Patents

Literature

42 results about "Phosphate binding agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

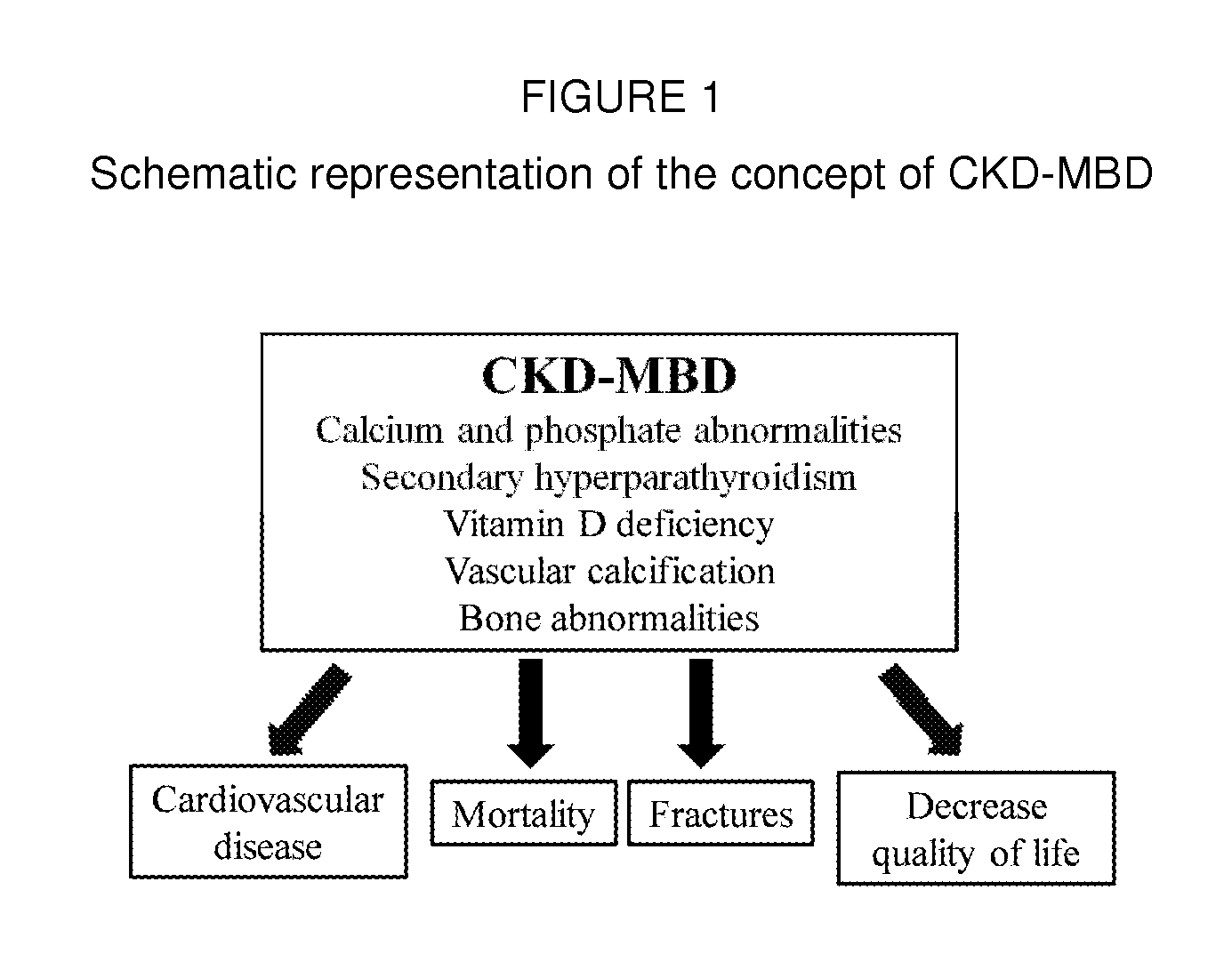

Summary: Overall, the phosphate binding agents are safe and efficacious in the reduction and prevention of hyperphosphatemia in patients with CKD. Choice of agent should be based on individual patient characteristics, phosphate and calcium consumption, lab values, tolerability, and cost.

Phosphate binder with reduced pill burden

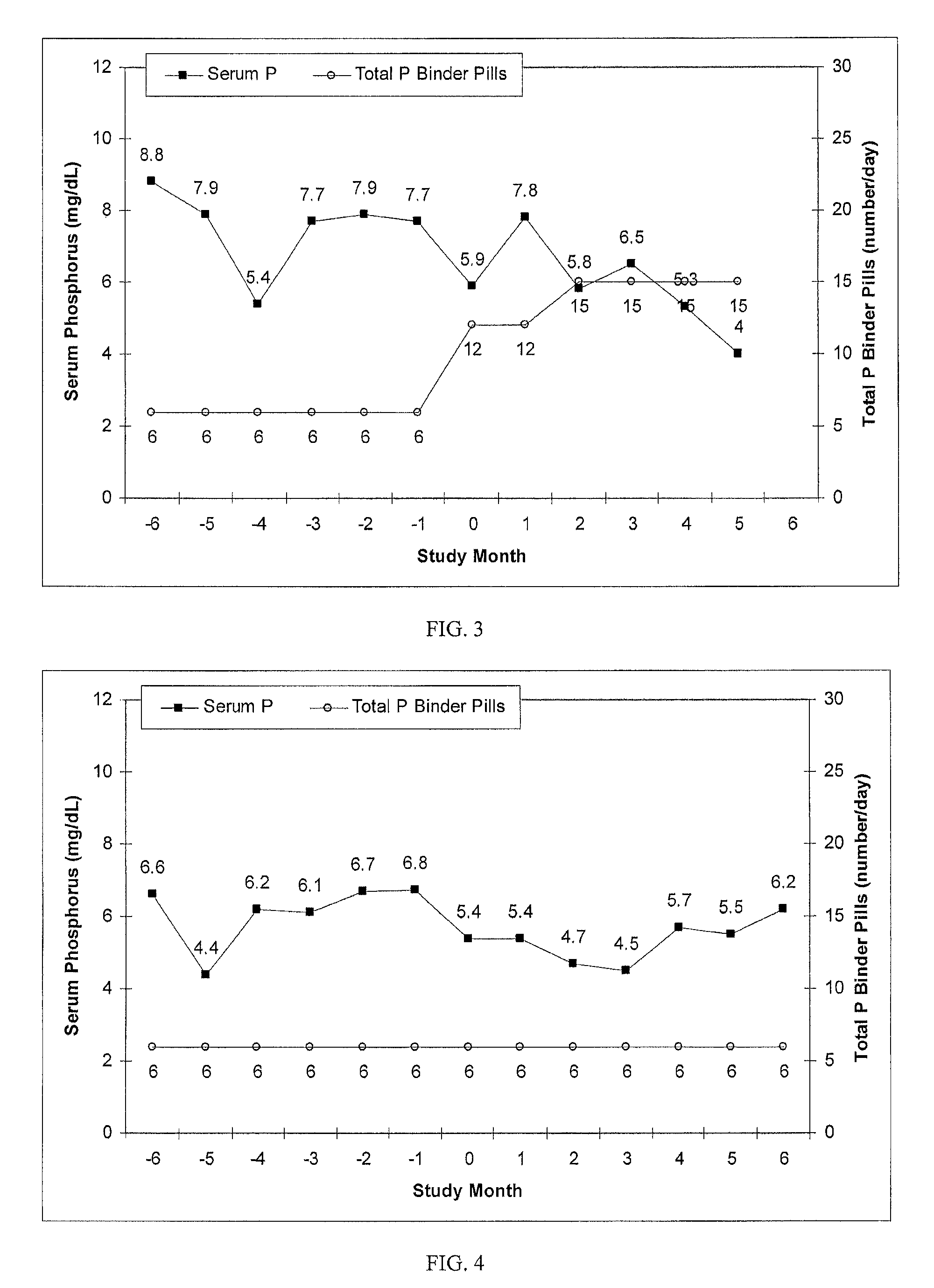

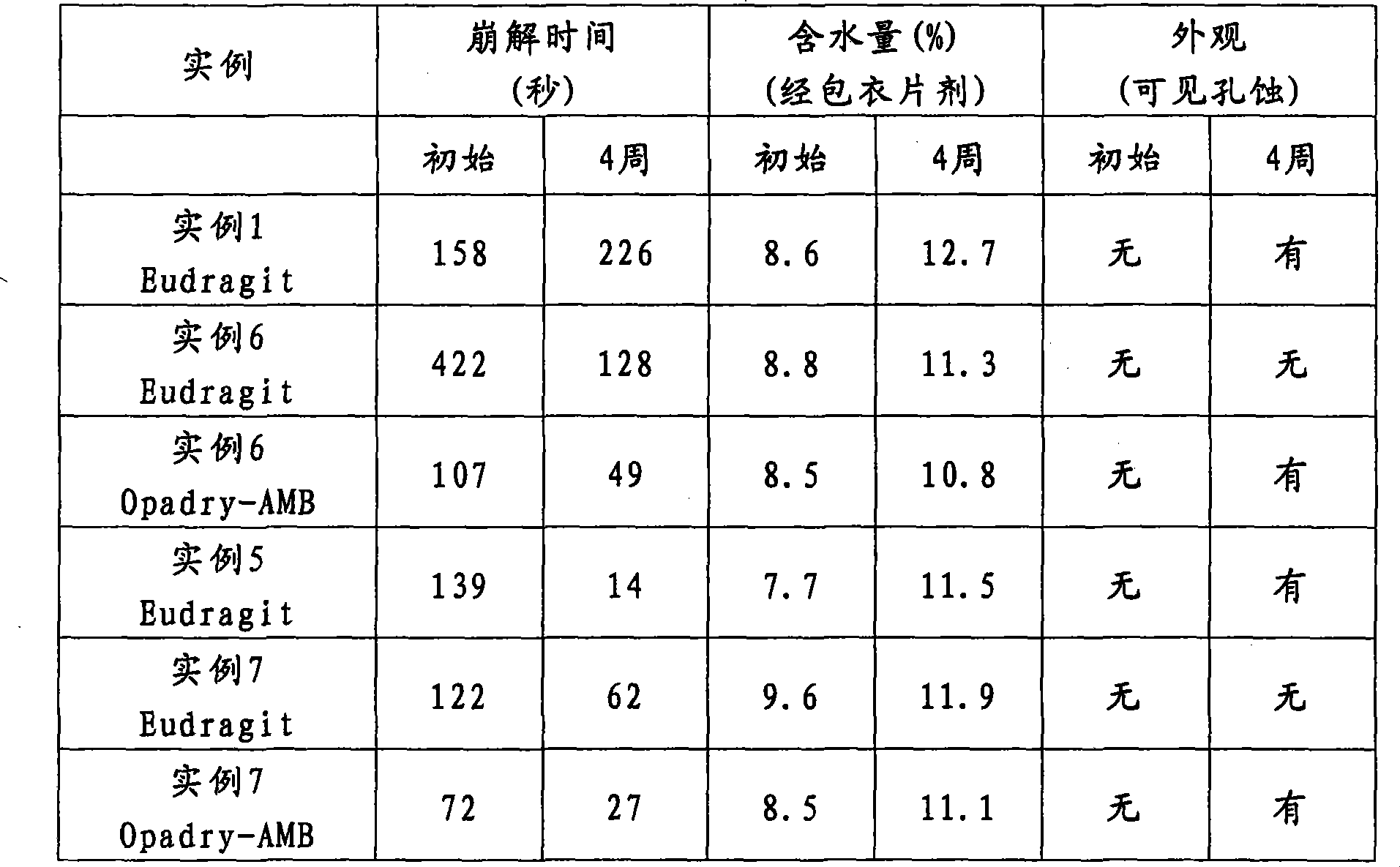

The present invention is generally directed to compositions and formulations that can be used for the treatment of diseases such as End Stage Renal Disease (“ESRD”) and Chronic Renal Insufficiency (“CRI”). Specifically, it is directed to lanthanum-based compounds that bind phosphate and that can be formulated to provide for a reduced pill burden relative to other phosphate binders. In a formulation aspect of the present invention, a formulation is provided the includes a lanthanum-based, phosphate binder. The formulation is typically characterized in that in may be swallowed without chewing. Formulations of the present invention, along with a lanthanum-based compound, may optionally include the following: mass diluting agents; binders; coatings; compression / encapsulation aids; disintegrants; lubricants; plasticizers; slip / anti-electrostatic agents; powder lubricants; and, sweeteners. Where the formulation is in the form of a tablet, it typically has a volume between 0.3 cm3 and 1.2 cm3, preferably between 0.35 cm3 and 0.50 cm3. Each tablet typically includes enough phosphate binder such that only 3 or less tablets need to be ingested each day for a patient suffering from ESRD.

Owner:SPECTRUM PHARMA INC

Pharmaceutical compositions comprising phosphate binder, calcium receptor-active compound and/or active vitamin d

InactiveUS20130085121A1Maintain good propertiesImprove bioavailabilityOrganic active ingredientsBiocideMineral bone diseaseCalcium Binder

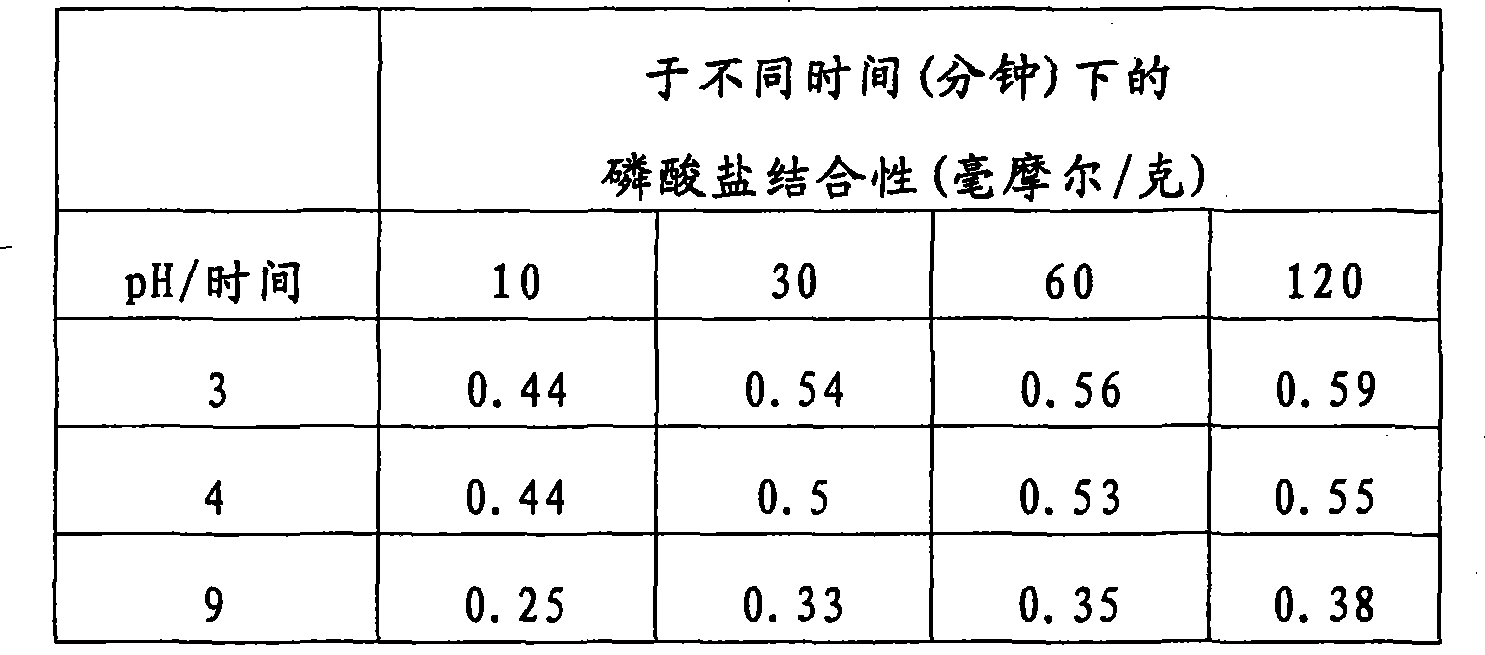

The present invention is an oral solid pharmaceutical compositions for the treatment of kidney diseases and mineral bone disorder including a phosphate binder, a calcium receptor-active compound and at least one pharmaceutically acceptable excipient, the invention further including a method for preparing the pharmaceutical compositions including the steps of granulating cinacalcet and / or sevelamer and / or vitamin D by one of a wet and a dry granulation process, each with at least one pharmaceutically acceptable excipient to form cinacalcet granules and / or sevelamer granules and / or vitamin D granules, mixing at least two of the cinacalcet granules, sevelamer granules and vitamin D granules to form a granules mixture and compressing the granules mixture to tablets or encapsulating the granules mixture into capsules or pulverizing the granules mixture into a dispersion powder.

