Method for reducing nitric oxides by using disposed sludge

A technology of nitrogen oxides and sludge, which is applied in chemical instruments and methods, combustion methods, sludge treatment, etc., can solve the problems of high and low denitrification efficiency, and achieve the reduction of nitrogen oxides, cost reduction, and nitrogen reduction The effect of oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

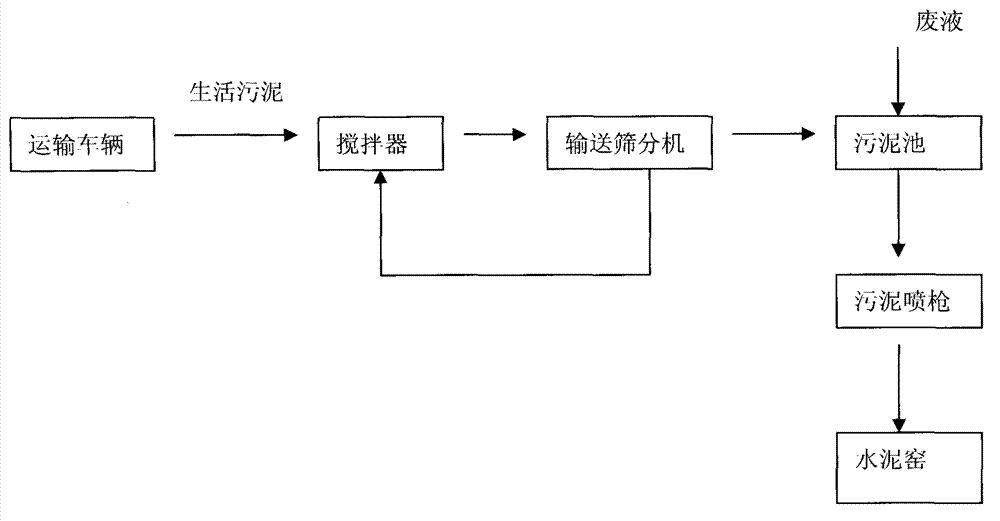

[0034]A kind of embodiment of the method that utilizes disposal sludge to reduce nitrogen oxides of the present invention, as shown in accompanying drawing, it comprises the following steps:

[0035] (1) After the domestic sludge from the sewage treatment plant is transported into the plant by vehicles, it enters the agitator for stirring;

[0036] (2) After the sludge is evenly stirred, it is transported to the conveyor screening machine to further break up the large particle sludge;

[0037] (3) After breaking up, the large particle sludge is thrown out through the small hole in the barrel wall of the conveying screening machine (due to the effect of centrifugal force), and directly enters the sludge tank for disposal, while the unbroken sludge is collected After that, it circulates again into the agitator for stirring;

[0038] (4) The sludge entering the sludge tank is stirred and mixed for the second time in the sludge tank, and waste liquid is appropriately added accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com