Plasma oil-free ignition combustor

An oil-free ignition, plasma generator technology, applied in burners, burners burning powder fuel, combustion ignition, etc., can solve major accidents and economic losses, poor adaptability, insufficient pulverized coal and other problems, and achieve investment and operation. Moderate cost, wide adaptability of coal types and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

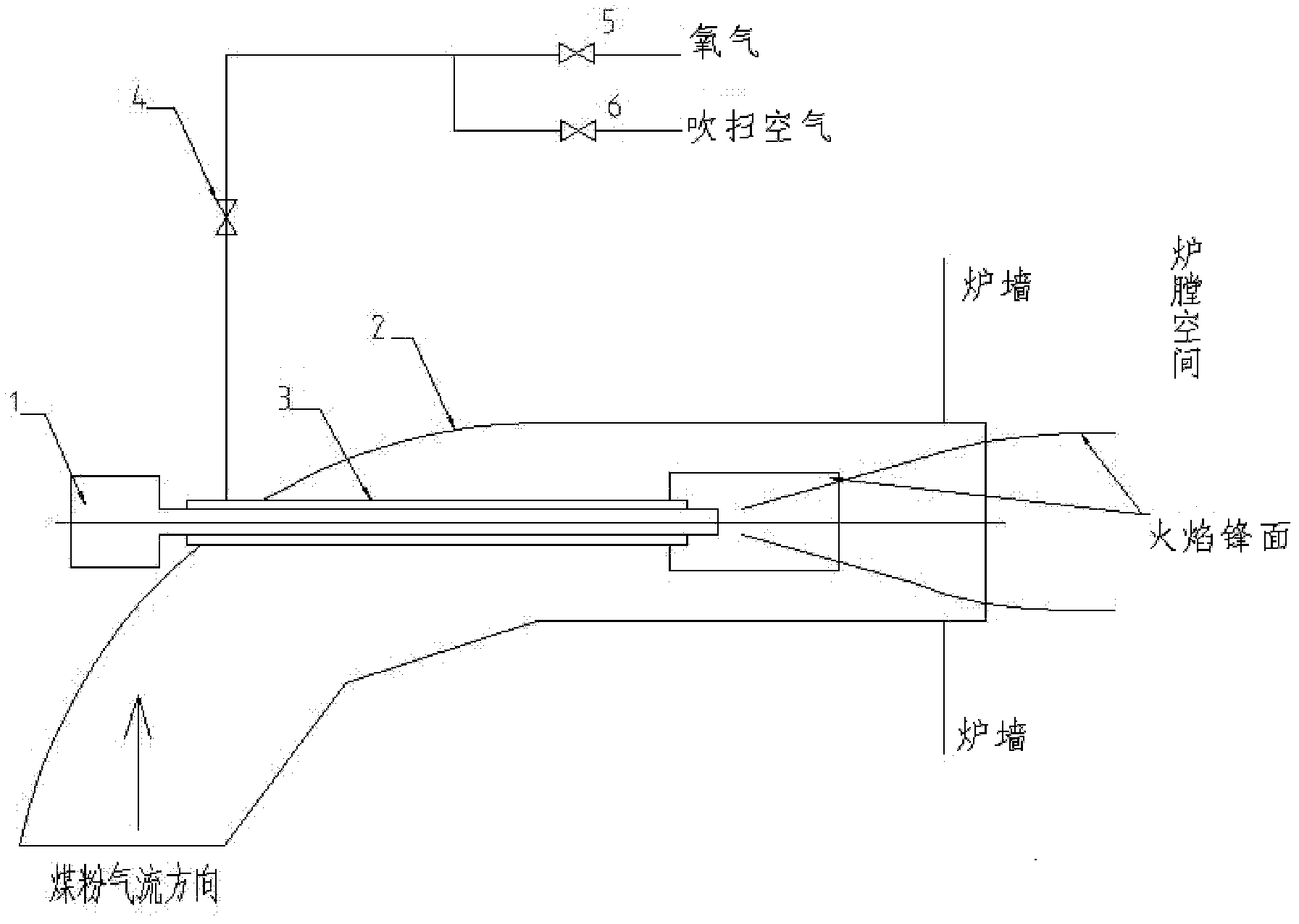

[0026] refer to figure 1 , image 3 , Figure 4 and Figure 5 , a kind of supplementary oxygen combustion-assisted plasma oil-free ignition burner of the present invention includes a plasma generator 1 and a burner 2. The plasma generator 1, the annular oxygen sleeve 3 and the burner 2 are arranged coaxially, and the annular oxygen sleeve 3 is connected to the oxygen pipeline.