Owner:WEIFANG SYNERPHARM

Low-porosity chrome corundum brick and preparation method thereof

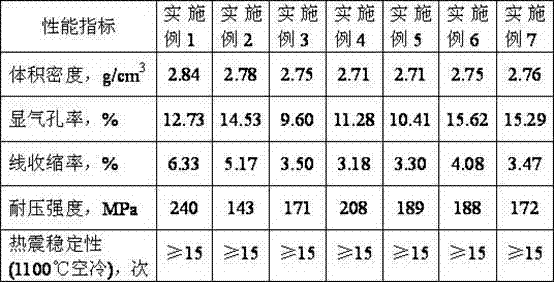

The invention discloses a low-porosity chrome corundum brick and a preparation method thereof. The low-porosity chrome corundum brick is prepared from the following raw materials in percentage by mass: 18-28 percent of corundum with the raw material granularity being 5-3mm, 30-40 percent of corundum with the raw material granularity being 3-1mm, 10-20 percent of corundum with the raw material granularity being 1-0mm, 10-20 percent of corundum with the raw material granularity being smaller than 0.088mm, 1-15 percent of high-content chromium ore or fused chrome oxide with the raw material granularity being 1-0mm and 2-15 percent of high-purity chromium oxide with the raw material granularity being smaller than 0.088mm; and in addition, a phosphate binder accounting 2-5 percent for the total mass of all the raw materials is added. According to the low-porosity chrome corundum brick and the preparation method, a product is prepared by material mixing, forming, sintering, impregnating with a nanometer oxide suspension and microwave drying according to burdening of the low-porosity chrome corundum brick, can lower the apparent porosity and the porosity aperture of a chrome corundum material, and reacts with permeated molten slag to form a high melting point substance, increases the viscosity of the molten slag, and slows down permeation of the molten slag.

