Oxygen-enriched combustion method of lignite methyl alcohol coal slurry fuel material in compression-type internal combustion engine

An oxygen-enriched combustion, internal combustion engine technology, applied in combustion methods, internal combustion piston engines, adding non-fuel substances to fuel, etc., can solve problems such as difficulty in ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

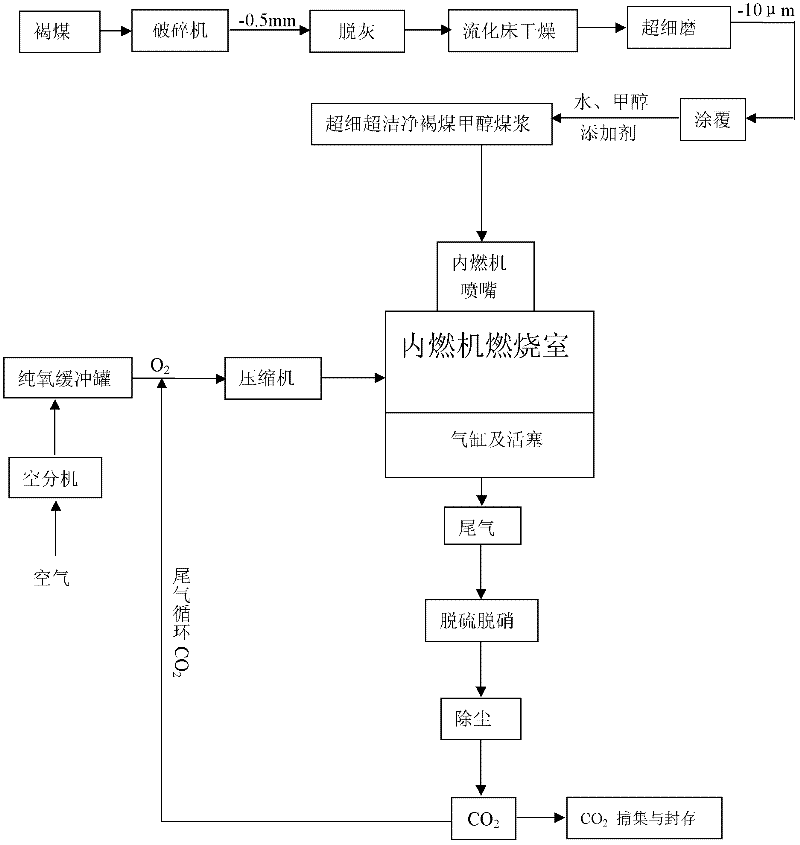

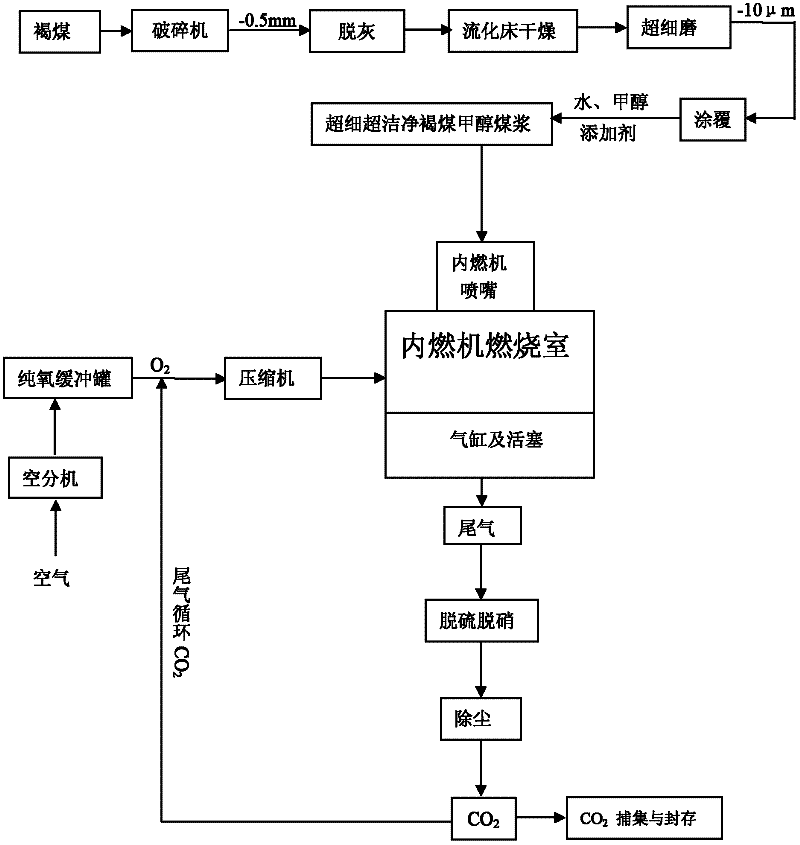

[0028] Such as figure 1As shown, using lignite from Xilinhot area, Inner Mongolia, China, its industrial analysis composition is: moisture 39%, volatile matter 40%, ash content 4.0%, total sulfur 0.3%, calorific value 3800 kcal / kg. The lignite raw coal is roughly ground and screened by a crusher, and the coal powder below 0.5mm after coarse grinding is selected for physical deashing by flotation to obtain an ultra-low ash lignite with an ash content of 0.8% by mass of the coal powder. The moisture in the lignite is dried and removed by using a steam fluidized bed with a production capacity of 10 tons of water evaporation per hour, so that the moisture content in the lignite is reduced to less than 1% of the mass of pulverized coal. Utilize the high-energy ball mill filled with nitrogen to grind the pulverized coal particle size to less than 10 μm. In order to prevent the explosion of ultra-fine coal pulverized in the fluidized bed drying process, the coarse coal pulverized is ...

Embodiment 2

[0032] Such as figure 1 As shown, using lignite produced in China, its industrial analysis composition is: moisture 35-39%, volatile matter 38-40%, ash content 3.5-4.0%, total sulfur less than 0.3%, calorific value greater than 3500 kcal / kg. The lignite raw coal is roughly ground and screened by a crusher, and the coal powder below 0.5mm after coarse grinding is selected for physical deashing by flotation to obtain ultra-low ash lignite with an ash content less than 0.8% of the mass of the coal powder. The steam fluidized bed drying is used to remove the moisture in the lignite, so that the moisture content in the lignite is reduced to less than 1% of the mass of the pulverized coal. Utilize the high-energy ball mill filled with nitrogen to grind the pulverized coal particle size to less than 10 μm. In order to prevent the explosion of ultra-fine coal pulverized in the fluidized bed drying process, the coarse coal pulverized is first dried and then ultra-finely ground. In orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com