Low-NOx pulverized coal burner

A pulverized coal burner and pre-combustion chamber technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., to achieve the effects of improving burnout rate, high combustion efficiency, and promoting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

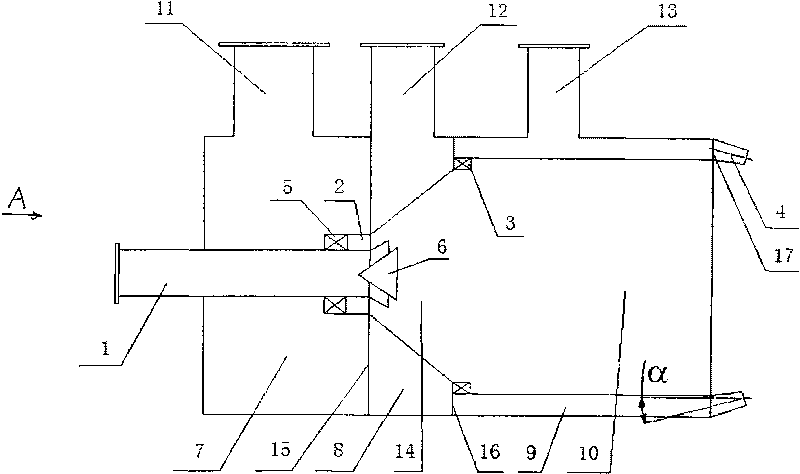

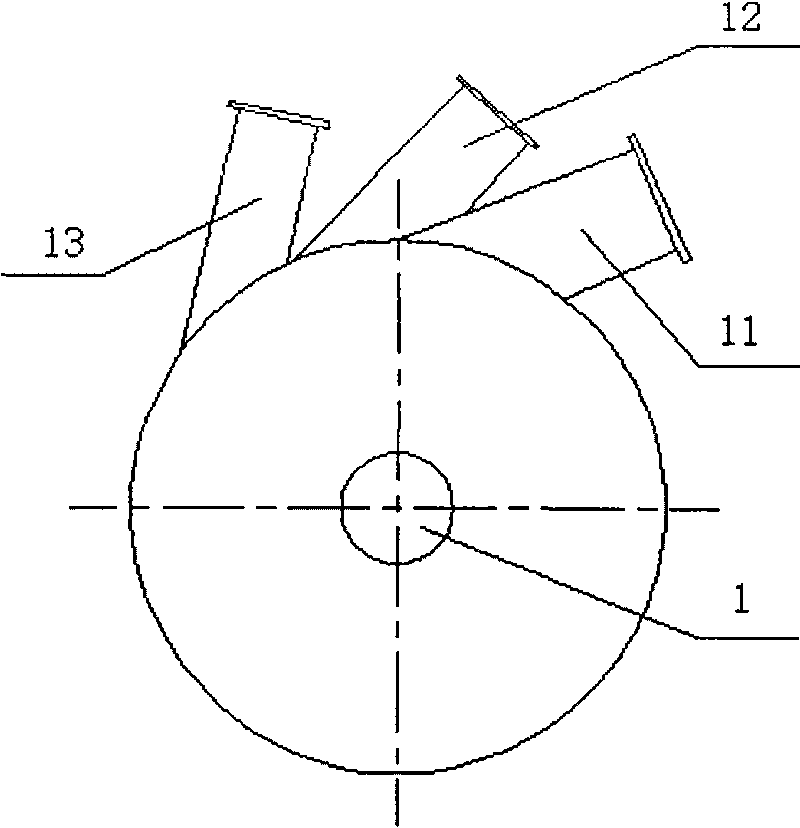

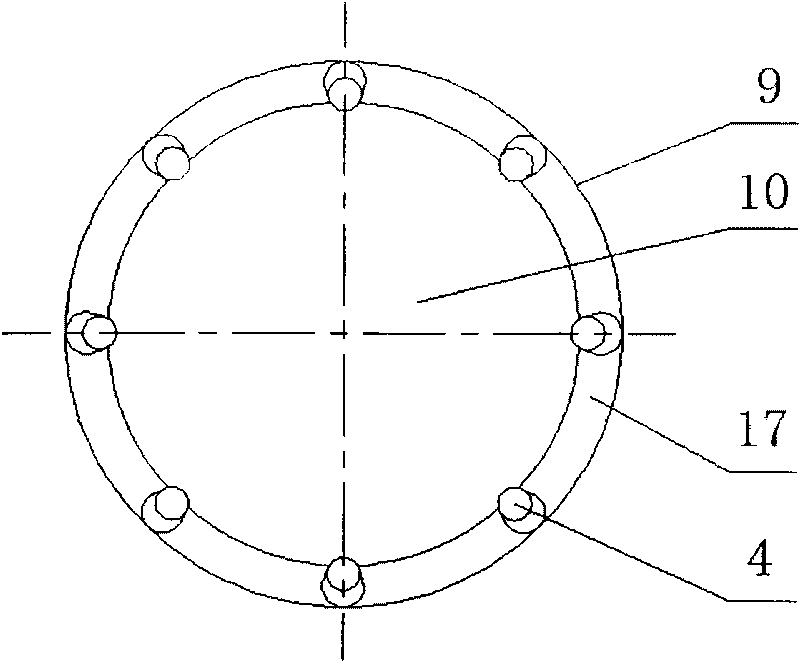

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] like figure 1 , figure 2 As shown, the pulverized coal burner of the present invention is fixedly installed with a first baffle 15 and a second baffle 16 at intervals, and the centers of the two baffles have round holes. Through the first partition 15 and the second partition 16, the inside of the pulverized coal burner is partitioned to form an inner secondary wind box 7, a classification wind box 8 and a disturbance wind box 9 arranged in sequence. like figure 2 As shown, internal secondary air inlets 11 , classified air inlets 12 , and disturbance air inlets 13 are correspondingly provided on the respective pipe walls of the above three wind boxes, which are inclined toward the circumferential direction of the pipe walls. The three air inlets are designed with a circumferential inclination. According to the principle of fluid mechanics, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com