Water-based self-drying casting paint, and preparation method and application method

A casting coating, self-drying technology, applied in casting molding equipment, coatings, molds, etc., can solve the problems of non-flammable and non-explosive, and achieve the effect of dense coating, tight bonding and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

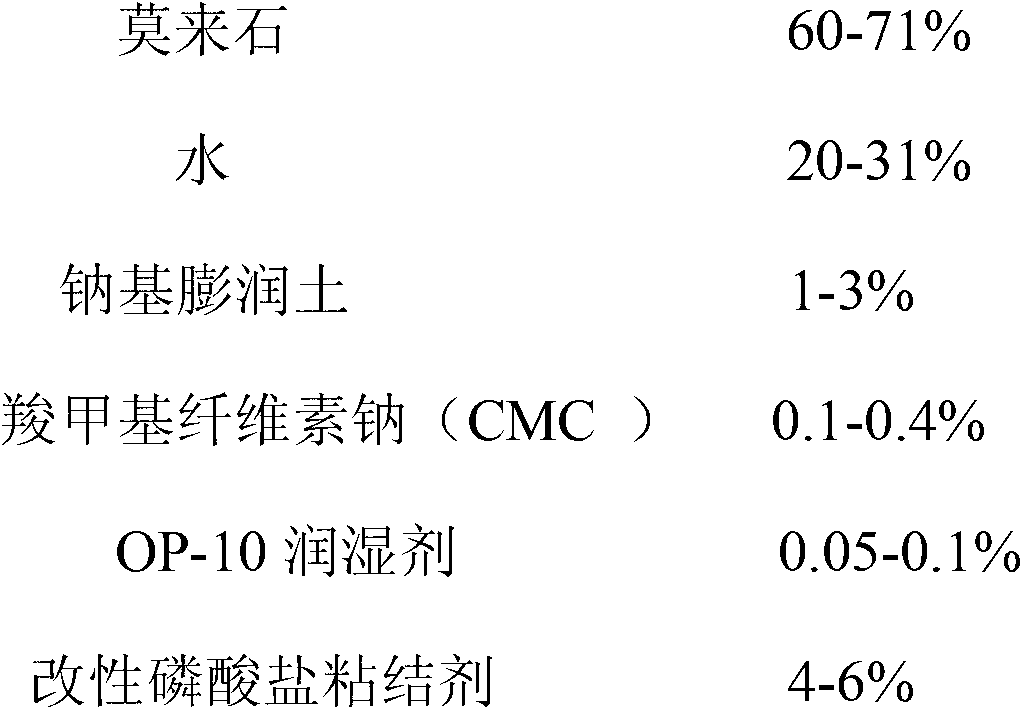

[0039] Table 1 is 6 groups of formulas (raw material components and content) of the present invention in the following table

[0040]

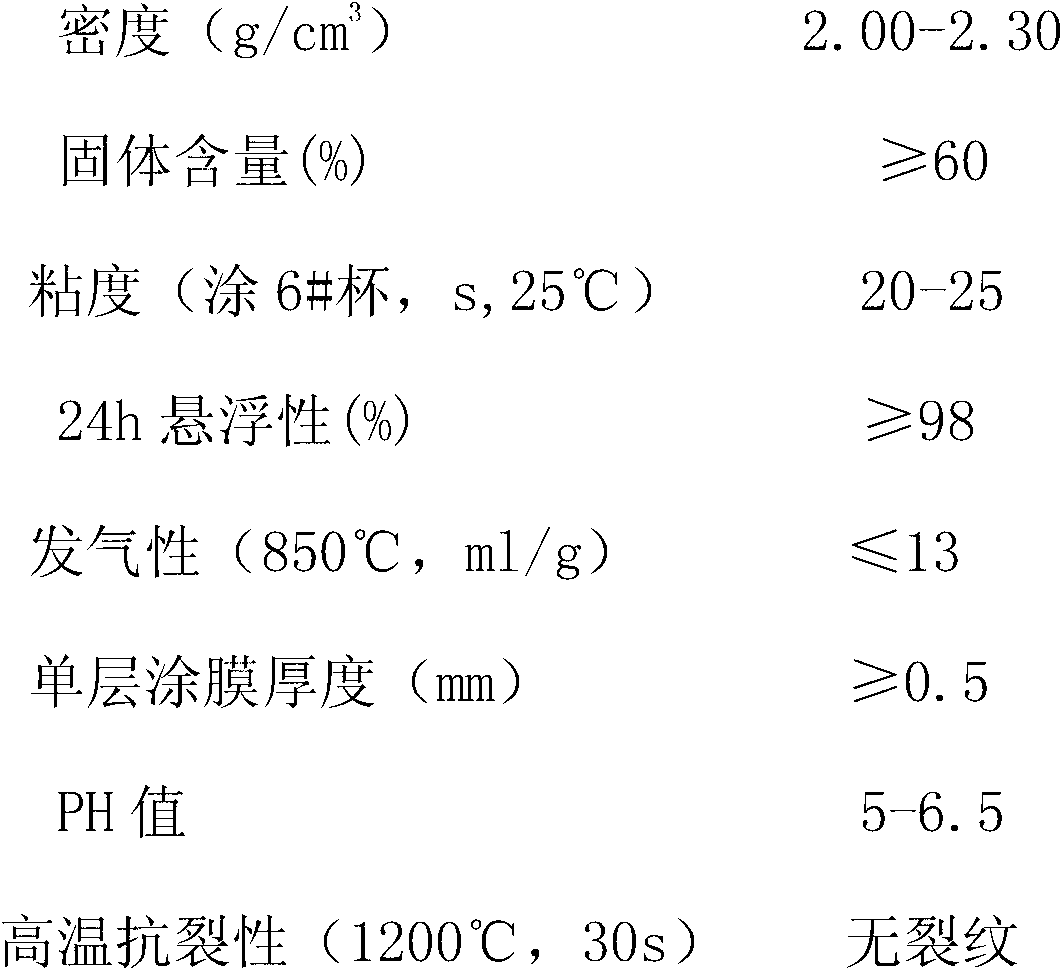

[0041] The above raw materials are required to meet the following indicators:

[0042] Mullite: Al 2 o 3 ≥75%, the average particle size is 325 mesh; water: fresh and clean tap water;

[0043] Sodium bentonite: expansion capacity ≥ 20ml / g, water content ≤ 10%, particle size 300-325 mesh.

[0044] Sodium carboxymethyl cellulose: medium viscosity, dynamic viscosity of 2% aqueous solution is 300-600MPa·s, pH value: 6.5-8.0;

[0045] The specific preparation method of the modified phosphate binder: first, aluminum hydroxide and industrial phosphoric acid with a mass concentration of 85% are added to the three-port reaction kettle according to the molar ratio of 1:3, and the stirrer is started, and the temperature is slowly raised to 100°C At this time, phosphoric acid reacts violently with aluminum hydroxide, and the reaction material is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com