Weighing-sorting system

A weighing and electromagnet technology, which is applied in the field of weighing and distributing systems for iron or steel materials, can solve the problems of high air jet noise from the air jet of pneumatic components, reliability depends on the placement method, and high automation costs, so as to improve efficiency and Reliability, light weight, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A preferred mode of the present invention will be described below with reference to the accompanying drawings.

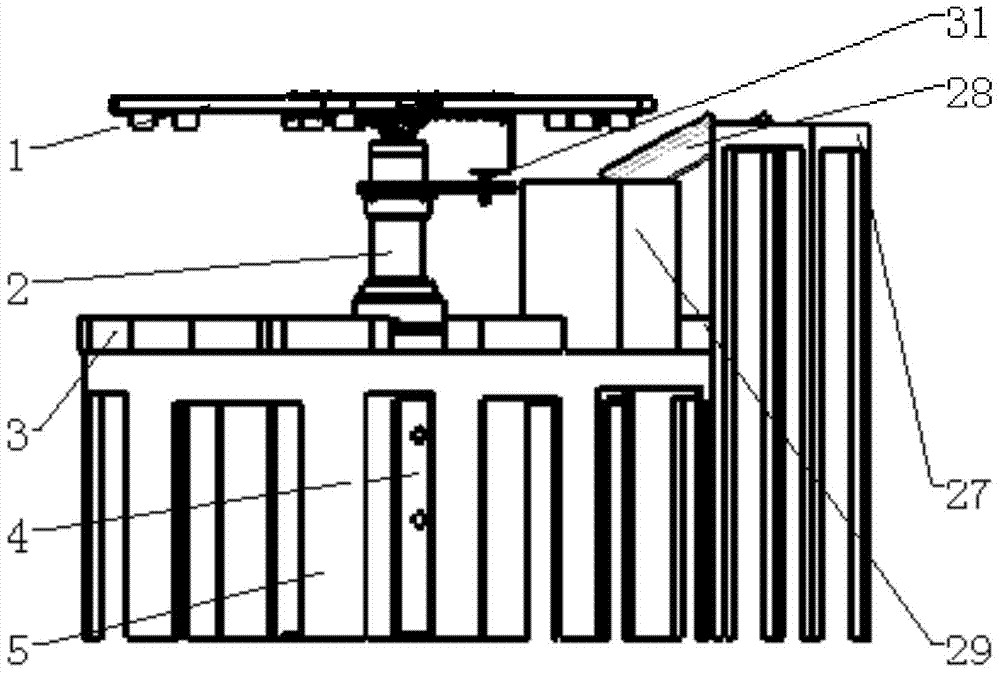

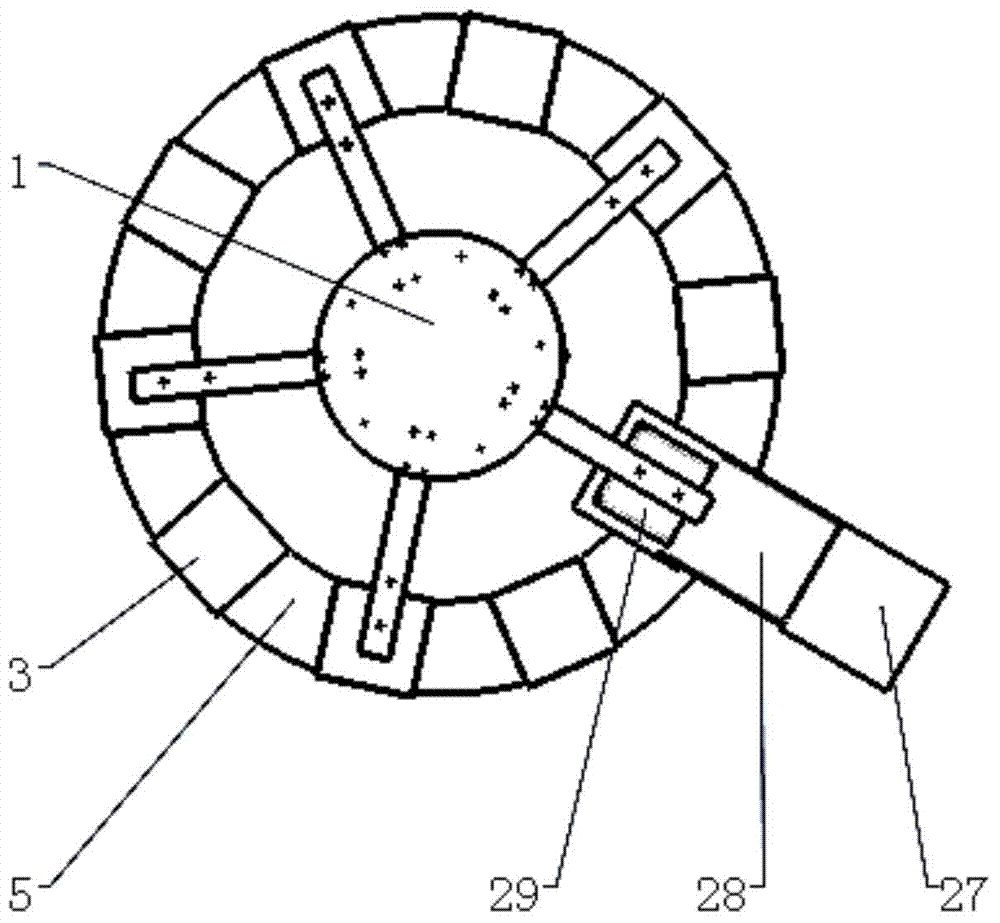

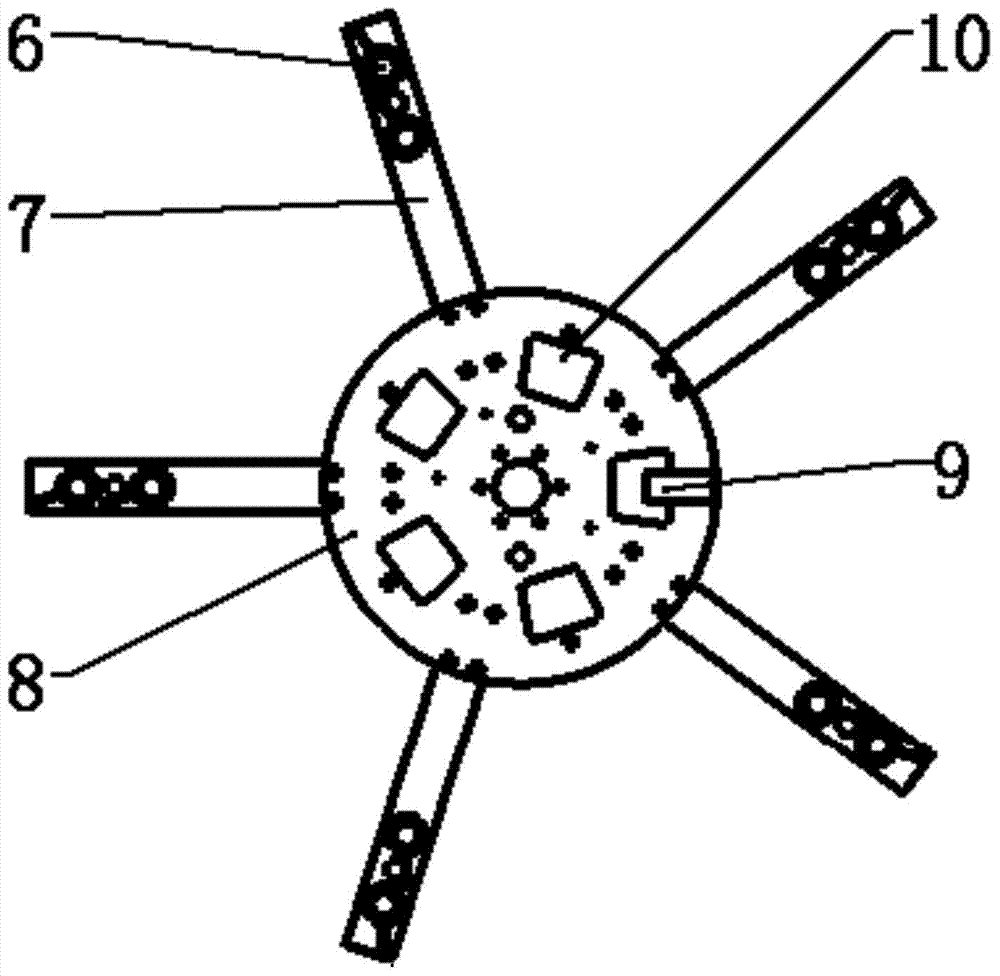

[0030] The weighing and distributing system proposed by the present invention includes a turntable, a transmission assembly, an electromagnet assembly, a weighing assembly, a material holding assembly and a control assembly. The transmission assembly is fixedly connected to the turntable to drive the turntable to perform circular motion. The electromagnetic control assembly includes: The transmission assembly is a plurality of groups of electromagnets distributed on the lower surface of the turntable around the center. The weighing assembly is arranged at the exit of the material conveying line and below the electromagnet. Or the attraction of steel substances, the material holding component includes multiple hoppers arranged under multiple groups of electromagnets, the input information of the control component is the quality of the material weighed by the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com