Patents

Literature

46results about How to "Reduce mechanical strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

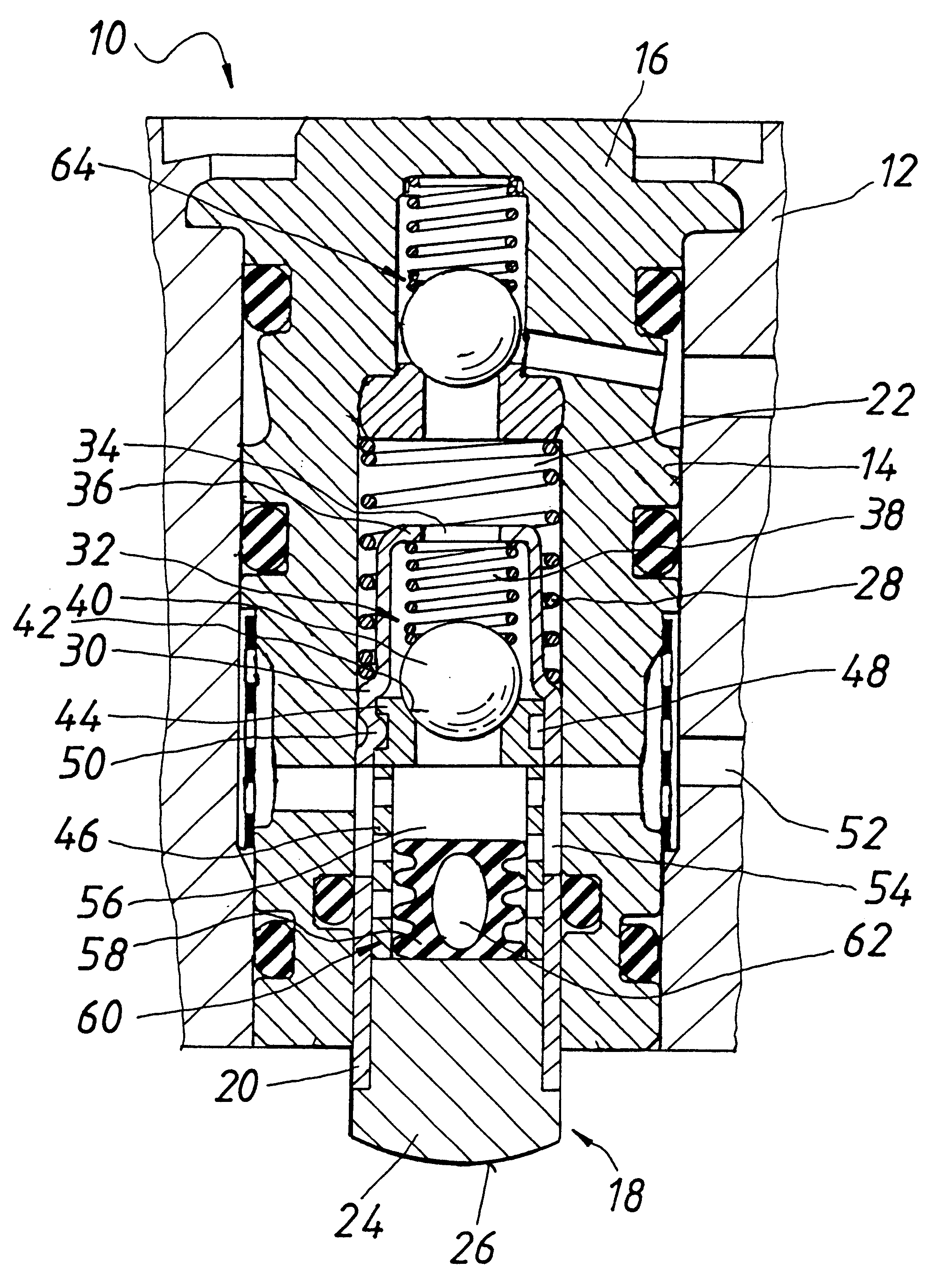

