A sintering machine trolley

A machine trolley and trolley technology, applied in the direction of furnaces, lighting and heating equipment, furnace types, etc., can solve problems such as temperature accumulation, deformation and cracking of heat insulation boards, and harsh working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

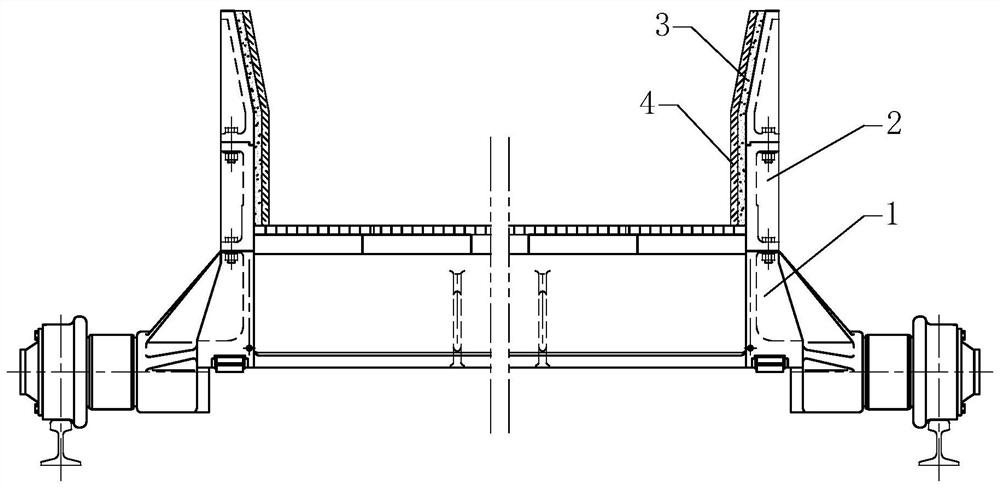

[0015] Such as figure 1 As shown, the sintering machine trolley of the present invention includes a trolley body 1 and trolley baffles 2 arranged on both sides of the trolley body, and the inner surface of the trolley baffle 2 is coated with heat-insulating Coating 3, the surface of the heat-insulating coating 3 is coated with a wear-resistant and anti-corrosion coating 4 .

[0016] The thermal insulation coating 3 and the wear-resistant and anti-corrosion coating 4 are sprayed by plasma spraying. The spraying of the thermal insulation coating 3 and the wear-resistant and anti-corrosion coating 4 can be carried out in a thermal spraying workshop. The implementation process is carried out according to the thermal spraying processing flow and technical requirements. The inner surface (inner wall) of the trolley baffle 2 needs to be pre-treated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com