Steel structure surface paint spraying device

A technology of steel structure and mounting plate, applied in the direction of spraying device, etc., can solve the problems of low work efficiency, waste of staff energy, unadjustable fixation of spraying head, etc., to achieve uniformity, prevent uneven spraying, and reduce spraying dead angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

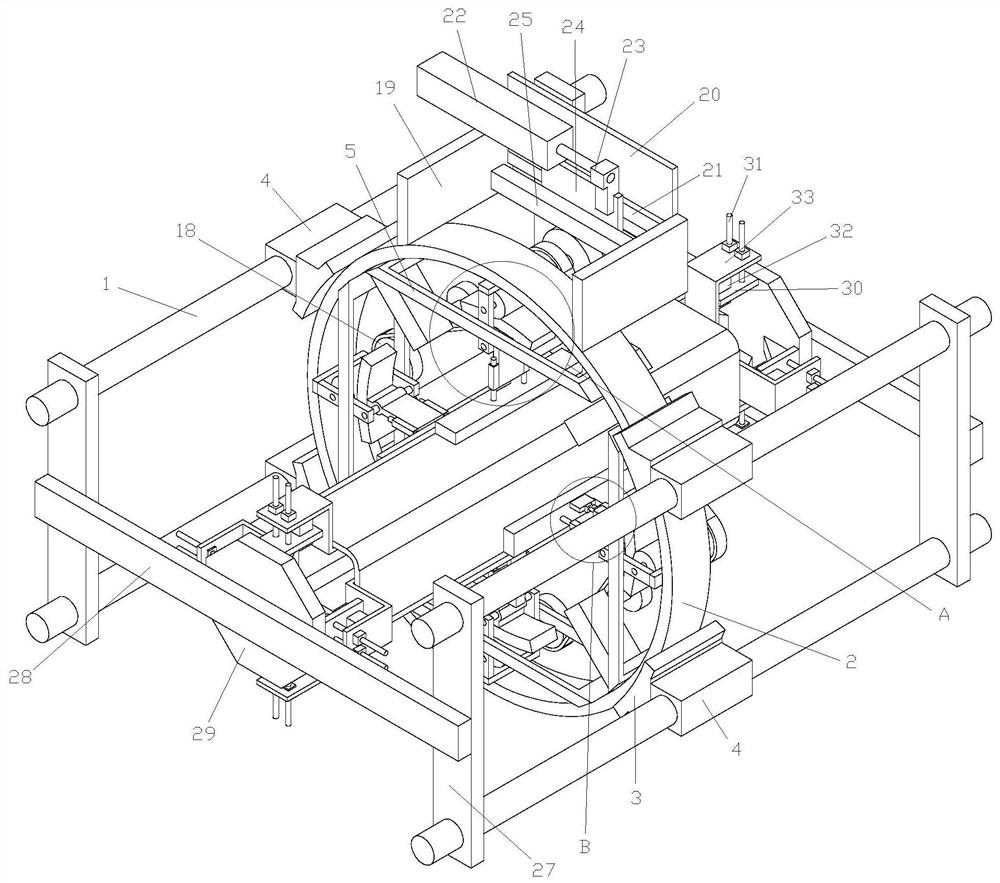

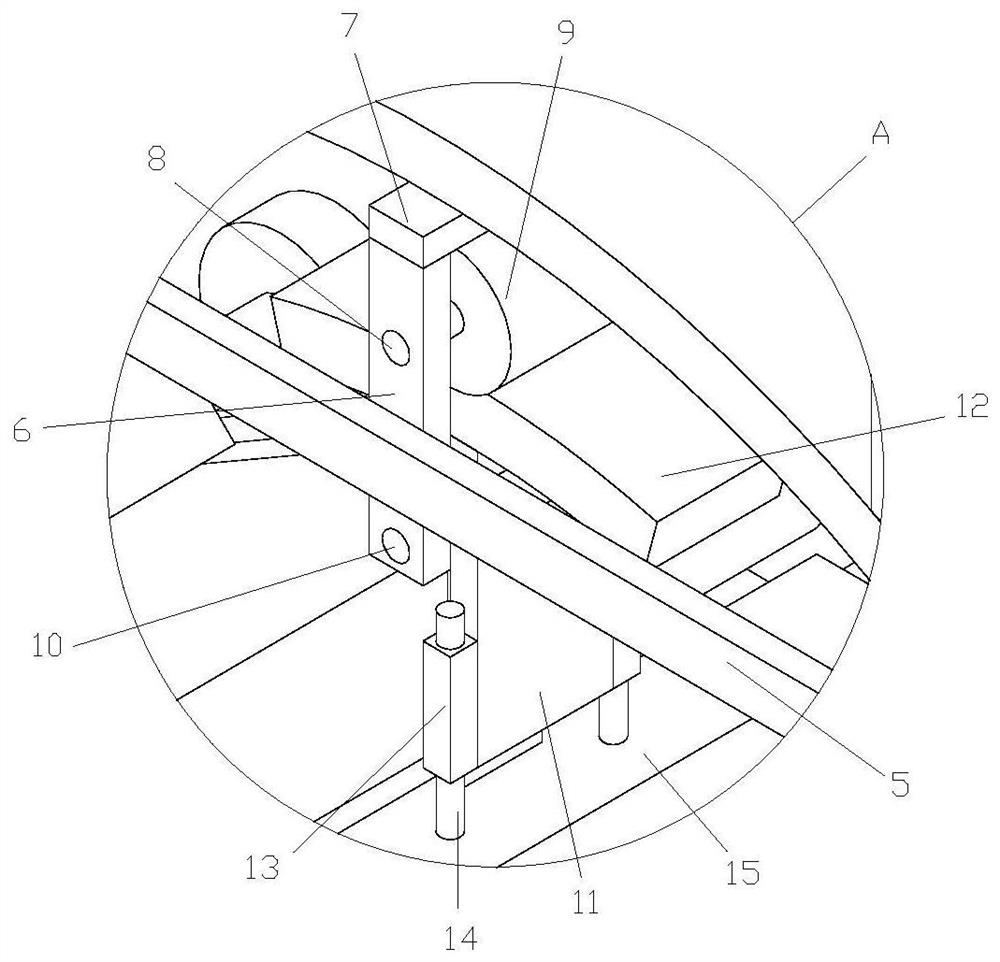

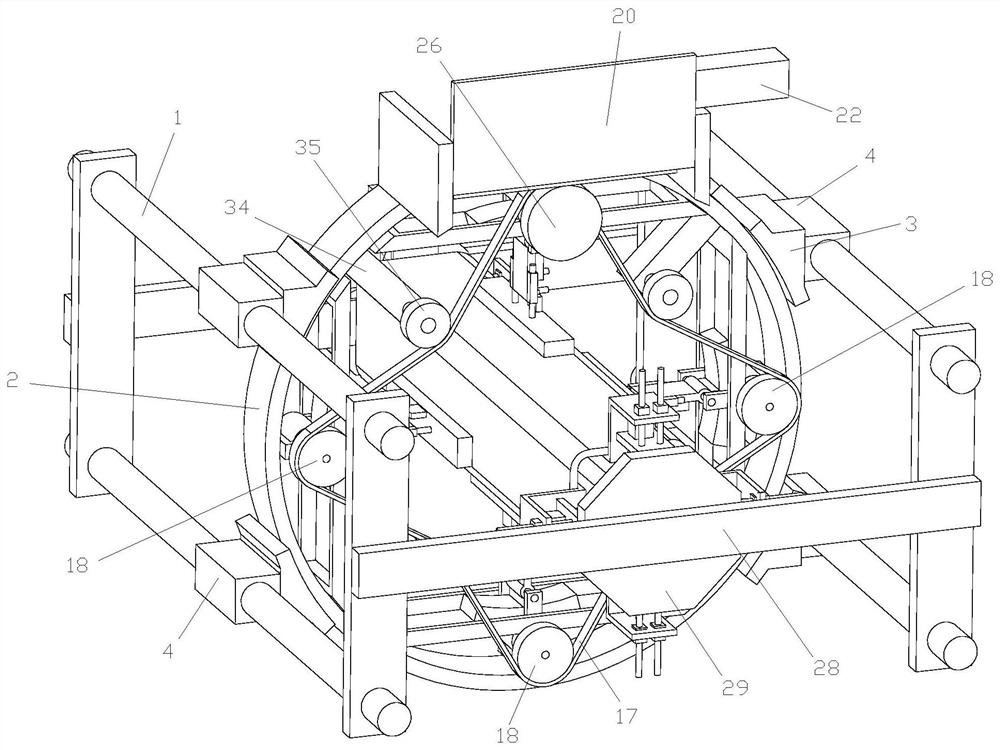

[0022] Embodiment: a kind of steel structure surface painting device, as Figure 1-Figure 4 As shown, it includes four guide rails 1, a painting mechanism and two sets of support mechanisms. The four guide rails 1 are arranged in a rectangular shape. The painting mechanism is slidably fitted on the four guide rails 1. The positions corresponding to the four guide rails 21 on the outer ring surface of the annular mounting bracket 2 are respectively provided with four connecting seats 3, each of the connecting seats 3 is fixedly connected with a guide slider 4, by setting the guide slide The guide slide 4 is slidably fitted on the guide rail 1, which can realize the longitudinal movement of the painting mechanism and realize the all-round spraying of the steel. The four guide slides 4 are slidably fitted on the corresponding four guide rails 1. , the inner ring surface of the ring mounting frame 2 is equidistantly provided with four sets of painting assemblies, the painting asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com