Owner:河南瑞泰耐火材料科技有限公司

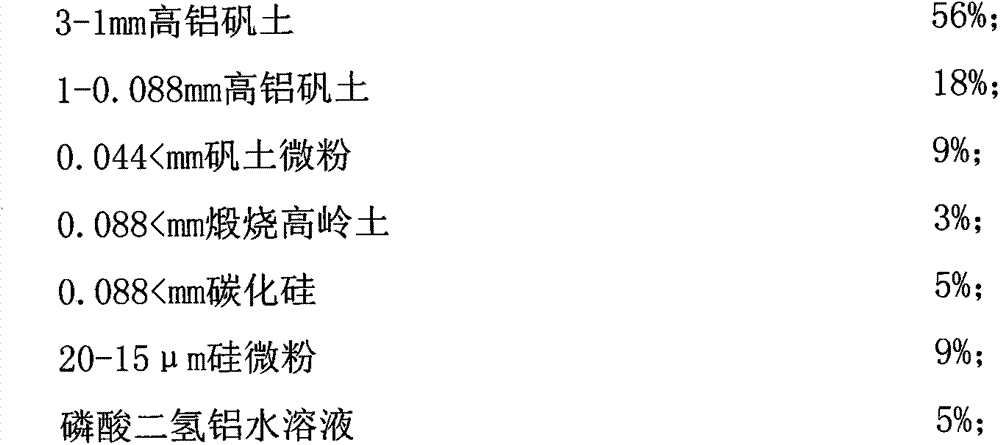

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

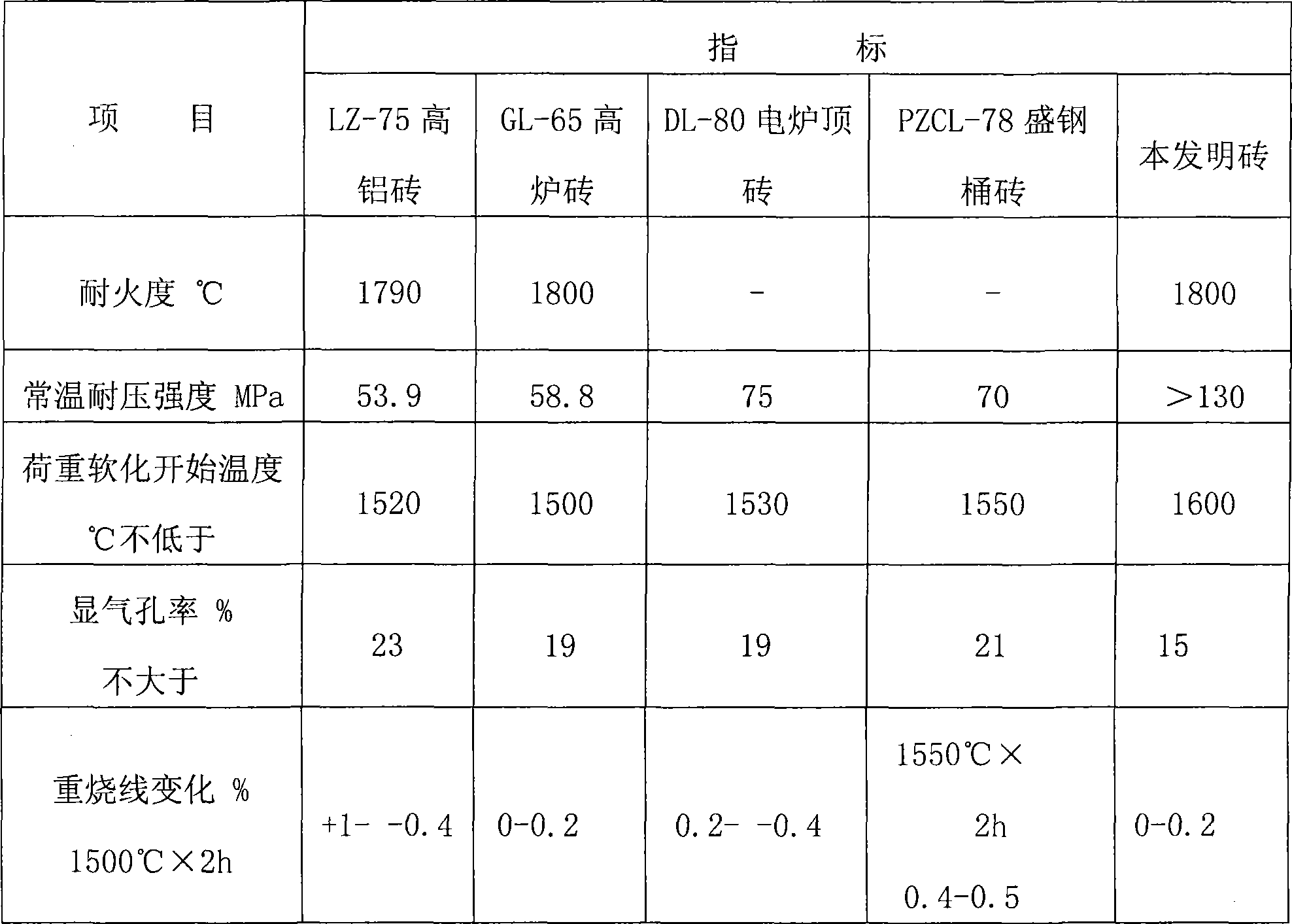

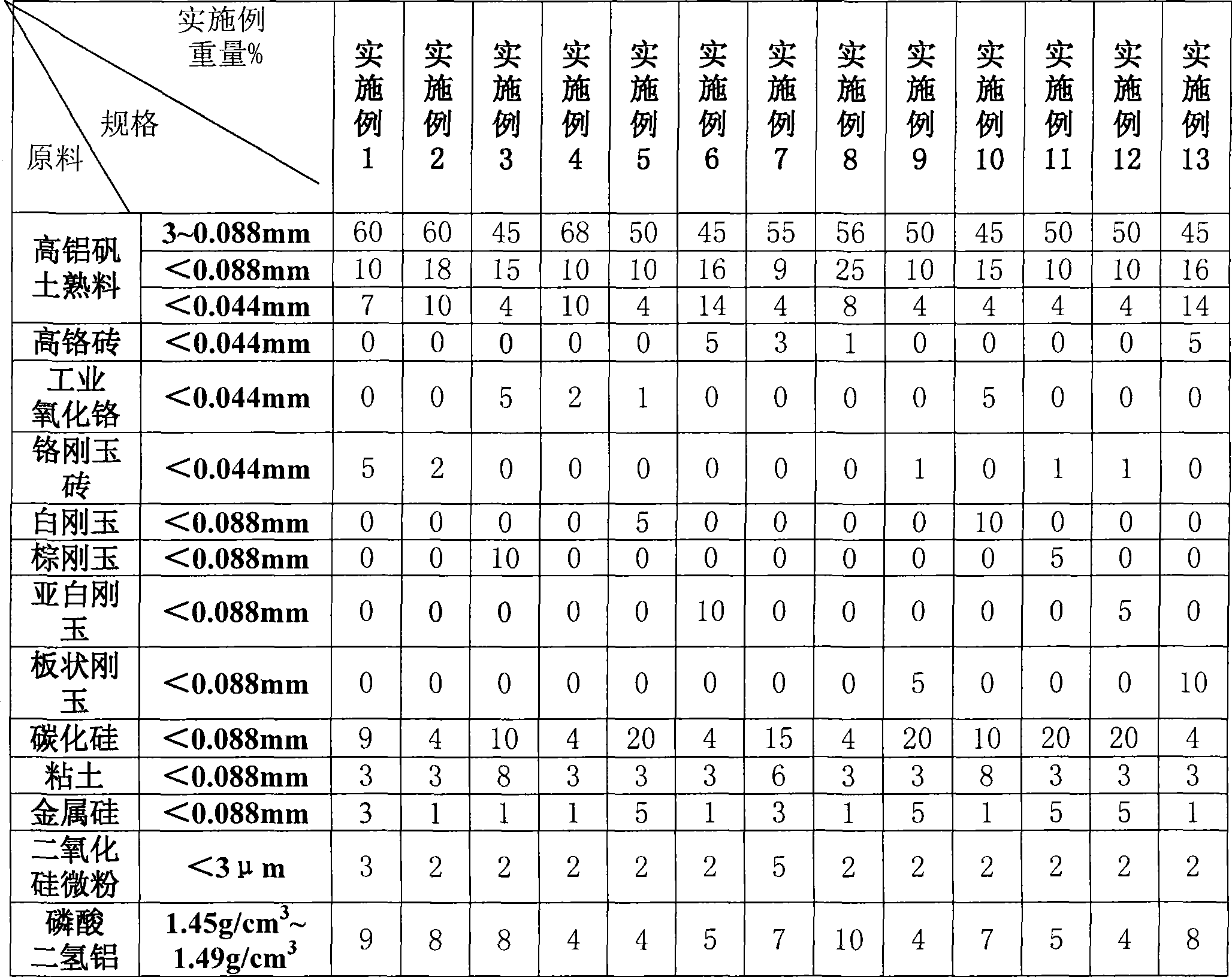

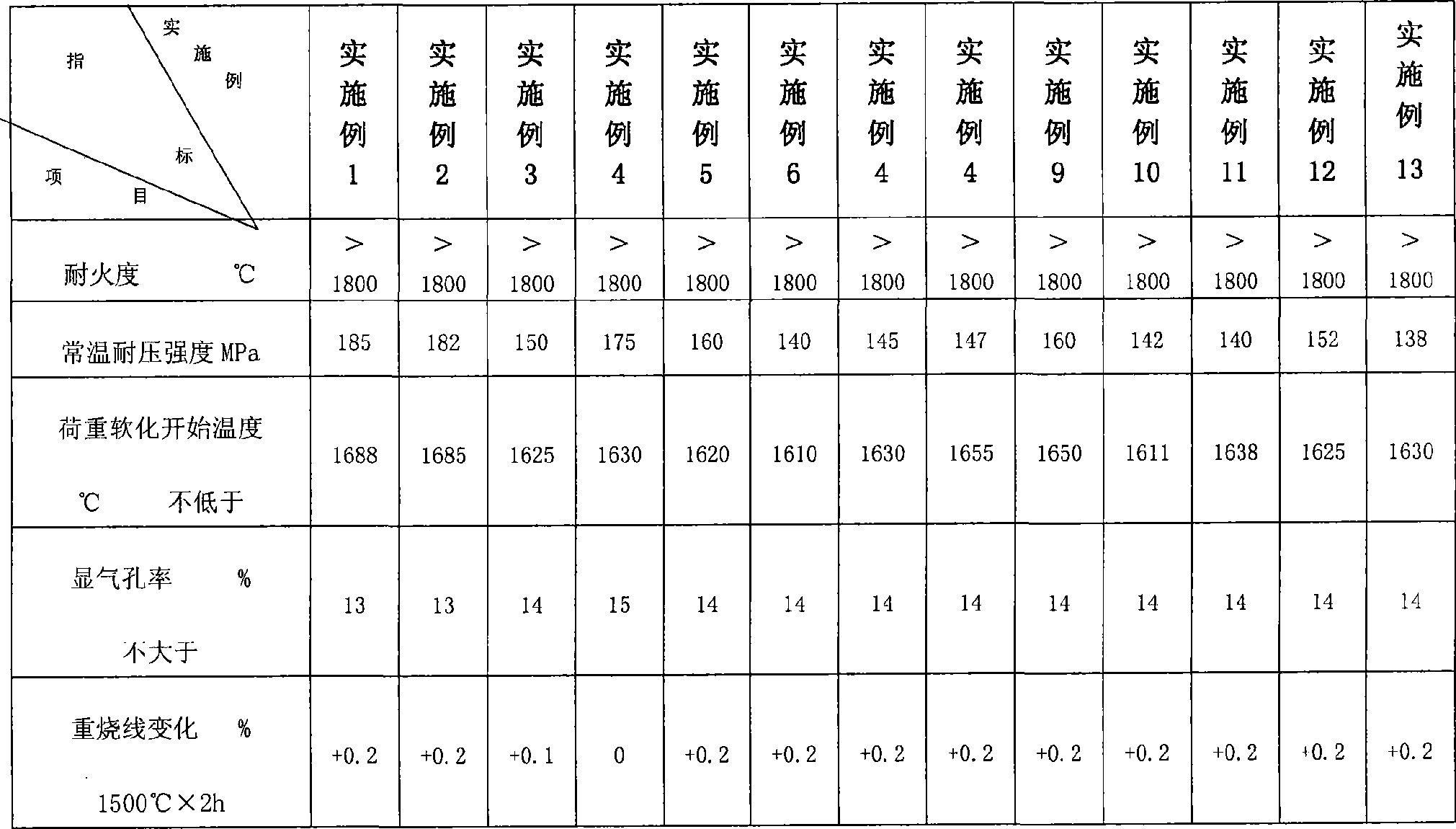

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

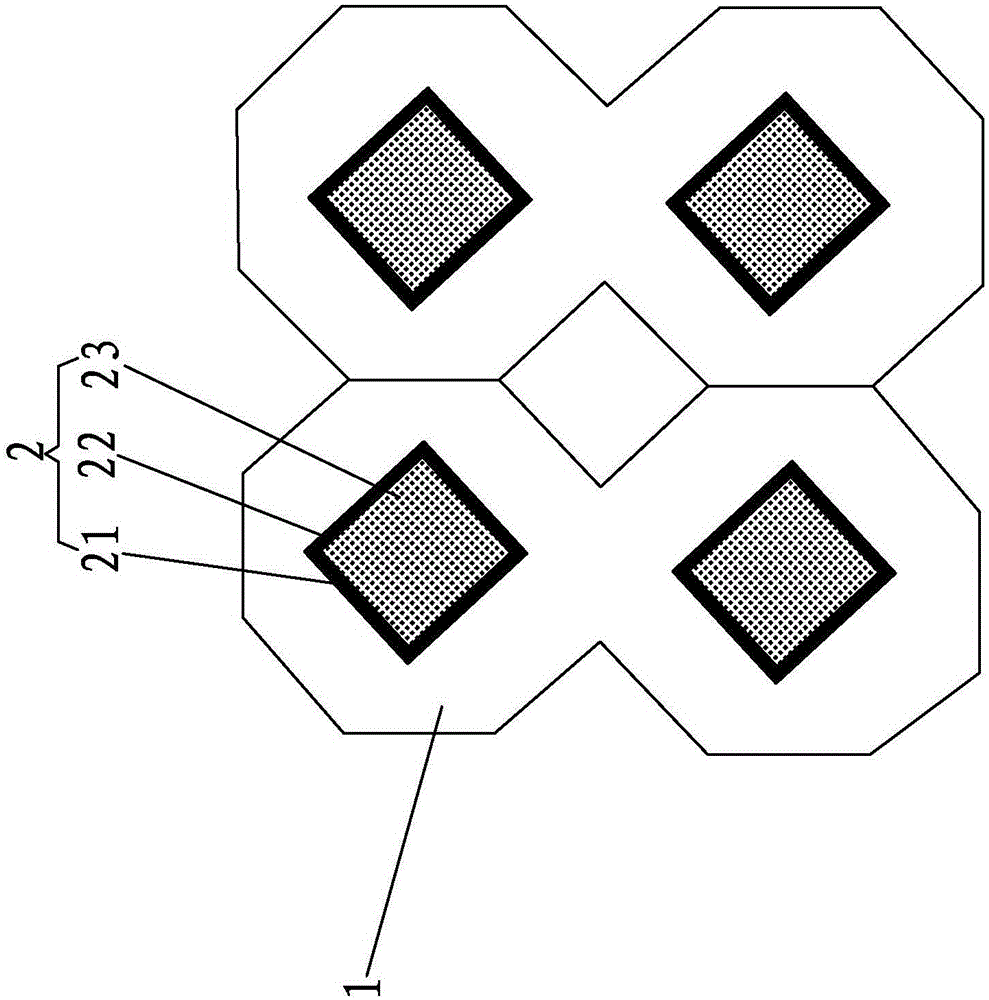

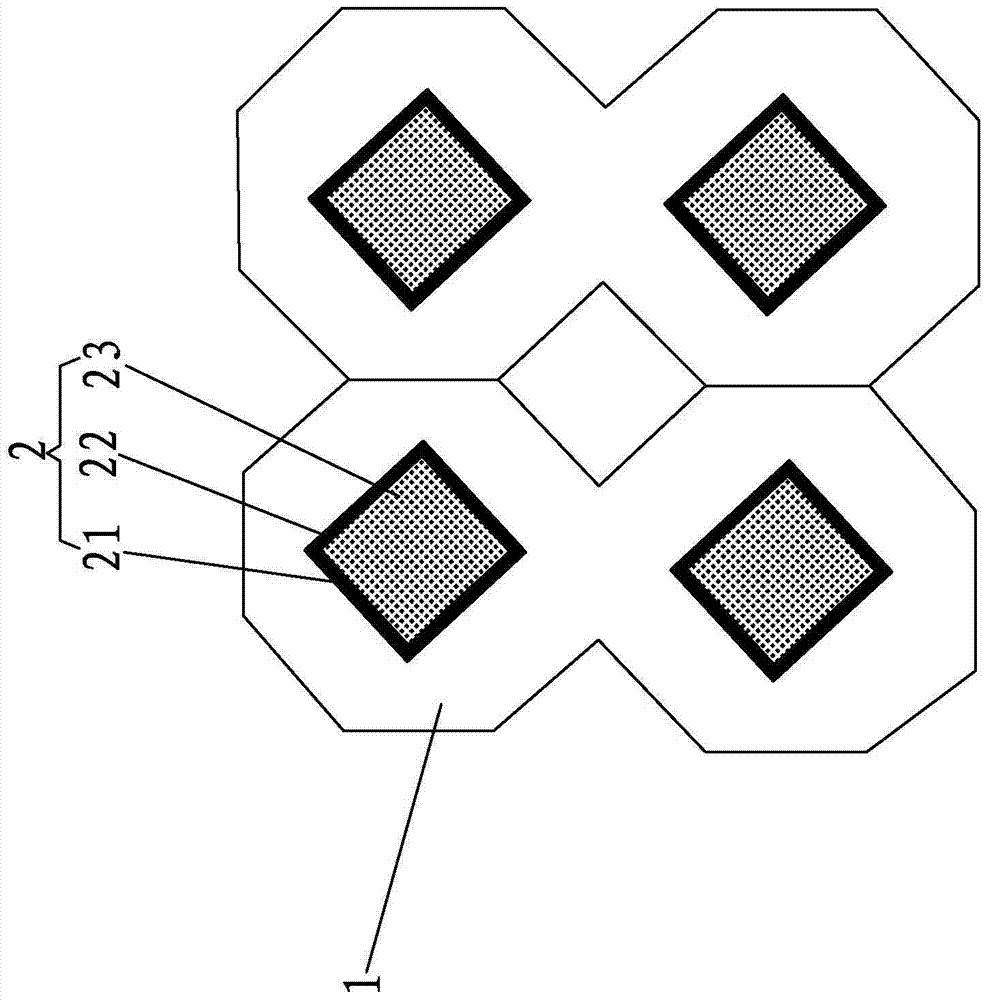

Sewage interception water-permeable brick

ActiveCN105155389AFlat surfaceEasy to walkSolid waste managementPaving gutters/kerbsBrickGroundwater pollution

The invention discloses a sewage interception water-permeable brick which comprises a brick body and filter pieces. The filter pieces comprise bags and filter objects located in the bags. The filter pieces comprise pearl wool sleeves, the non-woven bags and the filter objects located in the non-woven bags. An organic flocculant layer is arranged on the inner surface of each pearl wool sleeve. Each filter object is prepared from, by weight, 20-60 parts of flaky high-strength material, 20-50 parts of fine aggregate and 5-20 parts of binding agent, and the flaky high-strength material, the fine aggregate and the binding agent are mixed and compacted into a blocky structure. The flaky high-strength material is a mixture of one or two or more of long-laid shells, broken earthenware bricks and lamina schist, the fine aggregate is formed by mixing 5-50 parts of alkalescent porous minerals and 0-45 parts of carbonaceous filter materials by weight, and the binding agent is one of high-alumina cement, magnesium oxychloride cement, phosphate binding agent and hydration glass. The water-permeable brick has the beneficial effects that walking is facilitated, and heavy metal, toxic organic substances and colloid of water can be captured so as to avoid groundwater pollution.

Owner:QUANZHOU NORMAL UNIV

Method for preparing corundum mullite crucible

The invention relates to a crucible applied to the fields of ceramic industry, metal smelting, powder high-temperature calcination and the like, in particular to a method for preparing a corundum mullite crucible. The corundum mullite crucible takes mullite particles with the particle size being 2-0.1mm and fine mullite powder with the particle size being 0.061-0.075mm as aggregates, and a matrix part comprises sintered alumina micro powder with the particle size being 0.003mm at most and also comprises mullite micro powder with the particle size being 0.045mm at most or adds clay with the particle size being 0.045mm at most at the same time. A binder is a phosphate binder or adds an aluminate binder, magnesium oxide micro powder with the particle size being at most 0.045mm is adopted as a coagulant, and a water reducer adopts a high-efficiency water reducer or sodium tripolyphosphate. According to the method, the deformation and the yield of the casting crucible products sintering processing are improved and increased, and the purposes of cost reducing, efficiency increasing, energy saving and consumption reducing are achieved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Phosphate combined low-aluminum Guimo brick and preparation method thereof

The invention relates to a phosphate combined low-aluminum Guimo brick and a preparation method thereof. The brick comprises 30-59% of 3-1mm high-aluminum bauxite, 11-28% of 1-0.088mm high-aluminum bauxite, 0-20% of 0.044<mm bauxite micropowder, 0-18% of 0.088<mm alumina micropowder, 5-19% of 0.088<mm calcined kaolin, 5-16% of 0.088<mm silicon carbide, 8-22% of 20-15mu m silicon micropowder and 3-10% of phosphate binder. The preparation technique comprises the following steps: proportionally mixing the raw materials, adding the phosphate binder, aging, grinding, mechanically forming, drying, heating the dried green brick to 450-600 DEG C, and keeping the temperature for 2-8 hours. The phosphate combined low-aluminum Guimo brick can utilize the low-grade raw material, and has the advantages of favorable alkali resistance and better high-temperature resistance.

