A kind of nano silver powder, preparation method, silver paste and application

A nano silver powder, silver powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as affecting product performance, affecting separation, etc., to prevent particle growth, easy cleaning, particle size small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

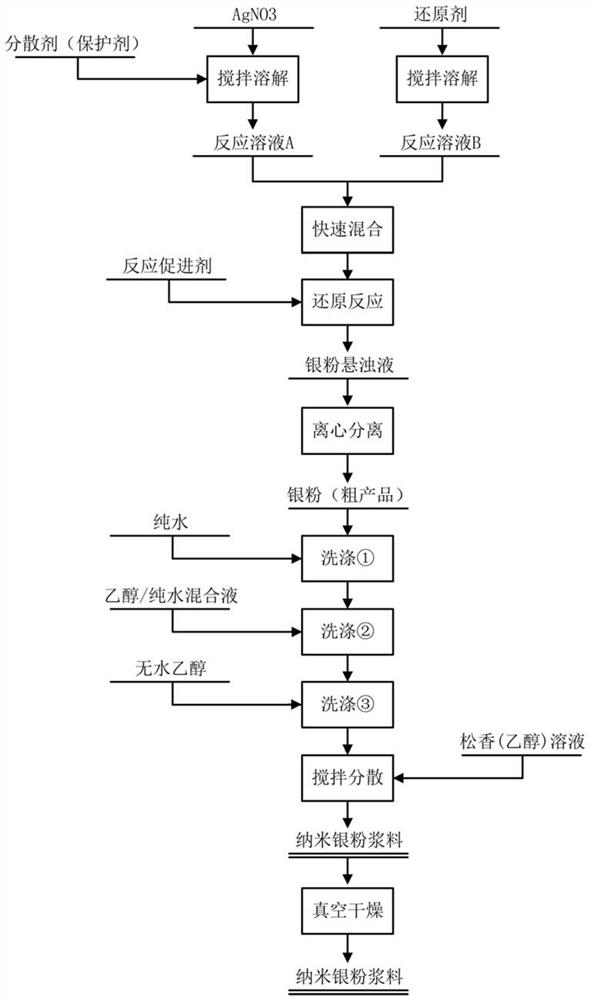

Method used

Image

Examples

Embodiment 1

[0036] (1) with silver nitrate (AgNO 3 ) as raw material under constant temperature stirring conditions, take appropriate amount of pure water to dissolve AgNO 3 , configure AgNO 3 solution, the concentration is 0.5mol / L. And the silver nitrate dissolution process was carried out at a constant temperature of 40°C, and the stirring speed was 1000r / min.

[0037] (2) under constant temperature stirring condition, take benzyltrimethylammonium bromide as dispersant, take dispersant according to 40% of silver powder output (quality), and dissolve in the AgNO of step (1) configuration 3 solution, the reaction solution A was obtained after stirring evenly. And the temperature of the dispersant dissolution process is 40°C, and the stirring speed is 1000r / min.

[0038] (3) Under the condition of constant temperature and stirring, triethanolamine was used as the reducing agent, and an appropriate amount of pure water was taken to dissolve the reducing agent at a concentration of 2 mo...

Embodiment 2

[0049] Compared with Example 1, the present Example 2 differs in that the dispersant is tetramethylammonium hydroxide, the reducing agent is ethylene glycol, the accelerator is hydrogen peroxide, and other parts are the same as Example 1.

