Pulse-combustion control method of steel rolling heating furnace

A technology of pulse combustion and control method, which is applied in heat treatment furnaces, controlled combustion, lighting and heating equipment, etc., can solve the problems of large changes in burner workload, poor flexibility in furnace temperature control, and poor maintenance and operating environment, so as to save fuel. Consumption, improve the accuracy and flexibility of furnace temperature control, and facilitate the effect of maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The pulse combustion control method of the steel rolling heating furnace of the present invention comprises at least four gas burners and a PID controller of the automatic control system of the heating furnace, and is characterized in that the method comprises the following steps:

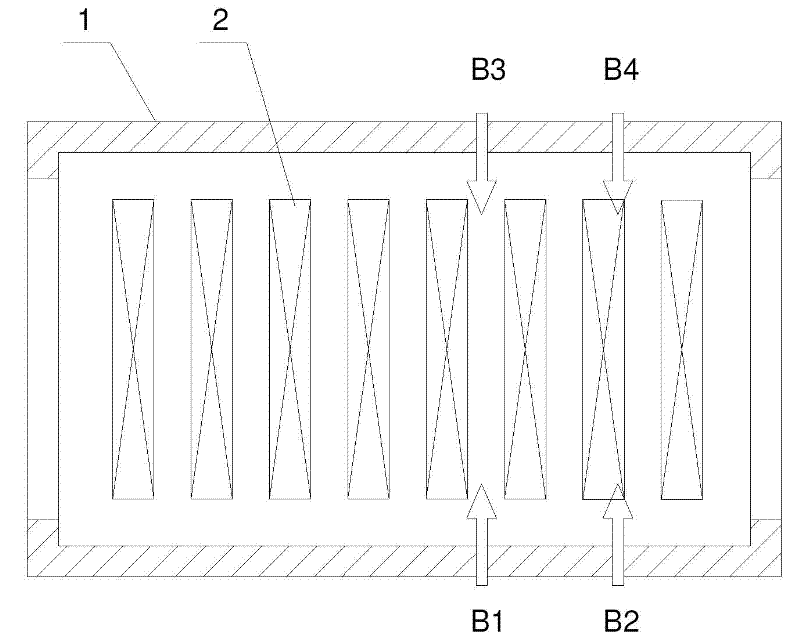

[0020] Step 1, such as figure 1 As shown, the gas burners B1, B2, B3, and B4 are arranged in pairs on both sides of the heating furnace 1 along the length of the furnace, and are located above and below the billet 2 in the furnace, so that the heating furnace 1 forms full-side burning;

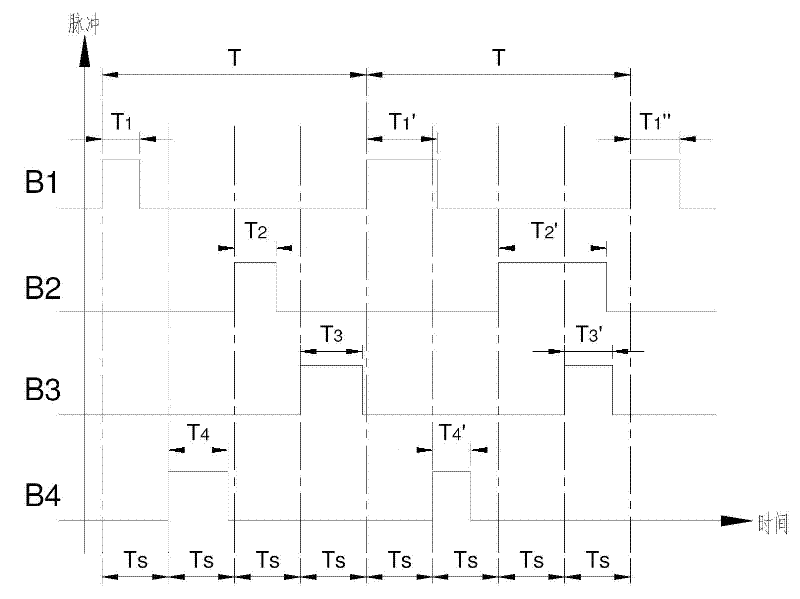

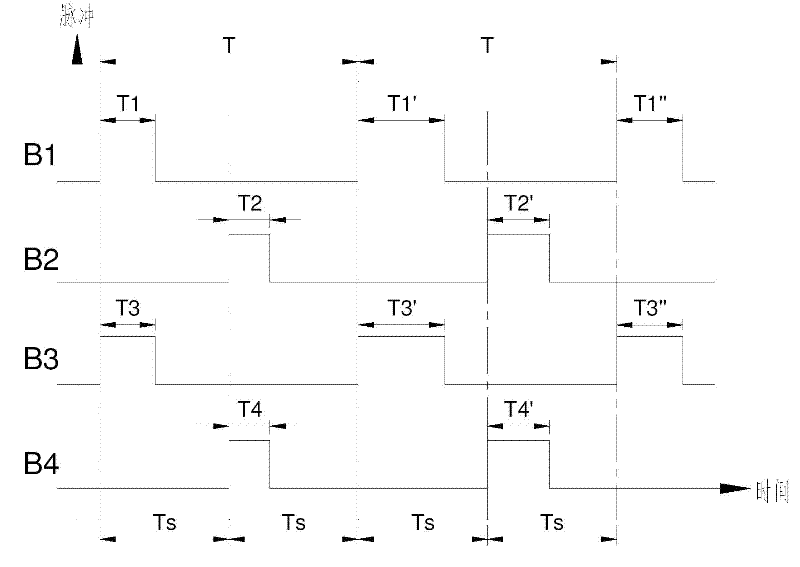

[0021] Step 2. The opening and closing pulses of all gas burners are completed within T time and T time is the cycle period. Each gas burner is turned on sequentially and at an interval of Ts time. The number of gas burners is Q, then within a pulse cycle period Ts =T / Q or Ts=T / (Q / 2);

[0022] Step 3. Adjust the opening pulse sequence of each gas burner according to 2. Every time each gas burner is opened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com