Phosphate binding agent modified by 1-hydroxyethylidene-1,1-diphosphonic acid and preparing method of phosphate binding agent

A technology of hydroxyethylidene diphosphonic acid and phosphate, which is used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problem of insignificant improvement of sand sample strength and fluidity, poor fluidity of molding sand, unstable performance, etc. problem, to achieve the effect of enhanced wrapping effect, enhanced bonding performance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

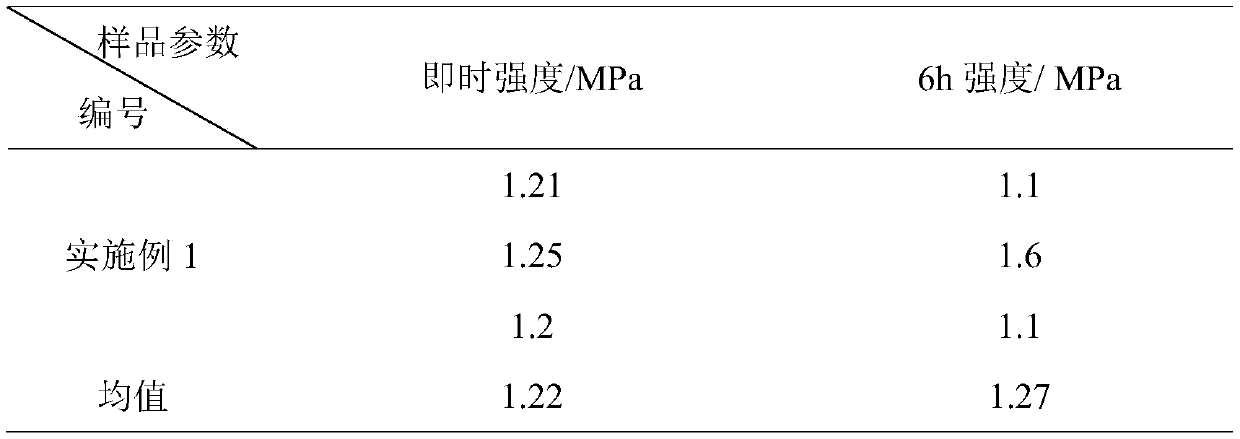

Embodiment 1

[0028] Preparation of Phosphate Binder Modified by Hydroxyethylidene Diphosphonic Acid

[0029] 1. Raw material ratio

[0030] 338g of 85% industrial phosphoric acid, 77.5g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 4.9g of hydroxyethylidene diphosphonic acid, and 200g of purified water.

[0031] 2. Preparation steps

[0032] (1) Add phosphoric acid into the reaction kettle and heat to 180-200°C while stirring;

[0033] (2) adding aluminum hydroxide powder in the reaction kettle several times in a small amount, and continuing to stir until the reaction solution is transparent;

[0034] (3) Add 50g of water, heat and stir until the temperature of the reaction solution returns to the temperature before adding water;

[0035] (4) Add boric acid powder, continue heating and stirring until the reaction solution is transparent;

[0036] (5) Add silicic acid powder, continue heating and stirring until the reaction so...

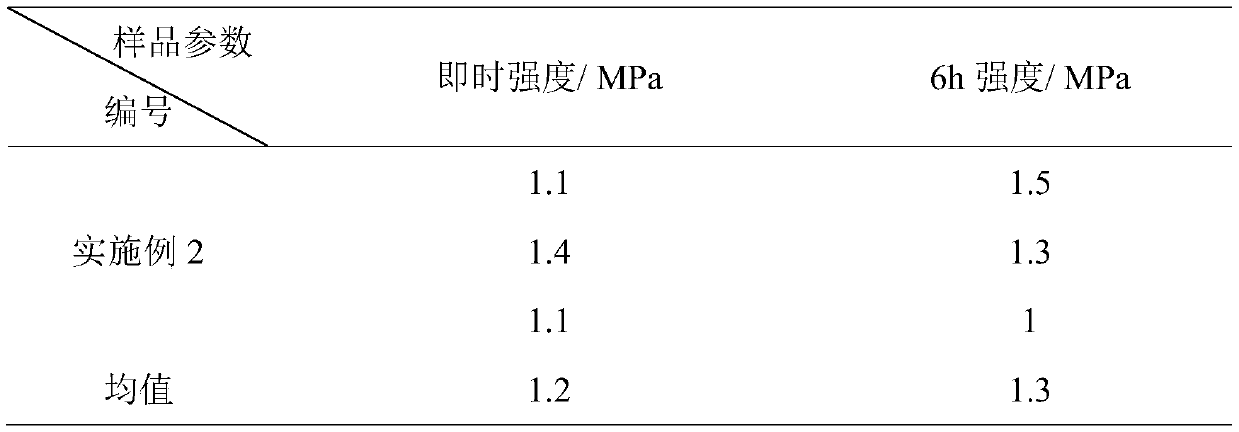

Embodiment 2

[0043] Preparation of Phosphate Binder Modified by Hydroxyethylidene Diphosphonic Acid

[0044] 1. Raw material ratio

[0045] 338g of 85% industrial phosphoric acid, 77.5g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 9.8g of hydroxyethylidene diphosphonic acid, and 200g of purified water.

[0046] 2. The preparation steps are the same as those in Example 1.

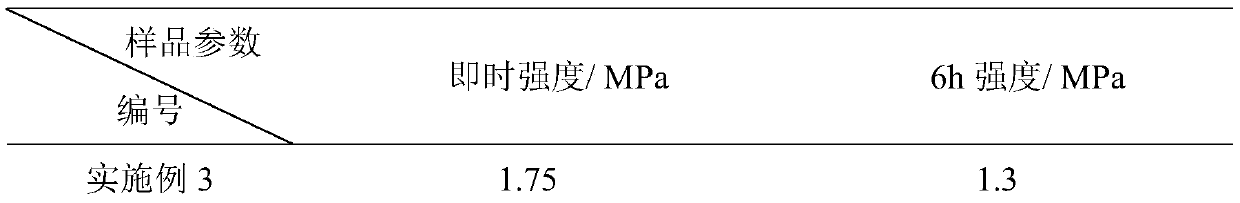

Embodiment 3

[0048] Preparation of Phosphate Binder Modified by Hydroxyethylidene Diphosphonic Acid

[0049] 1. Raw material ratio

[0050] 338g of 85% industrial phosphoric acid, 77.5g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 15.7g of hydroxyethylidene diphosphonic acid, 200g of purified water.

[0051] 2. The preparation steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com