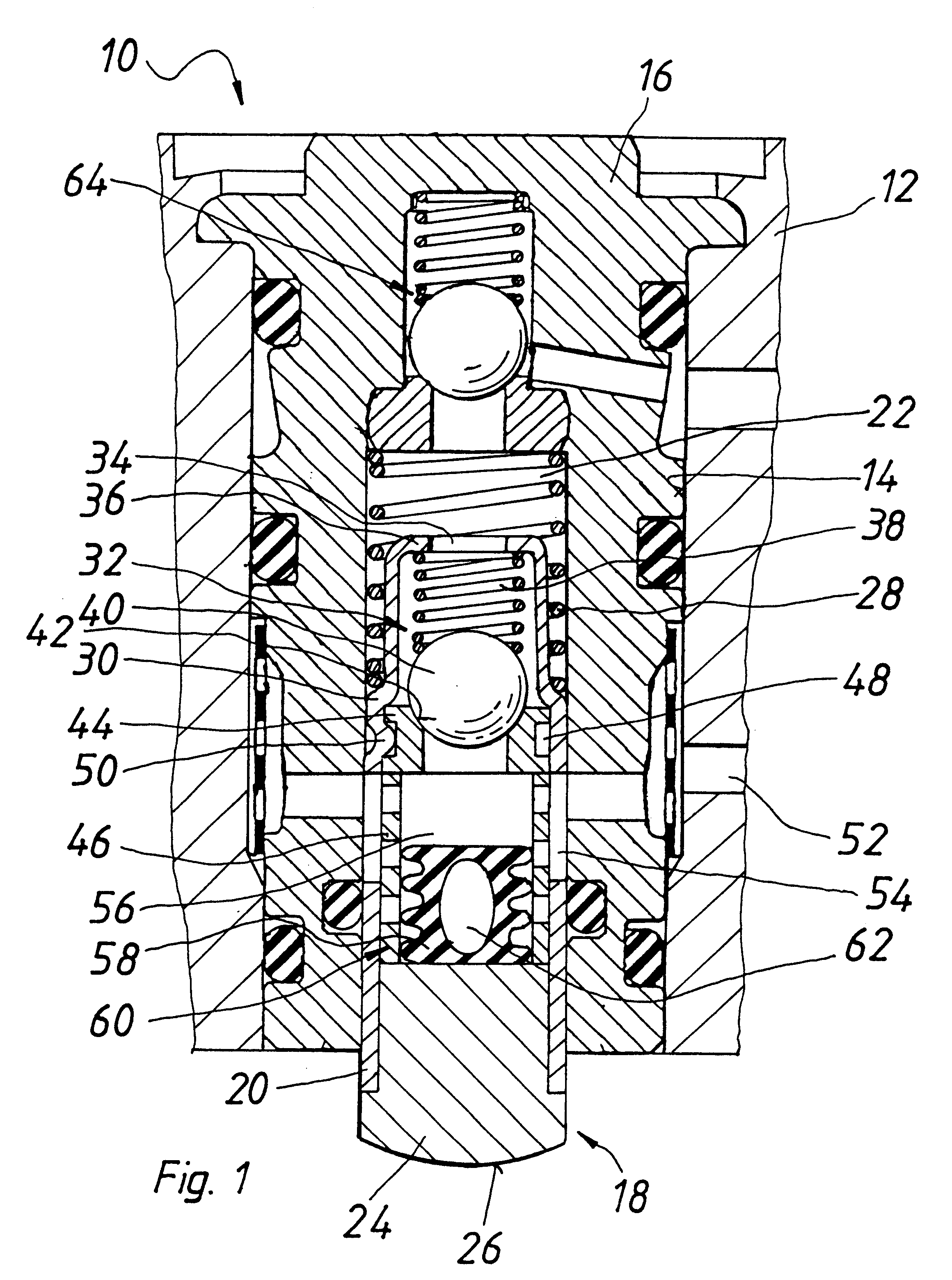

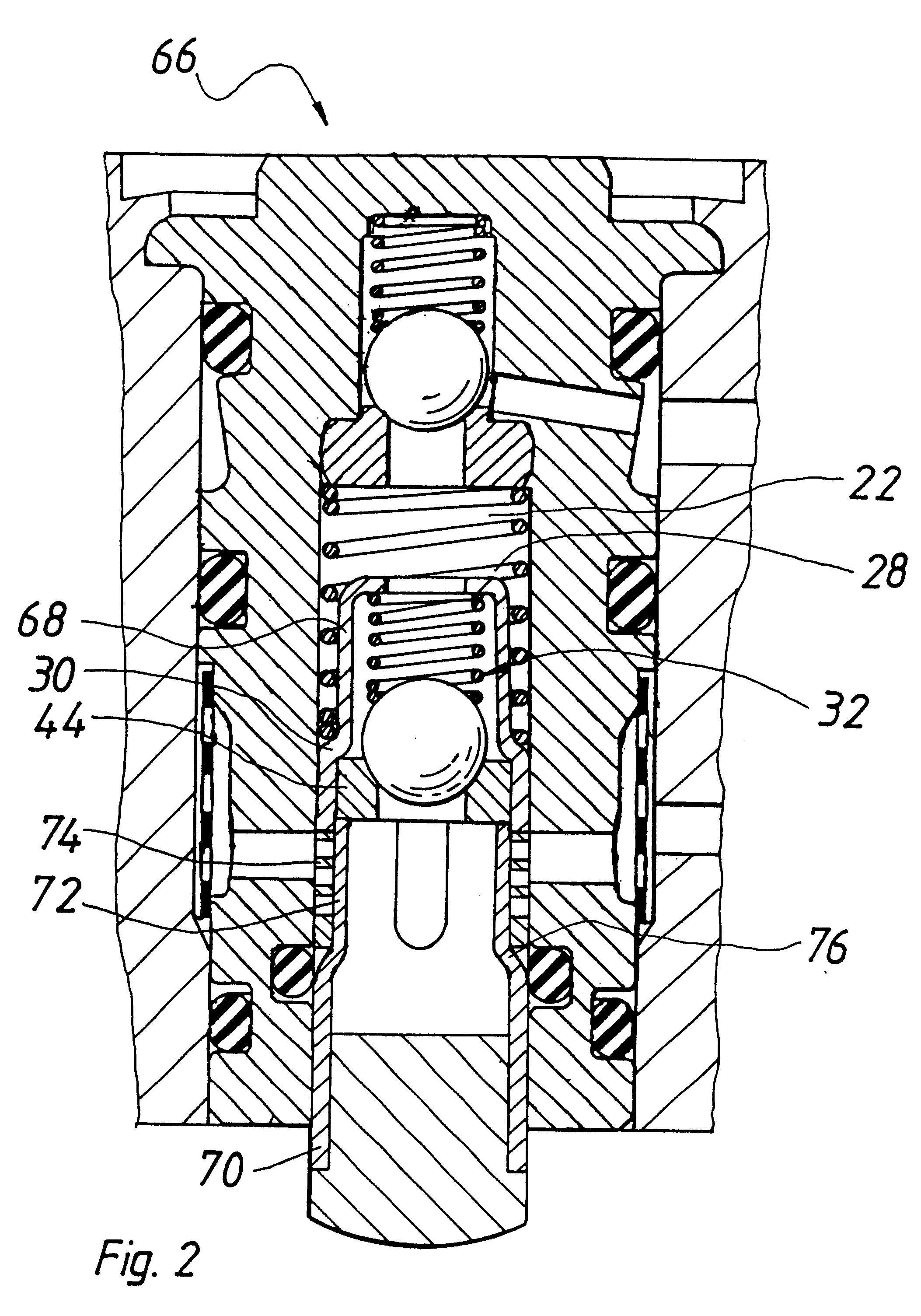

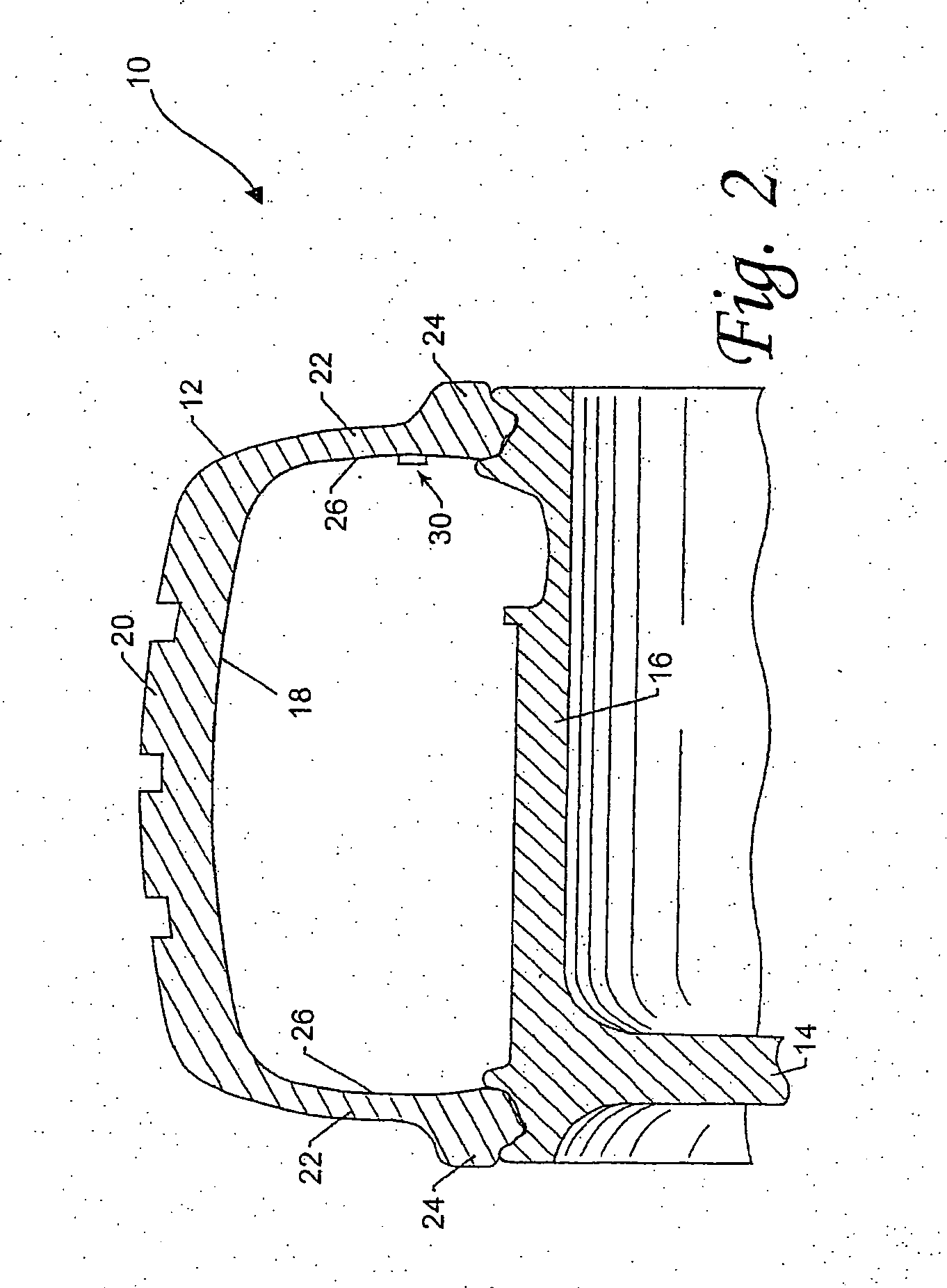

Piston pump

InactiveUS6341950B1Manufactured quickly and economicallyDamp pressure pulsationPositive displacement pump componentsPlungersEngineeringMechanical engineering

The invention relates to a piston pump, which is intended for use as a return pump for a slip-controlled hydraulic vehicle brake system. To simplify the manufacture of a piston of the piston pump, the piston includes a thin sleeve.

