Municipal sludge chain rolling suspension drying clean incineration equipment and incineration method

A technology for municipal sludge and incineration equipment, which is applied in the direction of combustion methods, sludge drying, chemical instruments and methods, etc., and can solve problems such as large floor area, high processing cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

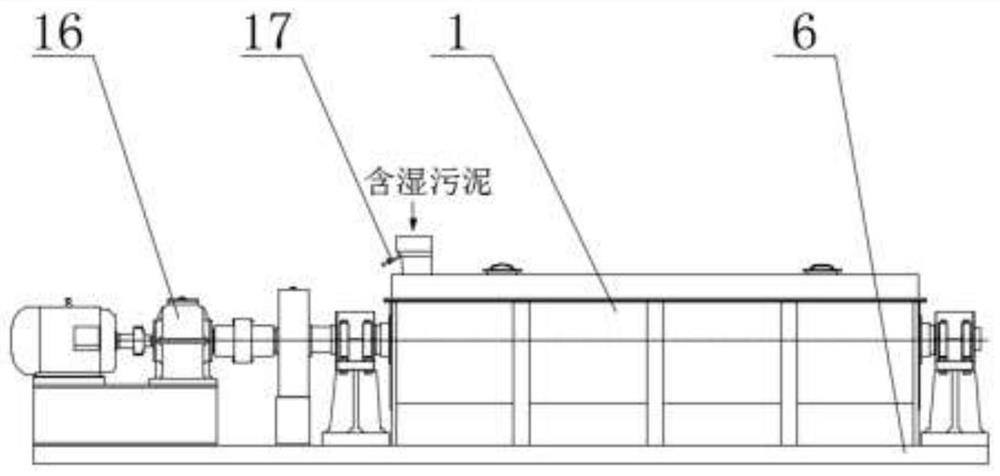

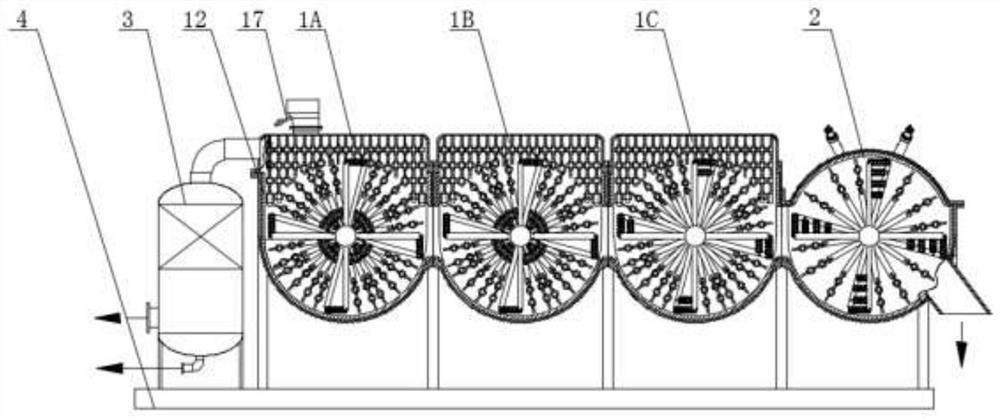

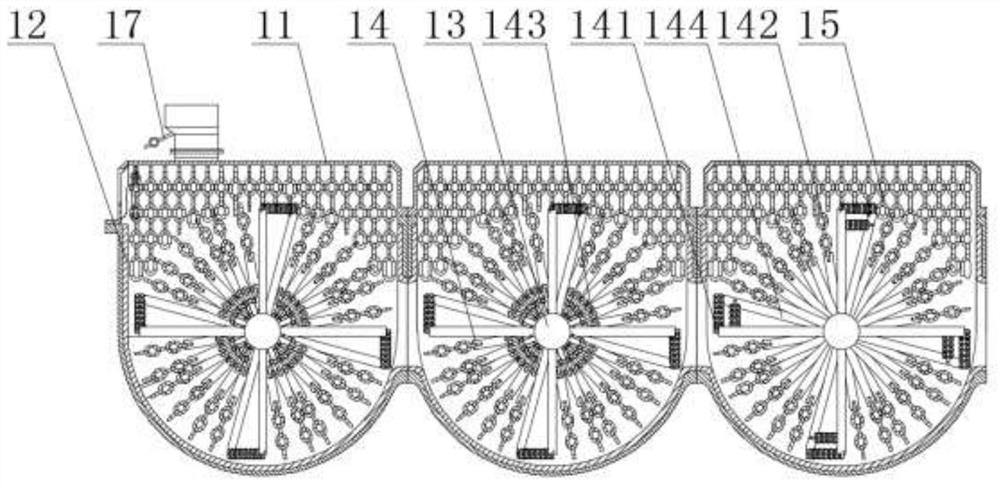

[0074] refer to Figure 1-8 , this embodiment mainly includes 3 levels of successively connected rod chain rolling suspension drying device 1, 1st level plasma suspension incineration device 2, exhaust gas purification device 3, support 4, and the discharge port of rod chain rolling suspension drying device 1 It is connected with the feed port of the plasma suspension incineration device 2, and the air outlet of the first-stage horizontal rod chain suspension drying device 1A is connected with the air inlet of the waste gas purification device 3, and the rod chain suspension drying device 1 , the plasma suspension incineration device 2, and the waste gas purification device 3 are all fixed on the support 4.

[0075] The three-stage rod chain suspension drying device 1 is the first rod chain suspension drying device 1A, the second rod chain suspension drying device 1B, and the third rod chain suspension drying device 1C, its adjacent two-stage discharge port (also hot air inle...

Embodiment 2

[0085] refer to Figure 9-11 , the difference between this example and Example 1 is that the sludge chain roller suspension drying cleaning incineration equipment includes 5-stage horizontal rod chain rolling suspension drying devices (1A, 1B, 1C, 1D and 1E) and 2-stage belt stirring Structured plasma suspension incinerators (2A, 2B).

[0086] The flexible chain agitator 14 of the fourth-stage rod chain suspension drying device 1D is the same as that of the rod chain suspension drying device 1A, 1B, and 1C, and the scraper 14 of the fifth rod chain suspension drying device 1E The difference between the chain 141 and the scraper chains 141 of the rod chain suspension drying devices 1A~1D is that there are 12 scraper chains 141, and two scraper chains 141 arranged concentrically are arranged on each pole, and no pendulum is installed at the same time. Chain 143.

[0087] The cleaning chain 15 in the present embodiment adopts chain plate type.

[0088] The pendulum chain 143 in ...

Embodiment 3

[0107] refer to Figure 12 The difference between this embodiment and Embodiment 1 is that the sludge chain roller suspension drying clean incineration equipment in this embodiment mainly includes 4-stage horizontal rod chain rolling suspension drying devices (1A, 1B, 1C and 1D) and Level 1 plasma suspension incinerator 2.

[0108] The flexible chain agitator 14 of the fourth-stage rod chain suspension drying device 1D is the same as that of the first three rod chain suspension drying devices 1A, 1B, and 1C.

[0109] The sludge chain mill suspension drying clean incineration equipment also includes garden wood waste pulverized material feeding device, which is set on the top of the front end of the second-stage horizontal rod chain rolling suspension drying device 1B .

[0110] High-temperature plasma torches 23, high-temperature plasma The bulk torch 23 is located at the feed inlet to regulate the temperature of the hot gas entering the rod chain suspension drying devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com