Transformer substation insulator hot-line work robot system and method

A robot system and live working technology, applied in manipulators, electrical components, program-controlled manipulators, etc., can solve problems such as uneven spraying, difficulty in guaranteeing coating quality, poor cleaning effect of oily dirt, etc., to ensure spraying quality and improve operations Efficiency, the effect of solving the dead angle of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

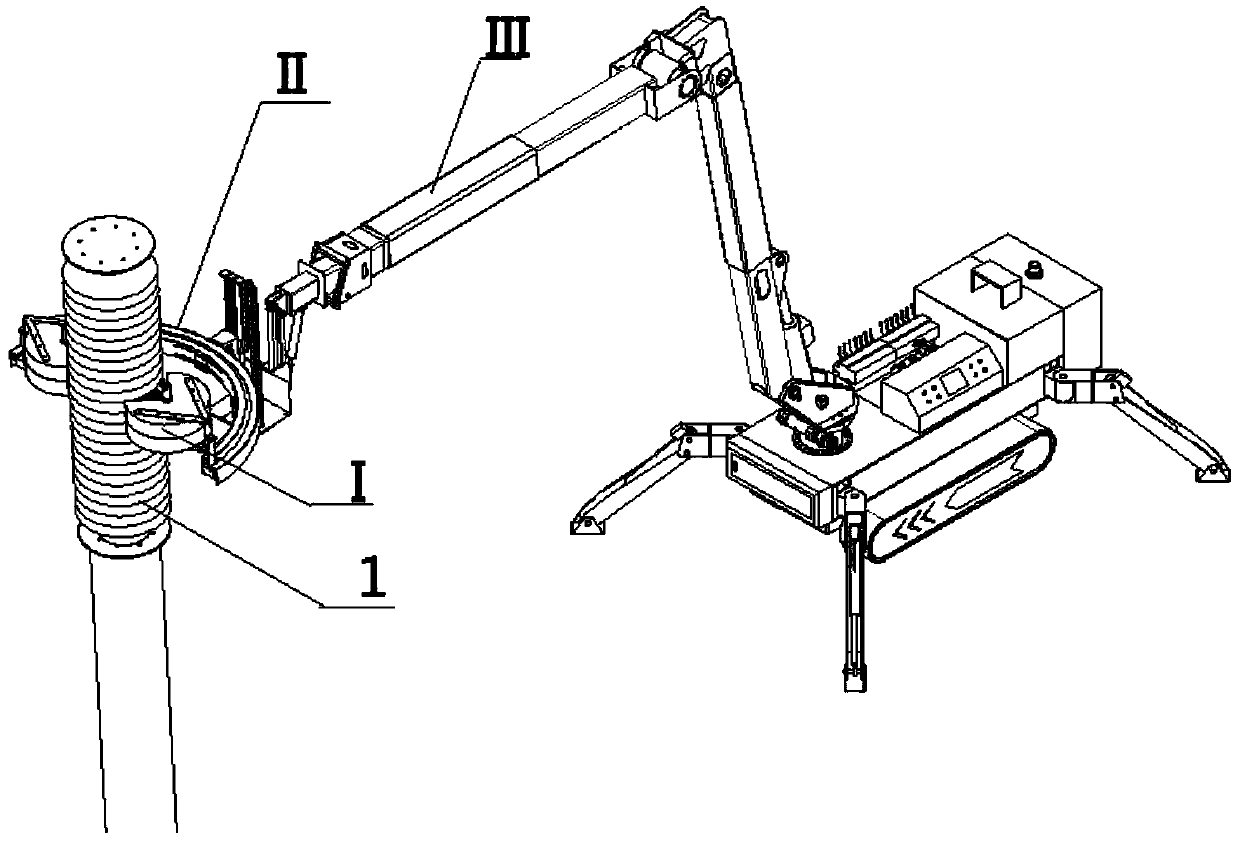

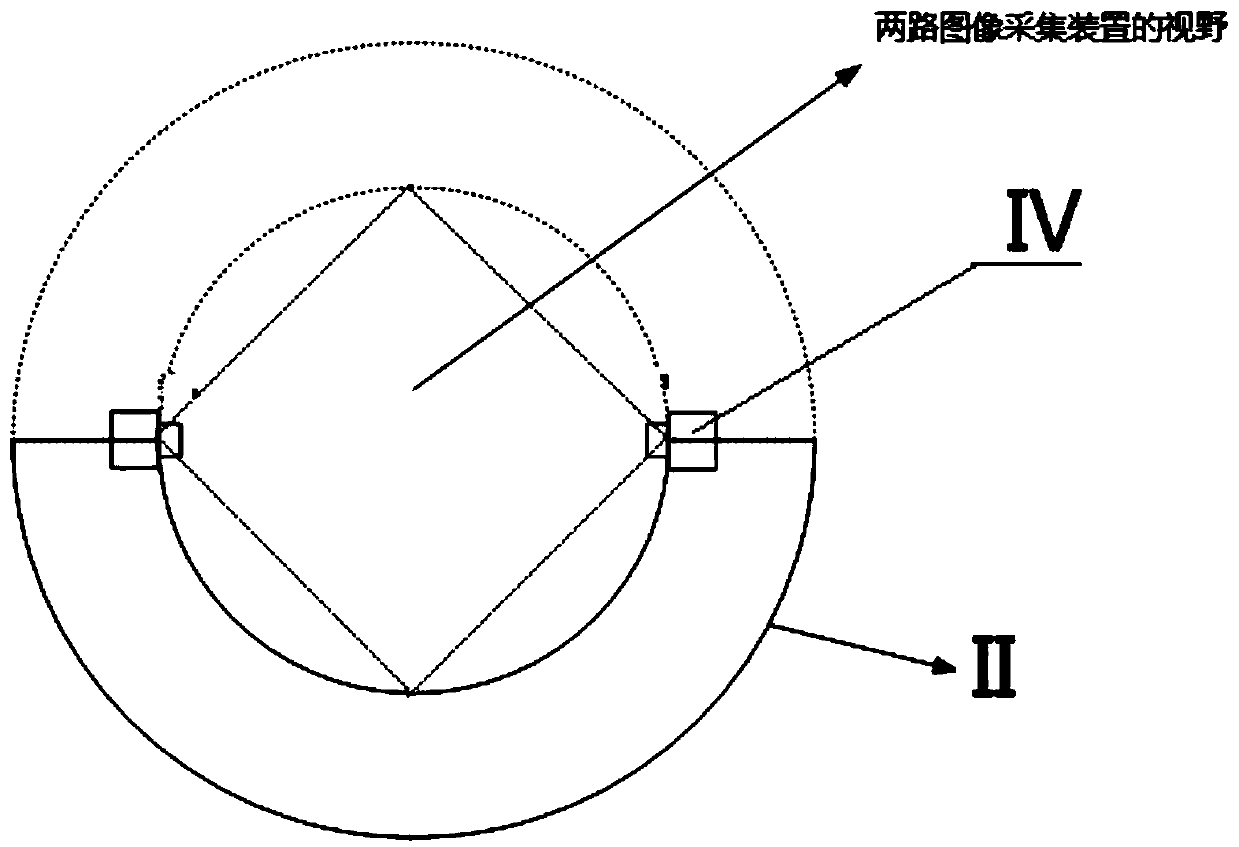

[0083] In one or more embodiments, a live working robot system for substation insulators is disclosed, referring to figure 1 , including: the robot body, the control module set in the robot body, and the insulation lifting mechanism set on the robot body; the end of the insulation lifting mechanism is connected to the live working tool through a quick connector; using electromagnetic field detection, leakage current detection, ultrasonic The multi-sensor fusion technology based on various detection technologies such as detection and visual detection solves the safety protection problem of live-line operation of robots under high voltage levels.

[0084] Live working tools include: live cleaning device or RTV spraying device.

[0085] Among them, the robot body includes: a mobile chassis, an insulating lifting arm set on the mobile chassis, the front end of the insulating lifting arm is connected to the small flying arm, and the front end of the small flying arm is provided with ...

