Curing agent for inorganic phosphate binder precoated sand and application thereof

A technology of inorganic phosphate and binder, which is used in casting molding equipment, molds, cores, etc., can solve the problems of insufficient strength and poor fluidity, and achieve the effect of improving fluidity and good surface safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

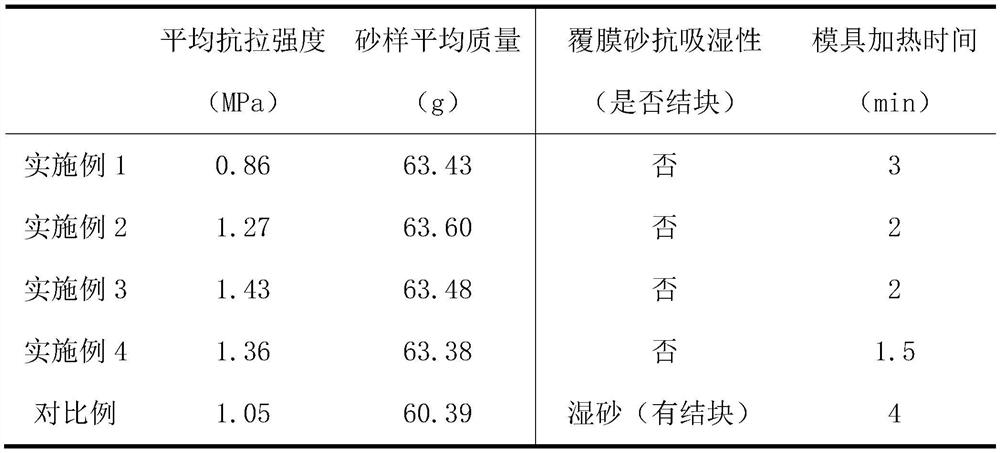

Examples

Embodiment 1

[0043] 1. Weigh 1000g of standard sand, 2g of silane coupling agent, and set aside;

[0044] 2. Add the standard sand and silane coupling agent into the mixer and stir for 90 seconds;

[0045] 3. Weigh and mix 25g of phosphate binder, 2g of citric acid aqueous solution with a mass ratio of 1:2, and 25g of aluminum sulfate octadecahydrate, and then add it to the sand prepared in step 2 and continue sand mixing for 120s;

[0046] 4. Put the wet sand prepared in step 3 in a hot air mixer, and feed hot air at 40°C while stirring. When the sand particles in the mixer are evenly dispersed and there is no obvious agglomeration, dry coated sand is prepared and passed through sieving. Afterwards, keep it airtight for later use;

[0047] 5. Add 30g of PVP-coated magnesia powder to the above dry coated sand and mix the sand for 30 seconds,

[0048] 6. Use the core shooter to shoot the sand, the mold temperature is 130°C, the mold heating time is 3min, and the mold is solidified and for...

Embodiment 2

[0051] 1. Weigh 1000g of standard sand, 2g of silane coupling agent, and set aside;

[0052]2. Add the standard sand and silane coupling agent into the mixer and stir for 90 seconds;

[0053] 3. Weigh and mix 30g of phosphate binder, 4g of citric acid aqueous solution with a mass ratio of 1:2, and 30g of aluminum sulfate octadecahydrate, and then add it to the sand prepared in step 2 and continue sand mixing for 120s;

[0054] 4. Put the wet sand prepared in step 3 in a hot air mixer, and feed hot air at 45°C while stirring. When the sand particles in the mixer are evenly dispersed and there is no obvious agglomeration, dry coated sand is prepared and passed through sieving. Afterwards, keep it airtight for later use;

[0055] 5. Add 40g of PVP-coated magnesia powder to the above-mentioned dry coated sand, mix the sand for 30 seconds, and use a core shooter to shoot the sand. The mold temperature is 150°C, and the mold heating time is 2 minutes to solidify and form;

[0056]...

Embodiment 3

[0058] 1. Weigh 1000g of standard sand, 4g of silane coupling agent, and set aside;

[0059] 2. Add the standard sand and silane coupling agent into the mixer and stir for 90 seconds;

[0060] 3. Weigh and mix 35g of phosphate binder, 6g of citric acid aqueous solution with a mass ratio of 1:2, and 30g of aluminum sulfate octadecahydrate, and then add it to the sand prepared in step 2 and continue sand mixing for 120s;

[0061] 4. Put the wet sand prepared in step 3 in a hot air mixer, and feed hot air at 45°C while stirring. When the sand particles in the mixer are evenly dispersed and there is no obvious agglomeration, dry coated sand is prepared and passed through sieving. Afterwards, keep it airtight for later use;

[0062] 5. Add 50g of PVP-coated magnesia powder to the above-mentioned dry coated sand, mix the sand for 30 seconds, and use a core shooter to shoot the sand. The mold temperature is 150°C, and the mold heating time is 2 minutes to solidify and form;

[0063...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com