Structure for metal cap applications

a technology of metal caps and structures, applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of delay in using metallic capping layers, affecting the reliability of prior art interconnect structures, etc., to improve the reliability, improve the strength of dielectric breakdown, and improve the effect of technology extendibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

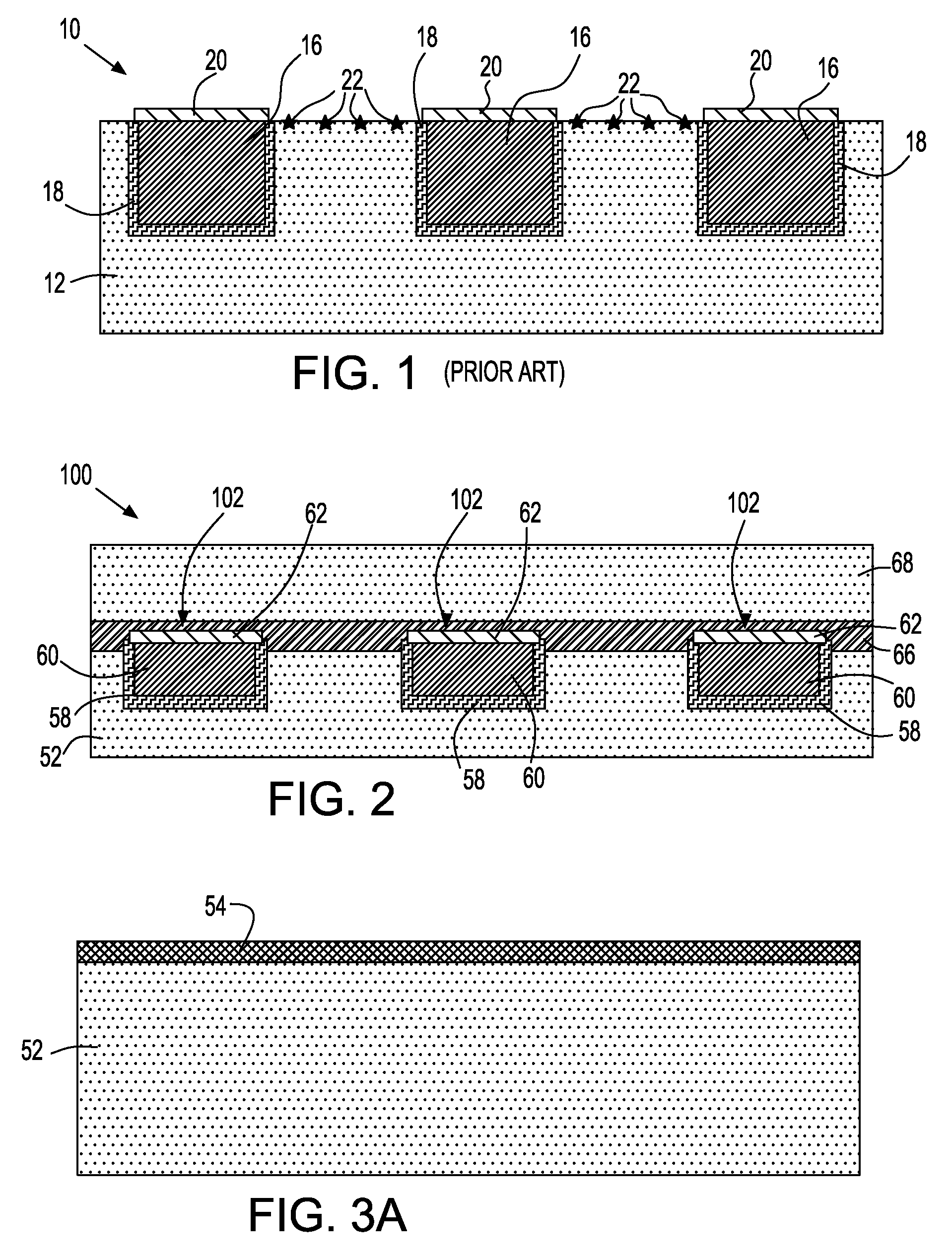

[0028]FIG. 3A shows an initial structure that is employed in the present invention. As illustrated, the initial structure includes a dielectric material 52 which contains a sacrificial dielectric layer 54 on an upper surface of the dielectric material 52. The dielectric material 52 is typically located on a surface of a substrate (not shown).