specific Embodiment approach

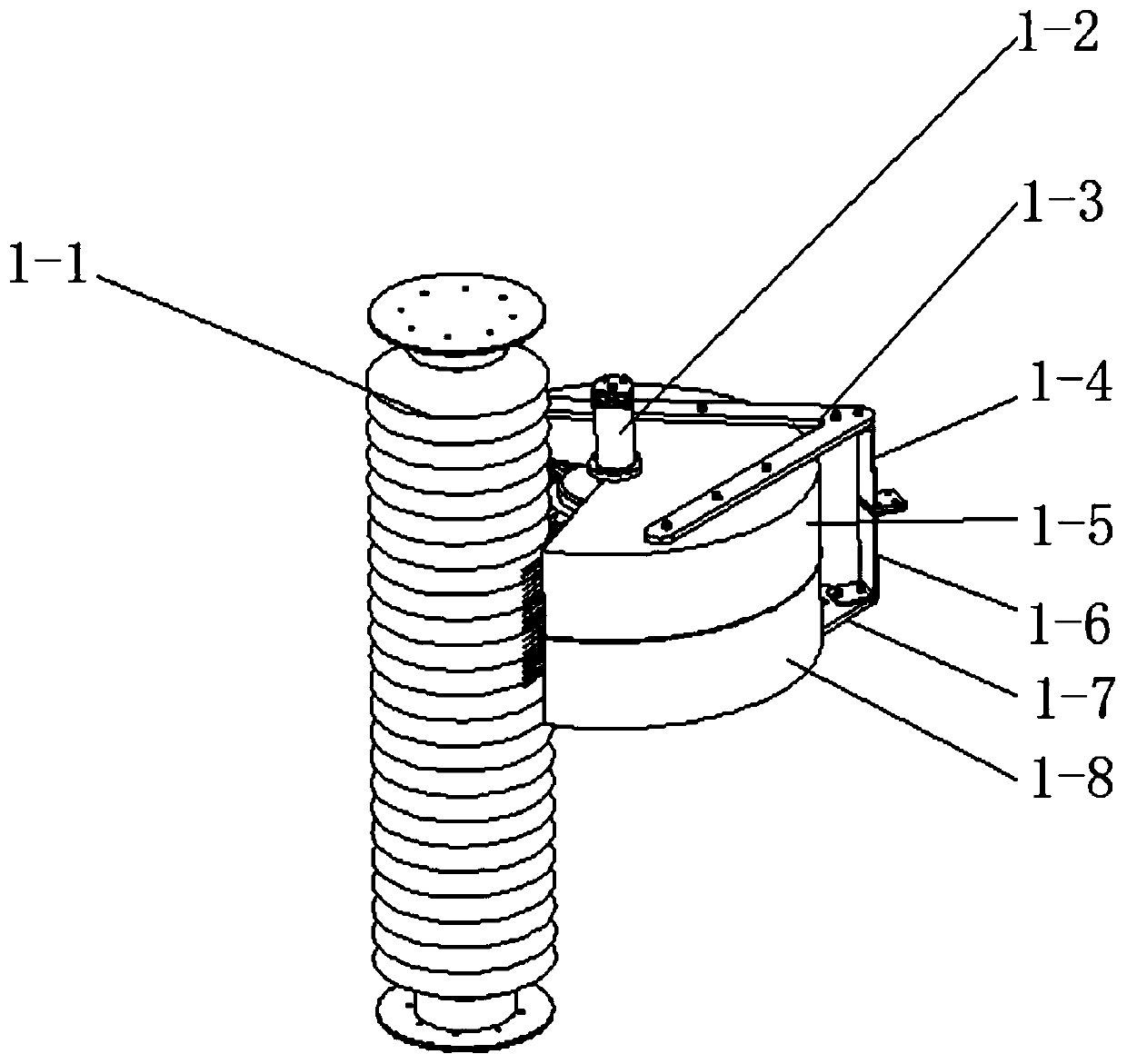

[0090] As a specific embodiment, the cleaning part includes a cleaning brush structure and a driving motor 1-2;

[0091] The cleaning brush structure includes a hollow structure cleaning brush, and an insulating agent sponge 1-16 and a centrifugal motor 1-14 arranged inside the hollow structure;

[0092] The driving motor 1-2 is connected with the cleaning brush, the output shaft of the centrifugal motor 1-14 is connected with the insulating agent centrifugal mechanism 1-15, and the insulating agent sponge 1-16 is located in the hollow cleaning brush 1-11 and the insulating agent centrifugal mechanism 1-15 between;

[0093] When the drive motor 1-2 and the centrifugal motor 1-14 make their output shafts rotate in opposite directions, the hollow cleaning brush 1-11 rotates in the opposite direction with the insulating agent centrifugal mechanism 1-15, and the insulating agent centrifugal mechanism 1-15 rotates and squeezes the insulation The agent sponge 1-16, the insulating a...

Embodiment 2

[0172] In one or more embodiments, a live working robot system for substation insulators is disclosed, referring to figure 1 , including: the robot body, the control module set in the robot body, and the insulation lifting mechanism set on the robot body; the end of the insulation lifting mechanism is connected to the live working tool through a quick connector; the live working tool includes: substation contact grinding device , Substation insulator defect live detection device and bolt fastening device.

[0173] Of course, the live working tool may also include the live cleaning device or the RTV spraying device in Embodiment 1, and those skilled in the art can make a reasonable design according to actual needs.

[0174] refer to Figure 13 , The substation contact grinding device includes:

[0175] The grinding part includes a grinding head 3-3 module and a cleaning module; the grinding head 3-3 module is used for grinding the isolating switch knife switch contact to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com