Phosphate binder self-hardening sand curing agent and preparation method thereof

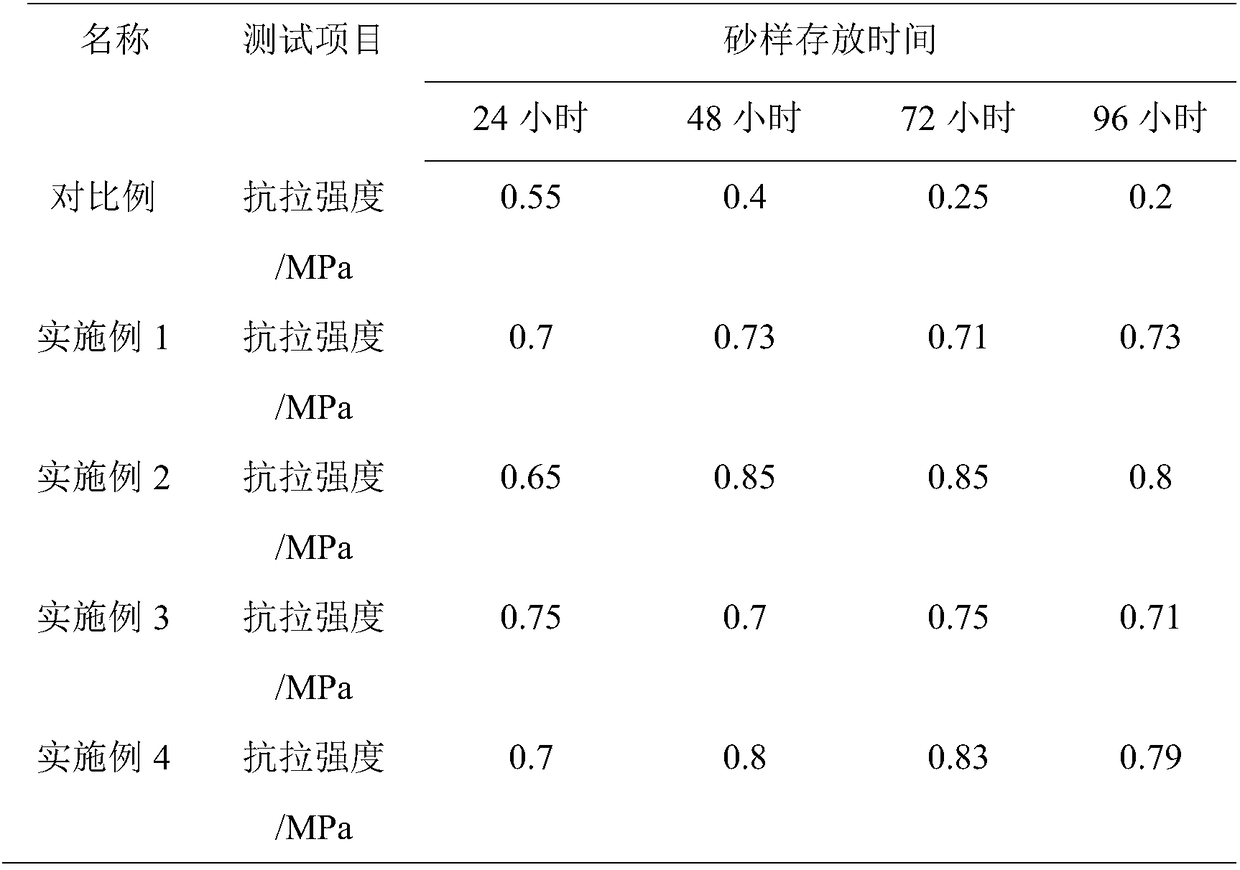

A curing agent and binder technology, applied in the field of molding materials, can solve problems such as poor strength stability, and achieve the effects of good performance, green storage, and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take a certain amount of metallurgical magnesia powder and crush it until the particle size is 1300-1600 mesh;

[0027] 2) Weigh 100g of crushed metallurgical magnesia powder, 15g of silica sol, 5g of coupling agent, 5g of urea, and 100g of water for subsequent use;

[0028] 3) Take 50g of water in 2) and add it to the mixing bucket, start the mixer, add urea, silica sol, and coupling agent into the mixing bucket respectively and stir, and at the same time slowly add the remaining 50g of water, continue stirring until it is uniform, and then set aside;

[0029] 4) Take the mixed solution in step 3) and slowly add it to the magnesia powder in 1), and stir while adding, until there is no obvious granular shape, and a suspension liquid mixture is obtained;

[0030] 5) Place the suspended liquid mixture in an oven for 6 hours at 100°C, then take it out and crush it until the particle size is 325-400 mesh;

[0031] 6) Weigh 1000g of raw sand, 25g of phosphate binder, and...

Embodiment 2

[0033] 1) Take a certain amount of metallurgical magnesia powder and crush it until the particle size is 1300-1600 mesh;

[0034] 2) Take by weighing 110g of crushed magnesia powder, 18g of silica sol, 3.5g of coupling agent, 7g of urea, and 105g of water for subsequent use;

[0035] 3) Take 50g of water in 2) and put it into the mixing bucket, start the mixer, add urea, silica sol, and coupling agent into the mixing bucket respectively and stir, and at the same time slowly add the remaining 60g of water, continue stirring until it is uniform, and then set aside;

[0036] 4) Take the mixed solution in step 3) and slowly add it to the magnesia powder in 1), and stir while adding, until there is no obvious granular shape, and a suspension liquid mixture is obtained;

[0037] 5) Place the suspended liquid mixture in an oven for 6 hours at 100°C, then take it out and crush it until the particle size is 325-400 mesh;

[0038] 6) Weigh 1000g of raw sand, 25g of phosphate binder, an...

Embodiment 3

[0040] 1) Take a certain amount of metallurgical magnesia powder and crush it until the particle size is 1300-1600 mesh;

[0041] 2) Weigh 120g of crushed magnesia powder, 20g of silica sol, 4.5g of coupling agent, 8g of urea, and 115g of water for subsequent use;

[0042] 3) Take 55g of water in 2) and put it into the mixing bucket, start the mixer, add urea, silica sol, and coupling agent into the mixing bucket respectively and stir, and at the same time slowly add the remaining 60g of water, continue stirring until uniform and then set aside;

[0043] 4) Take the mixed solution in step 3) and slowly add it to the magnesia powder in 1), and stir while adding, until there is no obvious granular shape, and a suspension liquid mixture is obtained;

[0044] 5) Place the suspended liquid mixture in an oven for 6 hours at 100°C, then take it out and crush it until the particle size is 325-400 mesh;

[0045] 6) Weigh 1000g of raw sand, 25g of phosphate binder, and 2.5g of curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com