Fire coal liquid oxidizer for cement production and preparation method thereof

A liquid combustion enhancer and cement technology, which is applied in the field of pulverized coal combustion, can solve the problems of serious corrosion of combustion equipment, low cost performance, and large dosage, and achieve the effects of improving burnout rate, promoting firing, and improving combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment prepares the coal-fired liquid combustion accelerant 1 for cement production, comprising the following steps:

[0034] (1) Preparation of emulsifier

[0035] The percentage of each component of the raw material in the total weight is as follows: 10% of one or more substances selected from the group consisting of soybean oil, rapeseed oil, castor oil and peanut oil; 20% of one or more substances selected from the group consisting of acids; 20% of one or more substances selected from the group consisting of ethanol, butanol, octanol and decanol; 20% of one or more substances selected from the group consisting of alcohol, diethylene glycol and polyethylene glycol; 20% of 30% concentration sodium hydroxide solution; 4% of sorbitan monooleate; poly Oxyethylene sorbitan fatty acid ester 1%; nonylphenol ethoxylate 2%; water 3%.

[0036] First, one or more substances selected from the above-mentioned group consisting of ethanol, butanol, octanol and decanyl al...

Embodiment 2

[0041] This embodiment prepares the coal-fired liquid combustion accelerant 2 for cement production, comprising the following steps:

[0042] (1) Preparation of emulsifier

[0043] The percentage of each component of the raw material in the total weight is as follows: 30% of one or more substances selected from the group consisting of soybean oil, rapeseed oil, castor oil and peanut oil; 15% of one or more substances selected from the group consisting of acids; 15% of one or more substances selected from the group consisting of ethanol, butanol, octanol and decanol; 15% of one or more substances selected from the group consisting of alcohol, diethylene glycol and polyethylene glycol; 15% of 30% concentration sodium hydroxide solution; 2% of sorbitan monooleate; poly Oxyethylene sorbitan fatty acid ester 0.5%; nonylphenol polyoxyethylene ether 1%; water 6.5%.

[0044] First, one or more substances selected from the above-mentioned group consisting of ethanol, butanol, octanol a...

Embodiment 3

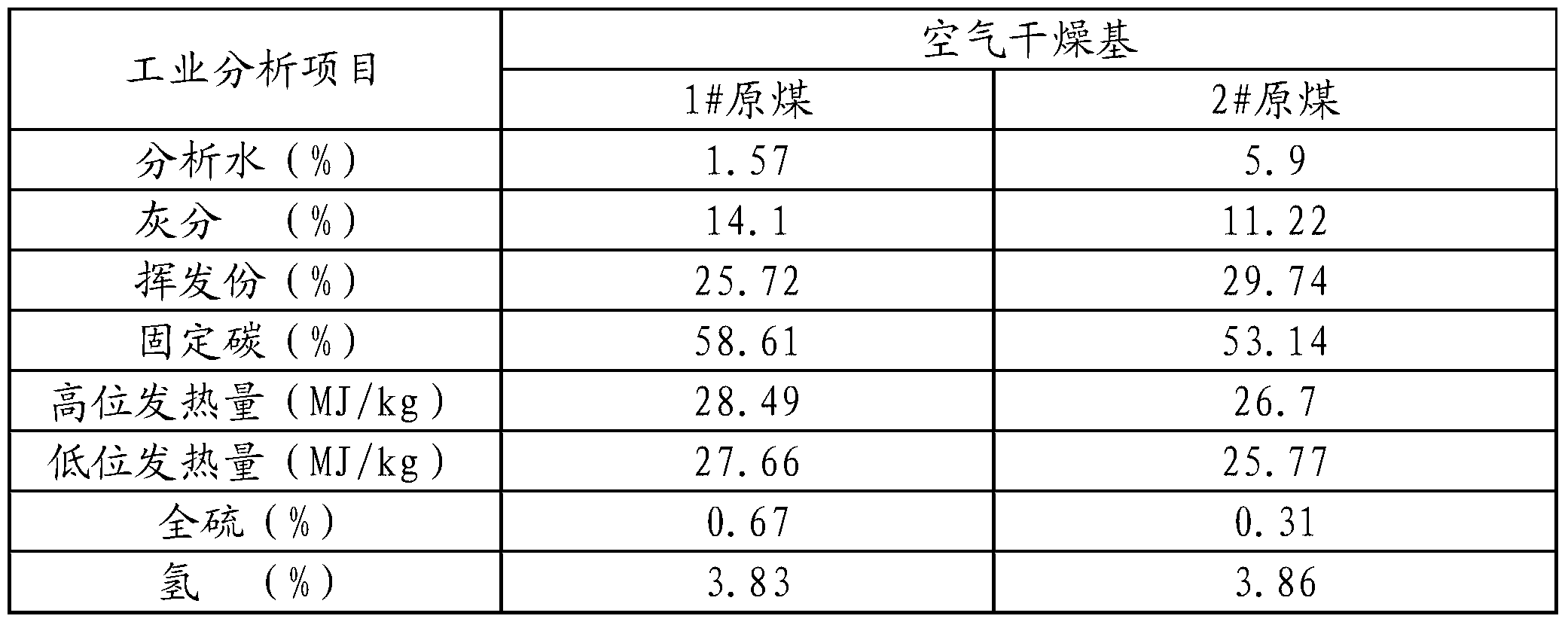

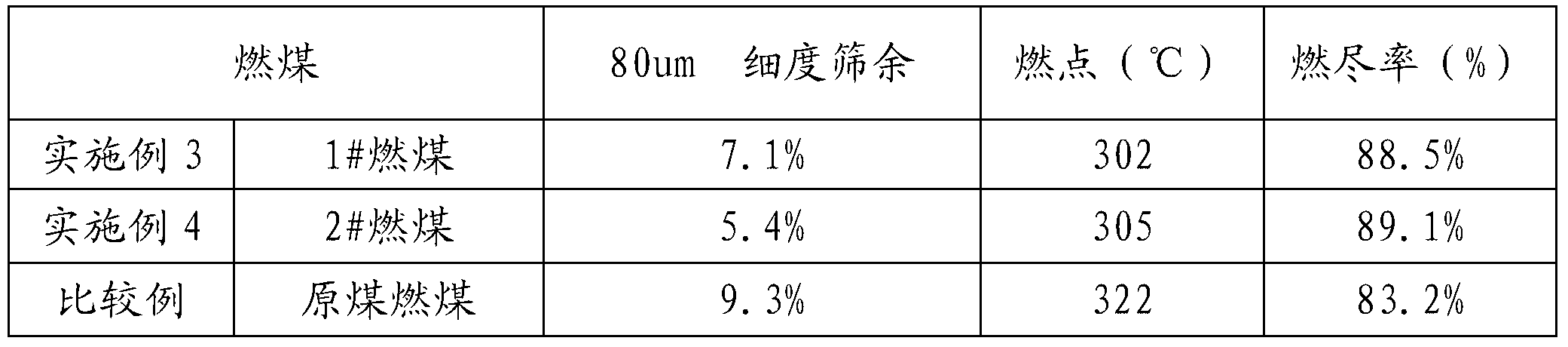

[0049] The product prepared in Example 1, that is, the coal-fired liquid combustion improver 1 for cement production, is mixed with raw coal, and the amount is 0.06%-0.08% of the weight of the raw coal in % by weight. This kind of coal mixed with combustion improver 1 is called 1# coal is burned in a conventional way, and the combustion characteristics of 1# coal are measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com