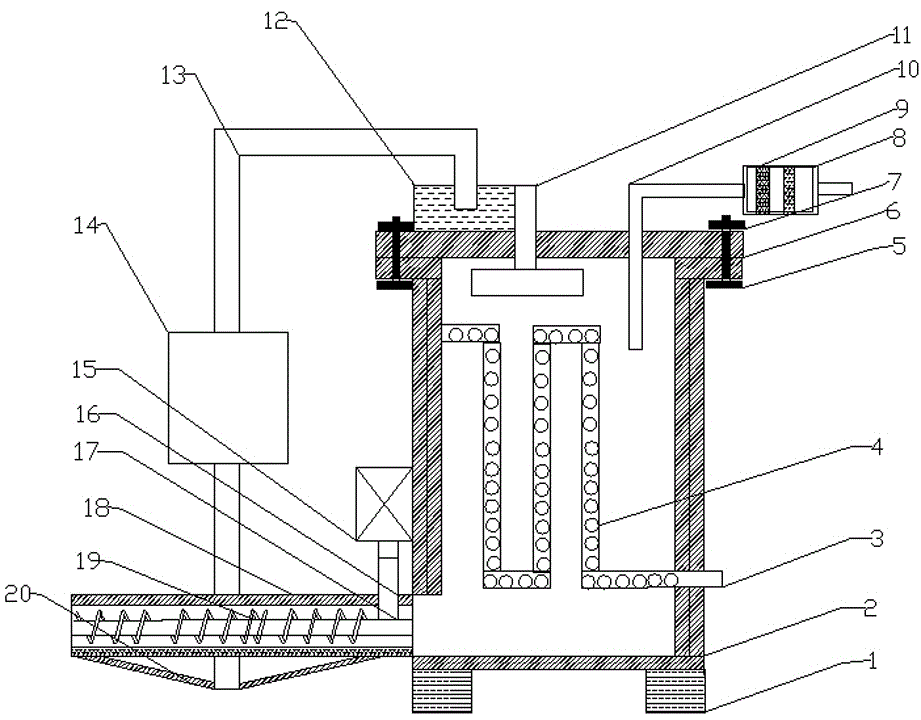

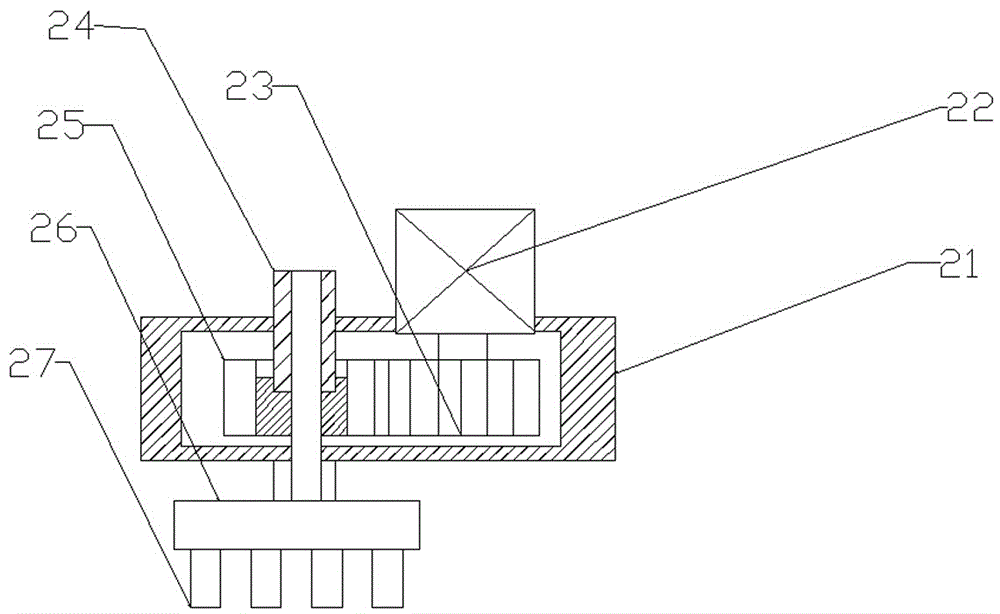

[0015] see Figure 1-2 , a water circulation type dust gas filter tank, including a buffer seat 1, a filter tank 2, an upper cover 6, a spray device 11, a first servo motor 15, a screw conveyor 18, a housing 21, a second servo motor 22 and Bearing 24; one end of the filter tank 2 is provided with a dust intake pipe 3, the other end of the filter tank 2 is provided with a first servo motor 15 and a screw conveyor 18, the bottom of the filter tank 2 is fixedly connected with the buffer seat 1, and the filter tank 2 2 is made of steel; the dust inlet pipe 3 runs through the filter tank 2 and is fixedly arranged, and a through hole 4 is hollowed out on the dust inlet pipe 3, and the dust inlet pipe 3 is made of PVC material, and the dust enters through the dust inlet pipe 3 and then Discharge from the through hole 4; the upper end cover 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com