[0027] When igniting, open the main valve 4 and the oxygen valve 5, and close the purge air valve 6. Oxygen is injected into the burner 2 through the annular oxygen sleeve 3, forming a local oxygen-enriched area in the burner and the area where the pulverized coal flow flows in the boiler, which promotes the combustion of volatile matter and coke in the pulverized coal flow, and improves the pulverized coal flow. The burnout rate reduces the possibility of boiler fire extinguishing, and finally makes the primary air flow quickly ignite and stably burn.

[0028] After the ignition process is comple...

Embodiment 2

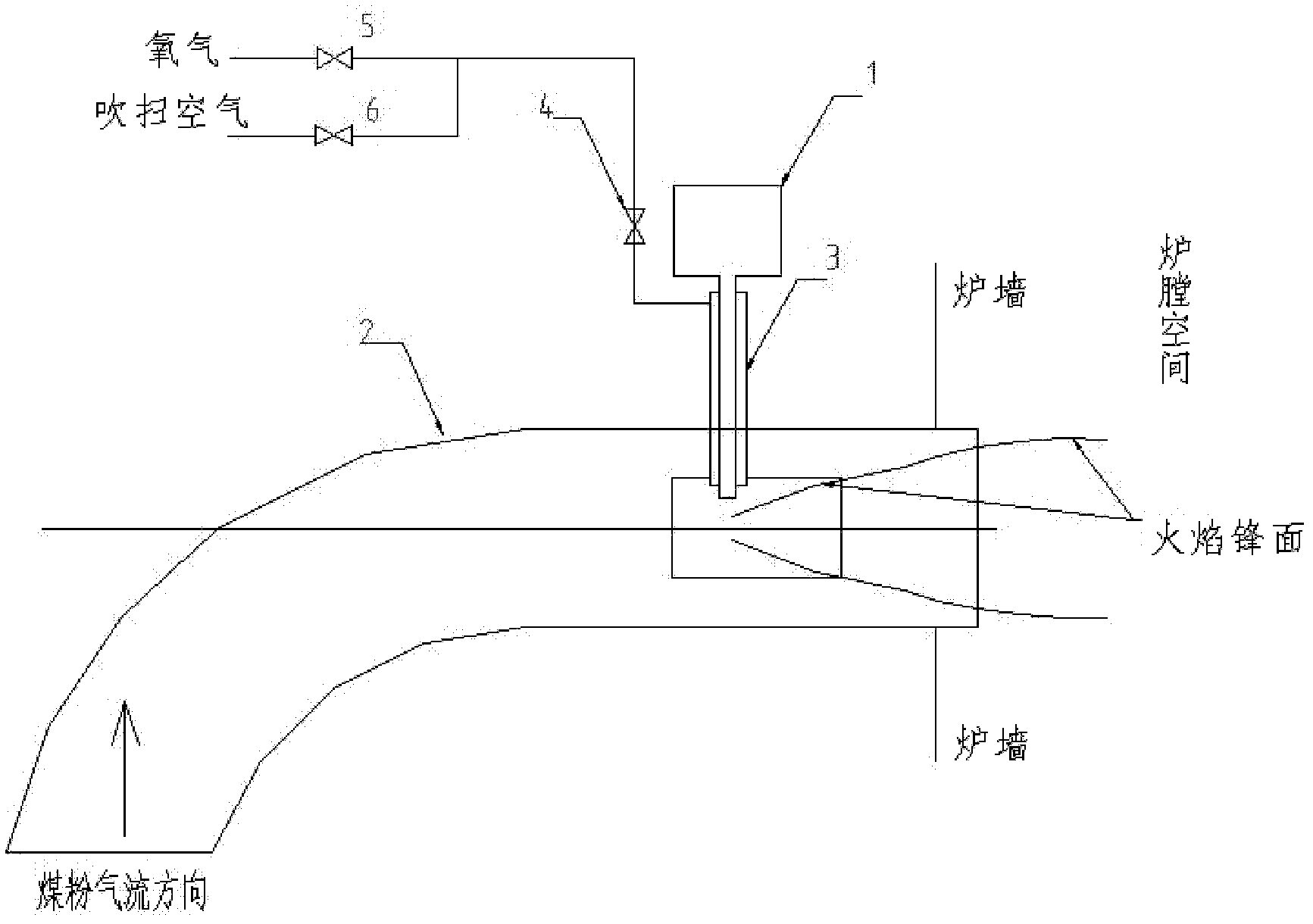

[0030] refer to figure 2 , image 3 , Figure 4 and Figure 5 , The difference between this embodiment and Embodiment 1 is that the plasma generator 1 and the annular oxygen sleeve 3 are inserted into the plasma burner from the radial direction of the burner 2, and the high-temperature plasma ejected by the plasma generator can fill the burner internal.

