Bipolar Electrostatic Chuck

a bipolar electrostatic and chuck technology, applied in the direction of electrostatic holding devices, basic electric elements, electric devices, etc., can solve the problems of deterioration of dielectric breakdown strength between adjacent electrodes, discharge limit, voids, etc., and achieve excellent attracting performance, excellent flatness of held samples, and shorten the distance between the first electrode and the second electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

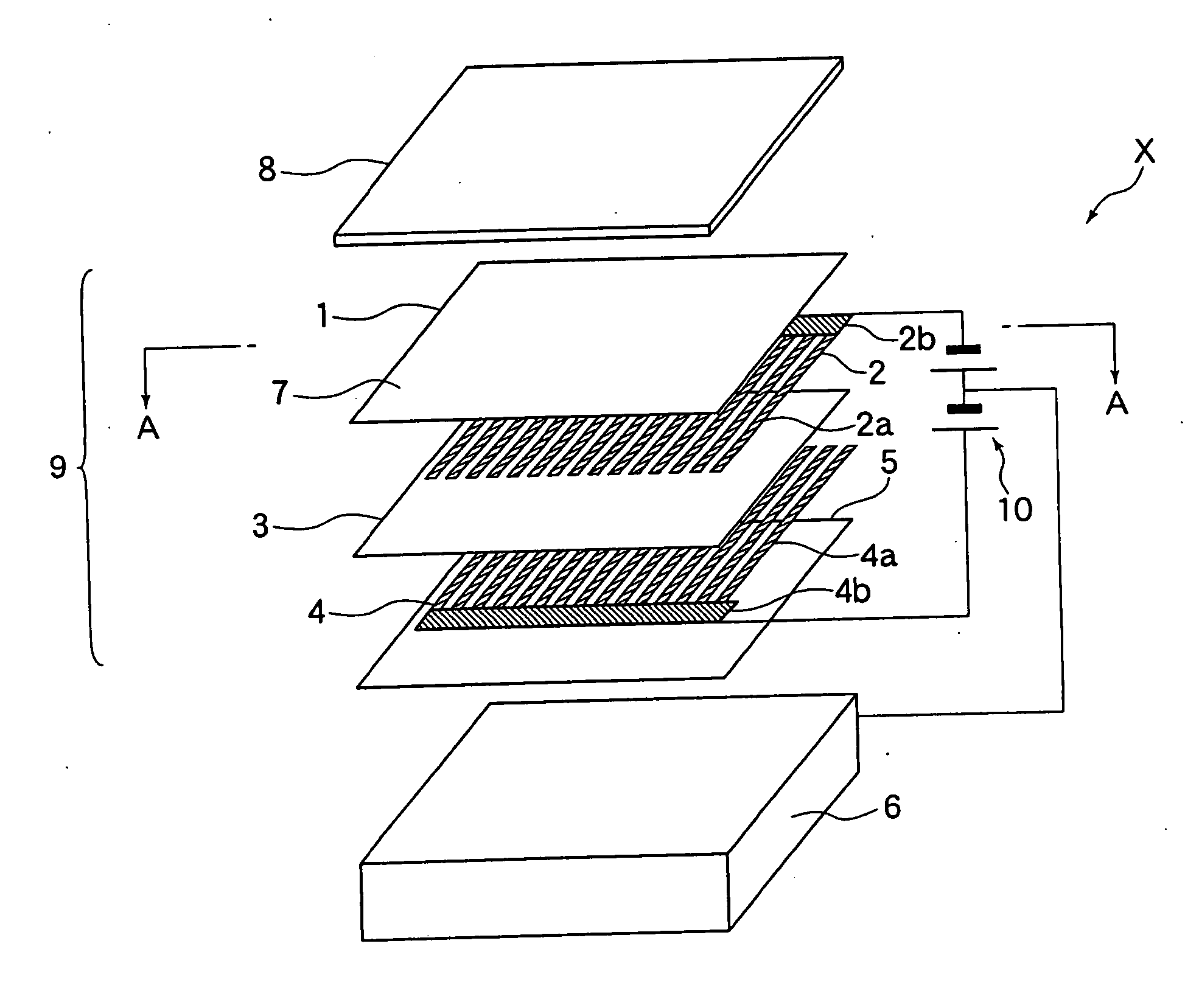

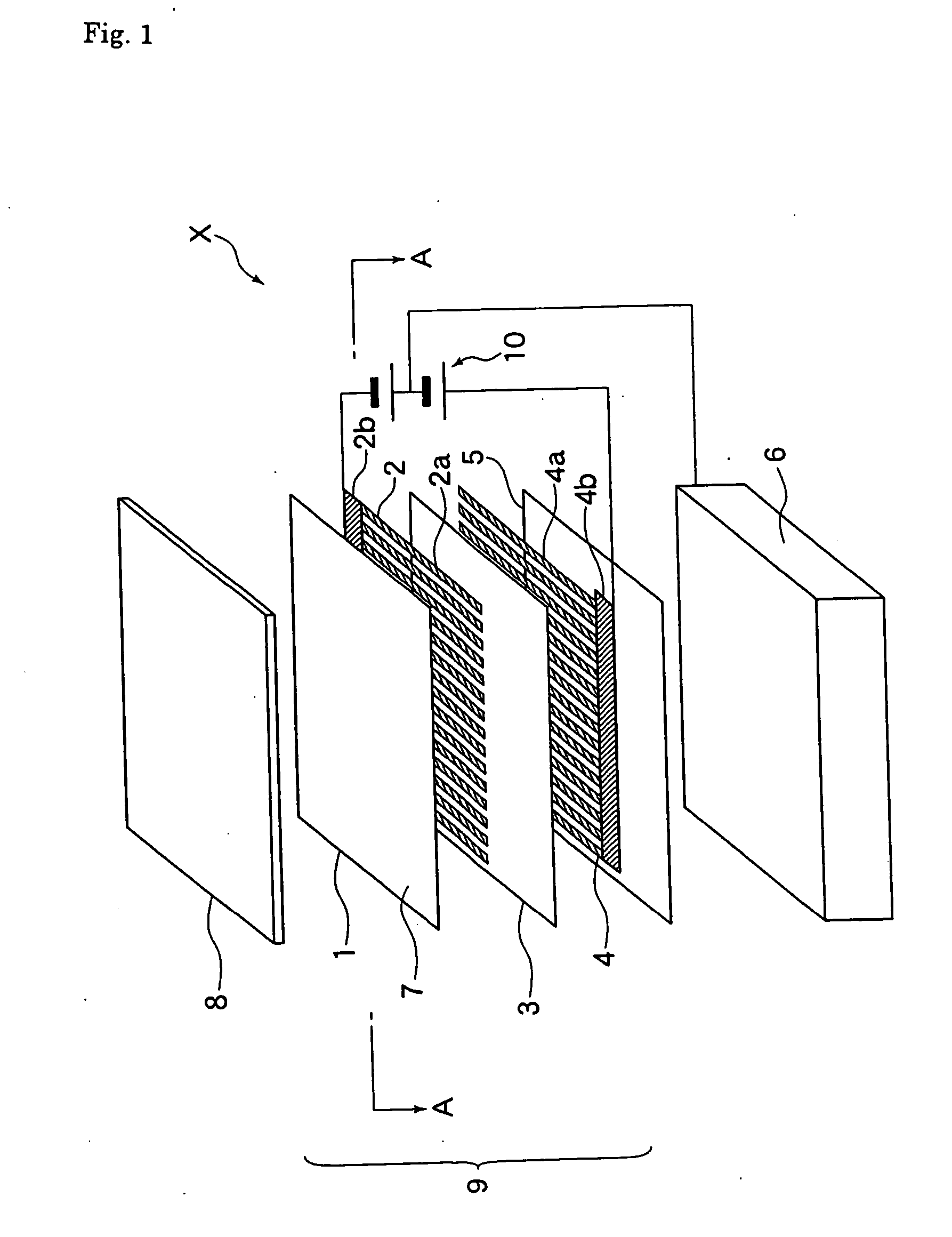

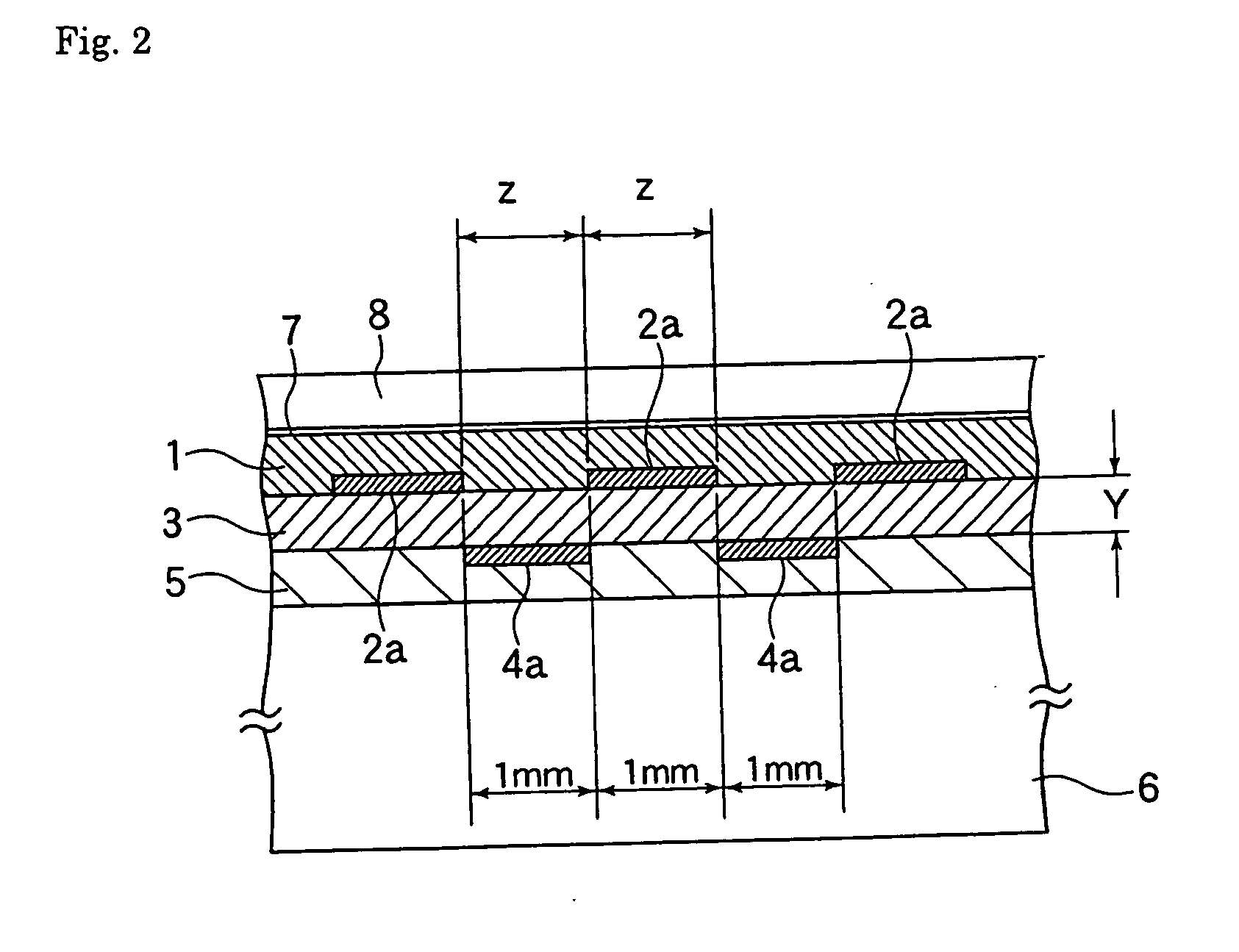

[0092]FIG. 1 shows an explanatory exploded perspective view of a bipolar electrostatic chuck X according to a first embodiment of the present invention. The bipolar electrostatic chuck X includes an upper insulating layer 1 that is formed of a polyimide film having a thermoplastic polyimide film on a lower surface thereof which is 100 mm in height×100 mm in width, 50 μm in thickness, and a dielectric constant ε=3.5, a first electrode 2 made of copper which is 3 μm in thickness, and an interelectrode insulating layer 3 that is formed of a polyimide film which is 100 mm in height×100 mm in