Device and method for regenerating filling material by using solid waste

A technology for solid waste and earth filling materials, which is applied in the field of devices that utilize solid waste to regenerate earth filling materials, can solve problems such as difficult mechanization and automatic production, lack of on-site applicability, and complicated processes, and achieve low cost, Good effect, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

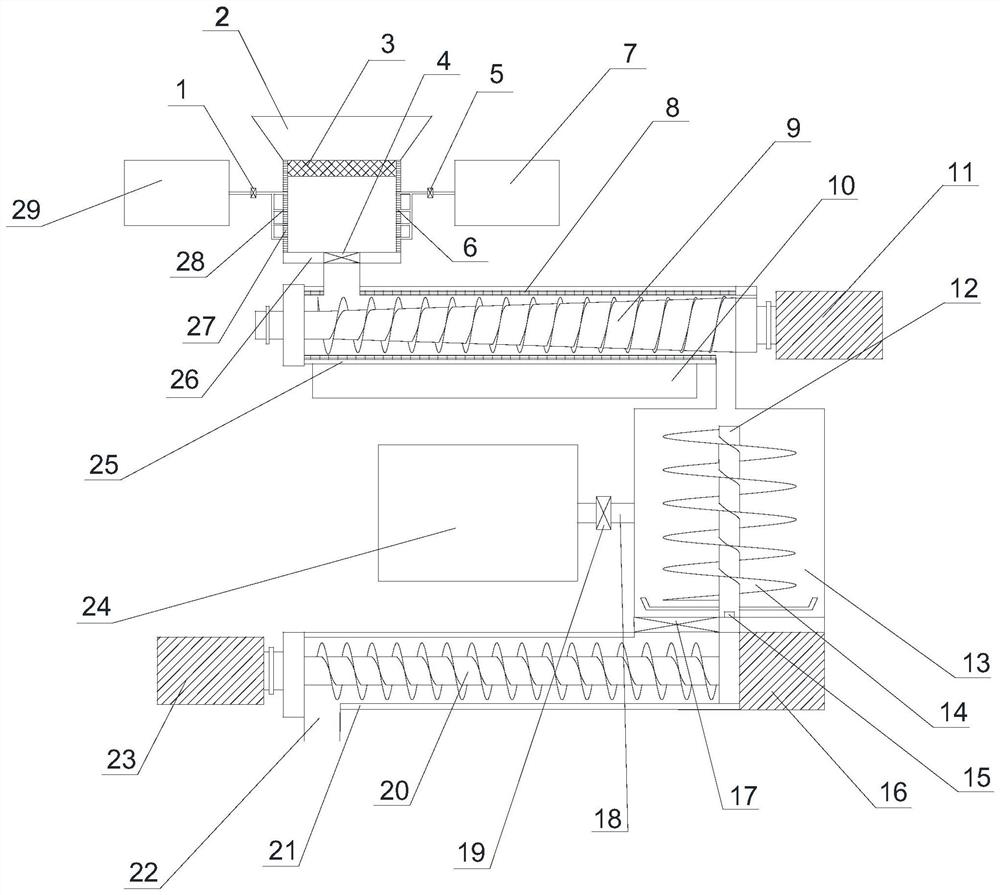

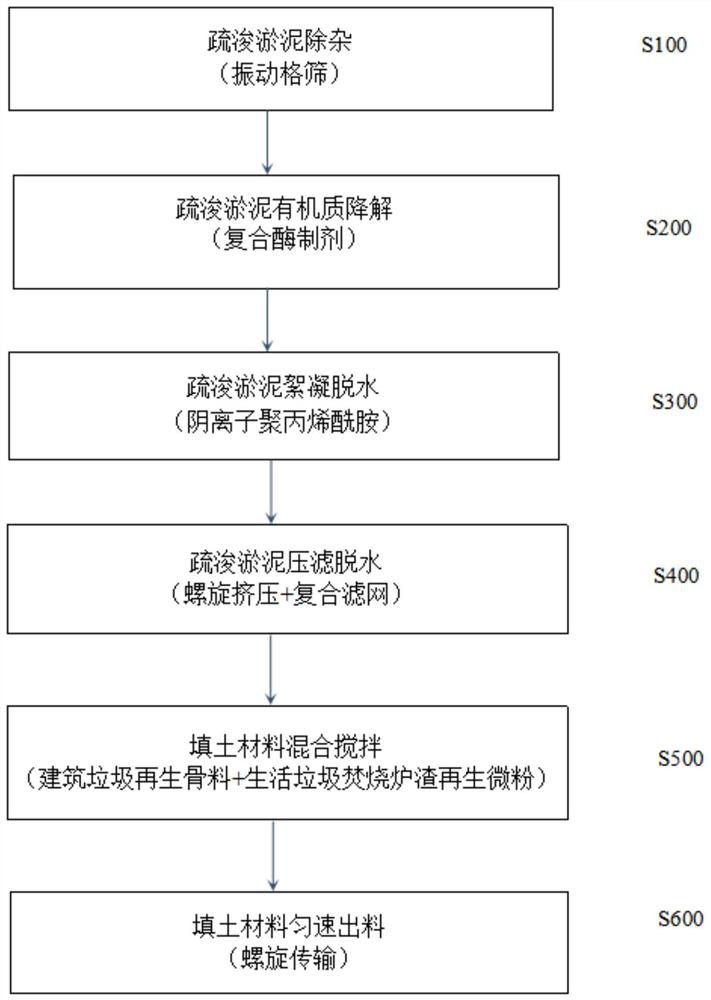

[0038] see Figure 1~2, in an embodiment of the present invention, a device and method for utilizing solid waste to regenerate earth filling materials, including a sludge pretreatment bin, the lower end of the sludge pretreatment bin is connected with a filter press dewatering system through a pipeline, and the filter press dewatering system is connected through a pipeline There is a mixing and stirring system, the left end of the mixing and stirring system is connected to the regeneration collecting bin 24 through the discharge pipe 18, and the lower end of the mixing chamber is connected to the discharging system;

[0039] The upper end of the sludge pretreatment chamber is fixedly connected with a mud inlet 2, and the lower end of the mud inlet 2 is located in the sludge pretreatment chamber and is fixedly connected with a vibrating grid sieve plate 3, and the inner wall of the sludge pretreatment chamber is fixedly connected with a ring wall filter 27 , the aperture of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com