Method for processing paint slag muck by separating slag muck from water

A technology of slag water separation and treatment method, which is applied in the direction of separation method, filtration separation, chemical instruments and methods, etc., can solve the problem that the disposal method cannot meet the actual production needs, and achieve the goal of solving disposal difficulties, eliminating potential hazards, and reducing fuel The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

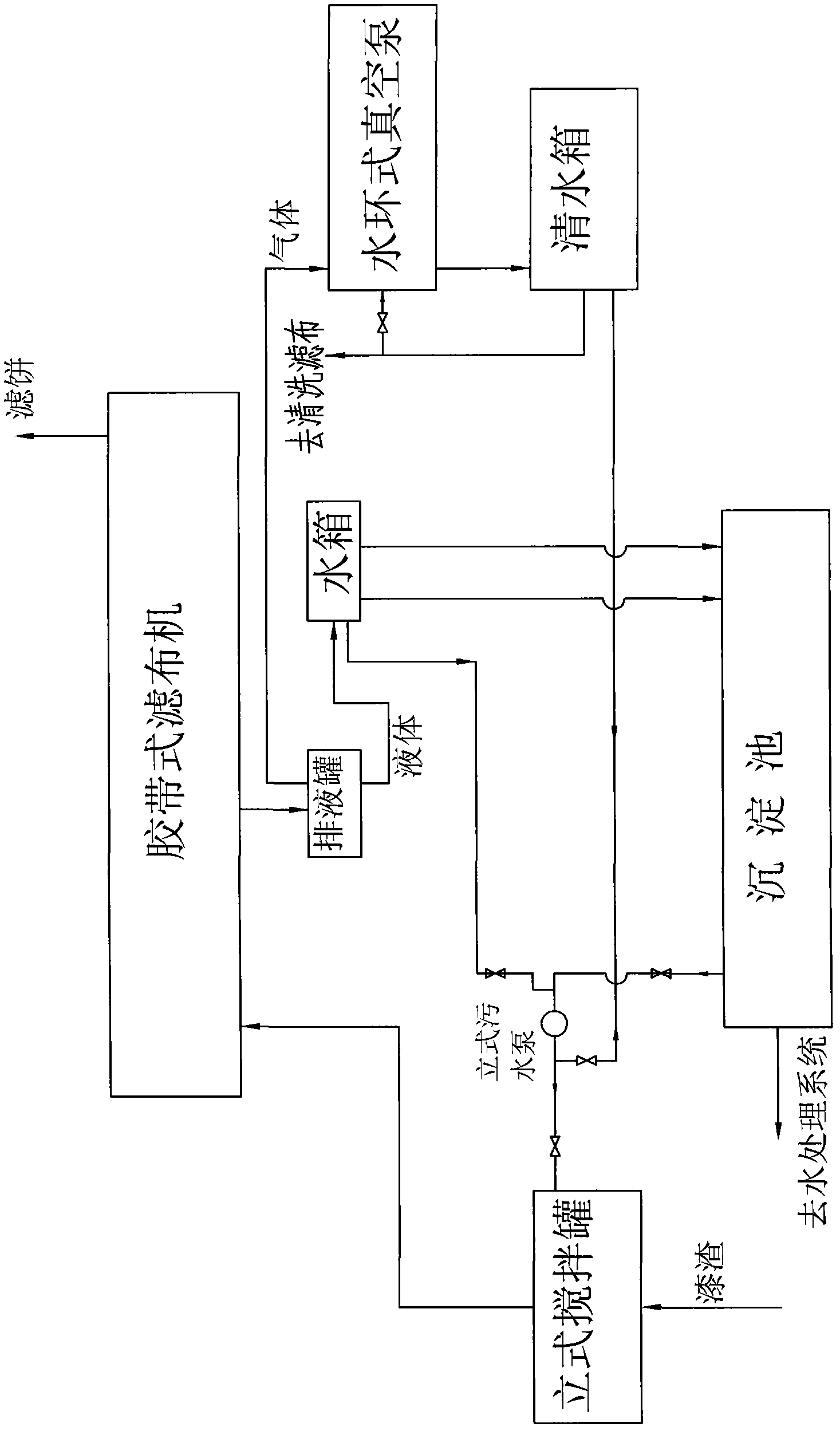

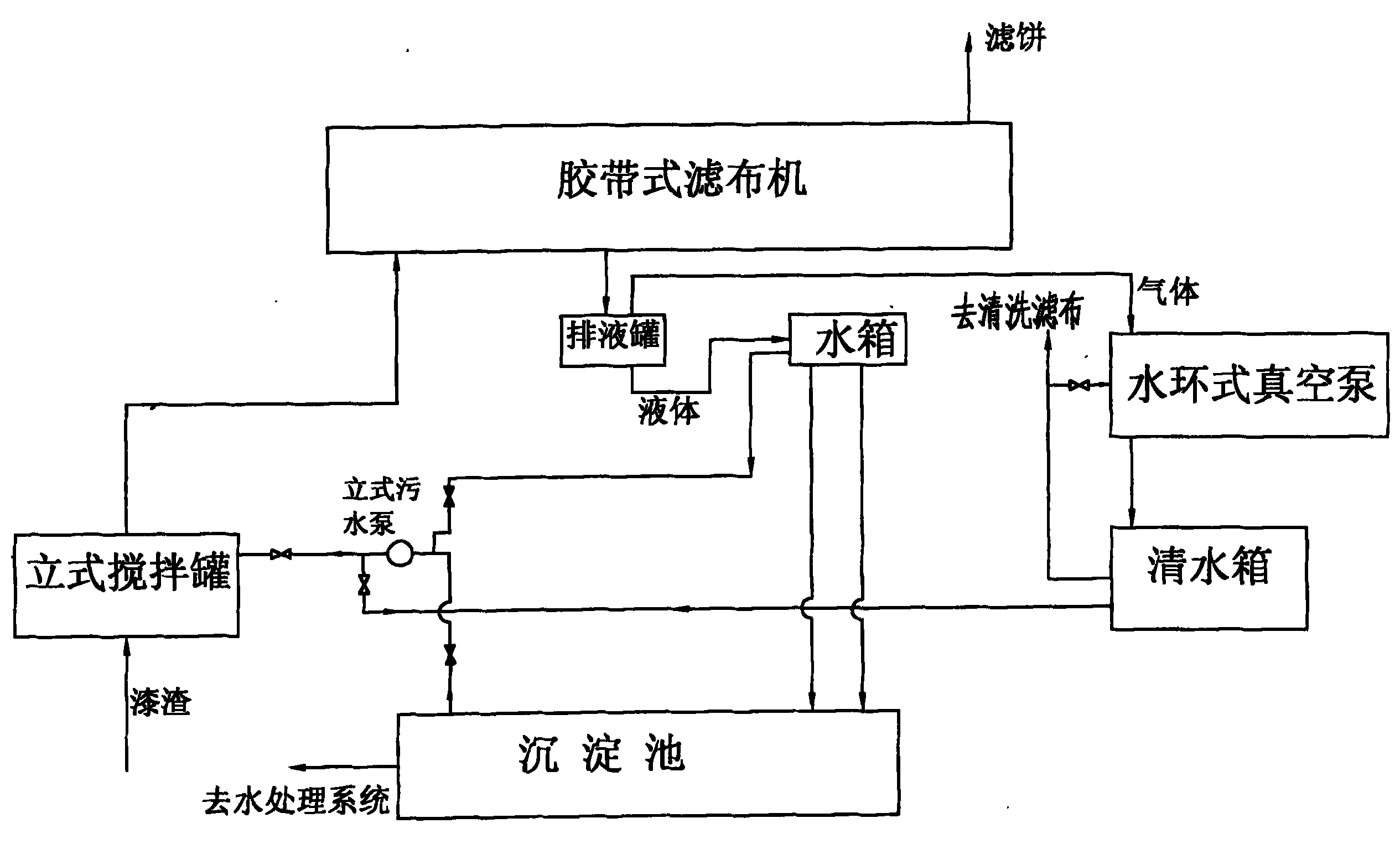

[0028] An embodiment of a treatment method for water separation of paint slag according to the present invention, its process flow includes the following steps as shown in the accompanying drawings:

[0029] (1) The water-containing paint waste collected from the market first enters the vertical mixing tank, and after mixing and stirring evenly, the water-containing paint residue in the tank is sent to the belt-type filter cloth machine by the air pump, and the belt-type filter cloth machine The distributor evenly distributes the paint slag on the filter cloth arranged on the annular belt; the entrance of the vertical mixing tank is provided with a grate, which can filter out larger cloth and other sundries contained in the paint slag. In this embodiment, the model of the tape-type filter cloth machine is: WG5 / 700; the aperture of the filter cloth is 200 mesh, that is, 0.074 mm.

[0030] (2) The ring-shaped belt on the belt-type filter cloth machine is driven continuously by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com