Owner:ZAOZHUANG GAIZE FURNACE ENG

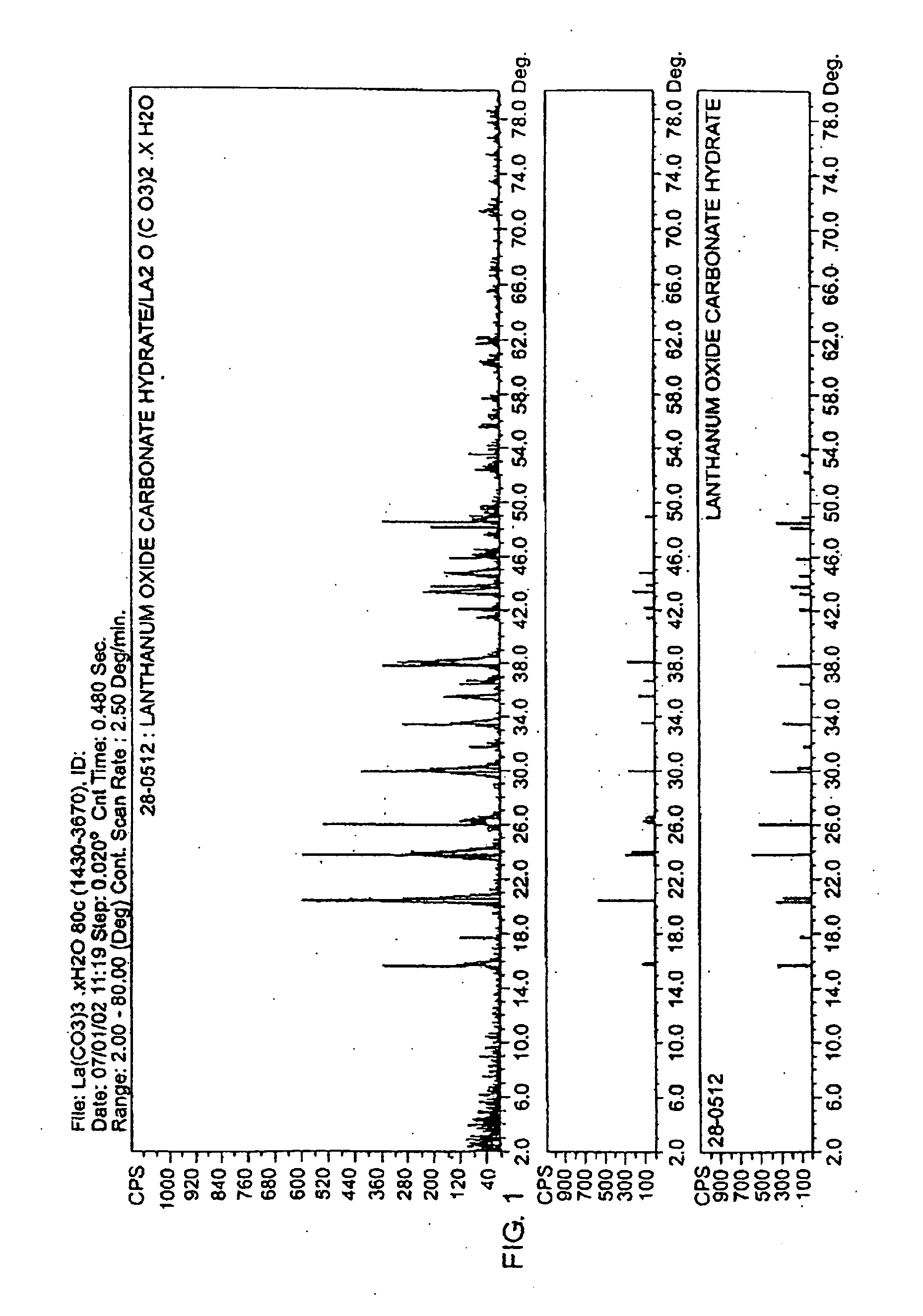

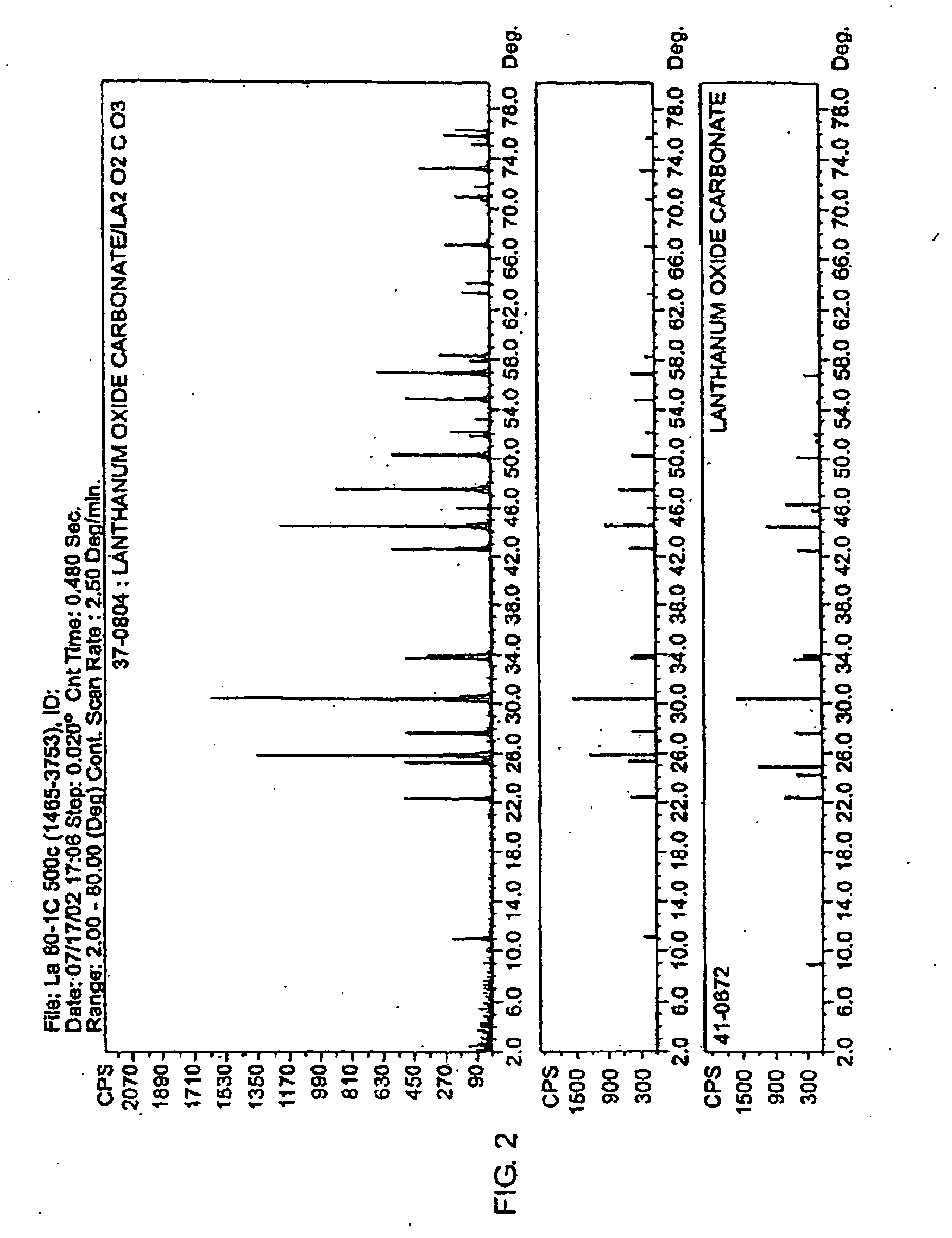

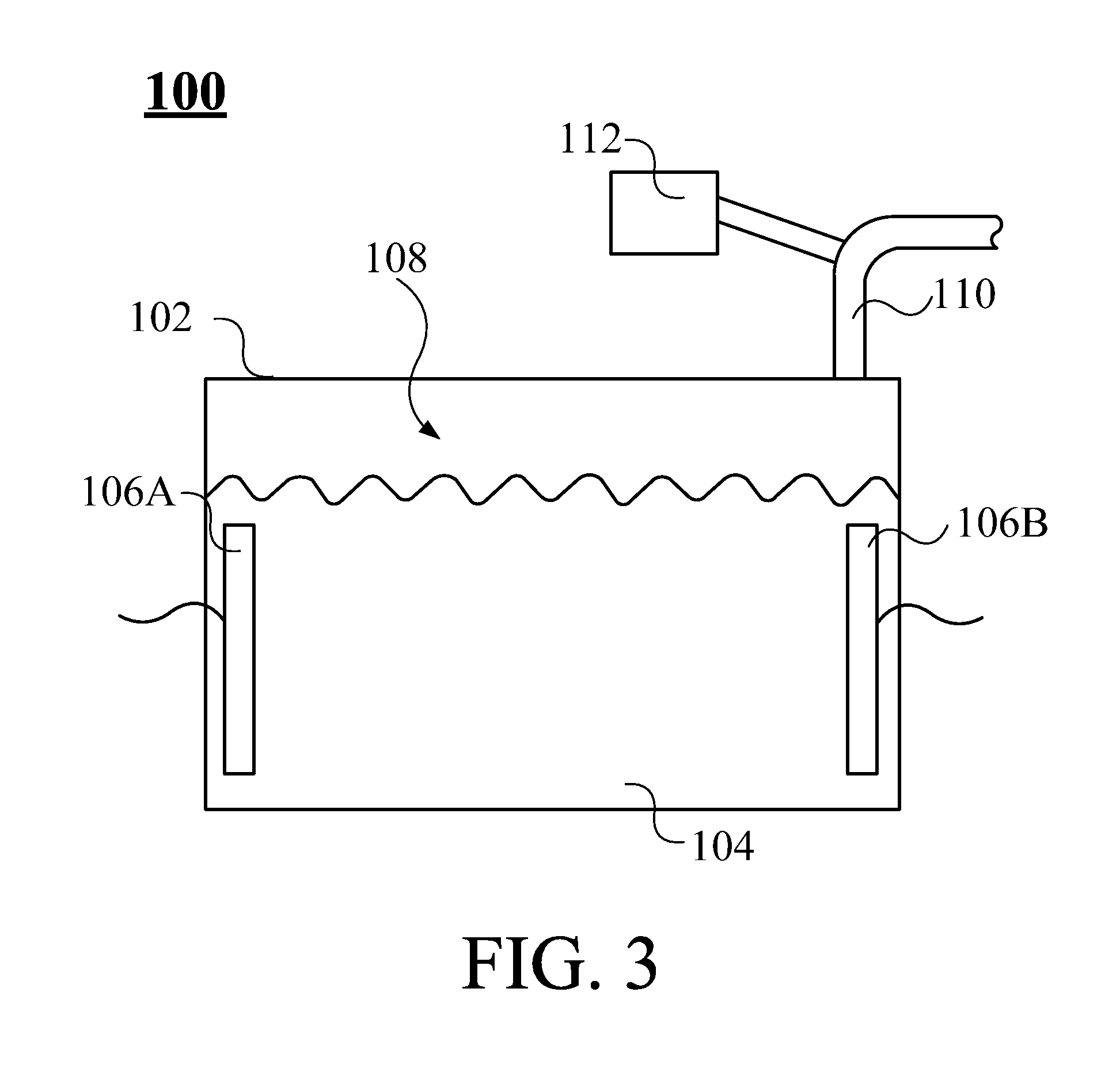

Hyperphosphatemia in domestic animals: compositions and methods of treatment

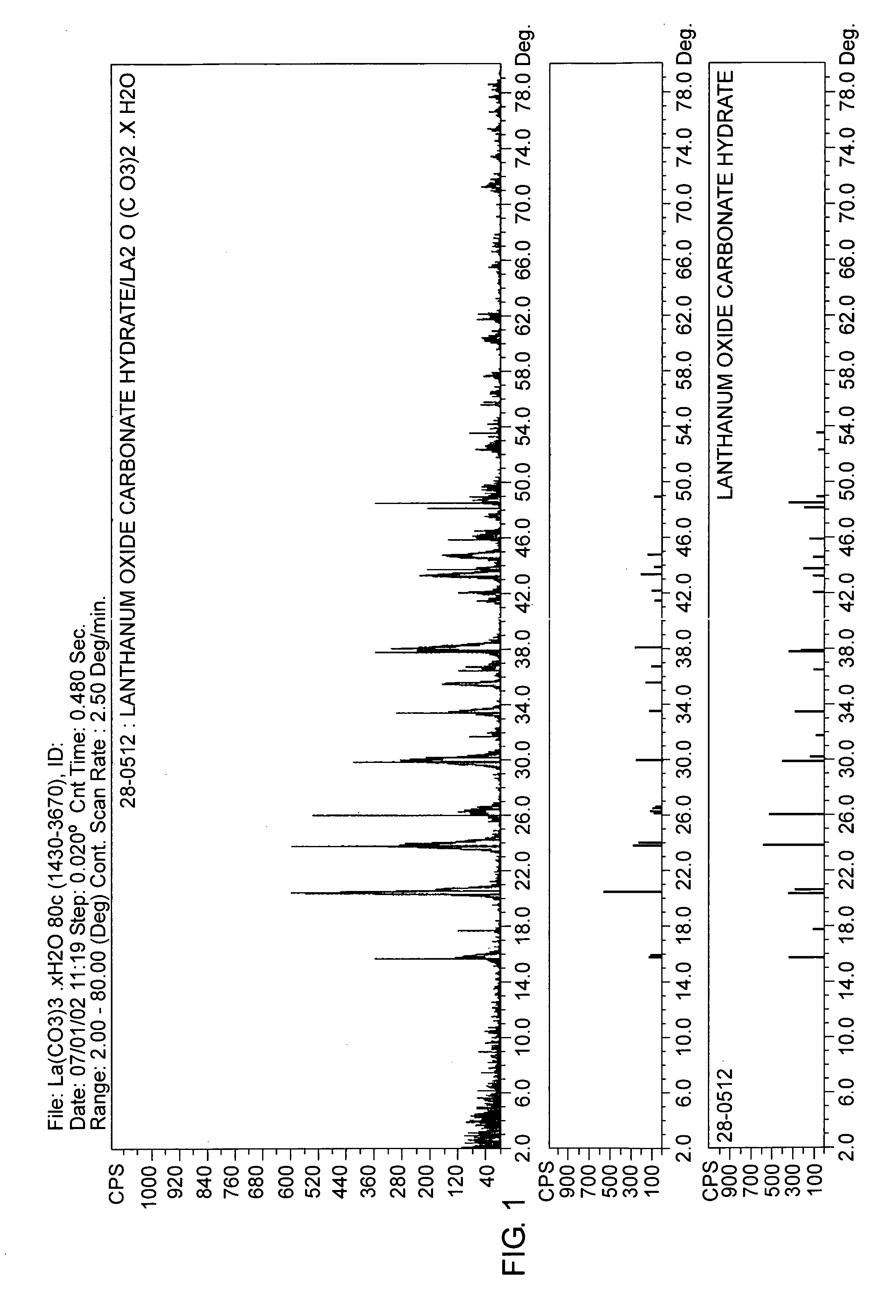

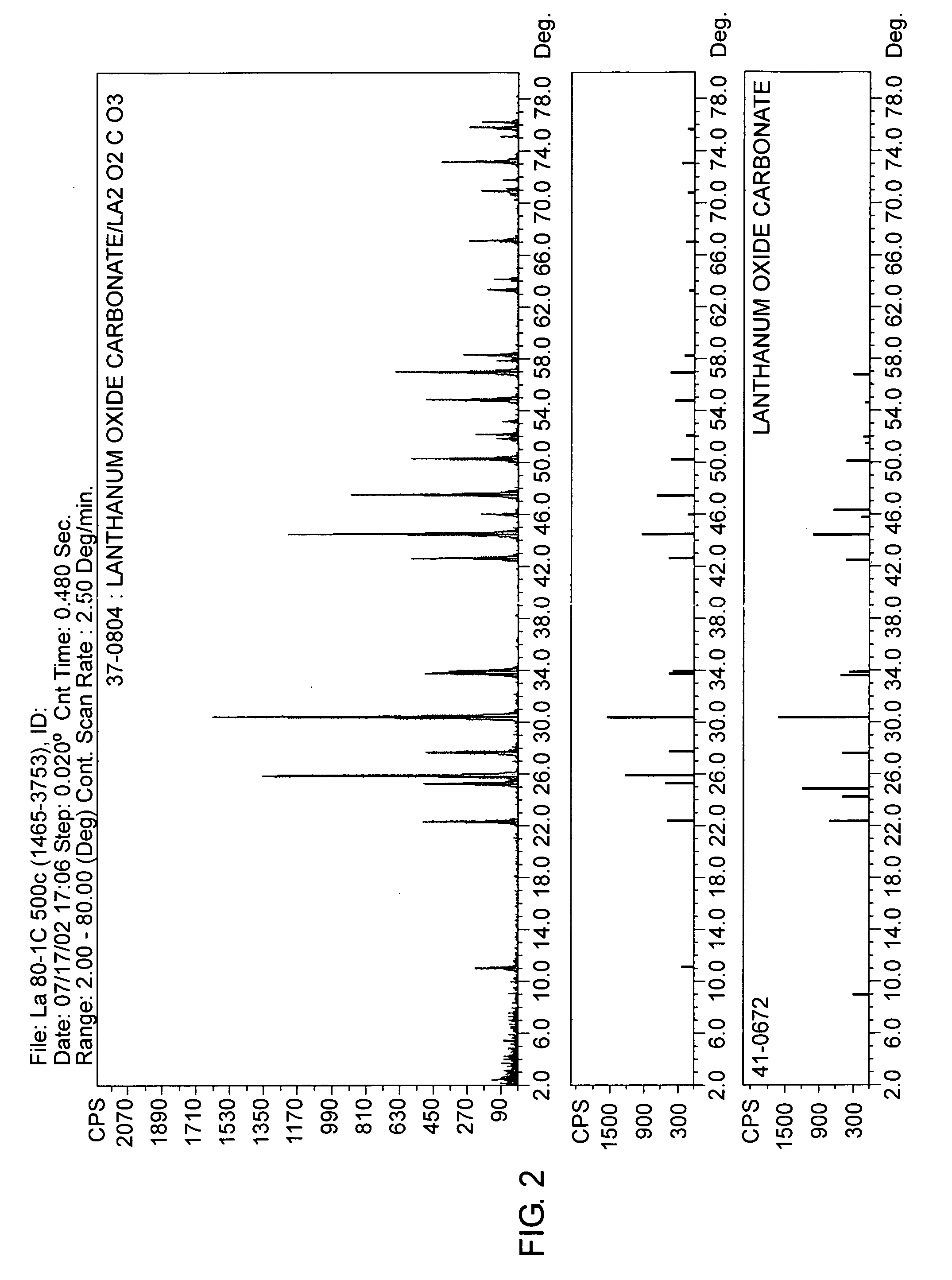

The present invention is generally related to the treatment of hyperphosphatemia in domestic animals. It is specifically directed to compositions containing phosphate binders that are palatable to domestic animals and methods using such compositions. In a composition aspect, the present invention provides a composition that includes: a rare earth compound (e.g., lanthanum oxycarbonate or lanthanum carbonate hydroxide), calcium salts (e.g, calcium carbonate or calcium acetate), aluminum salts (e.g., aluminum hydroxide or a hydrophilic exchange resin; and an ingredient of domestic animal food, wherein the ingredient is selected from a group consisting of chicken, beef, lamb, chicken meal or lamb meal, corn, rice, bone meal, fish meal, fish, egg product, beef, beef meal, corn gluten meal, poultry by-product meal, wheat flour, beef tallow, maple syrup, honey, apple, flaxseed, flaxseed meal, rice bran and germ, oats, barley, and wheat bran.

Owner:SPECTRUM PHARMA INC

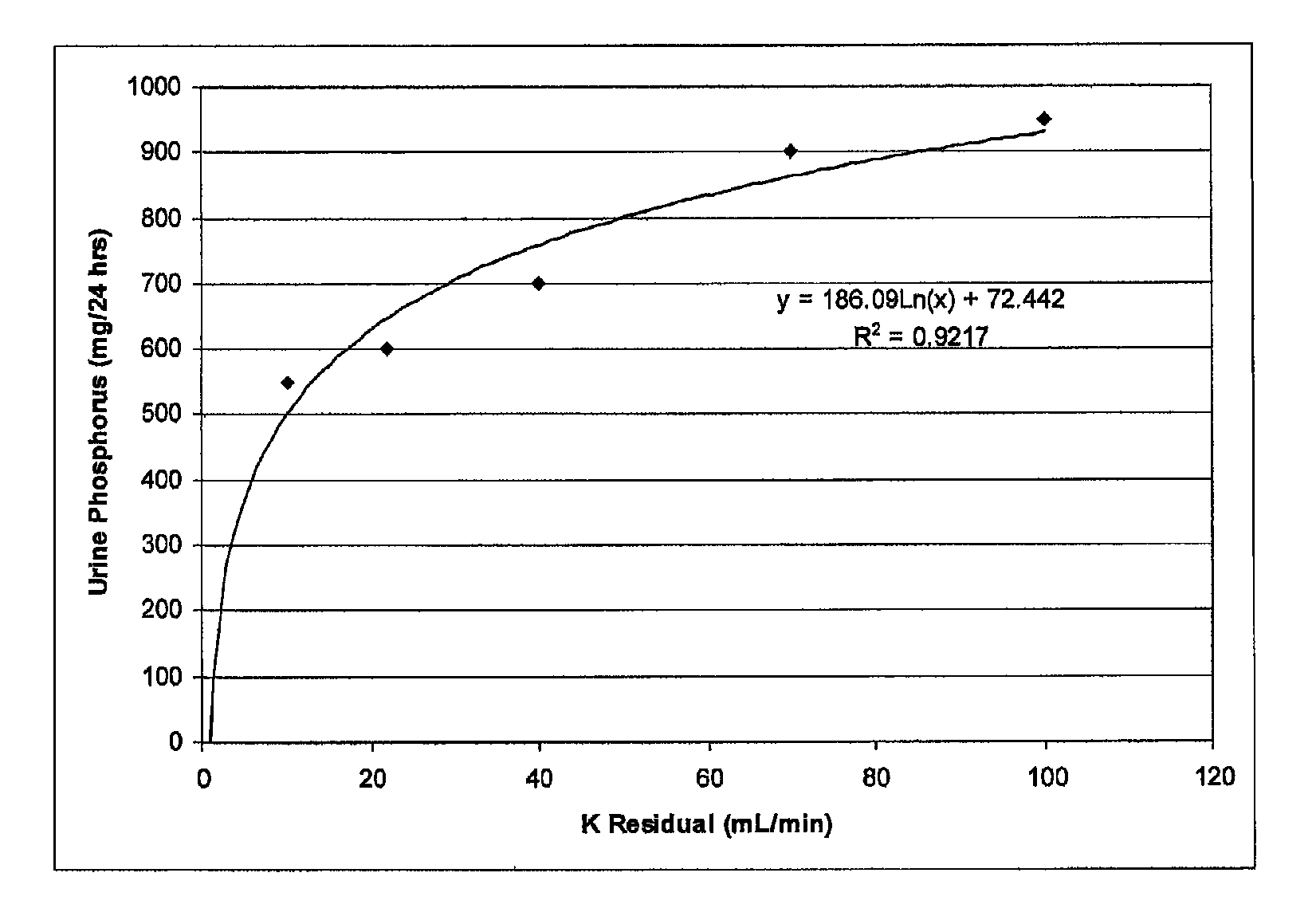

Method of calculating a phosphorus-protein ratio

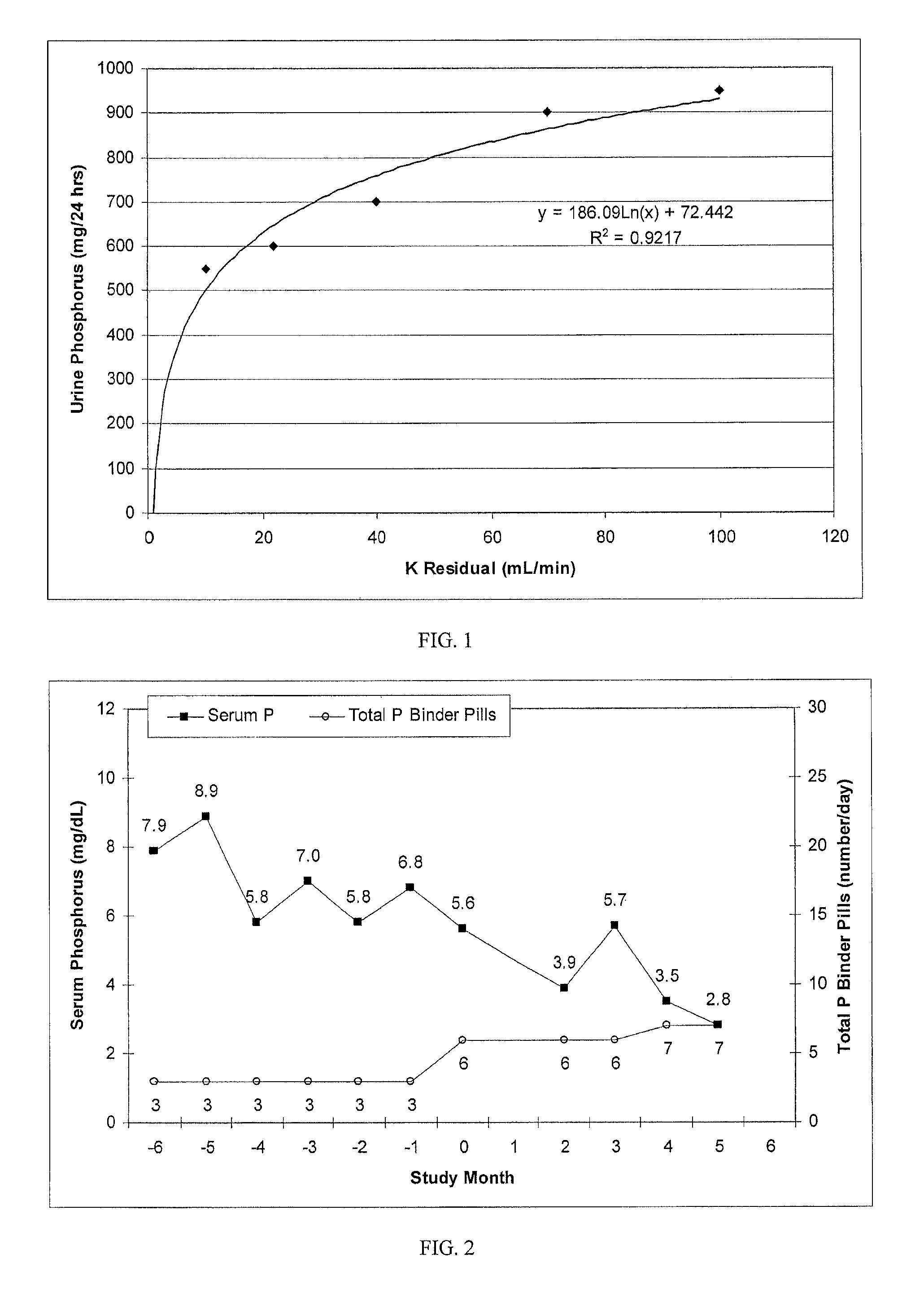

A method of identifying a patient who is non-compliant with prescribed diet and / or phosphate binder regimen calculates a phosphorus-protein ratio (PPR) by calculating the patient's protein intake, measuring the patient's serum phosphorus concentration, and estimating the amount of phosphorus removed by the patient's kidneys from measured residual urea clearance. The PPR is the ratio between the total amount of phosphorus removed from the patient and the patient's protein intake. The method enables identifying a patient that is non-compliant with prescribed diet and / or phosphate binder regimen if the PPR is outside of an acceptable range.

