Multi-point feeding system for co-processing rdf in cement kiln

A technology of co-processing and feeding system, which is applied in the direction of combustion type, combustion method, lighting and heating equipment, etc., and can solve problems such as the limitation of disposal amount and the influence of stable operation of kiln system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

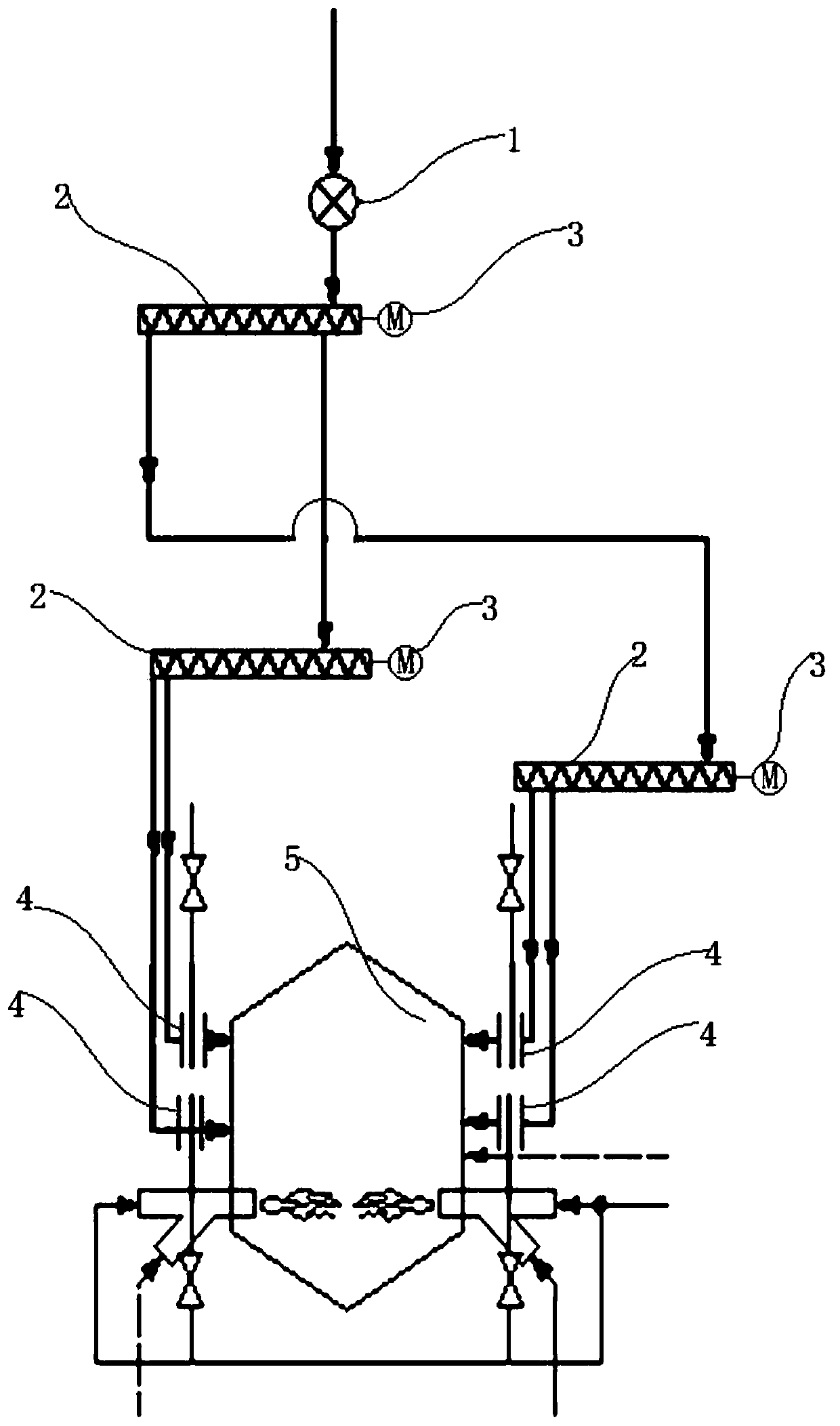

[0015] Such as figure 1 As shown, a multi-point feeding system for co-processing RDF in a cement kiln includes at least two stages of shaftless screw conveyor 2, the first stage of shaftless screw conveyor 2 has only one and the inlet is connected to the main pipeline, and the main pipeline is equipped with At least one rotary air lock valve 1, each shaftless screw conveyor 2 of the upper stage is connected to the entrance of at least two shaftless screw conveyors 2 of the next stage through a branch pipeline, and each shaftless screw conveyor of the last stage 2 are divided into at least two paths through branch pipelines, each of which is equipped with a gate valve 4 and is connected to the kiln system 5, and the branch pipeline inlet is connected to the shaftless screw conveyor Connection of screw conveyor 2. In this embodiment, two-stage shaftless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com