A sewage intercepting permeable brick

A technology of permeable bricks and grass-planting bricks, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of uneven grass-planting bricks and unfavorable walking, so as to achieve strong installation applicability and improve sewage interception capacity. , the effect of convenient walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

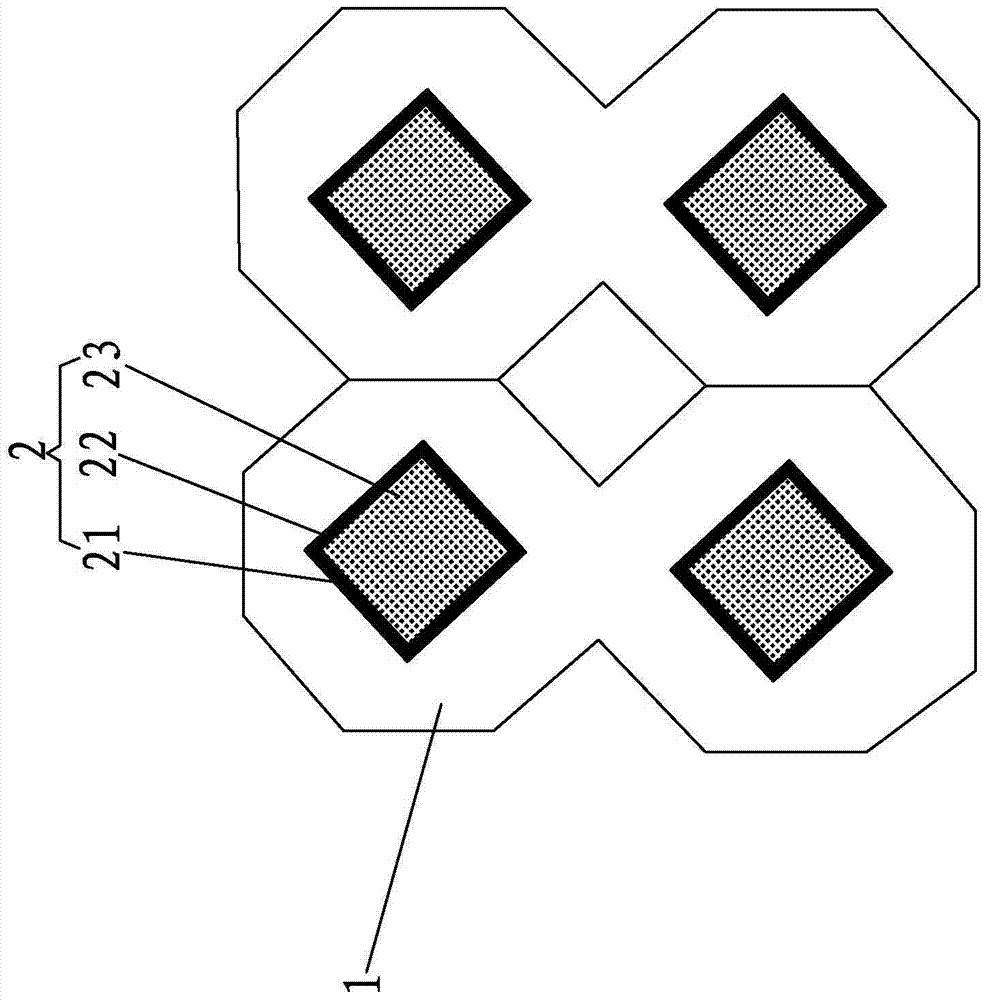

[0038] 1. Purchase the pearl cotton cover 21, the grass planting brick 1 and the non-woven bag body 22;

[0039] 2. Weigh its particle size as 0.5-20cm 2 Seashore aged shells, its particle diameter is the synthetic magnesite of 0.1-2mm (this synthetic magnesite is the general material of porous magnesium carbonate hard block fragmentation), its particle diameter is the sulfonated coal filter material of 2-4mm, and Magnesium oxychloride cement, wherein: the total weight of filtrate is 100 parts, seashore aged shells are 40 parts, synthetic magnesite is 25 parts, sulfonated coal filter material is 25 parts, magnesium oxychloride cement is 10 parts, After preparing the materials, they are mixed together to obtain the mixture;

[0040] 3. Fix 22 sets of non-woven bags in the honeycomb plate mold hole of the shaker, then add the mixture in step 2 into the non-woven bag, and vibrate horizontally while gradually feeding, and intermittently The mixture in the non-woven bag body is p...

Embodiment 2

[0046] 1. Purchase the pearl cotton cover 21, the grass planting brick 1 and the non-woven bag body 22;

[0047] 2. Weigh its area as 3-15cm 2 Broken thin ceramic bricks, broken slag with a particle size of 0.1-2mm and high calcium and magnesium content (the slag itself contains a large amount of unburned carbon, so there is no need to add activated carbon filter material), sodium hexametaphosphate and bentonite, Wherein: the total weight is 100 parts in terms of filtrate, 60 parts of broken ceramic tiles, 30 parts of slag, 5 parts of sodium hexametaphosphate, and 5 parts of bentonite, which are mixed together after preparing materials to obtain a mixture;

[0048] 3. Fix 22 sets of non-woven bags in the honeycomb plate mold hole of the shaker, then add the mixture in step 2 into the non-woven bag, and vibrate horizontally while gradually feeding, and intermittently The mixture in the non-woven bag is pressed downward by the elastic body, and the non-woven bag with the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com