Owner:FRESENIUS MEDICAL CARE HLDG INC

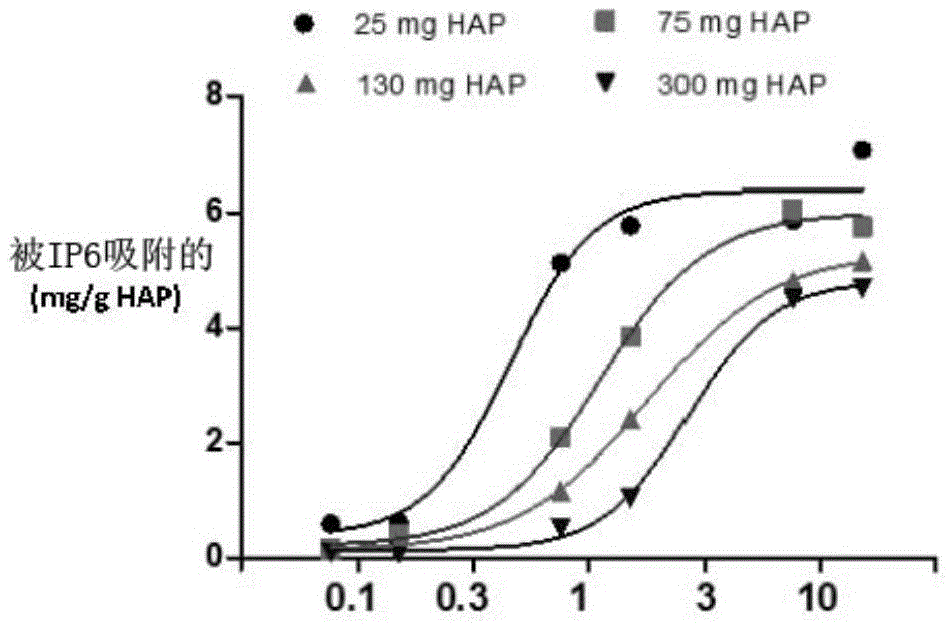

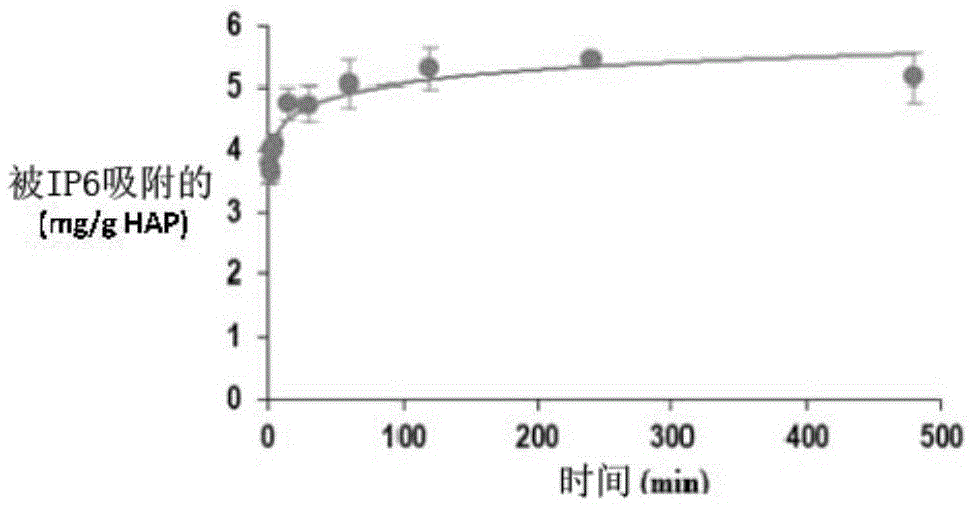

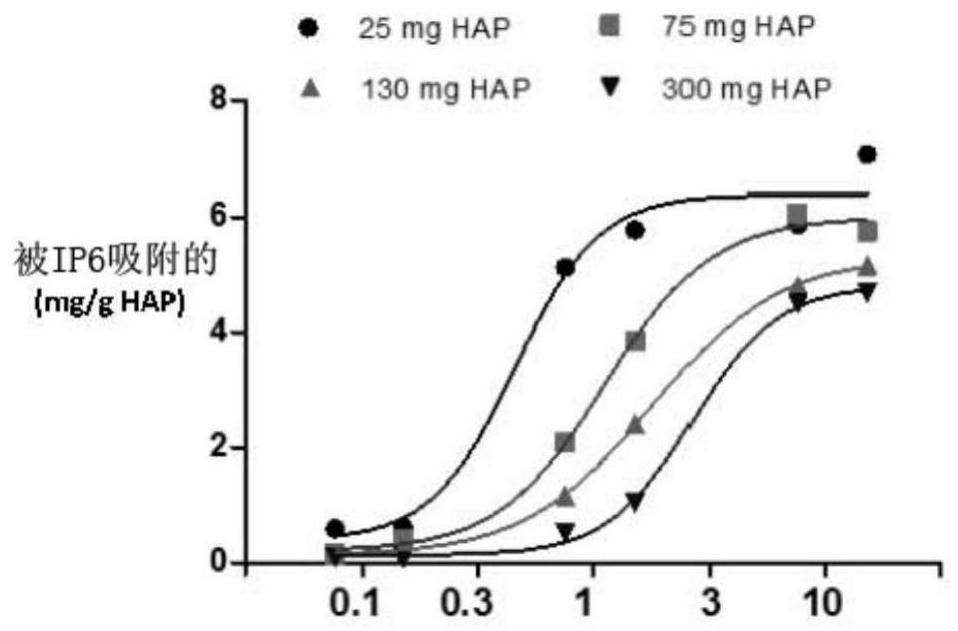

Granular material comprising water-insoluble inorganic phosphate binders

ActiveCN101378730AReduce absorptionHeavy metal active ingredientsAluminium compoundsWater insolubleCerium

The present invention provides a grainy material which comprises the following components: (i) at least 50wt% of solid water-insoluble mixed metal compound when the weight of the grainy material is taken as a reference, the mixed metal compound can combine with microcosmic salt of the formula (I): M<II>1-xM<II>x(OH)2A<n->y*zH2O (I), in the formula M<II> is magnesium, calcium, lanthanum and cerium; M<III> is iron at least; A<n-> is at least one n-valence anion; x is the summation of ny; 0<x<=0.67, 0<y<=1, and 0<=z<=10; (ii) non chemically combining water between 3 to 12wt% of the weight of the grainy material is taken as a reference; and (iii) excipient no larger than 47wt% of the weight of the grainy material is taken as a reference.

Owner:CYTOCHROMA DEV

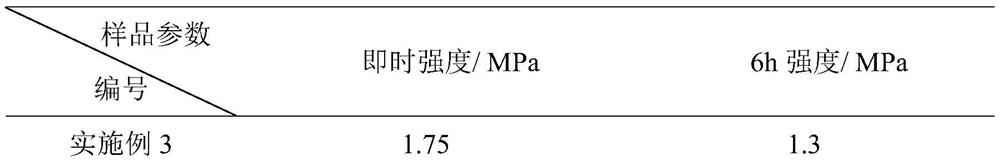

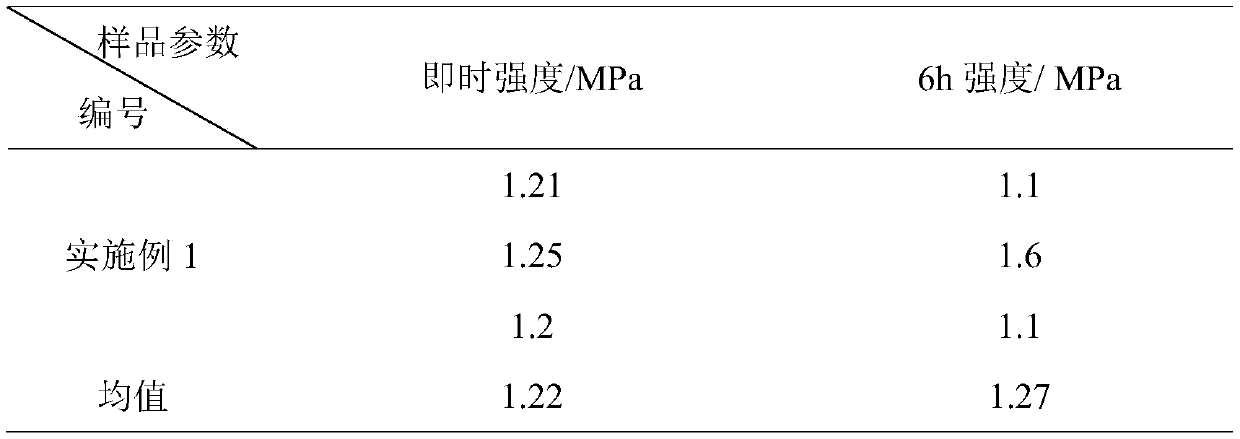

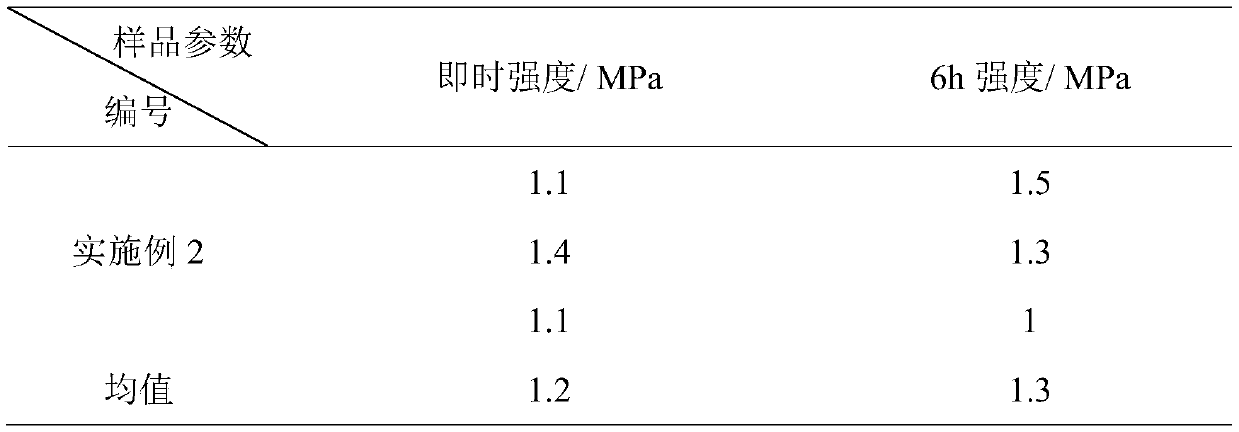

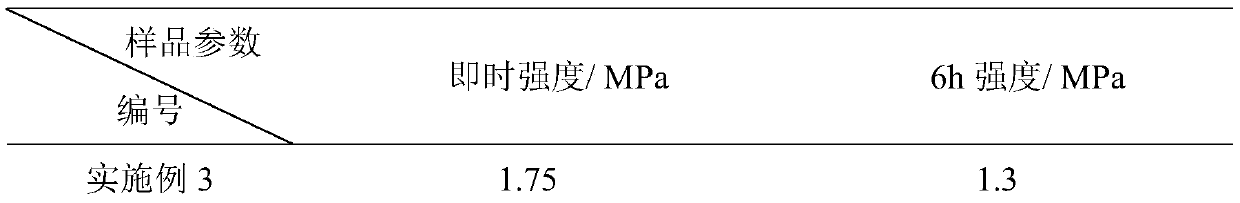

Phosphate binder self-hardening sand curing agent and preparation method thereof

ActiveCN108907070ASmall granularityLarge specific surface areaFoundry mouldsFoundry coresPhosphateFirming agent

The invention discloses a phosphate binder self-hardening sand curing agent and a preparation method thereof. The curing agent comprises the following components of metallurgical magnesite powder, silica sol, water, a coupling agent and urea. The preparation method comprises the following steps that (1) metallurgical magnesia powder particles are crushed and refined; (2) the urea, the silica sol and the coupling agent are correspondingly added into water, and fully stirring is carried out to obtain a uniform mixed solution; (3) the mixed solution is slowly added into the metallurgical magnesiapowder, stirring is carried out while adding is carried out, so that a uniform suspension-shaped mixture is obtained; and (4) the mixture obtained in the step (3) is put into a drying oven at 100 DEGC for fully drying and dehydrating, then is taken out and crushed into fine powder. The using method comprises the following steps that firstly, the curing agent and raw sand are uniformly mixed andthen added with a phosphate binding agent for uniformly mixing, then sand discharging is carried out, the uniformly-mixed sand material is poured into a standard 8-typeface mold for sample preparation, and demoulding and storing are carried out after hardening. The phosphate binding agent self-hardening sand curing agent is simple in preparation process, and the prepared self-hardening sand is good in performance, stable in storage, green, environment-friendly and pollution-free.

Owner:HUBEI UNIV OF TECH +1

Recovery and utilization method of electric fused zirconia alumina grinding waste material

The invention relates to a recovery and utilization method of an electric fused zirconia alumina grinding waste material, and belongs to the technical field of a refractory material. The recovery and utilization method provided by the invention is characterized in that a recovery powder material obtained through precipitating and drying powder-containing waste liquid produced through grinding an electric fused zirconia alumina product is uniformly mixed with phosphoric acid or phosphate bonding agents, hydroxycarboxylic acid and aminocarboxylic acid. The recovery and utilization method provided by the invention has the advantages that the grinding waste material of the electric fused zirconia alumina product is used as raw materials; the efficient recovery of zirconium resources is realized; the prepared ramming materials have low cost, stable performance, high sintering intensity and low sintering shrinkage rate, and can be used for zirconia alumina refractory brick caulked joint positions of glass kiln furnaces.

Owner:ZHENGZHOU XINGUANGSE REFRACTORY

Green and environment-friendly magnesia spinel gunning mix for converter as well as preparation and application of green and environment-friendly magnesia spinel gunning mix

PendingCN113666734ASuitable for gunning maintenanceImprove adhesionManufacturing convertersProcess efficiency improvementSteelmakingMetallurgy

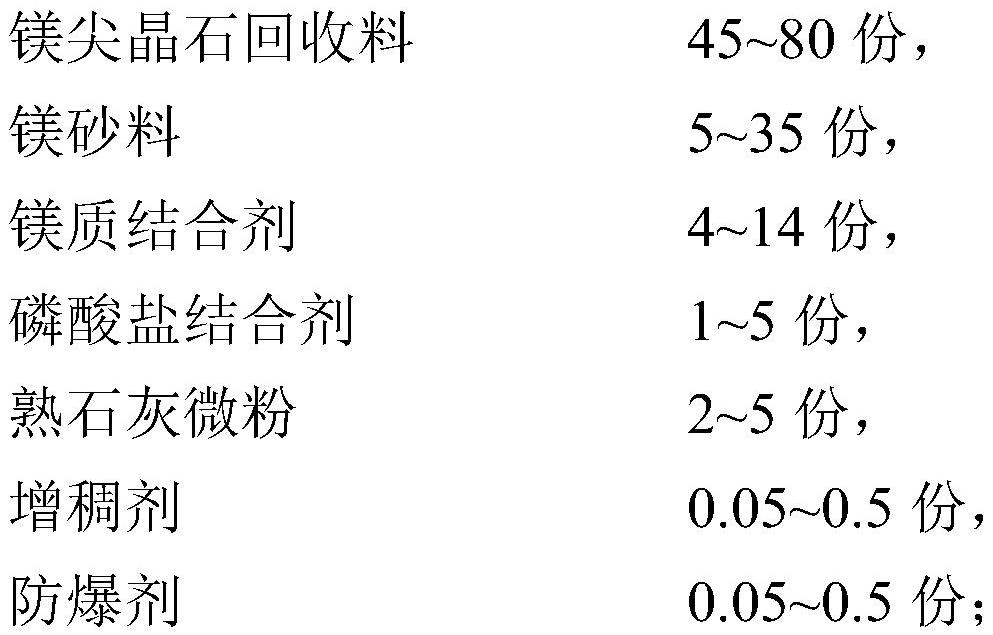

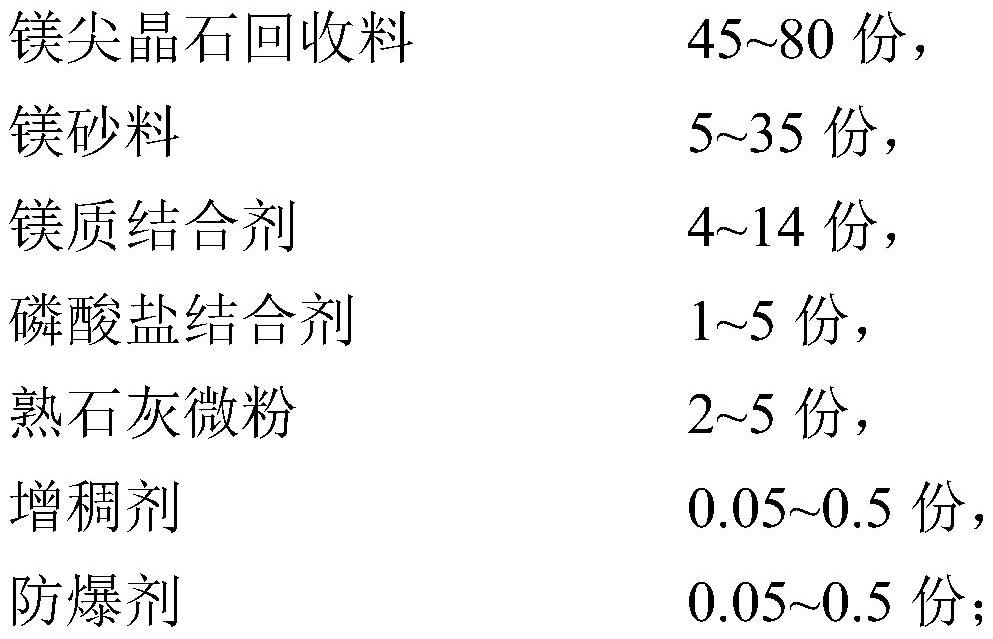

The invention discloses a green and environment-friendly magnesia spinel gunning mix for a converter, a preparation method of the green and environment-friendly magnesia spinel gunning mix and an application of the green and environment-friendly magnesia spinel gunning mix in converter maintenance. The magnesia spinel gunning mix comprises the following raw materials in parts by mass: 45-80 parts of a magnesia spinel reclaimed material, 5-35 parts of a magnesia material, 4-14 parts of a magnesia binding agent, 1-5 parts of a phosphate binding agent, 2-5 parts of slaked lime micro powder, 0.05-0.5 part of a thickening agent and 0.05-0.5 part of an anti-explosion agent. The gunning mix does not contain asphalt and resin, is environment-friendly, and has excellent adhesion and molten steel corrosion resistance by introducing the magnesium spinel reclaimed material and adopting the magnesium binding agent. The waste refractory materials are recycled, the green and environment-friendly development requirement is met, the service life of the gunning material is guaranteed, the steelmaking cost is reduced, and application and popularization are facilitated.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

