Composite curing agent for phosphate casting binder and preparation method of composite curing agent

A technology of composite curing agent and binder, which is applied in the direction of casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of low curing strength and difficult control of reaction speed, and achieve appropriate demoulding time and moderate demoulding time , good reusability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

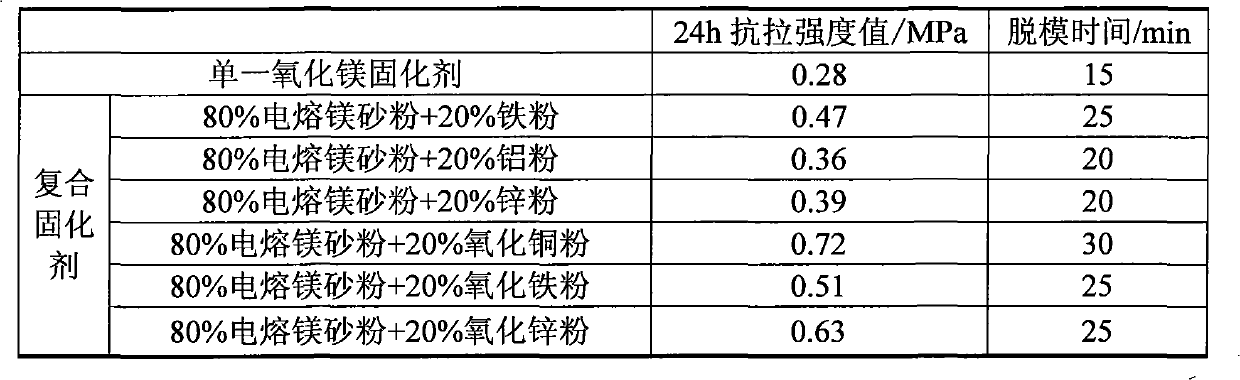

Embodiment 1

[0017] With 80 mass parts of magnesium oxide content greater than 96% (weight), 1000 mesh fused magnesia powder as the main body of the curing agent, then add 20 mass parts of iron powder, after preliminary stirring, pour into the rubber tank of the ball mill, ball mill 2 hours to make a composite curing agent.

Embodiment 2

[0019] With 90 mass parts of magnesium oxide content greater than 96% (weight), 1000 mesh fused magnesia powder as the main body of the curing agent, then add 10 mass parts of aluminum powder, after preliminary stirring, pour into the rubber tank of the ball mill, ball mill 2 hours to make a composite curing agent.

Embodiment 3

[0021] With 70 parts by mass of magnesium oxide content greater than 96% (weight), 1000 mesh fused magnesia powder as the main body of the curing agent, then add 30 parts by mass of zinc powder, after preliminary stirring, pour into the rubber tank of the ball mill, ball mill 2 hours to make a composite curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com