Embodiment 3

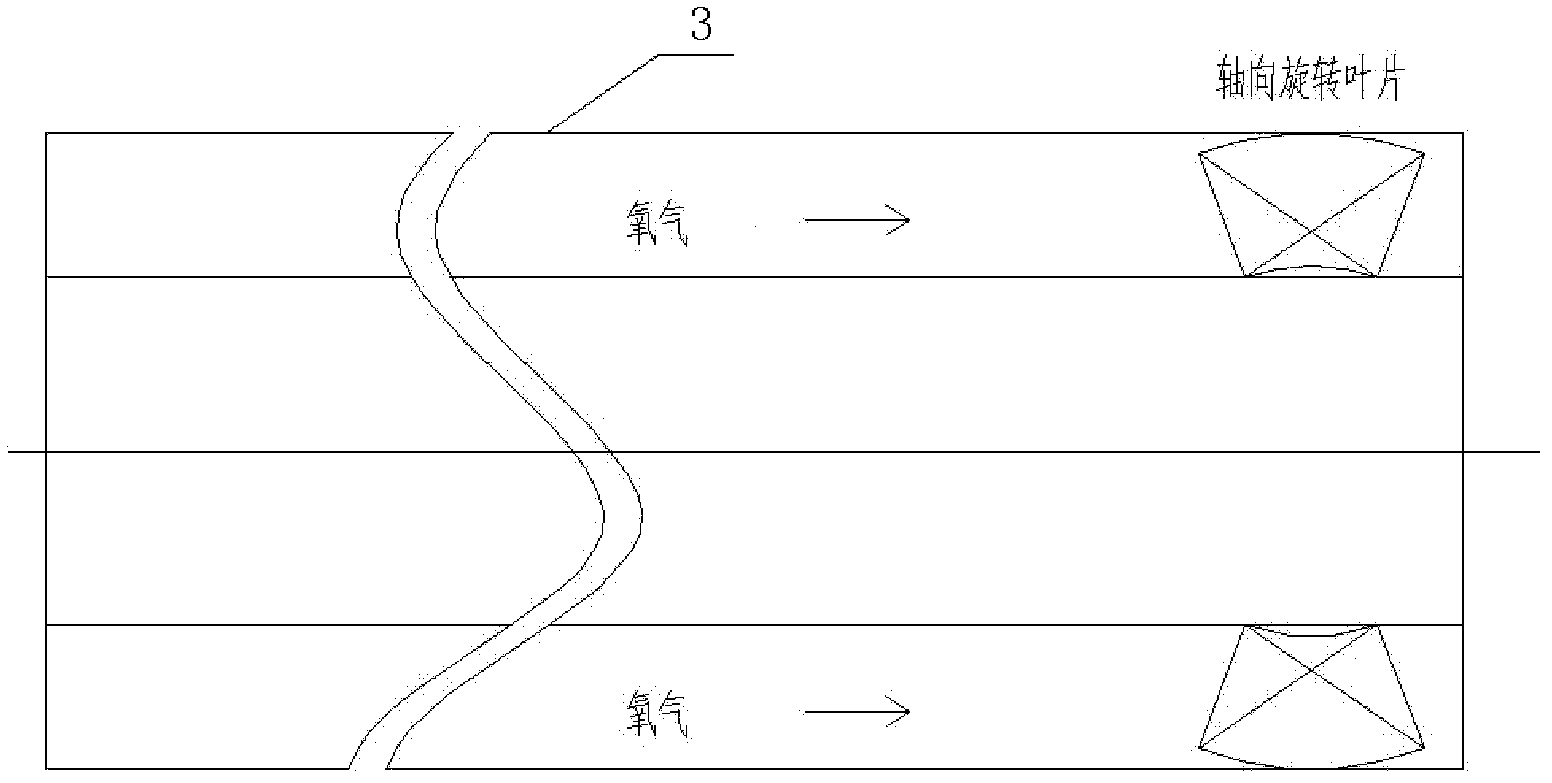

[0032] refer to image 3 As shown, the annular oxygen sleeve 3 is equipped with axially rotating blades at the outlet, and oxygen enters the burner in a swirling flow, which strengthens the mixing of oxygen and pulverized coal airflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com