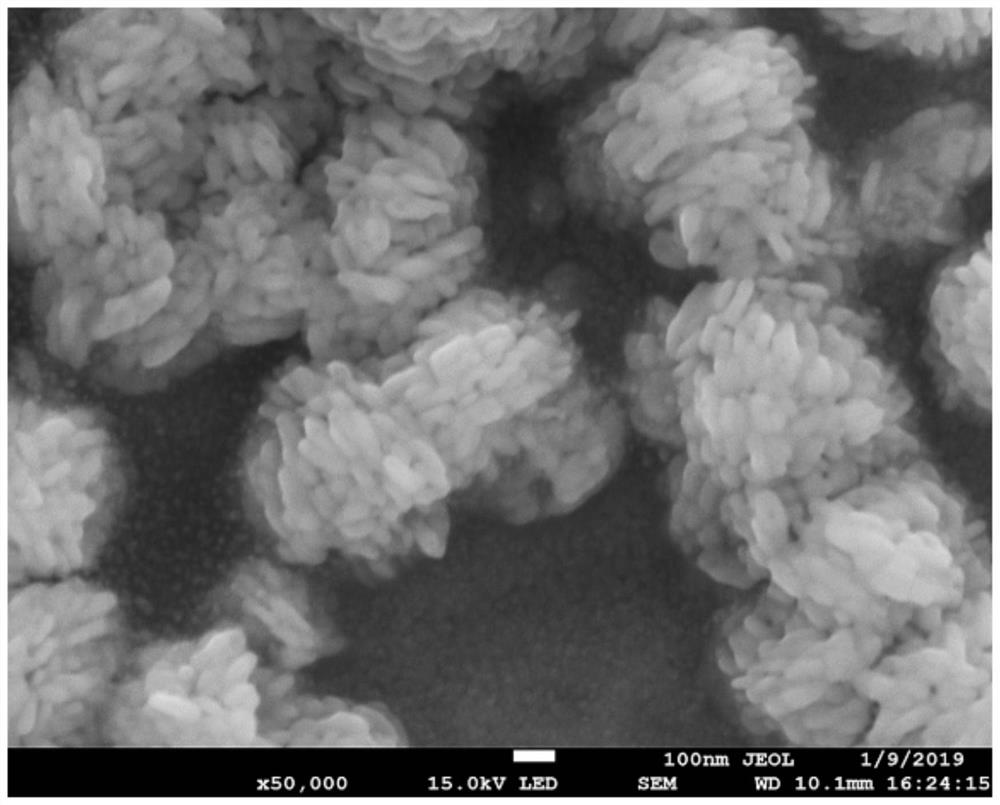

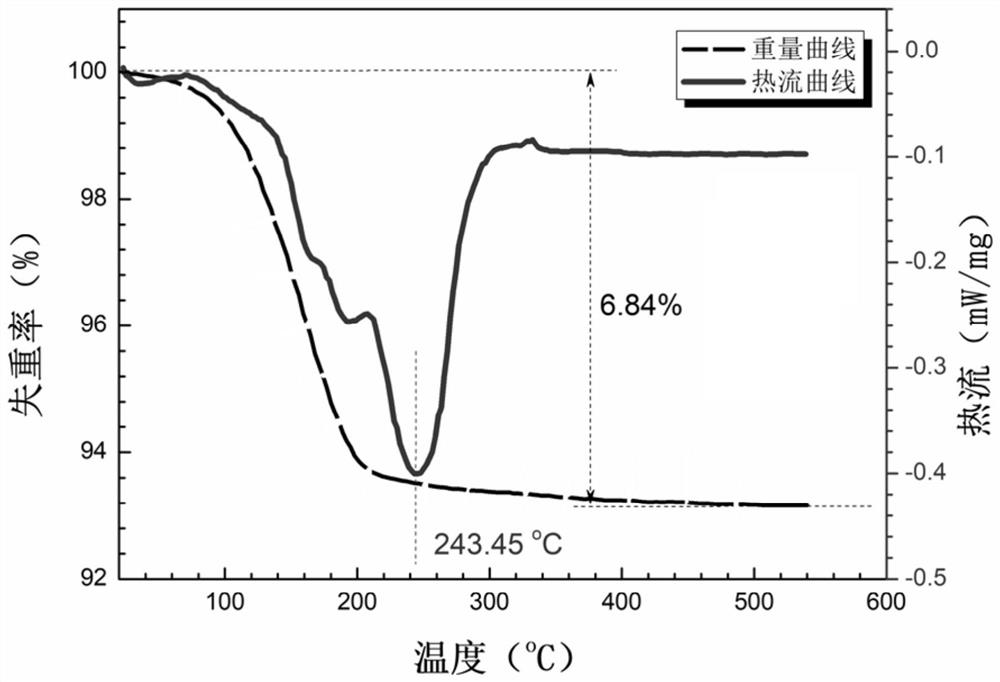

[0050] The nano-silver powder particle that embodiment 2 prepares is uniform, all presents spindle shape (length-to-diameter ratio is about 2.67:1), and the average length of major axis is about 80nm, and the length of minor axis is about 30nm, and the diameter of major axis is the diameter of minor axis. 2.67 times of that, there are obvious boundaries between particles, and the dispersibility is good. The nano-silver powder started to sinter at 210°C, sintered in a large area at 232.45°C, and sintered at 280°C. It shows that the sintering temperature of nano-silver powder is far lower than the melting temperature (961°C) of metallic silver. The metal content of this nano-silver powder is 95.43%, containing 4.57% organic components, but be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com