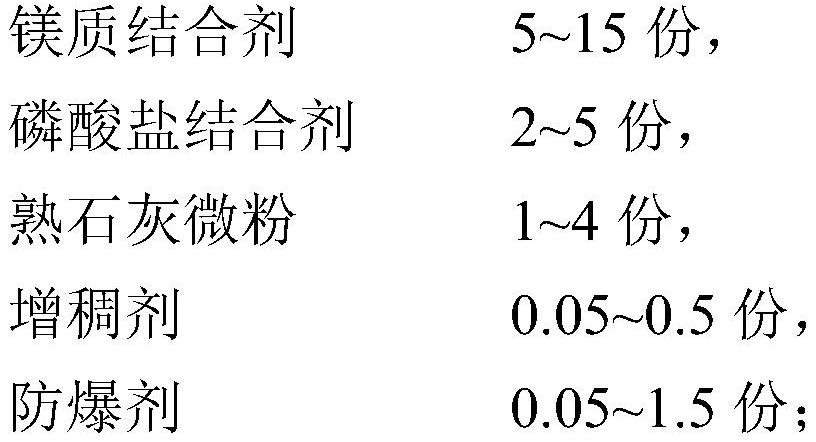

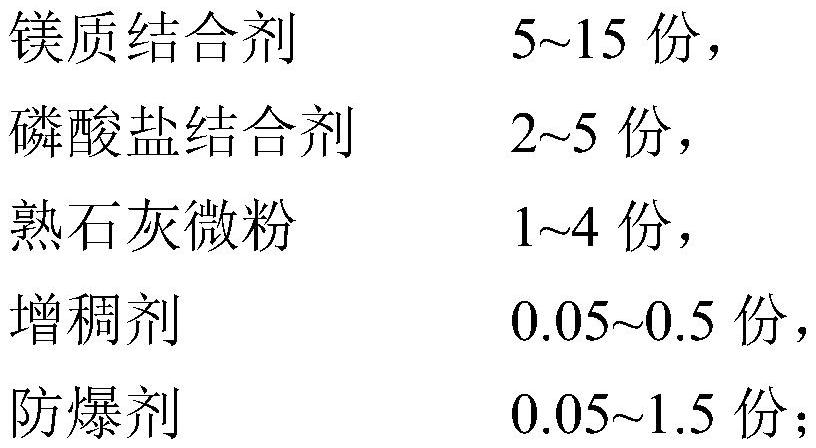

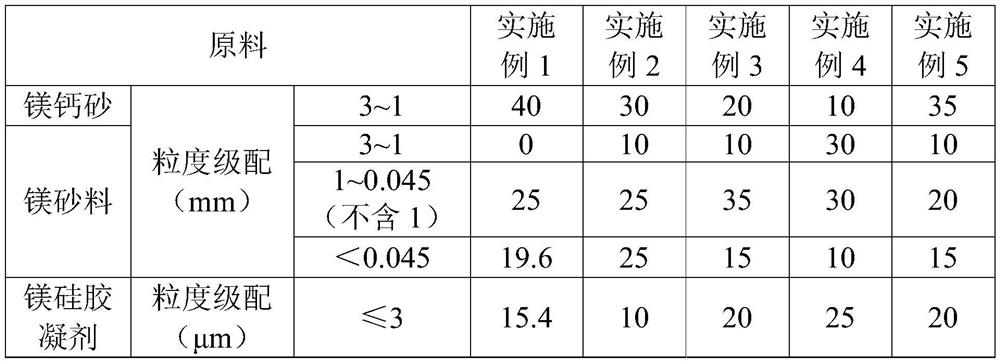

Magnesium-calcium gunning mix suitable for smelting clean steel, and preparation method and application thereof

ActiveCN113233906AReduce consumptionReduce contentMelt-holding vesselsManufacturing convertersPhosphateSilica gel

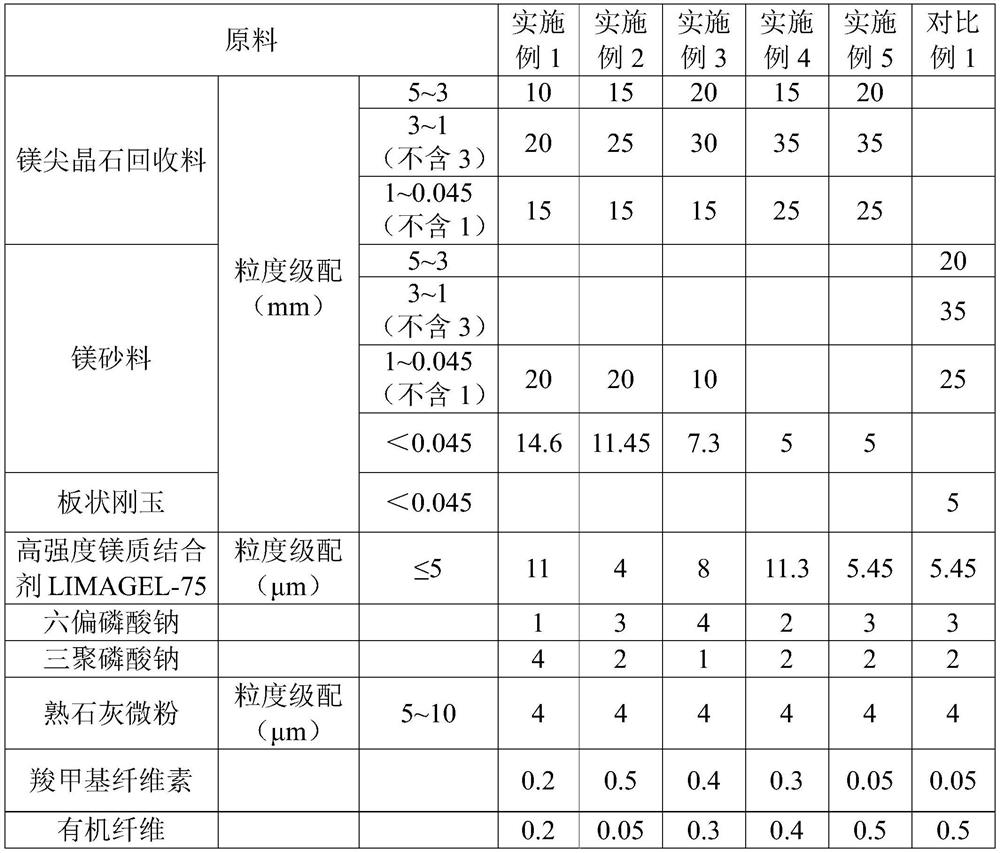

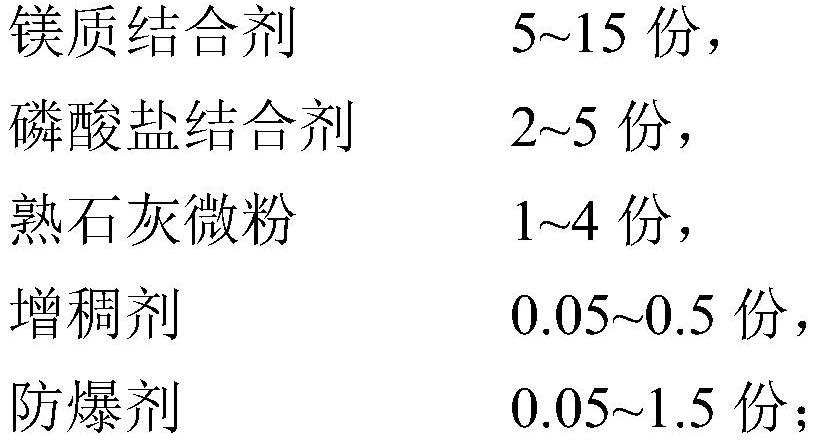

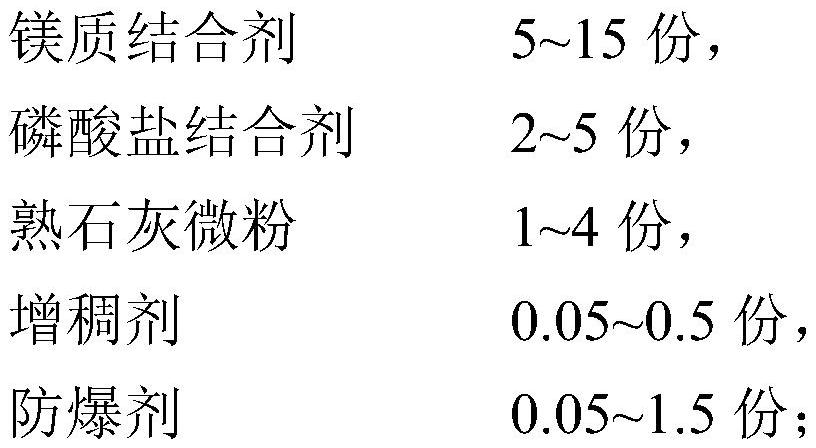

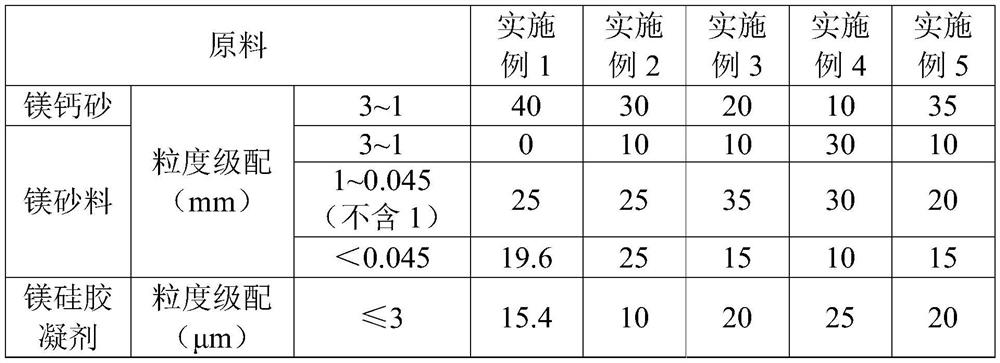

The invention discloses a magnesium-calcium gunning mix suitable for smelting clean steel, a preparation method thereof, and application of the magnesium-calcium gunning mix in smelting the clean steel. The magnesium-calcium gunning mix is prepared from, by mass, 10 to 40 parts of magnesium-calcium sand, 40 to 90 parts of magnesia material and 10 to 26 parts of magnesium-silicon gel agent; the magnesium-silicon gel agent is prepared from, by mass, 5 to 15 parts of a magnesium binding agent, 2 to 5 parts of a phosphate binding agent, 1 to 4 parts of slaked lime micro powder, 0.05 to 0.5 part of a thickening agent and 0.05 to 1.5 parts of an anti-explosion agent' the granularity of the magnesium binding agent is not greater than 5 [mu]m, the content of MgO in the magnesium binding agent is greater than or equal to 77.00 wt%, the content of SiO2 is greater than or equal to 13.00 wt%, and the ignition loss at 950 DEG C is less than or equal to 6.0 wt%; and the magnesium-silicon gel agent is obtained by co-grinding the raw materials, and the particle size is not greater than 3 [mu]m. The preparation method comprises the following steps: uniformly stirring the raw materials which comprise the magnesia-calcium sand, the magnesia material and the magnesia-silicon gel agent and form the magnesia-calcium gunning mix in a mixer to obtain the magnesia-calcium gunning mix.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

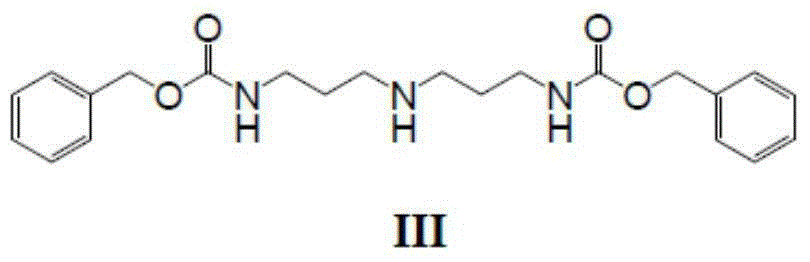

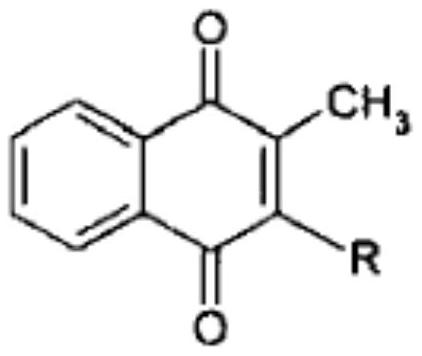

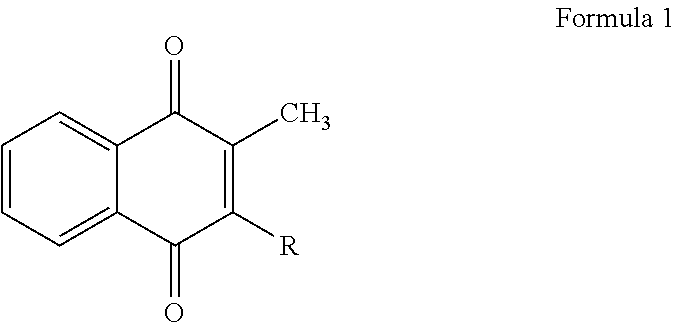

Bixalomer intermediate

ActiveCN105111089ARaw materials are cheap and easy to getThe reaction is easy to operateCarbamic acid derivatives preparationOrganic compound preparationBenzyl chloroformateCalcium Binder

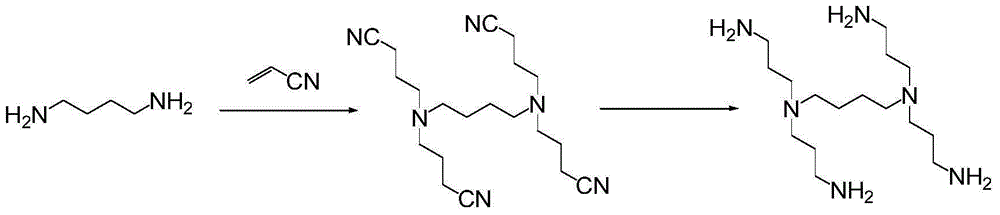

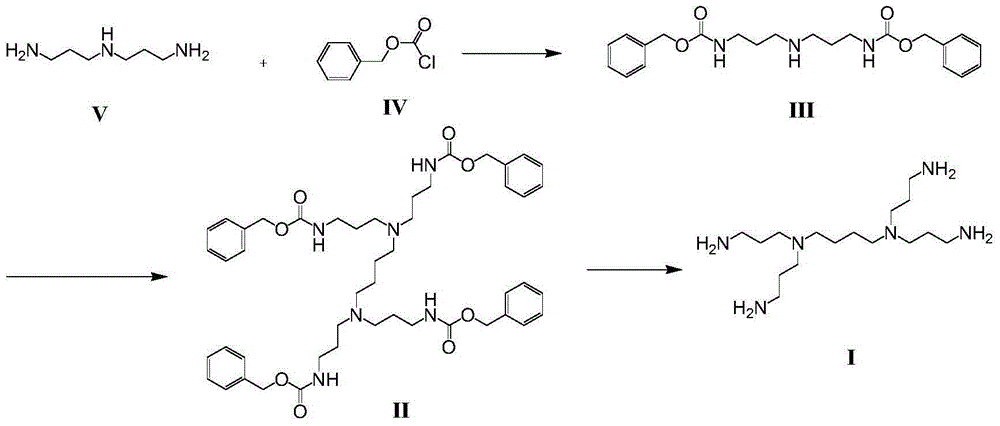

The invention particularly relates to an amine phosphate binder bixalomer intermediate and a preparation method thereof. The preparation method comprises the following steps: reacting a raw material 3,3'-diamidodipropyl amine under the action of benzyl chloroformate to obtain 3,3'-dibenzyloxyamidodipropyl amine, carrying out substitution reaction on the 3,3'-dibenzyloxyamidodipropyl amine and 1,4-dibromobutane or 1,4-dichlorobutane to obtain N,N,N',N'-tetra(3-dibenzyloxyamido)-1,4-butanediamine, and carrying out deprotection by pressure hydrogenation under the action of Pd-C to obtain N,N,N',N'-tetra(3-aminopropyl)-1,4-butanediamine. The method has the advantages of cheap and accessible raw materials, operable reaction, high yield and fewer three wastes, and thus, has excellent industrial prospects.

