Multi-layer reciprocating type gasified combustion furnace

A combustion furnace, reciprocating technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of long residence time, influence of burnout rate, large size of mechanical grate, etc., to reduce the volume of the incinerator and adapt to the scope The effect of widening and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

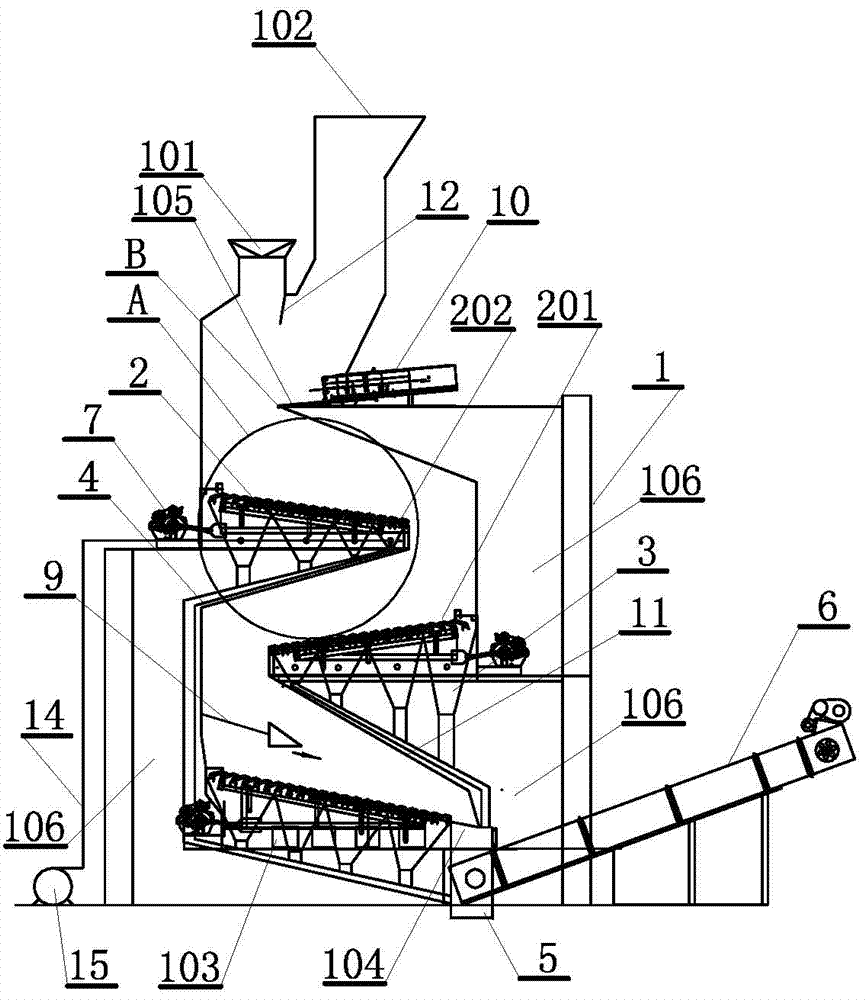

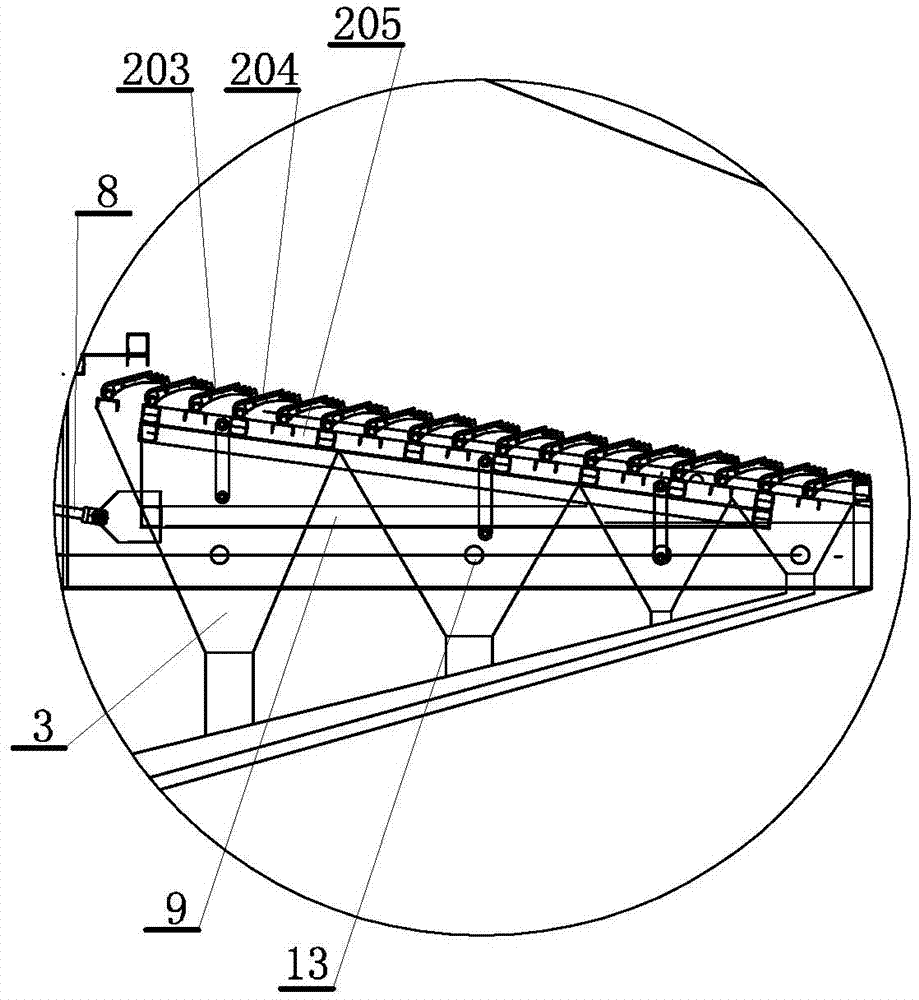

[0026] A multi-layer reciprocating gasification combustion furnace, such as figure 1 and figure 2 As shown, the multi-layer reciprocating gasification combustion furnace includes a combustion furnace body 1, which is a vertical cylindrical furnace body, and a gasification flue gas discharge port 101 and a gasification raw material garbage inlet 102 are arranged at the upper end of the combustion furnace body. , the gasification flue gas discharge port is used to connect the device or equipment that uses gasification flue gas, the feed port is set higher than the gasification flue gas discharge port, and the lower end side of the combustion furnace body is provided with a combustion gas inlet 103 and gasification raw material waste combustion The rear slag outlet 104; wherein, the hearth in the furnace body is provided with multi-layer fire grate 2 vertically from top to bottom, and at least three rows are shown in the figure, and each layer of fire grate is inclined downward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com