Sludge treatment system and method in cement kiln

A sludge system and cement kiln technology, applied in water/sludge/sewage treatment, sludge treatment, dewatering/drying/concentrated sludge treatment, etc. problems, to achieve the effect of large disposal volume, energy saving and pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below by specific examples.

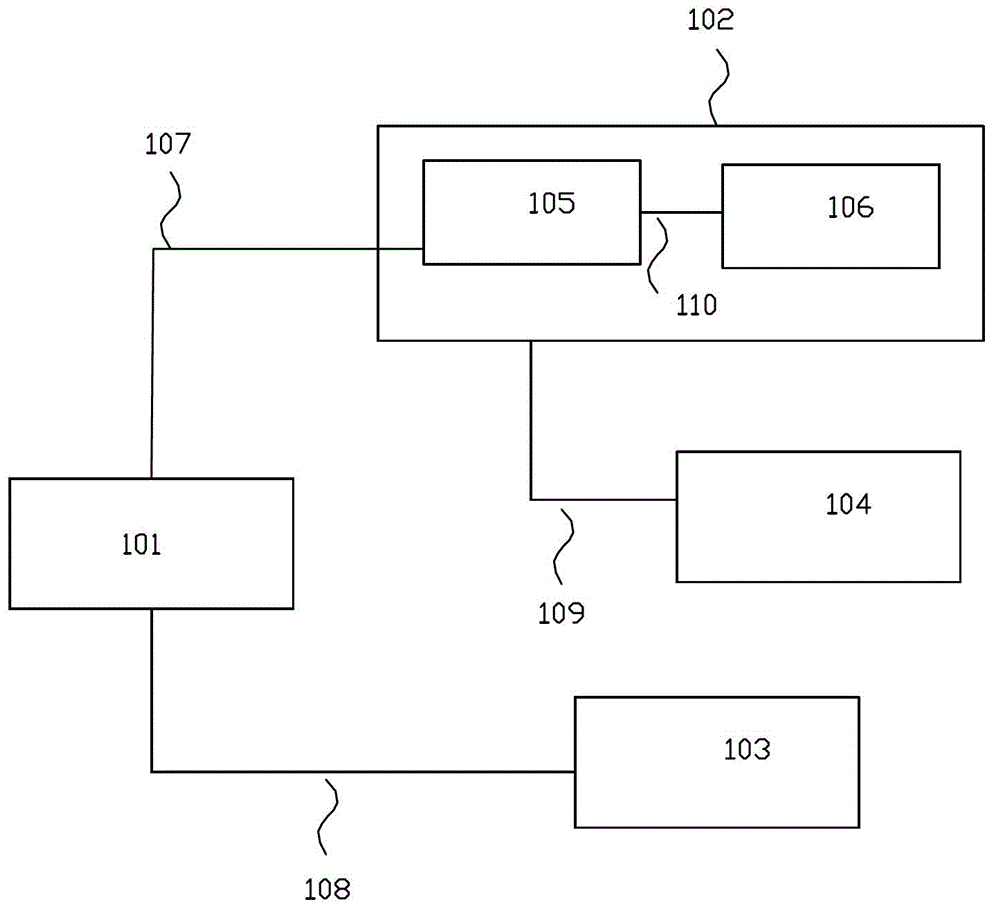

[0028] refer to figure 1 A cement kiln sludge treatment system described in this embodiment includes a sludge drying device 101, a sludge incineration device 103, a sludge drying waste gas treatment device 102, and a waste water treatment device 104, which are used to treat the dried sludge The first conveying mechanism 108 for conveying to the sludge incineration device, the second conveying mechanism 107 for conveying the sludge drying waste gas to the sludge drying waste gas treatment device, and the second conveying mechanism 107 for treating the sludge drying waste gas The waste water produced by the device is sent to the third transfer mechanism 109 of the waste water treatment device;

[0029] The sludge drying device 101 is connected to the sludge incineration device 103 through a first transmission mechanism 108, and the sludge drying device 101 is connected to the sludge drying was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com