Owner:NANJING HUAWE MEDICINE TECH DEV

Combination therapy of phosphate binders and vitamin K

PendingCN113260417ASmall doseFree from calcificationOrganic active ingredientsMetabolism disorderCalcium BinderP phosphate

Owner:NATTOPHARMA

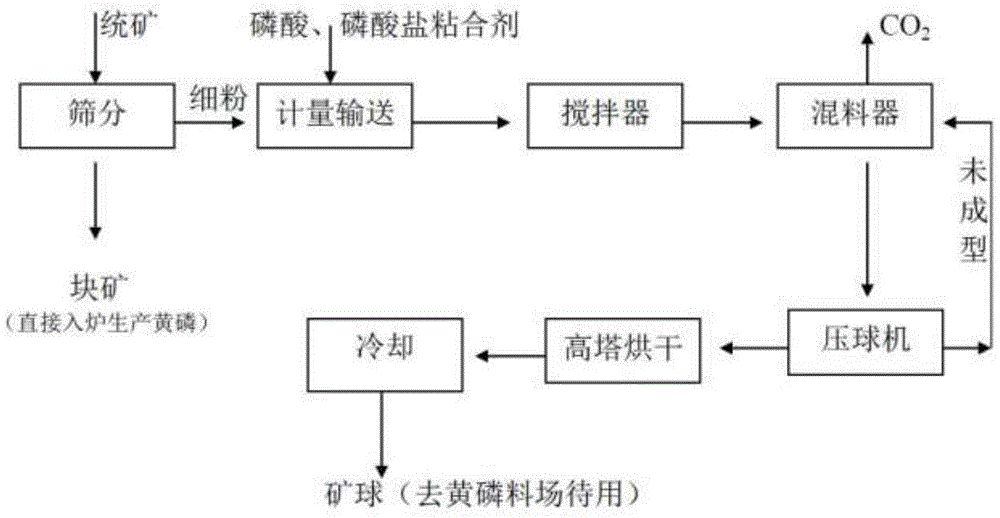

Method for producing phosphate rock powder balls from phosphate rock powder

ActiveCN103964404BIncrease contentRaise the gradeRaw phosphate material treatmentO-Phosphoric AcidEngineering

Owner:贵州福泉川东化工有限公司

High-temperature-resistant and anti-explosion cement and preparation method tehreof

The invention relates to high-temperature-resistant and anti-explosion cement. The cement comprises the following raw materials in parts by weight: 10-30 parts of a phosphoric acid-phosphate binding agent, 20-30 parts of silicon carbide, 20-30 parts of kyanite, 20-30 parts of zirconium dioxide, 20-30 parts of mullite, 10-20 parts of titanium dioxide, 5-10 parts of an enhancer, 5-10 parts of an anti-cracking sustained-release agent, 9-11 parts of ceramic powder resin, 2-5 parts of an accelerant and 2-5 parts of a grinding aid. The ceramic powder resin provided by the invention has the functionthat the core hardening speed, density and the like of inorganic mineral substances are improved, so that anti-explosion performance at a high temperature of the high-strength concrete is improved. The phosphoric acid-phosphate binding agent mainly exerts a micro-aggregate effect, so that the usage amount of cement can be saved, binding force between cement and aggregate is increased, fluidity ofthe concrete is increased, and compactness of the concrete is improved. After the high-strength concrete prepared by the method is treated by high-temperature open fire of 1200 DEG C for 1 hour, appearance is kept complete, no cracks are generated, and compressive strength is not lower than 90 MPa.

Owner:ZHEJIANG QIMO NEW MATERIAL TECH CO LTD

Magnesium-calcium gunning material suitable for smelting clean steel and its preparation method and application

ActiveCN113233906BReduce consumptionReduce contentMelt-holding vesselsManufacturing convertersPhosphateCalcium Binder

The invention discloses a magnesium-calcium gunning material suitable for smelting clean steel, a preparation method thereof and an application in smelting clean steel. In terms of parts by mass, the raw materials of magnesium-calcium gunning materials include: 10-40 parts of magnesia-calcium sand, 40-90 parts of magnesia material, 10-26 parts of magnesium silica gel coagulant; The raw materials of the agent include: 5-15 parts of magnesium binder, 2-5 parts of phosphate binder, 1-4 parts of slaked lime powder, 0.05-0.5 parts of thickener, 0.05-1.5 parts of explosion-proof agent; The particle size is not more than 5μm, and the MgO content in its composition is ≥77.00wt%, SiO 2 The content is ≥13.00wt%, and the loss on ignition at 950°C is ≤6.0wt%. The magnesium silica gel is obtained by co-grinding the raw materials that make it up, and the particle size is not greater than 3μm. The preparation method comprises: stirring evenly the raw materials constituting the magnesia-calcium gunning material including magnesia-calcium sand, magnesia material and magnesium-silica coagulant in a mixer to obtain the magnesia-calcium gunning material.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

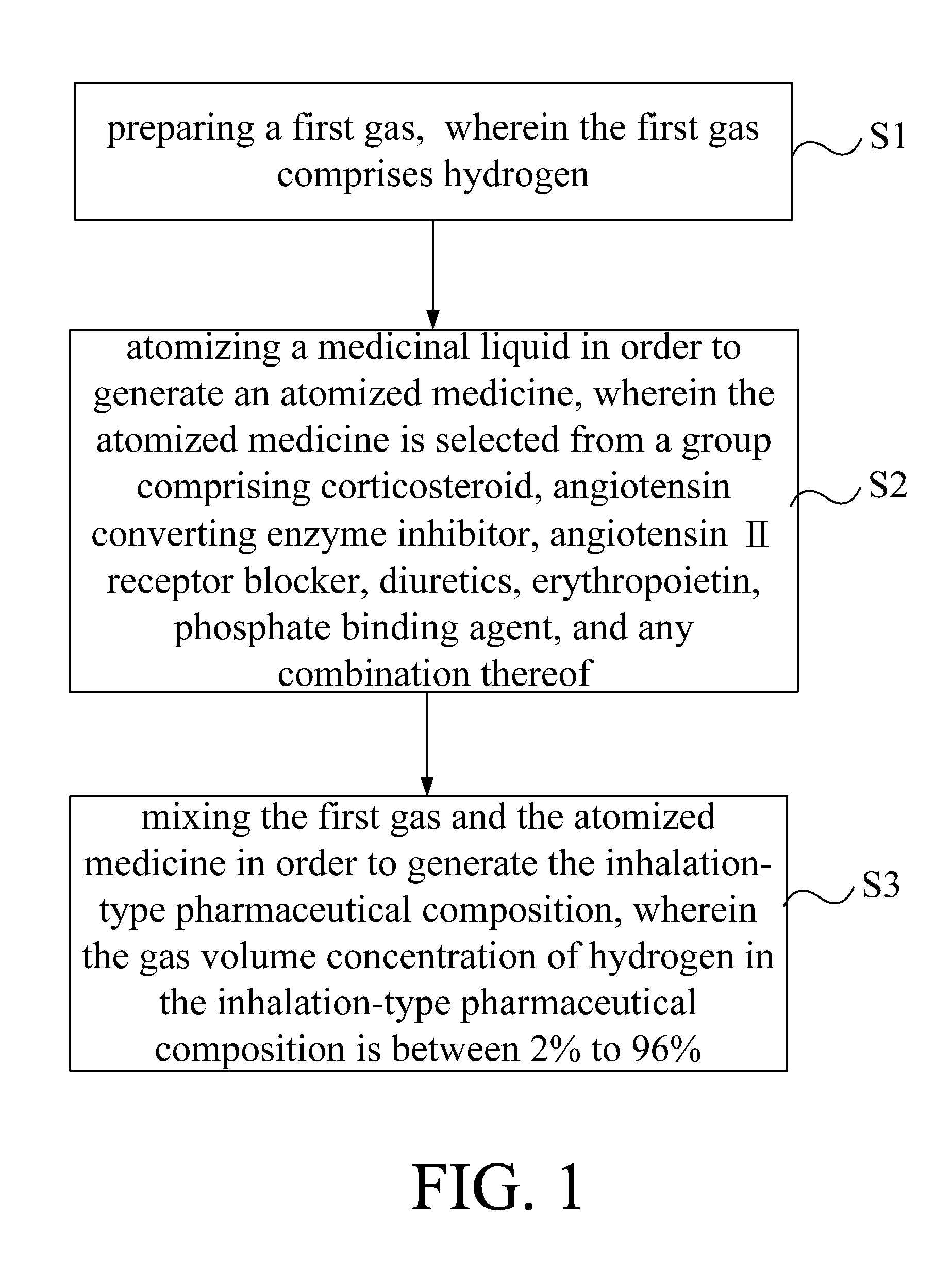

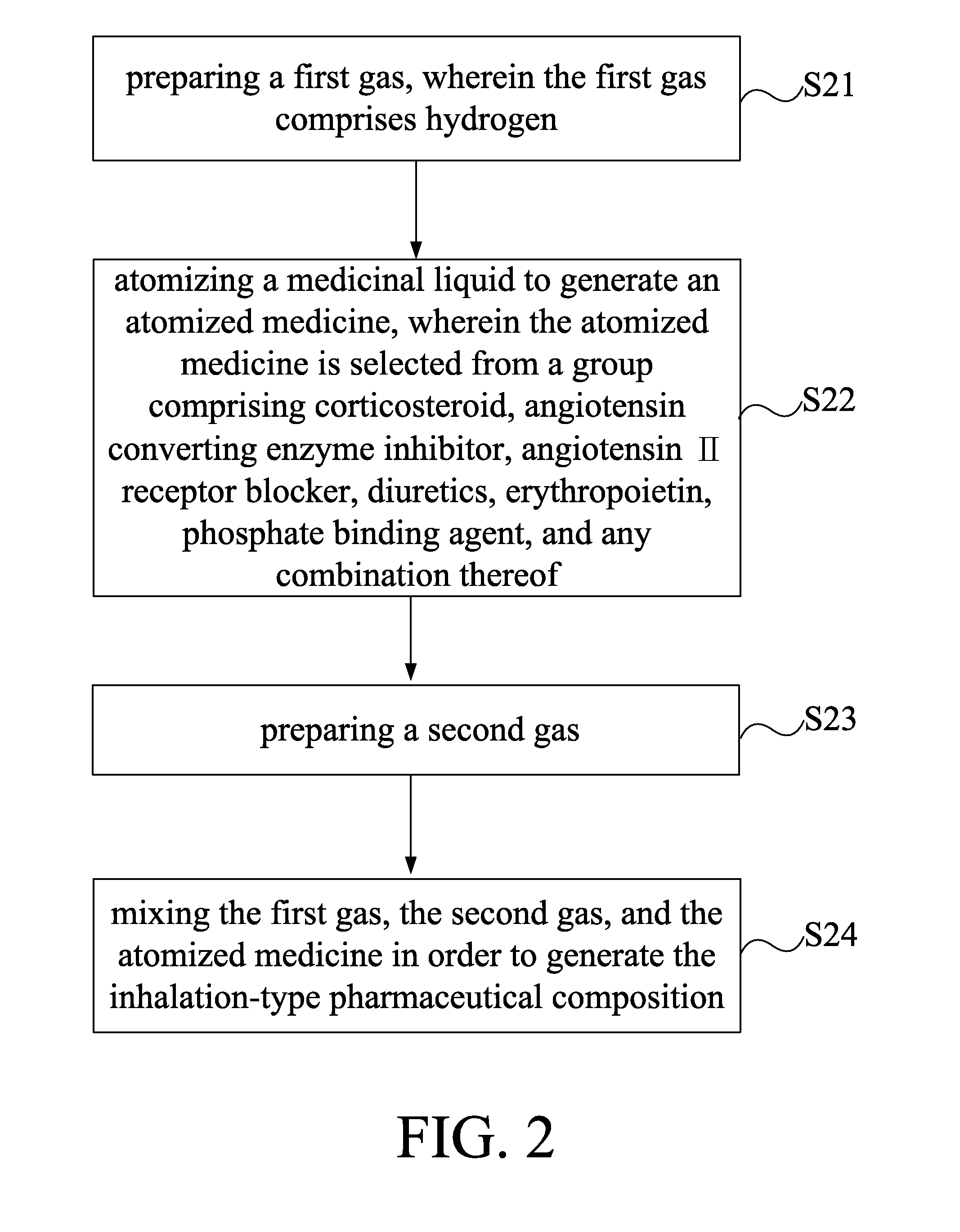

Inhalation-type pharmaceutical composition for the treatment of kidney disease and preparation method thereof

InactiveUS20150297513A1Promote absorptionGood curative effectPowder deliveryOrganic active ingredientsSide effectPhosphate

The present invention provides an inhalation-type pharmaceutical composition for kidney disease and preparation method thereof, comprising a first gas and an atomized medicine. The first gas comprises hydrogen. The gas volume concentration of hydrogen in the inhalation-type pharmaceutical composition is between 2 to 96%. The atomized medicine is selected from a group comprising corticosteroid, angiotensin converting enzyme inhibitor, angiotensin II receptor blocker, diuretics, erythropoietin, phosphate binding agent, and any combination thereof. The inhalation-type pharmaceutical composition of the present invention can remove harmful radicals in the body of the patient through the use of hydrogen while also increases the absorption effect of the medicine for the patient by using an atomized medicine. At the same time, because the use of the small amount of the vaporized pharmaceutical liquid can indirectly reduce the side effects on the user.

Owner:LIN HSIN YUNG

A sewage intercepting permeable brick

ActiveCN105155389BFlat surfaceEasy to walkSolid waste managementPaving gutters/kerbsBrickGroundwater pollution

The invention discloses a sewage interception water-permeable brick which comprises a brick body and filter pieces. The filter pieces comprise bags and filter objects located in the bags. The filter pieces comprise pearl wool sleeves, the non-woven bags and the filter objects located in the non-woven bags. An organic flocculant layer is arranged on the inner surface of each pearl wool sleeve. Each filter object is prepared from, by weight, 20-60 parts of flaky high-strength material, 20-50 parts of fine aggregate and 5-20 parts of binding agent, and the flaky high-strength material, the fine aggregate and the binding agent are mixed and compacted into a blocky structure. The flaky high-strength material is a mixture of one or two or more of long-laid shells, broken earthenware bricks and lamina schist, the fine aggregate is formed by mixing 5-50 parts of alkalescent porous minerals and 0-45 parts of carbonaceous filter materials by weight, and the binding agent is one of high-alumina cement, magnesium oxychloride cement, phosphate binding agent and hydration glass. The water-permeable brick has the beneficial effects that walking is facilitated, and heavy metal, toxic organic substances and colloid of water can be captured so as to avoid groundwater pollution.

Owner:QUANZHOU NORMAL UNIV

Use of derivatives with C-O-P bonds in patients with renal failure

The invention relates to the use of a derivative with C-O-P bonds in the form of controlled release for the treatment of patients with renal failure. The invention also relates to the use of said derived compounds together with other active substances, that can particularly be selected from the list comprising a calcimimetic, a vitamin, a phosphorus chelator, thiosulfate, biphosphonate, pyrophosphate, citrate, a diuretic, an antihypertensive and an anticholesterolemic agent.