width, 50 μm in thickness, and a dielectric constant ε=3.5. The bipolar electrostatic chuck X also includes a second electrode 4 made of copper that is 3 μm in thickness, a lower insulating layer 5 that is formed of a polyimide film having a thermoplastic polyimide film on an upper surface thereof which is 100 mm in height×100 mm in width, 50 μm in thickness, and a dielectric constant ε=3.5, and a m...

second embodiment

[0099]FIG. 4 shows an explanatory cross-sectional view of a bipolar electrostatic chuck X according to a second embodiment of the present invention. FIG. 5 shows an explanatory partial plan view of a first electrode 2 and a second electrode 14 of the bipolar electrostatic chuck X according to the second embodiment, viewed in a depth direction of the sample attracting plane 7.

[0100] In the bipolar electrostatic chuck X according to the second embodiment, an electrode width of the band-like portions 14a of the second electrode 14 is set to 0.6 mm, and the band-like portions 14a of the second electrode 14 are arranged in the center of gaps (1 mm) which are formed between the respective band-like portions 2a of the first electrode 2. Band-like comb teeth of the first electrode 2 and band-like comb teeth of the second electrode 14 are alternately arranged, and the first electrode 2 and the second electrode 14 are arranged when the sample attracting plane 7 is viewed in the depth directi...

third embodiment

[0101]FIG. 6 shows an explanatory exploded perspective view of a bipolar electrostatic chuck X according to a third embodiment of the present invention. FIG. 7 shows an explanatory cross-sectional view (a part of a cross-section A-A of FIG. 6) of the bipolar electrostatic chuck X according to the third embodiment. FIG. 8 shows an explanatory partial plan view of a first electrode 2 and a second electrode 24 of the bipolar electrostatic chuck X according to the third embodiment, viewed in a depth direction of the sample attracting plane 7. In FIG. 8, a dotted area portion represents a portion in which the second electrode 24 is overlapped with the first electrode 2 when the sample attracting plane 7 is viewed in the depth direction.

[0102] In the bipolar electrostatic chuck X according to the third embodiment, the conditions other than a condition in which the second electrode 24 is formed in a plane having a planar area that is 80 mm in height×80 mm in width are set to be identical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com