A kind of manufacturing process of jewelry protective film

A production process and protective film technology, applied in the field of jewelry protective film production technology, can solve the problems of fading, jade loss, darkening and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

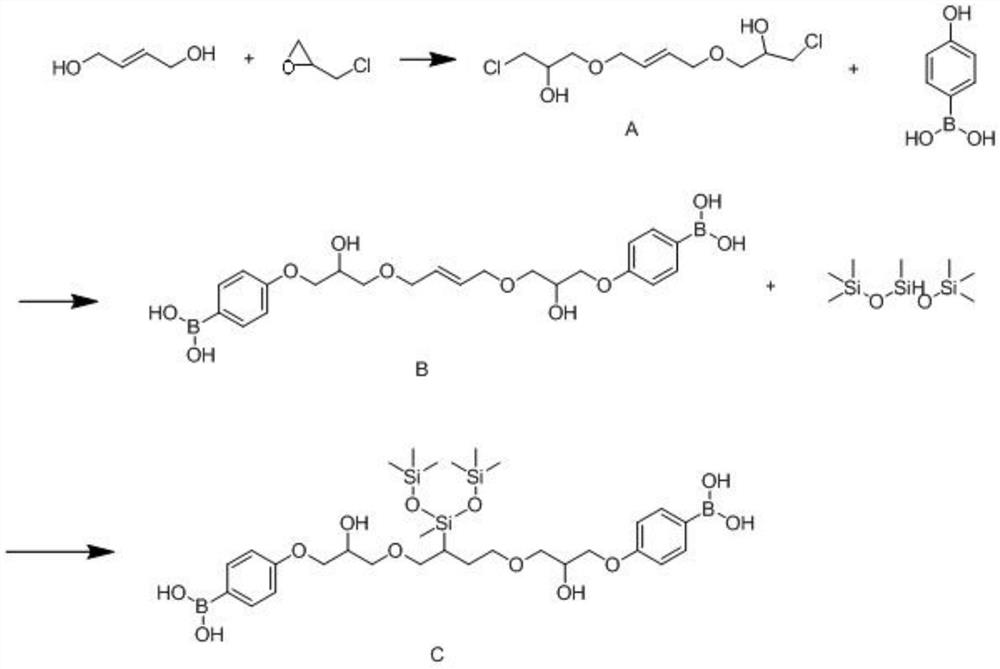

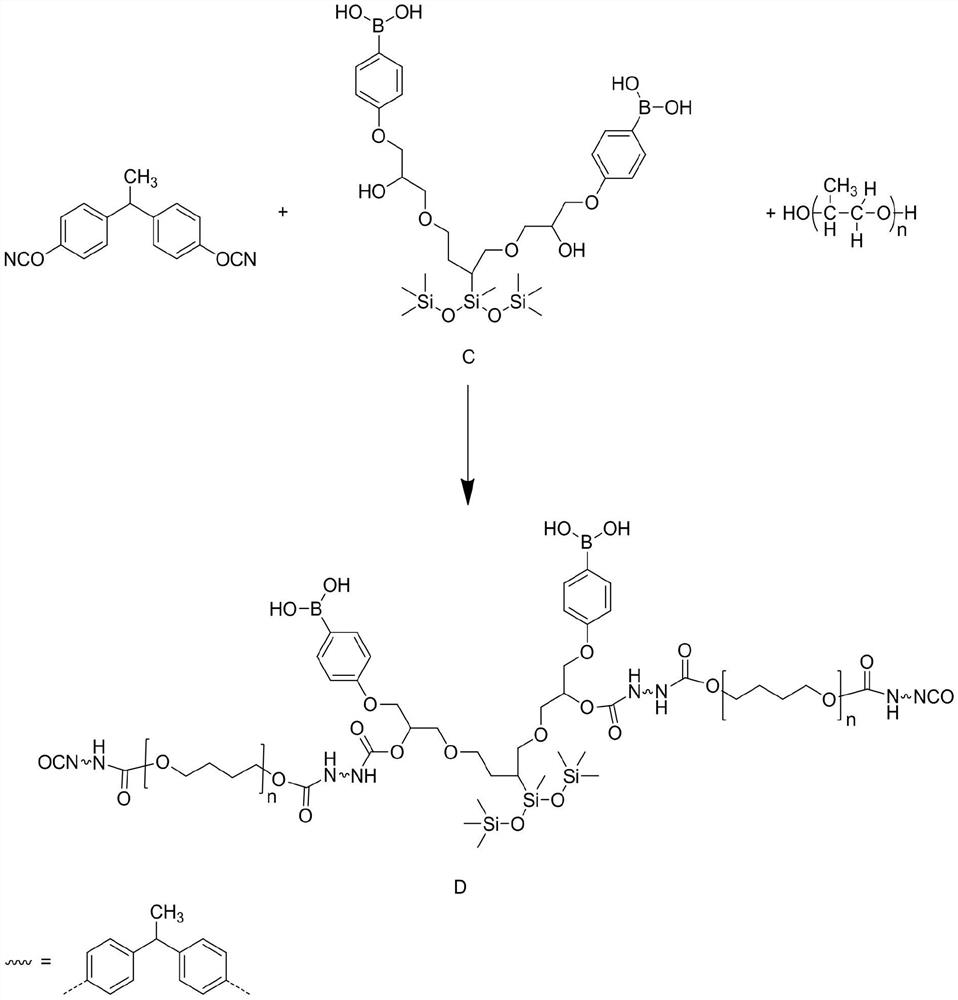

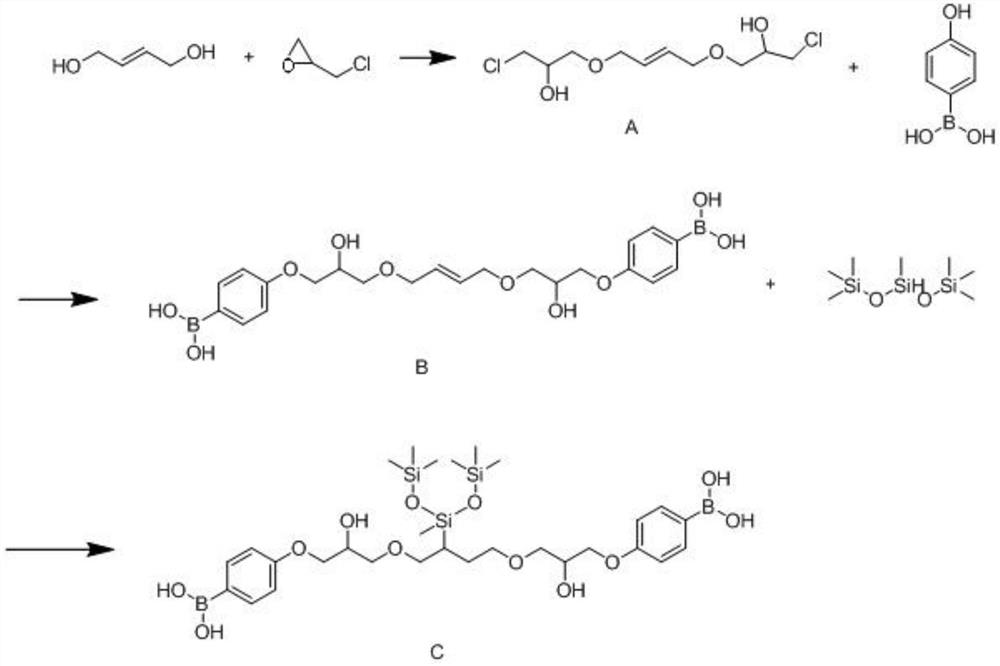

Method used

Image

Examples

Embodiment 1

[0045] A manufacturing process of a jewelry protective film, the protective film is composed of the following raw materials by weight: 100 parts of modified polyurethane, 5 parts of polyethylene glycol and 100 parts of isopropyl alcohol;

[0046] The specific production process is as follows: heating the modified polyurethane and polyethylene glycol to 80 °C to melt, stirring and mixing for 30 minutes, then slowly adding isopropyl alcohol, and cooling to 35 °C while stirring to obtain a jewelry protective liquid. Use a spray gun to spray the jewelry protective liquid evenly on the jewelry surface, and let it dry naturally for 2 hours to obtain a jewelry protective film with a thickness of 8-15 nm.

Embodiment 2

[0048] A production process of a jewelry protective film, the protective film is composed of the following raw materials by weight: 100 parts of modified polyurethane, 10 parts of polyethylene glycol and 100 parts of isopropyl alcohol;

[0049] The specific production process is as follows: heating the modified polyurethane and polyethylene glycol to 85°C to melt, stirring and mixing for 30min, then slowly adding isopropyl alcohol, and cooling to 40°C while stirring to obtain a jewelry protective liquid. Use a spray gun to spray the jewelry protective liquid evenly on the jewelry surface, and let it dry naturally for 2 hours to obtain a jewelry protective film with a thickness of 8-15 nm.

Embodiment 3

[0051] A production process of a jewelry protective film, the protective film is composed of the following raw materials by weight: 100 parts of modified polyurethane, 7 parts of polyethylene glycol and 100 parts of isopropyl alcohol;

[0052] The specific production process is as follows: heating the modified polyurethane and polyethylene glycol to 82°C to melt, stirring and mixing for 30min, then slowly adding isopropyl alcohol, and cooling to 39°C while stirring to obtain a jewelry protective liquid. Use a spray gun to spray the jewelry protective liquid evenly on the jewelry surface, and let it dry naturally for 1 hour to obtain a jewelry protective film with a thickness of 8-15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com