Owner:SANIFIT THERAPEUTICS SA

Combination therapy of phosphate binders and vitamin k

PendingUS20220079891A1High levelLower Level RequirementsOrganic active ingredientsUrinary disorderCalcium BinderP phosphate

Owner:NATTOPHARMA

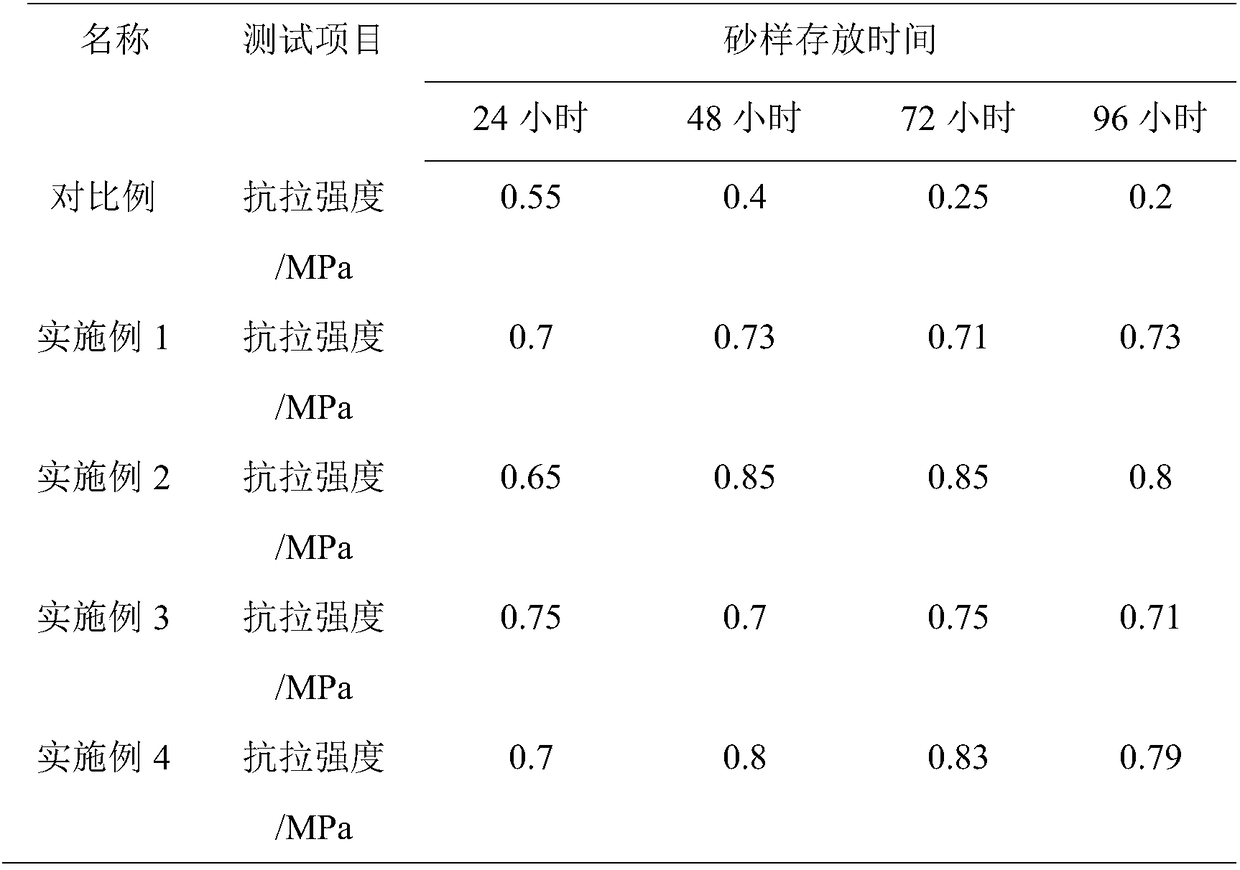

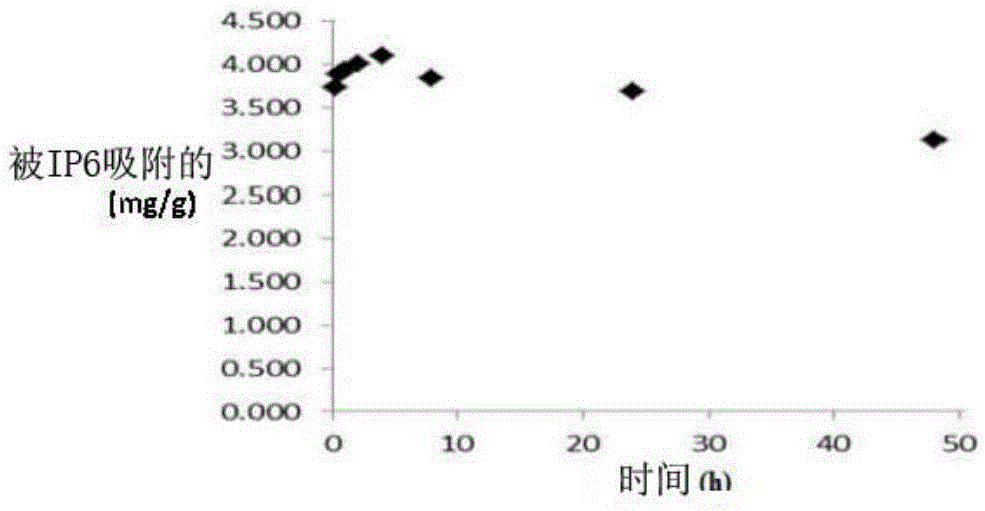

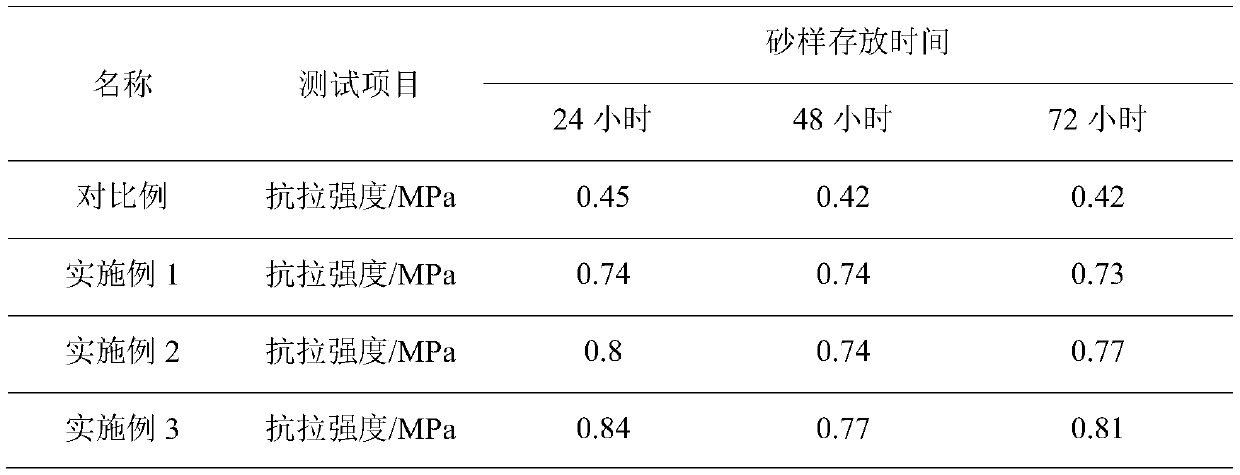

Matched liquid curing agent for phosphate binding agent in warm box process and using method of matched liquid curing agent

ActiveCN110496935AHigh tensile strengthReduce the amount addedFoundry mouldsFoundry coresHydrolysatePhosphate

The invention provides a matched liquid curing agent for a phosphate binding agent in the warm box process and a using method of the matched liquid curing agent. The matched liquid curing agent is prepared from a solution A and a solution B, and the mass ratio of the solution A and the solution B is (1.25-3):1, wherein the solution A is composed of a silane coupling agent KH-550 hydrolysate prepared from a silane coupling agent KH-550 and water at the mass ratio of 1:(1-5), and the solution B is composed of a sodium carbonate hydrolysate prepared from anhydrous sodium carbonate and water at the mass ratio of 1:3. The matched liquid curing agent can solve the technical problems that prepared sand moulds (cores) are unstable in strength in the storage process, and moulding sand mobility is poor; and operation is easy and convenient, cost is low, and the matched liquid curing agent can be applied and popularized.

Owner:HUBEI UNIV OF TECH

Use of derivatives with C-O-P bonds in patients with renal failure

The invention provides the use of a derivative with C-O-P bonds in the form of controlled release for the treatment of patients with renal failure. The invention also relates to the use of the derivative together with other active substances, that can particularly be selected from the list comprising a calcimimetic, a vitamin, a phosphorus chelator, thiosulfate, biphosphonate, pyrophosphate, citrate, a diuretic, an antihypertensive and an anticholesterolemic agent.

Owner:SANIFIT THERAPEUTICS SA

Phosphate binder modified by hydroxyethylidene diphosphonic acid and preparation method thereof

ActiveCN110625060BLow viscosityReduce intensityFoundry mouldsFoundry coresO-Phosphoric AcidSilicic acid

Owner:HUBEI UNIV OF TECH

Al-Mg-Cr Composite Spinel Brick

ActiveCN103030410BHigh temperature strengthImprove corrosion resistanceFireproof paintsMolten slagThermal shock

The invention is the field of refractory materials, which involves a kind of aluminum -magnesium chromium composite spine -spine tiles.At the quality percentage, the present invention includes the following raw materials: a particle size of 5-3mm plate-shaped Gang Jade 30-50%, 3-1mm plate-like Gangyu 15-35%, <0.088mm plate-shaped Gangyu 5-15%, <0.088mm magnesium magnesium magnesium magnesiumAluminum spikes are 2-15%, 1-0mm high chromium ore 5-30%, <0.088mm chromium green 1-10%, and a phosphate binding agent with a total weight of 2-5%of the above raw materials.The invention aluminum -magnesium chromium composite spine -spine tile melting point, high hardness, low pores, good thermal shock, anti -slag, especially silicon iron residue erosion and permeability, can meet the colorful high -temperature copper melting furnace, povertyizationThe use requirements of strict parts in the electric furnace, anode furnace, and flash furnace have significant economic benefits.

Owner:河南瑞泰耐火材料科技有限公司

Combination therapy of phosphate binders and vitamin k

PendingUS20200215000A1High serum phosphate levelReduced calcium levelOrganic active ingredientsUrinary disorderCalcium BinderP phosphate

Owner:KAYDENCE PHARMA AS

Water-based dotting glue and preparation method thereof

InactiveCN110066636AImprove adhesionGood formabilityPolyureas/polyurethane adhesivesFibre treatmentWater basedHigh strength concrete

The invention relates to water-based dotting glue. The water-based dotting glue is prepared from, by weight, 10-30 parts of a phosphoric acid-phosphate binding agent, 20-30 parts of silicon carbide, 20-30 parts of kyanite, 20-30 parts of zirconium dioxide, 20-30 parts of mullite, 10-20 parts of titanium dioxide, 5-10 parts of a reinforcing agent, 5-10 parts of an anti-cracking slow-release agent,9-11 parts of ceramic powder resin, 2-5 parts of an accelerator and 2-5 parts of a grinding aid. The dotting glue has the advantages that the ceramic powder resin has the functions of increasing the hardening speed of inorganic mineral nodules, improving the compactness and the like, so that the anti-burst performance of high-strength concrete at the high temperature is improved; the phosphoric acid-phosphate binding agent mainly achieves the effect of collecting microaggregates, correspondingly the using amount of cement can be decreased, the bonding force of the cement and aggregate is enhanced, and the fluidity of the concrete is improved, so that the compactness of the concrete is improved. The high-strength concrete made of the cement is subjected to a high-temperature effect under open fire at 1,200 DEG C for 1 hour, the appearance is kept complete, no crack is generated, and the compressive strength is not lower than 90 MPa.

Owner:ZHEJIANG QIMO NEW MATERIAL TECH CO LTD

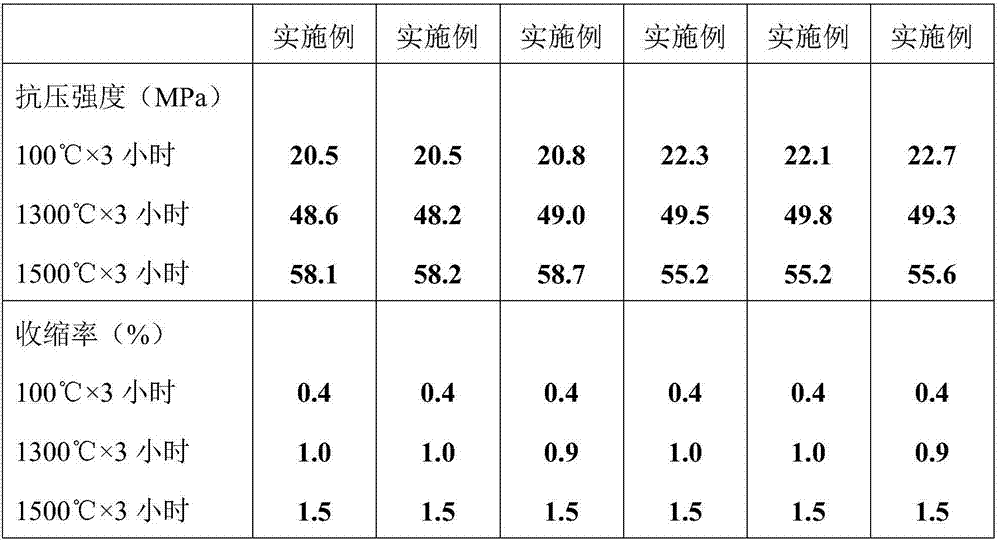

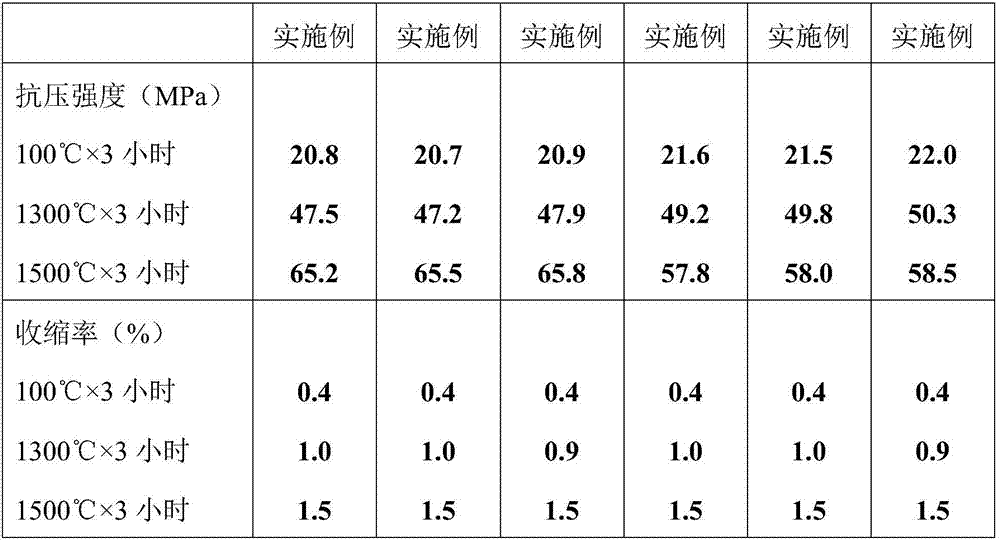

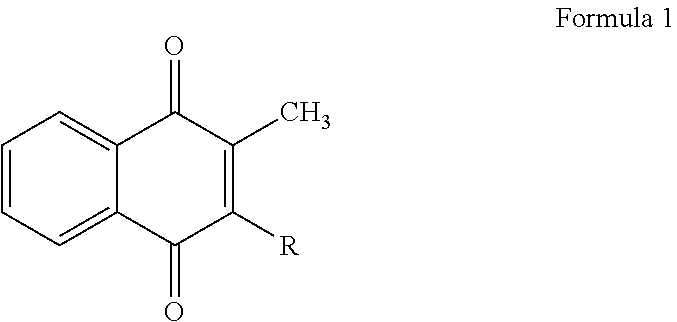

Phosphate binding agent modified by 1-hydroxyethylidene-1,1-diphosphonic acid and preparing method of phosphate binding agent

ActiveCN110625060AHigh strengthImprove high temperature resistanceFoundry mouldsFoundry coresFoundryPhosphate

The invention provides a phosphate binding agent modified by 1-hydroxyethylidene-1,1-diphosphonic acid and a preparing method of the phosphate binding agent. The phosphate binding agent modified by 1-hydroxyethylidene-1,1-diphosphonic acid is mainly prepared from, by mass percentage, 51.59-52.45% of industrial phosphoric acid, 11.83-12.03% of aluminum hydroxide powder, 0.61-0.62% of silicic acid,1.83-1.86% of boric acid, 1.22-1.24% of light magnesium oxide, 0.76-2.4% of 1-hydroxyethylidene-1,1-diphosphonic acid and 30.53-31.04% of water. According to the phosphate binding agent modified by 1-hydroxyethylidene-1,1-diphosphonic acid, 1-hydroxyethylidene-1,1-diphosphonic acid is adopted as a modifier, and even under the condition of a small addition amount, the viscosity of the binding agentcan be significantly lowered, the strength of a prepared sand sample can be significantly improved, added raw materials participate in the reaction to the greatest extent, few residues are generated,water loss is reduced to guarantee that the binding agent has low viscosity, and the fluidity of foundry sand is improved.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com