Novel process method of co-processing iron hazardous waste briquettes by blast furnace

A technology of co-processing and process method, applied in the direction of blast furnace, combustion method, blast furnace details, etc., can solve the problems of hazardous waste, small processing capacity, general economic benefits, etc., achieve simple process and operation, no disposal cost, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

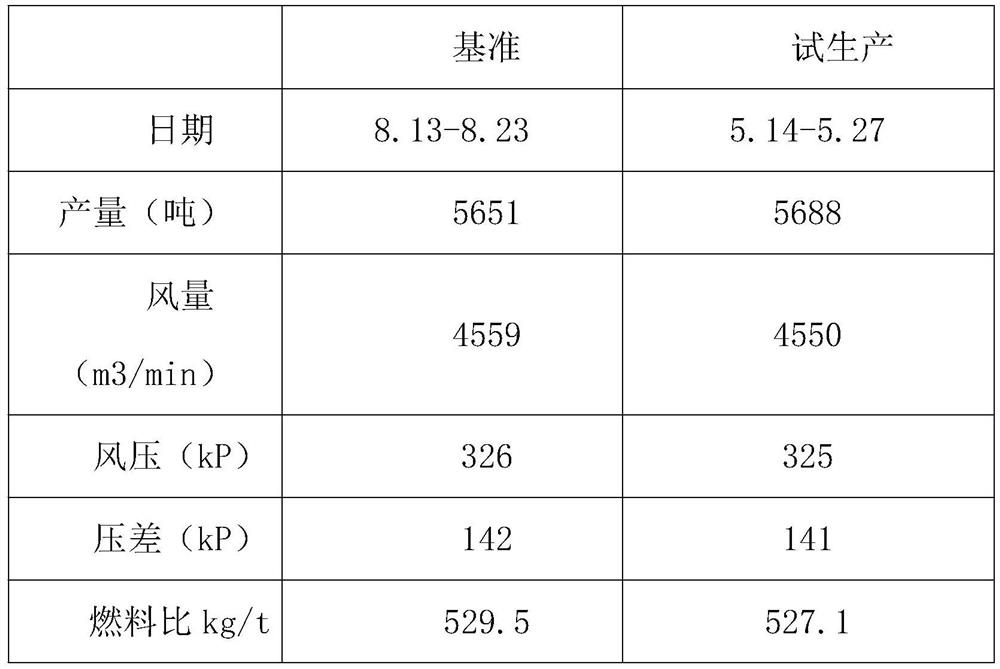

[0038] A new process method for co-processing iron hazardous waste briquettes with blast furnaces. There is no new equipment in the blast furnace process, and some equipment is added for pretreatment to make briquettes. The briquette raw materials mixed with hazardous iron wastes hw49, hw08, and hw09 are smelted in the blast furnace. The proportion of hazardous iron wastes hw49, hw08, and hw09 in the total raw material consumption is 0.14%, which is relatively small.

[0039] Such as figure 1 Shown is a new process method for blast furnace co-processing of hazardous iron waste briquettes. The iron hazardous waste includes hw49, hw08, and hw09. The process method includes the following steps:

[0040] (1) Pretreatment: The hazardous iron wastes hw49, hw08, and hw09 are identified, mixed into briquettes, and film-coated, wherein the volume of the briquettes in this embodiment is 100*100*100mm-150* 150*150mm, the number of layers of the film coating treatment is greater than or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com