Self-aligning sintering clamp and method for semiconductor laser chip

A technology of lasers and semiconductors, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of inapplicability to batch sintering, difficulty in processing and assembling precision parts, and lower pressing pressure, so as to achieve convenient and reliable operation and inspection. The effect of reducing sintering voids and improving sintering yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

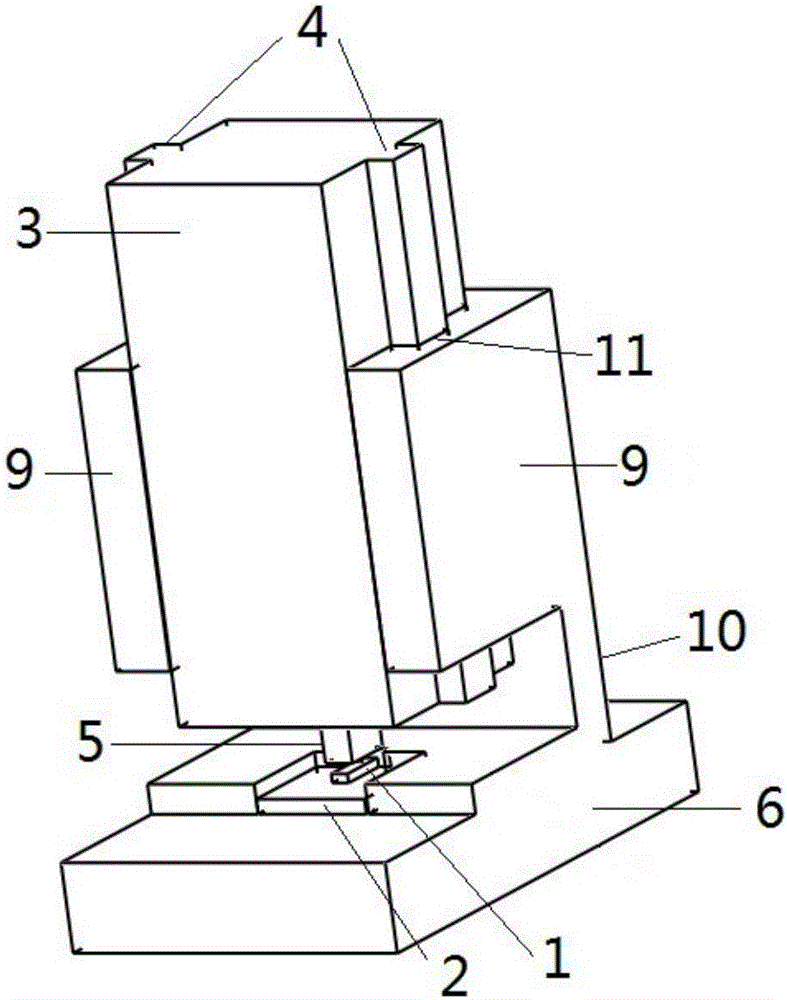

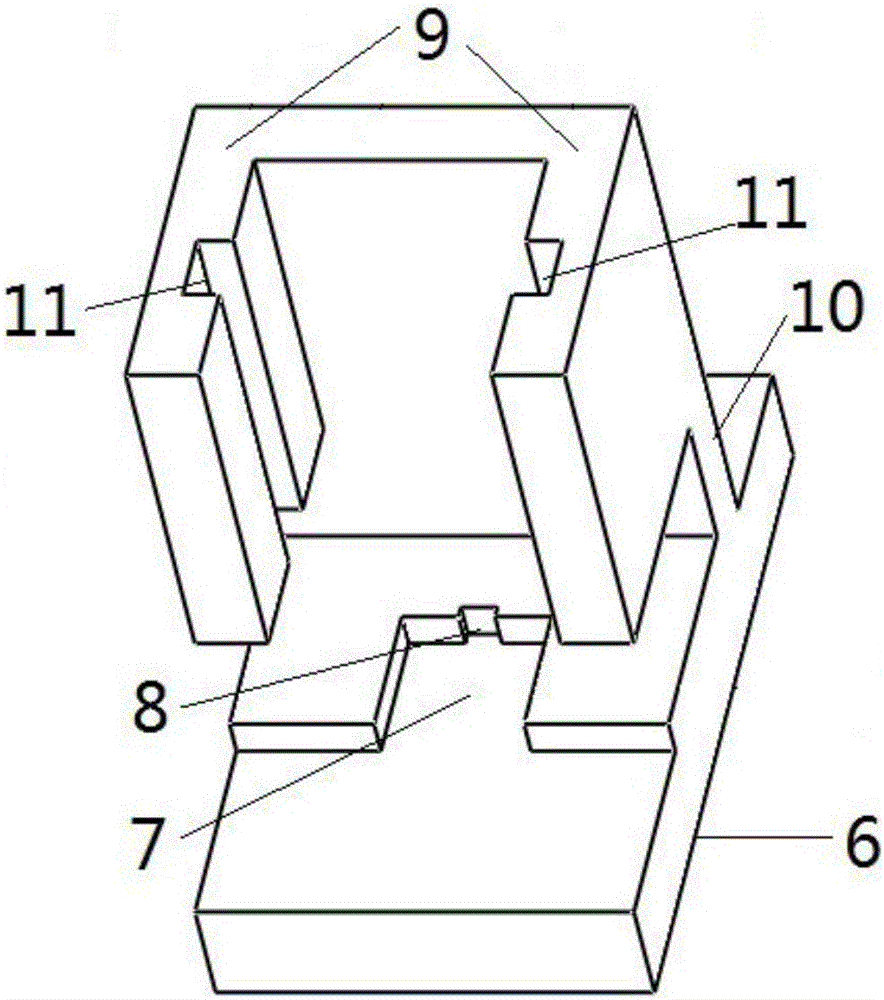

[0044] Self-aligned sintering fixtures for semiconductor laser chips, such as figure 1 As shown, it includes a base 6 , a guide rail bracket 10 and a pressing block 3 . The guide rail support is erected on the base, and there is a symmetrical cantilever 9 on the guide rail support, and a positioning guide rail 11 is arranged in the cantilever 9, and the positioning guide rail is a square groove. Such as image 3 shown. The base 6 has a positioning slot 7 that is compatible with the heat sink 2. The positioning slot 7 is a rectangular groove that is open on one side, so that the heat sink 2 can move in the positioning slot 7 and the side is attached to the inner wall of the slot. combine.

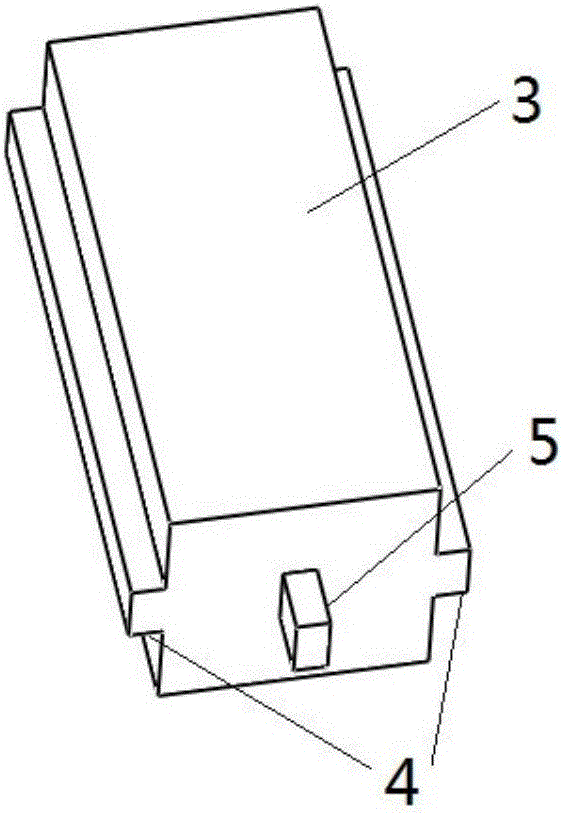

[0045] The structure of the briquetting block 3 is as figure 2 As shown, it includes a briquetting body 3, a briquetting positioning channel 4 and a briquetting post 5, and the size of the briquetting body 3 is adapted to the gap between the cantilevers 9 of the guide rail bracket; Roa...

Embodiment 2

[0051] Utilize the self-aligned sintering fixture of embodiment 1 to carry out the method for semiconductor laser chip sintering, the steps are as follows:

[0052] (1) place the semiconductor laser chip 1 on the solder on the heat sink 2 with an adsorption machine under a microscope;

[0053] (2) Insert the heat sink 2 loaded with the chip 1 into the positioning slot 7 of the base, and push it to the bottom;

[0054] (3) Observe from above with a microscope to confirm that the position of the laser chip 1 on the heat sink 2 has not shifted during operation;

[0055] (4) Place the pressing block positioning channels 4 on both sides of the pressing block in the positioning guide rail 11 of the cantilever on the guide rail bracket, insert the pressing block between the cantilevers and lower it, so that the lower end of the pressing column 5 is facing the laser chip 1 and pressing Tighten, complete the fixture clamping;

[0056] (5) Repeat the above steps (1) to (4), set up sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com