[0029]The substrate, which is not shown, may comprise a semiconducting material, an insulating material, a conductive material or any combination thereof. When the substrate is comprised of a semiconducting material, any semiconductor such as Si, SiGe, SiGeC, SiC, Ge alloys, GaAs, InAs, InP and other III / V or II / VI compound semiconductors may be used. In addition to these listed types of semiconducting materials, the present invention also contemplates cases in which the semiconductor substrate is a layered semiconductor such as, for example, Si / SiGe, Si / SiC, silicon-on-insulators (SOIs) or silicon germanium-on-insulators (SGOIs).

[0030]When the ...

second embodiment

[0052]FIG. 4B shows the structure after forming at least one opening 56 into the structure shown in FIG. 4A. The at least one opening 56 is formed as described above and the various types of openings mentioned above are also contemplated herein for the present invention.

[0053]FIG. 4C shows the structure after filling the at least one opening 56 with a diffusion barrier 58 and a conductive material 60 and after planarization. During the planarization process, the polishing selective layer 70 is removed. The second embodiment then proceeds by utilizing the processing steps associated with FIGS. 3D-3F above. After forming the dielectric capping layer 66 that encapsulates the extended top portion of the metallic capped conductive feature, the other dielectric material 68 is optionally formed as described above.

third embodiment

[0054]FIGS. 5A-5D illustrates the present invention which differs from that of the first two embodiments described above. In this embodiment, a chemical, e.g., oxygen, nitrogen, ammonia and / or hydrogen plasma process is used to remove the metallic residue from the structure.

