Negative micropressure ignition system for sintering machine bellows

An ignition device and micro-negative pressure technology, applied in the field of micro-negative pressure ignition devices for sintering machine bellows, can solve problems affecting the production process, unstable sintering process, double-layer valve stuck, etc., to reduce energy consumption and production costs, The effect of reducing valve spare parts and maintenance costs and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

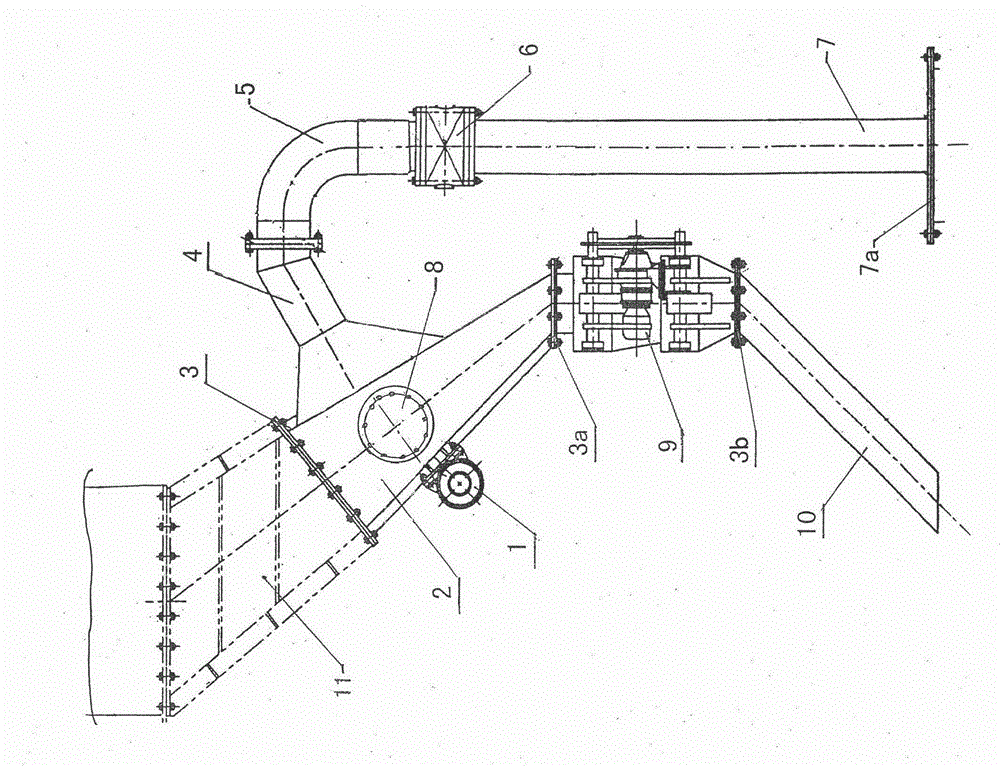

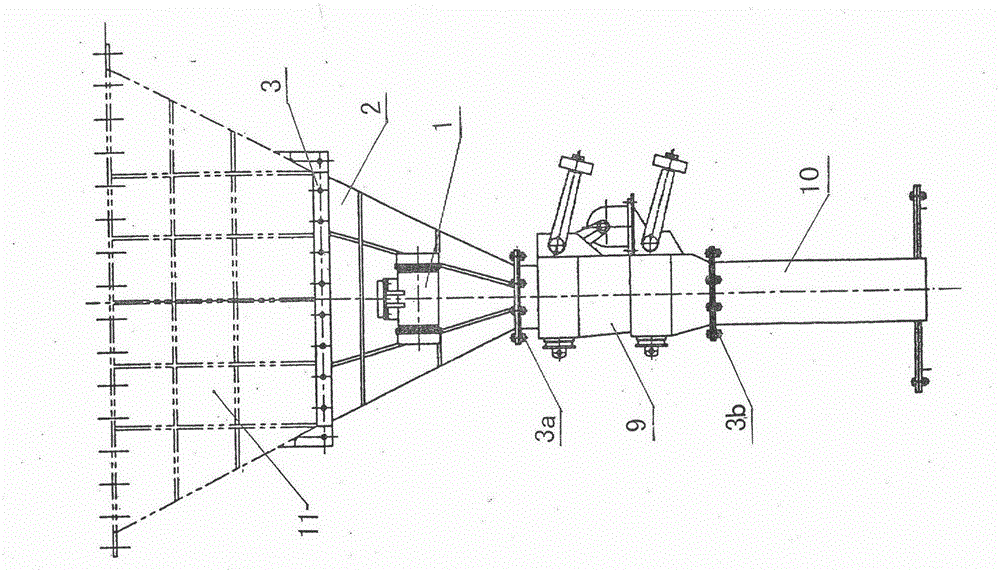

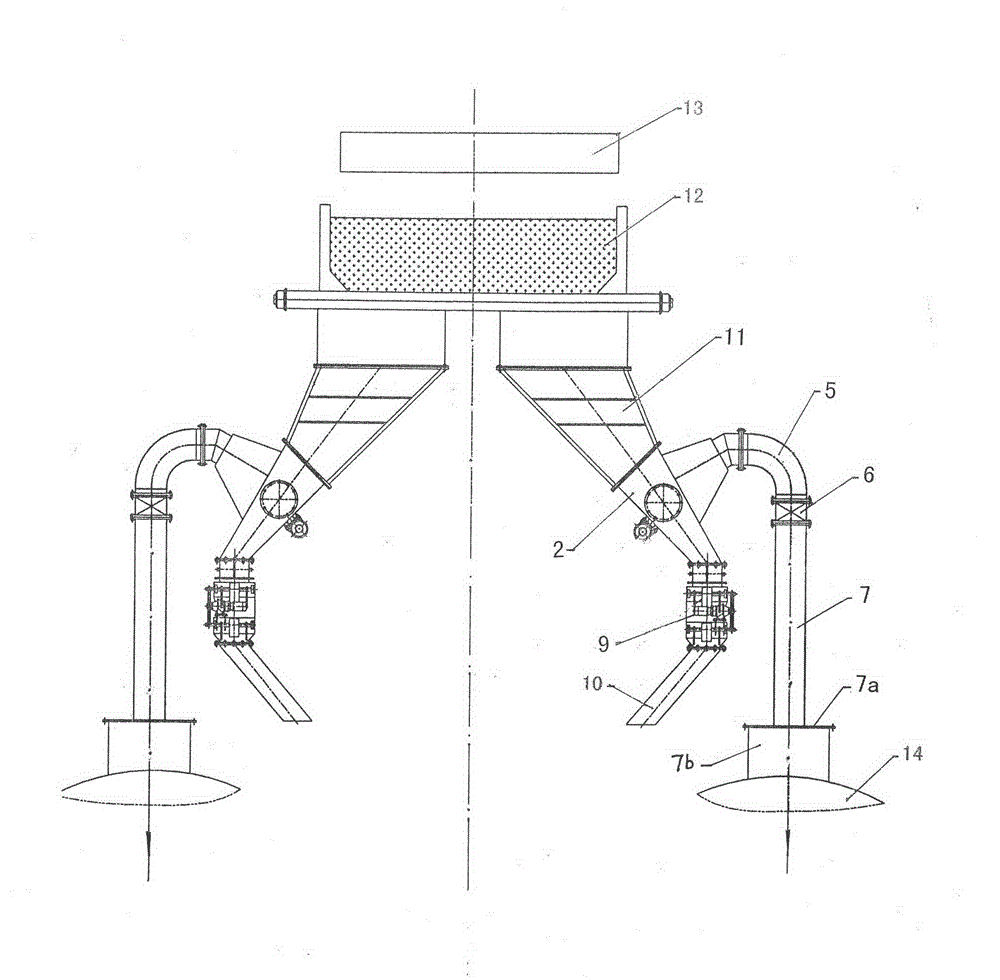

[0015] (As shown in the accompanying drawings) A sintering machine air box micro-negative pressure ignition device according to the present invention includes a vibration motor 1, an air box pipe 2, a first graphite packing 3, a second graphite packing 3a and a third graphite packing 3b, bellows wear-resistant pipe 4, wear-resistant elbow 5, resistance balance valve 6, vertical pipe 7, stuffy cover 7a, exhaust pipe 7b, observation hole cover 8, double-layer ash discharge valve 9, discharge pipe 10, bellows 11. The trolley 12 and the igniter 13, wherein the first graphite disc 3, the second graphite packing 3a and the third graphite packing 3b are high temperature resistant seals, which are available in the market, and the bellows pipe 2 has two ends Cylindrical or square barrels with equal or unequal cross-sectional dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com