Owner:ROBERT BOSCH GMBH

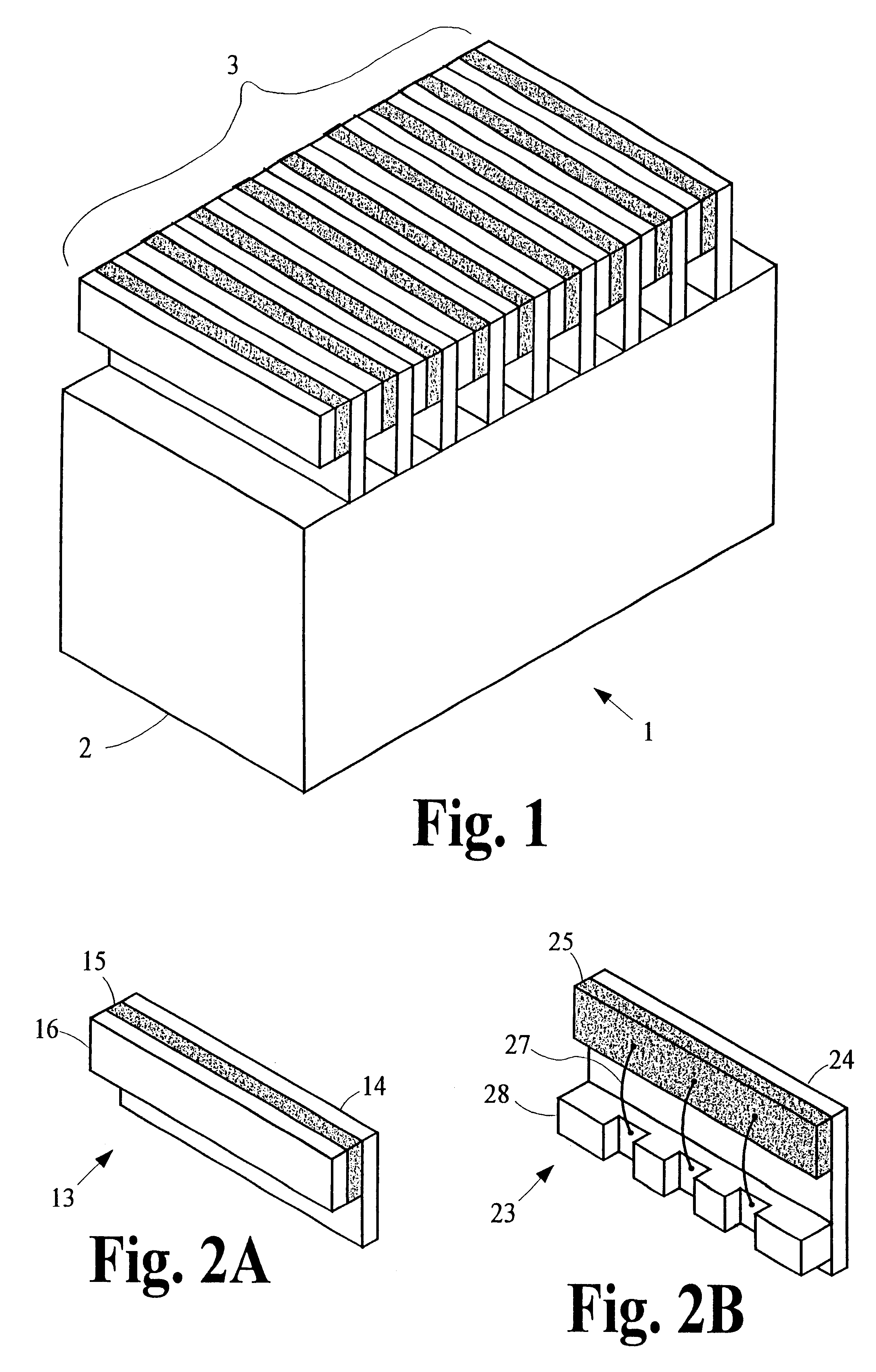