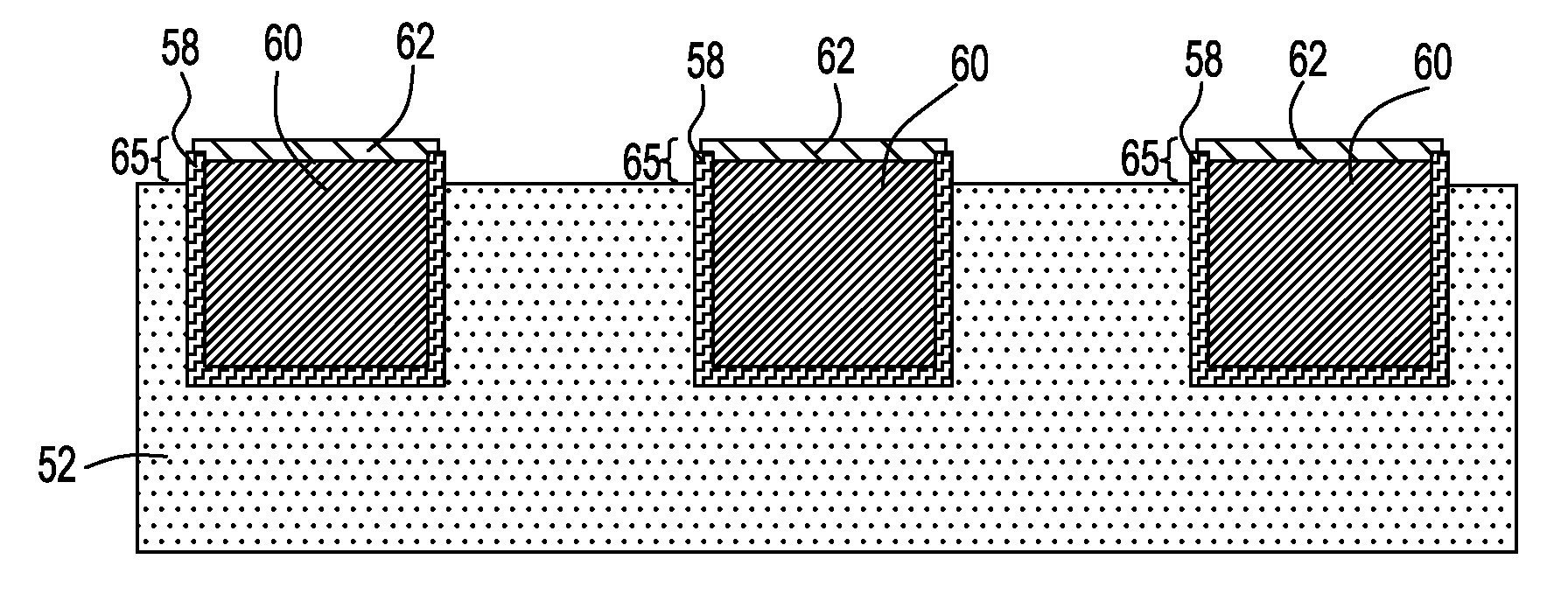

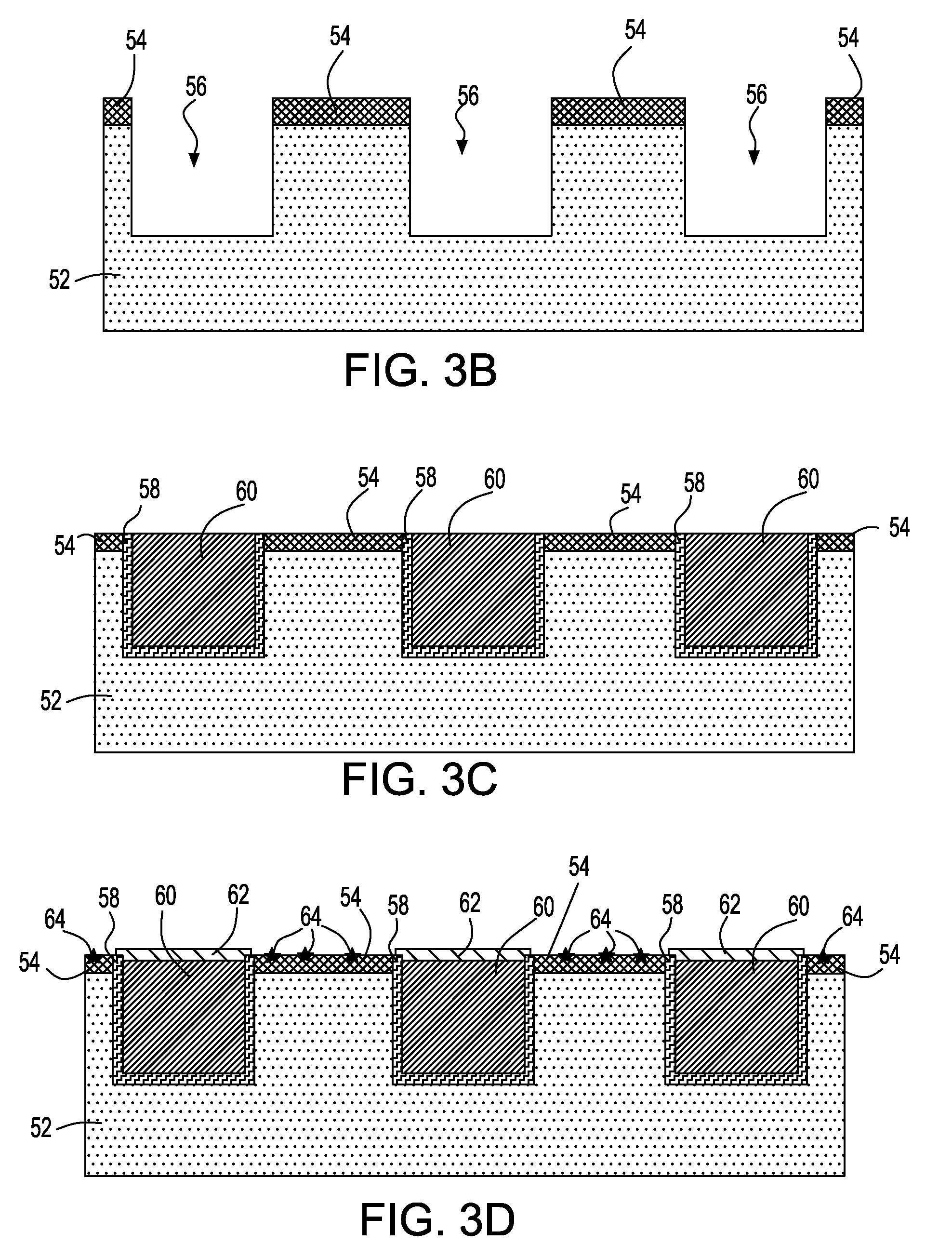

[0055]The third embodiment of the present invention begins by providing the structure shown in FIG. 3B utilizing the processing steps described above. Following the formation of the structure shown in FIG. 3B, and subsequent filling of the at least one opening 56 with a diffusion barrier 58 and a conductive material 60, a planarization process such as, for example, chemical mechanical polishing and / or grinding, is employed to provide the structure shown in FIG. 5A. As shown, the planarization process completely removes the sacrificial dielectric layer 54 from the structure such that the upper surfaces of the diffusion barrier 58, the conductive material 60, and the dielectric material 62 are substantially coplana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com