Encapsulation method and encapsulation equipment for OLED display panel

A technology for a display panel and a packaging method, which is applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as affecting the yield of laser sintering, and achieve the effects of improving reliability, yield, and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

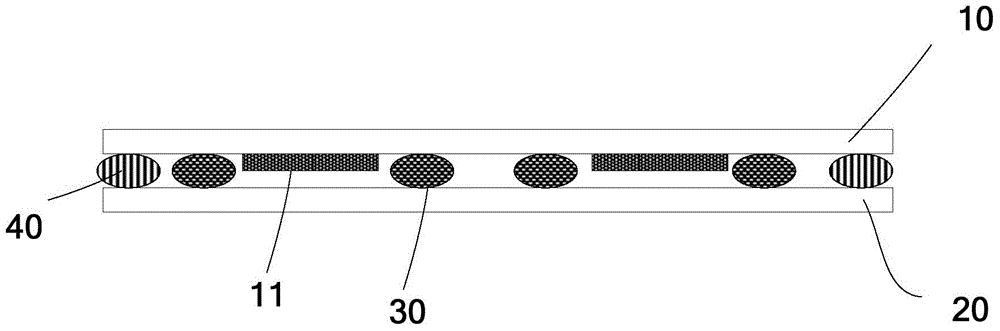

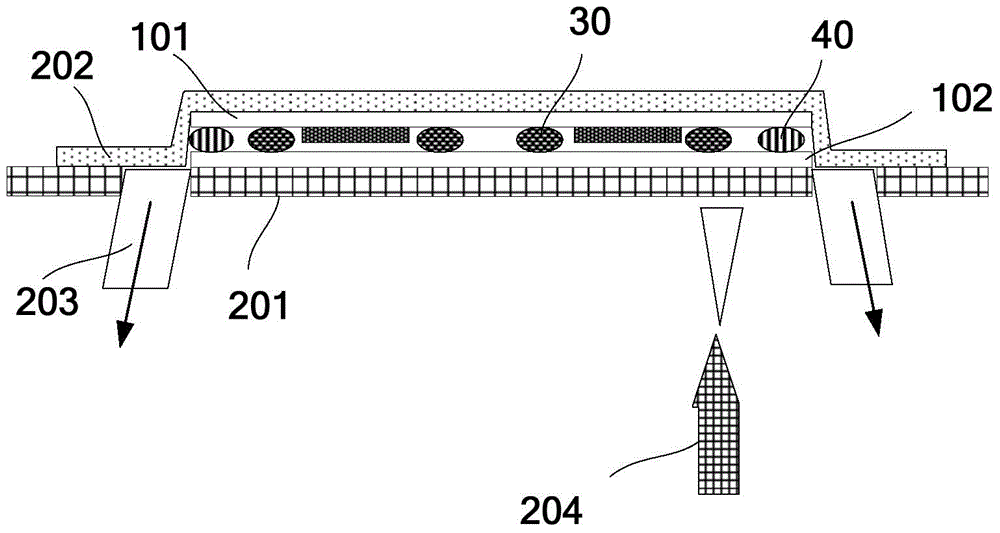

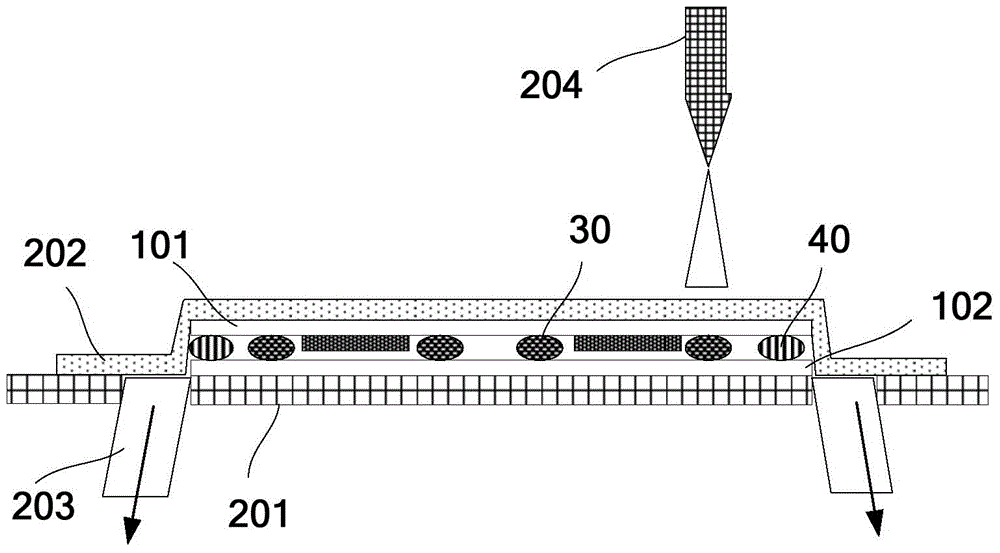

[0044] Please refer to figure 2 and image 3 Embodiment 1 of the present invention provides a packaging device for an OLED display panel, the packaging device is used for packaging an OLED display panel, and the display panel includes a first substrate 101 and a second substrate 102 with a glass glue 30 attached thereto. Glass glue 30 is located between the first substrate 101 and the second substrate 102, and the packaging device includes:

[0045] support abutment 201;

[0046] A flexible film 202, the size of the flexible film 202 is larger than the size of the display panel;

[0047] The air extraction unit 203 is used to extract the air between the support base 201 and the flexible film 202, so that the flexible film 202 is attached to the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com