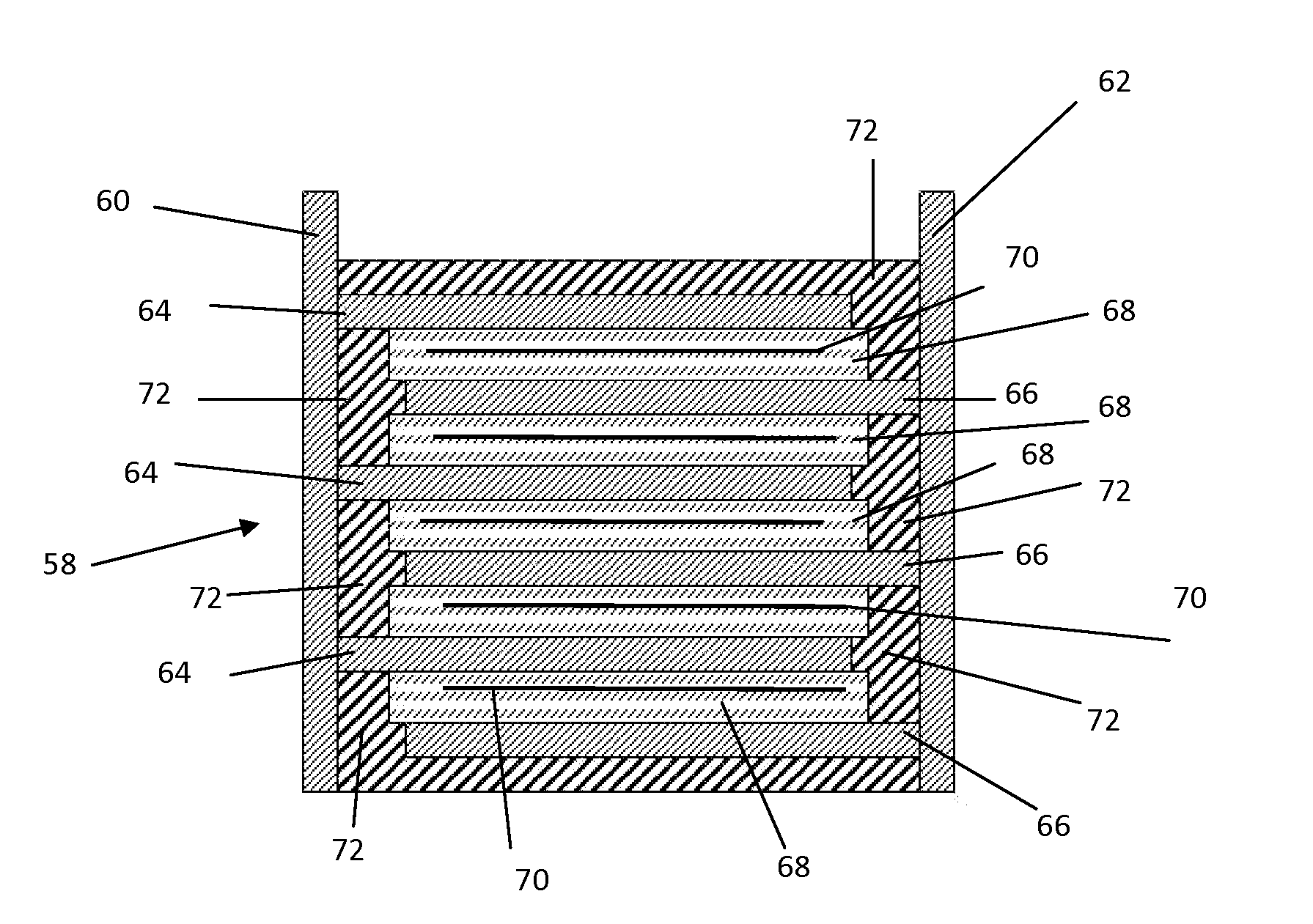

