High-strength lithium battery separator and production technology thereof

A lithium battery diaphragm and production process technology, applied in the field of high-strength lithium battery diaphragm and its production process, can solve the problems of not improving the safety of the lithium ion battery diaphragm, affecting the electrical performance of the lithium ion battery, and peeling off of the ceramic coating. Excellent chemical stability, extended life, small pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

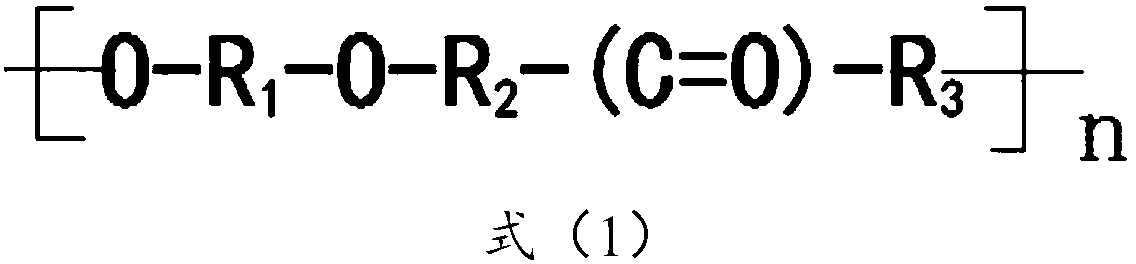

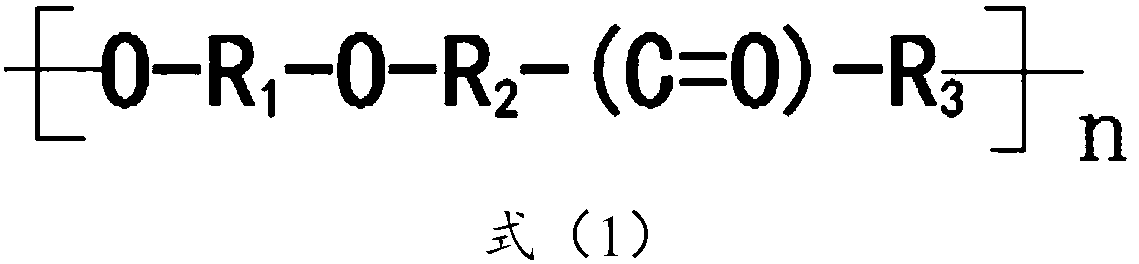

[0029] (1) Preparation of polyether ether ketone

[0030] Weigh 23.1kg 3,3'-dimethyl-4,4'-difluorobenzophenone, 10.4kg 2-methyl-1,4-butanediol, 52.3kg 1,1-sulfonyl bisphenyl Add it into the reaction kettle, blow nitrogen while stirring, and heat up to 150°C. After it is completely dissolved, add 25.2kg of nano-magnesium carbonate, heat up to 230°C for 2 hours, and then heat up to 310°C for 20 minutes to obtain a polymerized mucus. Quickly pour into distilled water and keep stirring to obtain crude polyether ether ketone particles. The crude polyetheretherketone was repeatedly extracted with acetone for 3 times, using 1L of acetone each time to remove the solvent diphenyl sulfone, and then washed with 30% nitric acid for 2 times to remove a small amount of magnesium fluoride produced by the reaction. Finally, it was washed with distilled water for 10 times, each time using 500 ml of distilled water to remove nitric acid, and dried to obtain polyether ether ketone with a purity...

Embodiment 2

[0036] (1) Preparation of polyether ether ketone

[0037] Weigh 26.3kg of 2-diphenyl-4,4'-difluorobenzophenone, 13.5kg of 4-hydroxyethyl p-cresol, and 45.6kg of sulfolane into the reaction kettle, and pass nitrogen gas while stirring And heat up to 150°C. After all the solution is dissolved, add 37.8kg of nano-magnesium carbonate, heat up to 230°C for 2 hours, and then heat up to 310°C for 20 minutes to obtain a polymeric viscous, which is quickly poured into distilled water and continuously stirred to obtain polymeric mucus. Ether ether ketone crude granules. The crude polyether ether ketone was repeatedly extracted with acetone 6 times, using 1L of acetone each time to remove the solvent sulfolane, and then washed with 30% nitric acid once to remove a small amount of magnesium fluoride produced by the reaction , and finally washed 6 times with distilled water, using 500ml of distilled water each time to remove nitric acid, and dried to obtain polyether ether ketone with a p...

Embodiment 3

[0043] (1) Preparation of polyether ether ketone

[0044] Weigh 22.4kg 3-chloro-4,4'-difluorobenzophenone, 17.8kg 1,3-dimethylhydroquinone, 35.9kg 1,1-sulfonyl bisphenyl, 24.6kg tetrahydrothiophene Add sulfone into the reaction kettle, pass nitrogen gas while stirring, and heat up to 150°C. After it is completely dissolved, add 30.2kg of sodium magnesium carbonate, heat up to 230°C for 2 hours, and then heat up to 310°C for 20 minutes to obtain polymerization The mucus was quickly poured into distilled water and stirred continuously to obtain crude polyether ether ketone particles. The crude polyether ether ketone was repeatedly extracted with acetone 5 times, using 1L of acetone each time to remove the solvents 1,1-sulfonylbiphenyl and sulfolane, and then the polyether ether ketone was washed once with 30% nitric acid. To remove a small amount of magnesium fluoride produced by the reaction, and finally wash with distilled water 8 times, each time using 500ml of distilled wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com