Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

A technology of phosphate binder and silicon carbide bricks, which is applied in the field of refractory production, can solve the problems of poor oxidation resistance, increased labor intensity, and high firing temperature, and achieves improved cold strength, saving raw material costs, and low firing temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

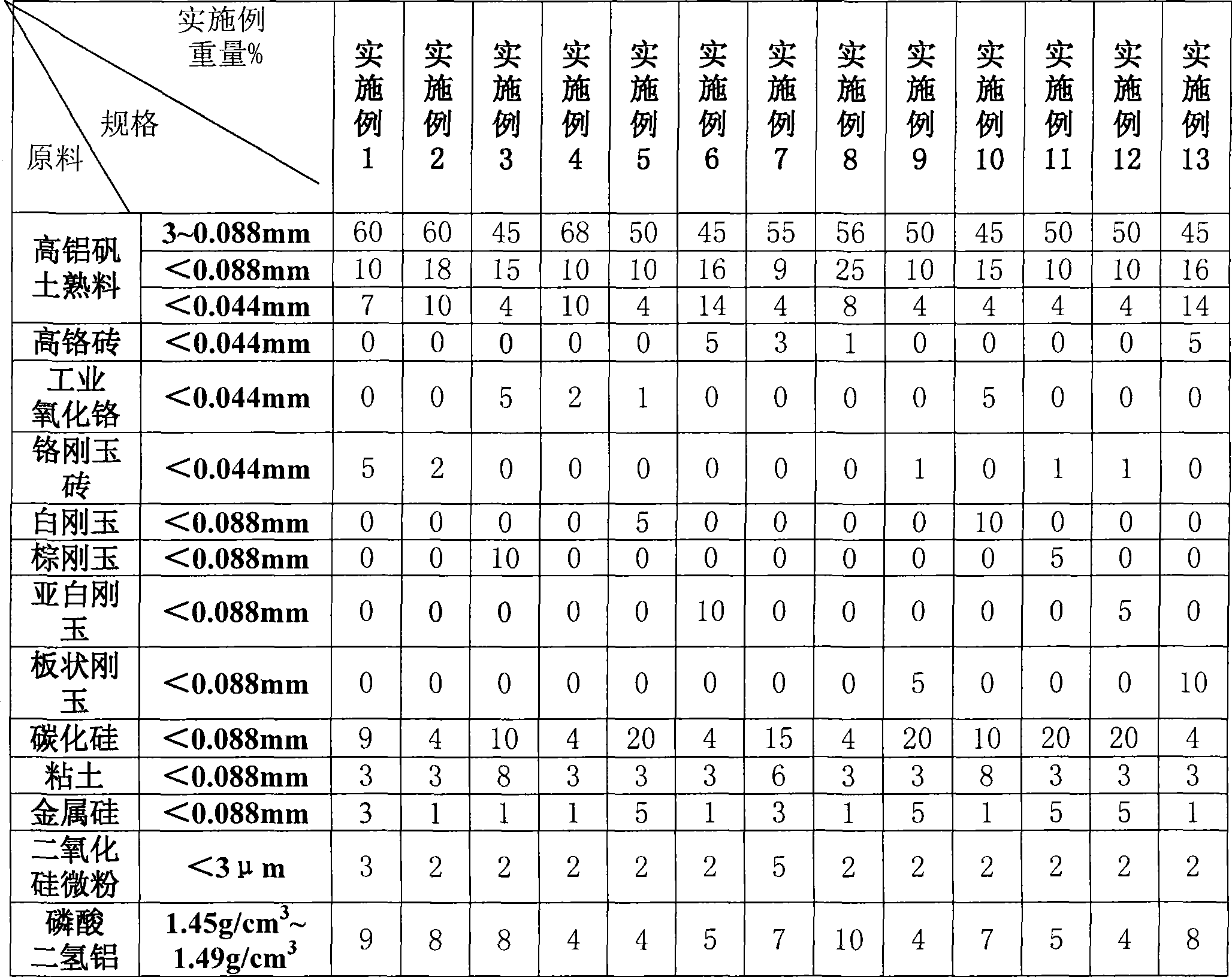

Embodiment 1

[0030] a. Weigh high alumina bauxite clinker with a particle size of less than 0.044mm, chromium oxide-containing materials with a particle size of less than 0.044mm, and metal silicon with a particle size of less than 0.044mm according to the raw materials, specifications, and weight percentages corresponding to Example 1 in Attached Table 2 The fine powder prepared by the method of co-mixing and grinding by dry method is set aside;

[0031] B. Take the required raw materials by weighing the required raw materials according to the silicon dioxide micropowder and particle raw materials, specifications and weight percentages corresponding to Example 1 in Table 2, and set aside;

[0032] c. Take by weighing the phosphate binder-aluminum dihydrogen phosphate binder according to the corresponding raw materials, specifications and weight percentages of Example 1 in Table 2, and set aside;

[0033] d. Mix the fine powder, silicon dioxide micropowder and granular raw materials obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com