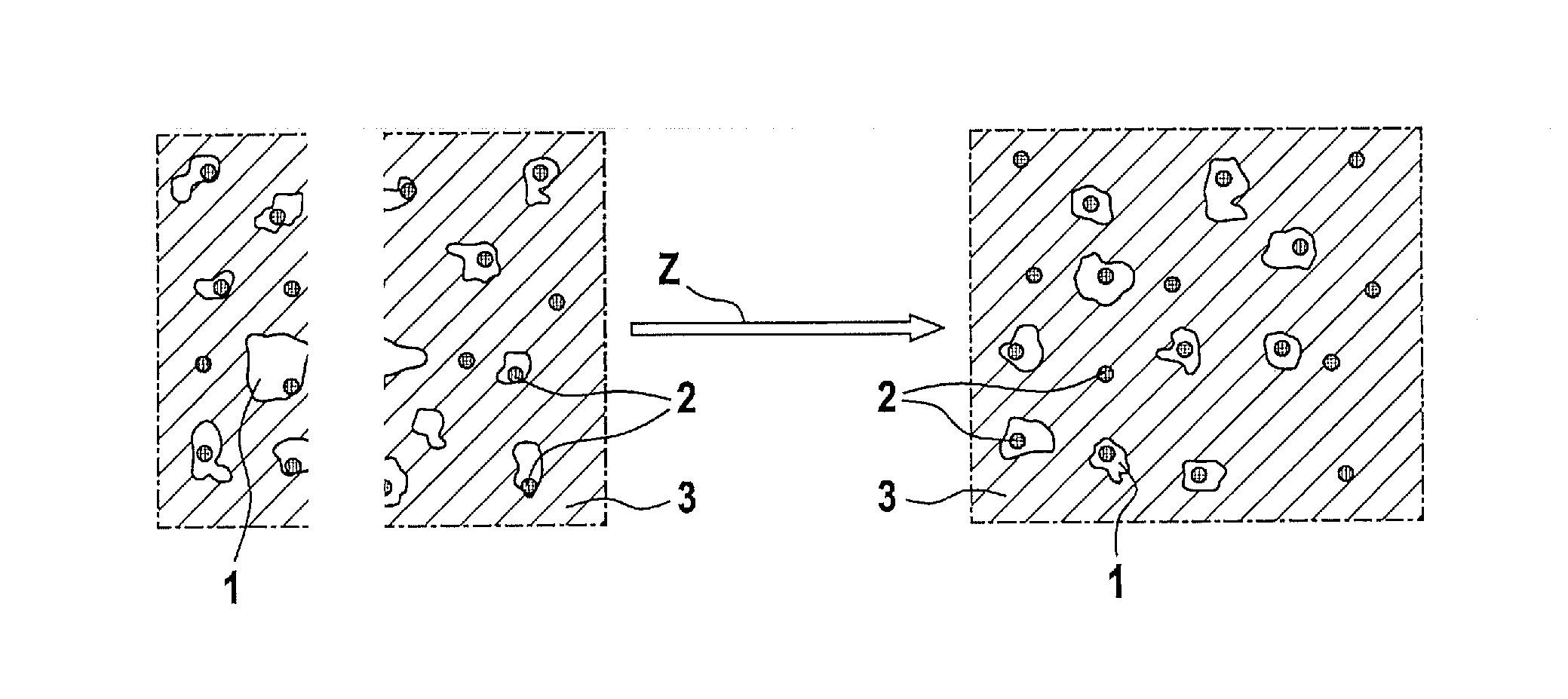

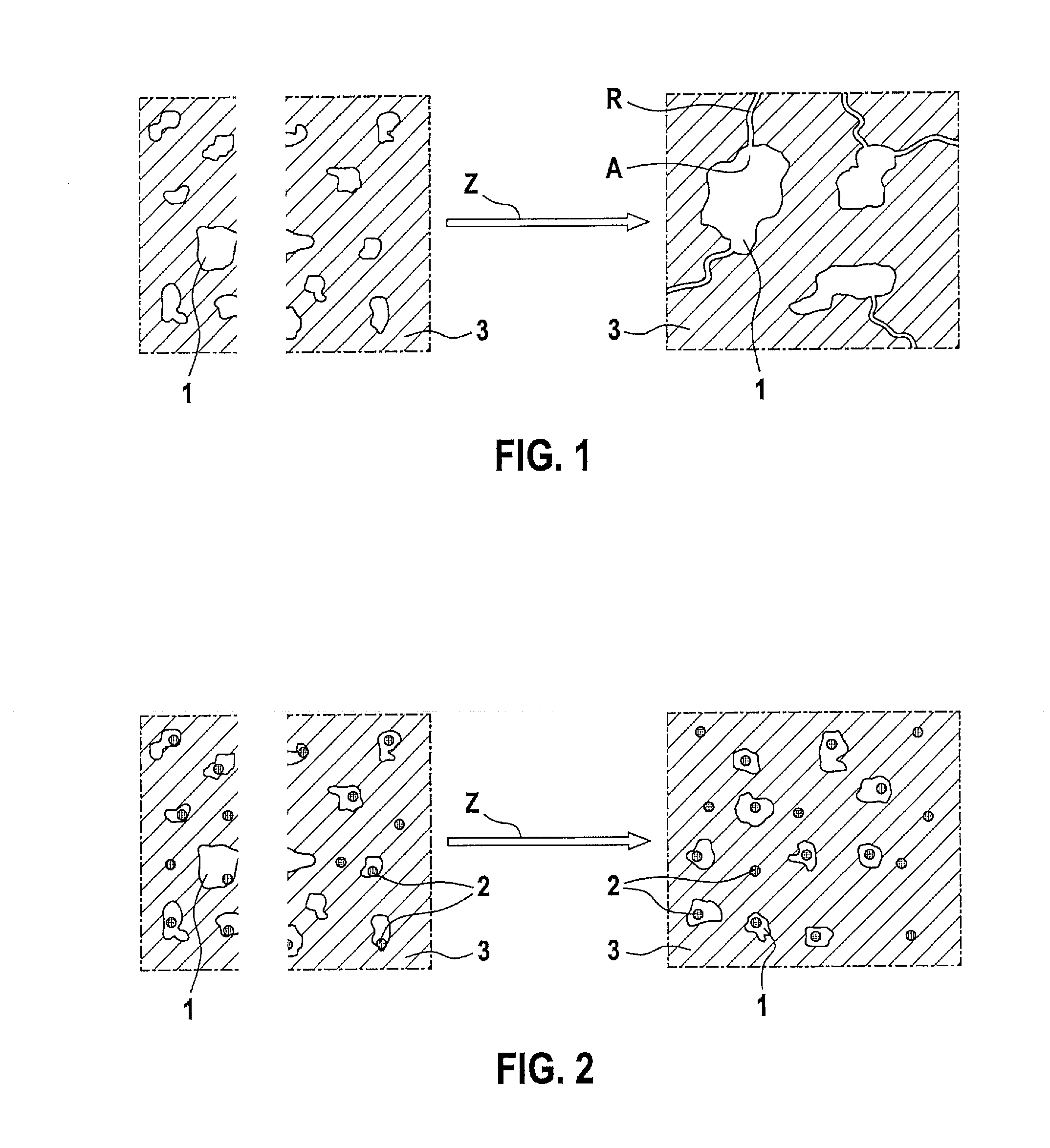

