Plasma oil-free ignition system in oxygen-enriched environments

一种无油点火、等离子的技术,应用在热力锅炉领域,能够解决重大事故和经济损失、煤粉二次燃烧、负荷高等问题,达到投资和运行费用适中、燃尽率高、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

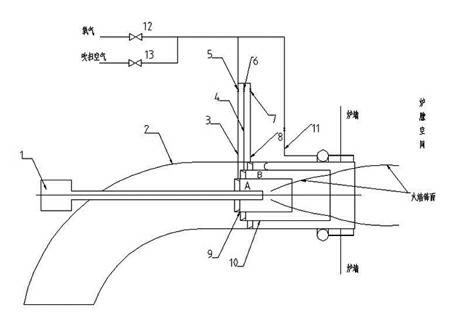

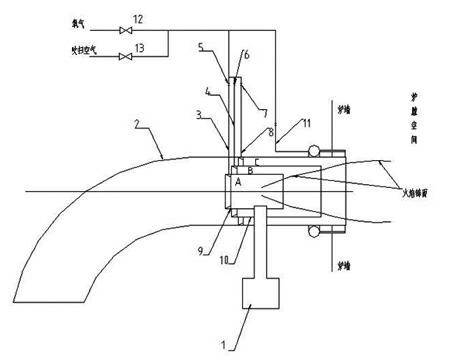

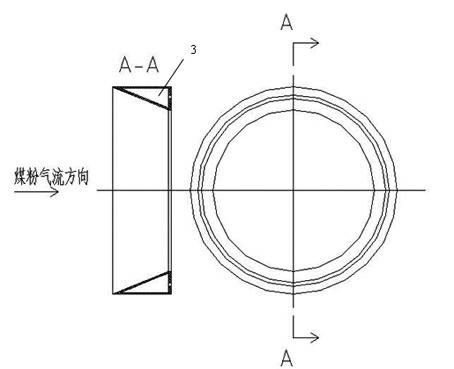

[0040] Such as figure 1 , image 3 with Figure 4 As shown, the present invention provides a plasma oil-free ignition system in an oxygen-enriched environment, including a plasma generator 1 and a burner 2 . The burner 2 contains a sleeve 9 and a sleeve 10, and the plasma generator 1, the burner 2, the sleeve 9 and the sleeve 10 are arranged coaxially. There is an annular space A between the sleeve 9 and the plasma generator 1, and the oxygen conduit 3 is installed on the inner wall of the left end of the sleeve 9. In addition to providing oxygen, the oxygen conduit 3 also functions as a pulverized coal concentration ring. The oxygen conduit 3 The outside of the pipe wall facing the pulverized coal flow direction is surfacing with wear-resistant metal, and the oxygen conduit 3 is arranged with an annular groove 101 on the pipe wall facing away from the pulverized coal flow direction. Oxygen enters the annular space A through the annular groove 101 and mixes with the pulveriz...

Embodiment 2

[0044] Such as figure 2 , image 3 with Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the plasma generator 1 is inserted into the plasma burner from the radial direction of the burner 2 , and the high-temperature plasma ejected by the plasma generator can fill the sleeve 9 .

Embodiment 3

[0046] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the oxygen conduits 3, 4, 8 is a triangle shape, and the wall facing the direction of the pulverized coal flow is an arc surface. An annular groove 101 is arranged on the wall surface away from the gas flow direction of the pulverized coal, and oxygen enters the burner through the annular groove 101 and is mixed with the pulverized coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com