Phosphate combined low-aluminum Guimo brick and preparation method thereof

A technology of phosphate and silicon molybdenum bricks, which is applied in the field of refractory material production, can solve the problems of decreased alkali resistance of materials, increased maintenance costs, frequent maintenance and other problems, and achieves the goals of improving high temperature resistance, good alkali resistance, and reducing consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

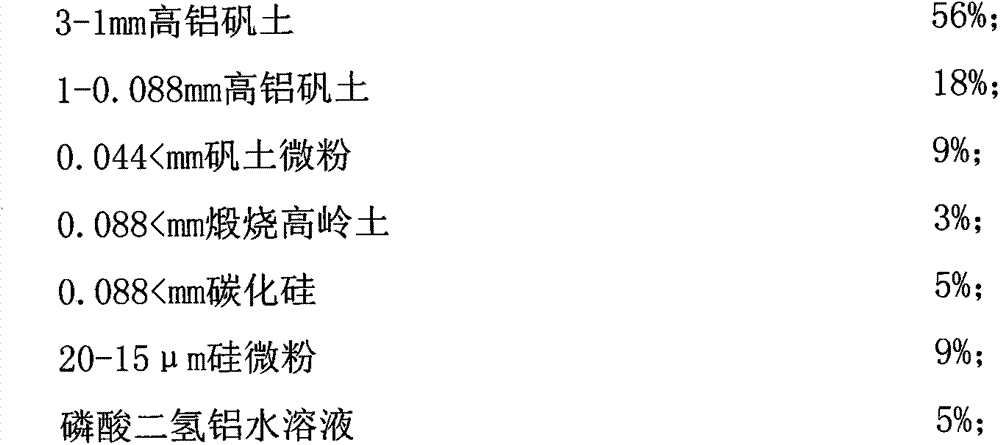

[0012] (1) Preparation of materials

[0013]

[0014] 1) Mix the raw materials according to the formula ratio, and then add phosphate binder; 2) Carry out material trapping, back-rolling, machine pressing, and drying; 3) Heat the dried adobe to 500°C and keep it warm for 3 hours.

Embodiment 2

[0016] (1) Preparation of materials

[0017]

[0018] 1) Mix the raw materials according to the formula ratio, and then add phosphate binder; 2) Carry out material trapping, back-rolling, machine pressing, and drying; 3) Heat the dried adobe to 530°C for 3 hours.

Embodiment 3

[0020] (1) Preparation of materials

[0021]

[0022] 1) Mix the three-grade high-alumina bauxite aggregate and micro-powder binder in proportion, and then add phosphate binder; 2) Carry out material trapping, back-rolling, machine pressing, and drying; 3) Dry bricks are heated to 530°C temperature for 3 hours.

[0023] The low-alumina silica molybdenum bricks prepared by the above implementation examples are used for routine experimental analysis. The performance parameters of each finished product are compared with those of ordinary alkali-resistant bricks, as shown in the table below:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com