Liquid hazardous waste pre-treatment and exhaust gas collection device

A technology for hazardous waste and waste gas collection, applied in the direction of combustion methods, combustion types, incinerators, etc., to achieve the effects of reducing accident risks, improving efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

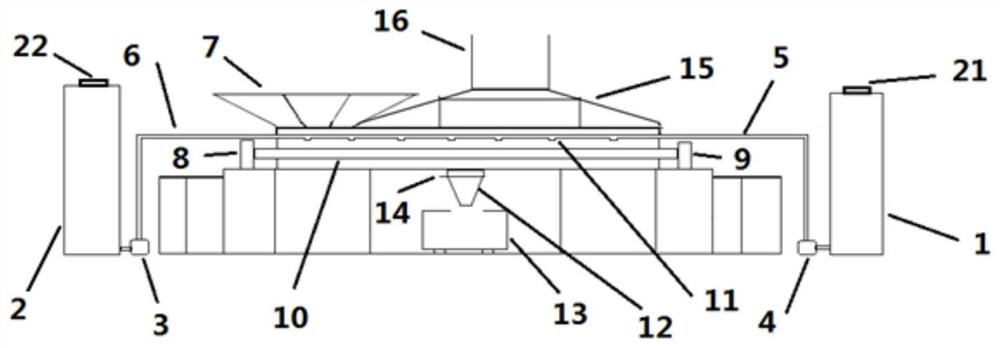

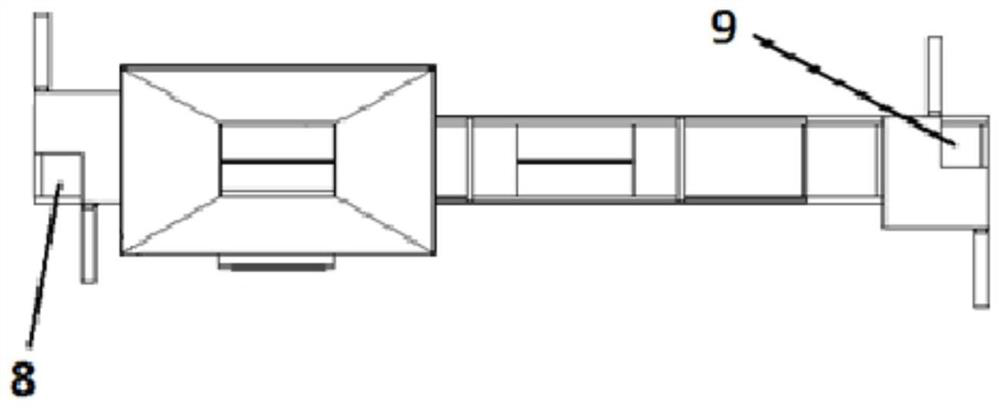

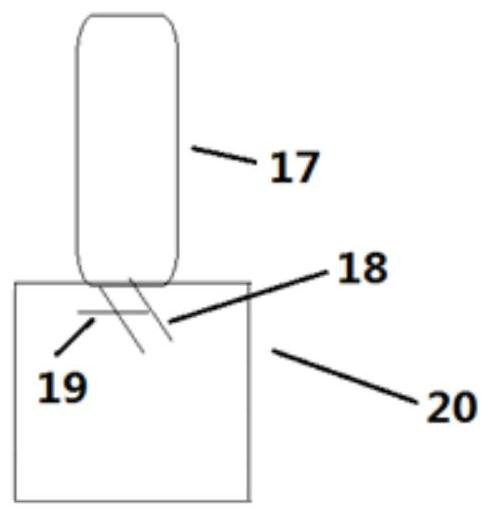

[0020] Specific implementation mode one: see Figure 1-3 This embodiment will be described. The liquid hazardous waste pretreatment and exhaust gas collection device described in this embodiment includes a reclaimed water storage tank 1, a hazardous liquid waste storage tank 2, a No. 1 self-priming pump 3, a No. 2 self-priming pump 4, a hopper 7, a mixing Stirring device, spray pipe, feeding device, feeding device 12, No. 1 valve 14, sealing cover 15 and gas collection pipeline 16, one end of the spray pipe is connected to the reclaimed water storage tank 1, and the other end is connected to the dangerous liquid waste storage tank 2, the waste liquid in the hazardous waste storage tank 2 is sucked into the spray pipe through No. 1 self-priming pump 3, and the reused water storage tank 1 is sucked into the spray pipe through No. A mixing and stirring device is installed below the spray pipe, a hopper 7 is installed on the upper side of the mixing and stirring device, a feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com