Matched liquid curing agent for phosphate binding agent in warm box process and using method of matched liquid curing agent

A phosphate and binder technology, which is applied in the field of supporting liquid curing agent for phosphate binder in the warm core box process, can solve the problems of poor fluidity and unstable strength of molding sand, and achieve low cost, easy operation and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

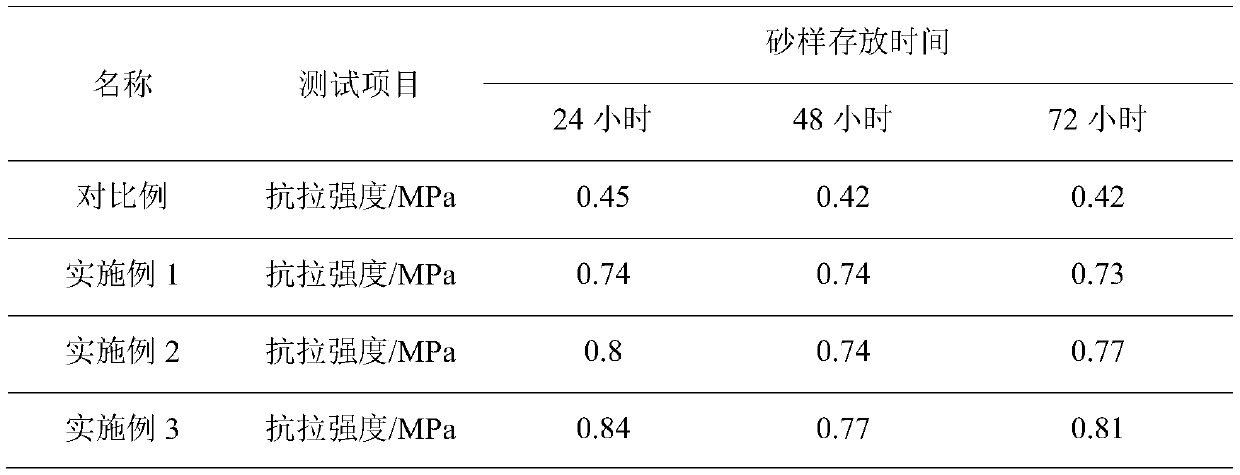

Embodiment 1

[0022] 1. Mix the silane coupling agent KH-550 and water evenly at a mass ratio of 1:1, and obtain liquid A after the coupling agent is fully hydrolyzed, and set aside;

[0023] 2. Mix anhydrous sodium carbonate and water evenly at a mass ratio of 1:3 to obtain liquid B for later use;

[0024] 3. Weigh 1000g of raw sand, 25g of phosphate binder, 5g of solution A, and 4g of solution B for later use.

[0025] 4. Mix the raw sand with liquid A and stir for 30 seconds, then add phosphate binder and stir for 60 seconds, and finally add liquid B and stir for 60 seconds to produce sand.

[0026] 5. Molding sand performance test: Use the coated sand sample making machine to make a standard "8"-shaped sand sample, set the mold temperature at 60°C, sand injection pressure 0.4Mpa, blowing pressure 0.2Mpa, blowing time 2 minutes, demold after hardening Store and test the tensile strength every 24 hours.

Embodiment 2

[0028] 1. Mix the silane coupling agent KH-550 and water evenly at a mass ratio of 1:3, and obtain liquid A after the coupling agent is fully hydrolyzed, and set aside;

[0029] 2. Mix anhydrous sodium carbonate and water evenly at a mass ratio of 1:3 to obtain liquid B, which is set aside;

[0030] 3. Weigh 1000g of raw sand, 20g of phosphate binder, 6g of A solution and 2g of B solution for later use.

[0031] 4. Mix the raw sand with liquid A and stir for 40 seconds, then add phosphate binder and stir for 70 seconds, and finally add liquid B and stir for 70 seconds to produce sand.

[0032] 5. Molding sand performance test: Use the coated sand sample making machine to make a standard "8"-shaped sand sample, set the mold temperature at 60°C, sand injection pressure 0.4Mpa, blowing pressure 0.2Mpa, blowing time 2 minutes, demold after hardening Store and test the tensile strength every 24 hours.

Embodiment 3

[0034] 1. Mix the silane coupling agent KH-550 and water evenly at a mass ratio of 1:5, and obtain liquid A after the coupling agent is fully hydrolyzed, and set aside;

[0035] 2. Mix anhydrous sodium carbonate and water evenly at a mass ratio of 1:3 to obtain liquid B, which is set aside;

[0036] 3. Weigh 1000g of raw sand, 24g of phosphate binder, 8g of solution A, and 3g of solution B for later use.

[0037] 4. Mix the original sand with liquid A and stir for 50 seconds, then add phosphate binder and stir for 80 seconds, and finally add liquid B and stir for 80 seconds to produce sand.

[0038] 5. Molding sand performance test: Use the coated sand sample making machine to make a standard "8"-shaped sand sample, set the mold temperature at 60°C, sand injection pressure 0.4Mpa, blowing pressure 0.2Mpa, blowing time 2 minutes, demold after hardening Store and test the tensile strength every 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com