A method of treating sludge with a cement kiln and a sludge gasification cement kiln system

A sludge gasification and cement kiln technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, cement production, etc., can solve sludge agglomeration and uneven distribution, high energy consumption , Disposal scale is not large, etc., to achieve low cost, increase disposal scale, and reduce moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

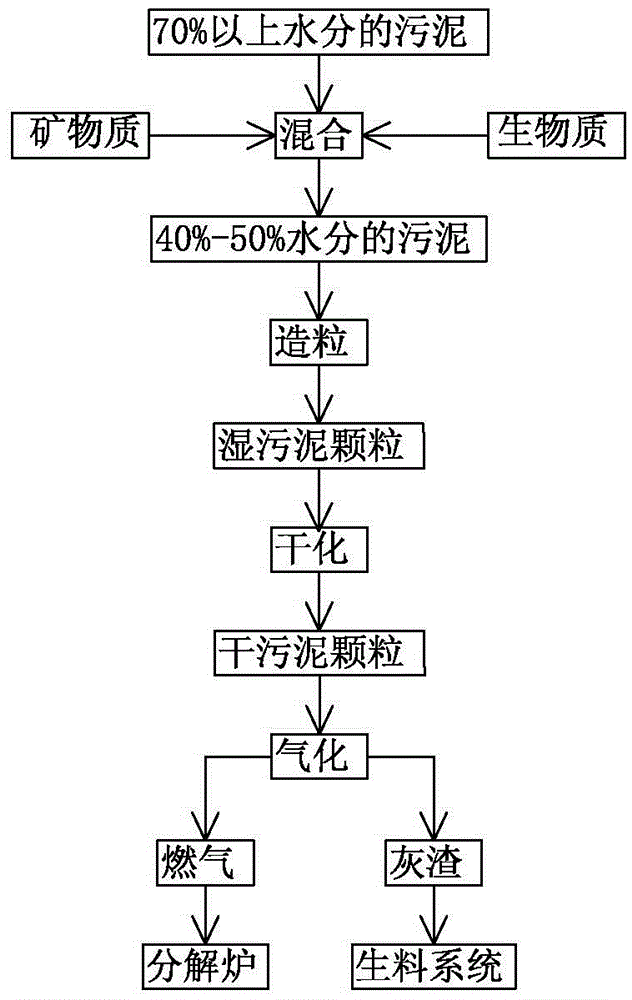

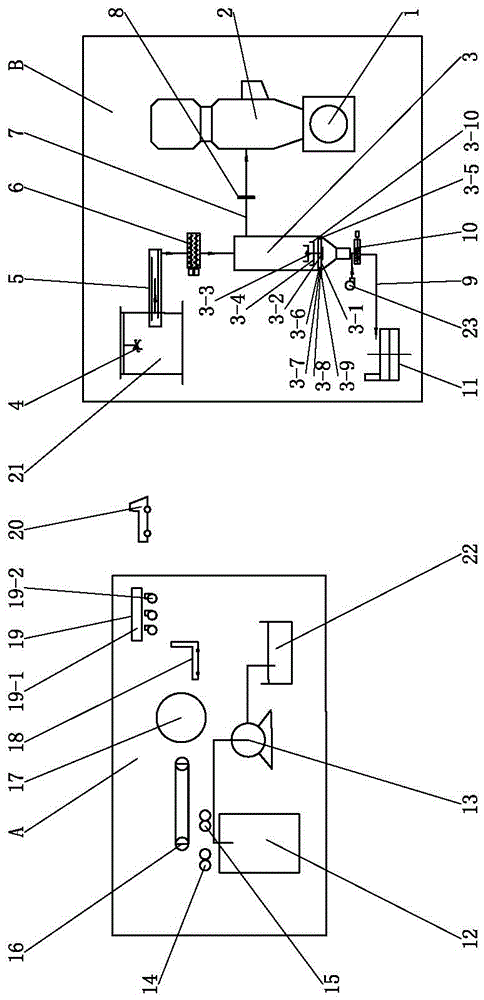

[0032] Such as figure 1 with figure 2 As shown, the method of sludge disposal in cement kiln in this embodiment is to first make wet sludge into dry sludge particles, then gasify the dry sludge particles, and then send the gas obtained after gasification into the decomposition furnace 2 , sending the ash obtained after gasification into the raw meal system 11 . As a preference, the gasification of the dry sludge particles is to generate gas by degasifying another part of the dry sludge particles with heat generated by burning a part of the dry sludge particles. This can greatly save energy consumption.

[0033] In this embodiment, the wet sludge is first made into dry sludge particles, and then the dry sludge particles are gasified, and then the gas obtained after gasification is sent to the decomposition furnace, and the ash obtained after gasification is sent to Therefore, the scale of sludge disposal can be greatly increased; the difference between the shape of solid sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com