Recovery and utilization method of electric fused zirconia alumina grinding waste material

A technology for grinding waste and fused zirconium, applied in the field of refractory materials, can solve the problems of further improvement of performance, expansion of zirconium raw material sources, waste of zirconium resources, etc., and achieves the effects of low cost, low sintering shrinkage and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

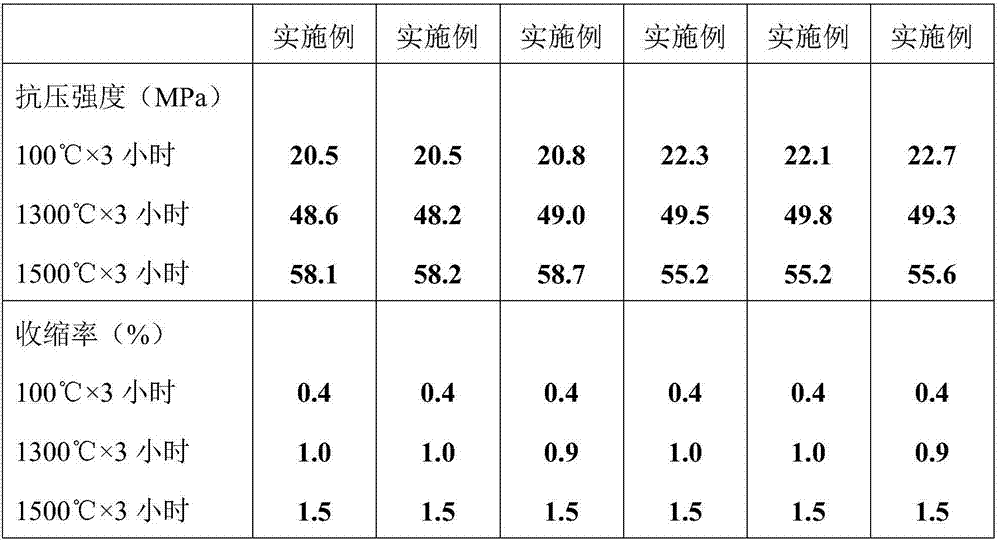

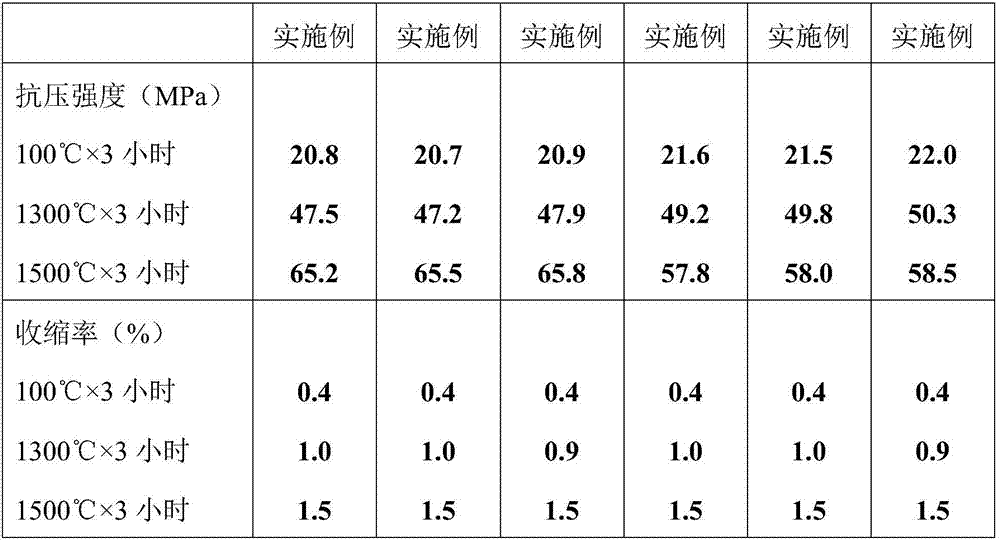

Examples

Embodiment 1

[0015] The method for recycling fused zirconium corundum grinding waste in this embodiment includes the following steps: ① The waste coolant containing fused zirconium corundum powder produced after grinding by the fused AZS-33 zirconium corundum brick grinder is drained to The sediment is placed in the recovery tank to collect the wet sludge settled on the bottom of the tank. ②The collected wet powder sludge is naturally dried and crushed, then dried with hot air and collected to obtain recycled powder. The recycled powder contains 33.2wt% ZrO 2 , 51.6wt% Al 2 O 3 , 14.8wt% SiO 2 , 0.2wt% Fe 2 O 3 , The balance is other impurities, and the particle size is less than 50μm. ③ Based on 100 parts by weight of the recycled powder, take 8.0 parts by weight of phosphoric acid (85%), 1.2 parts by weight of citric acid, and 0.3 parts by weight of iminodiacetic acid, mix them with the recycled powder, and then manually mash them. The ramming material can be obtained by beating or rammin...

Embodiment 2

[0017] The method for recycling fused zirconium corundum grinding waste in this embodiment includes the following steps: ① The waste coolant containing fused zirconium corundum powder produced after grinding by the fused AZS-33 zirconium corundum brick grinder is drained to The sediment is placed in the recovery tank to collect the wet sludge settled on the bottom of the tank. ②The collected wet powder sludge is naturally dried and crushed, then dried with hot air and collected to obtain recycled powder. The recycled powder contains 33.2wt% ZrO 2 , 51.6wt% Al 2 O 3 , 14.8wt% SiO 2 , 0.2wt% Fe 2 O 3 , The balance is other impurities, and the particle size is less than 50μm. ③ Based on 100 parts by weight of recycled powder, take 8.0 parts by weight of phosphoric acid (85%), 1.3 parts by weight of hydroxyacetic acid, and 0.2 parts by weight of iminodiacetic acid, mix them with the recycled powder, and then perform manual ramming. The ramming material can be obtained by beating or...

Embodiment 3

[0019] The method for recycling fused zirconium corundum grinding waste of this embodiment includes the following steps: ① The waste coolant containing fused zirconium corundum powder produced after grinding by the fused AZS-33 zirconium corundum brick grinder is drained to The sediment is placed in the recovery tank to collect the wet sludge settled on the bottom of the tank. ②The collected wet powder sludge is naturally dried and crushed, then dried with hot air and collected to obtain recycled powder. The recycled powder contains 33.2wt% ZrO 2 , 51.6wt% Al 2 O 3 , 14.8wt% SiO 2 , 0.2wt% Fe 2 O 3 , The balance is other impurities, and the particle size is less than 50μm. ③Based on 100 parts by weight of recycled powder, take 8.7 parts by weight of aluminum dihydrogen phosphate (60%), 1.2 parts by weight of malic acid, and 0.3 parts by weight of DL-2-aminosuccinic acid to combine them with the recycled powder. Mix together and then perform manual ramming or pneumatic hammer ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com