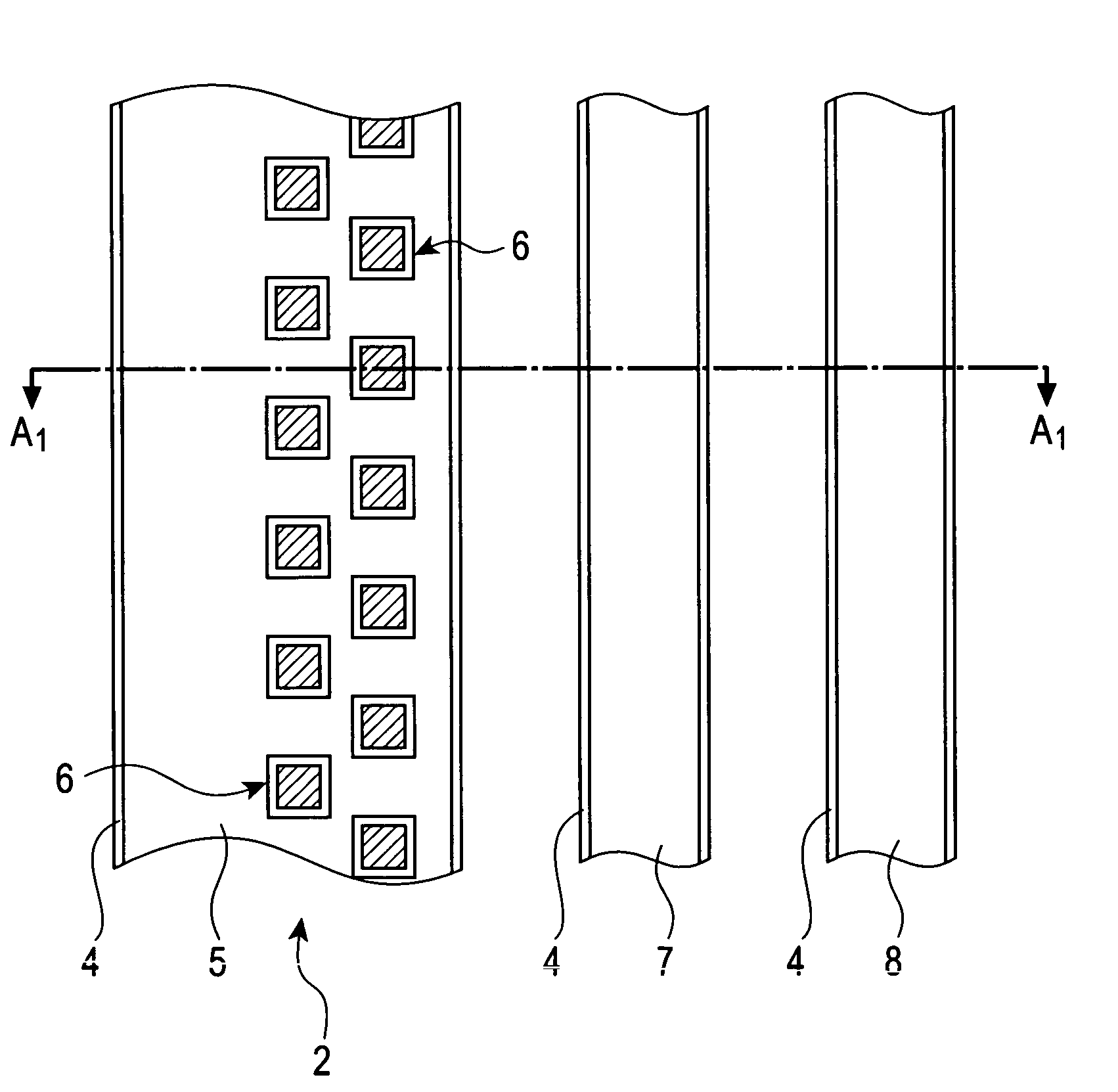

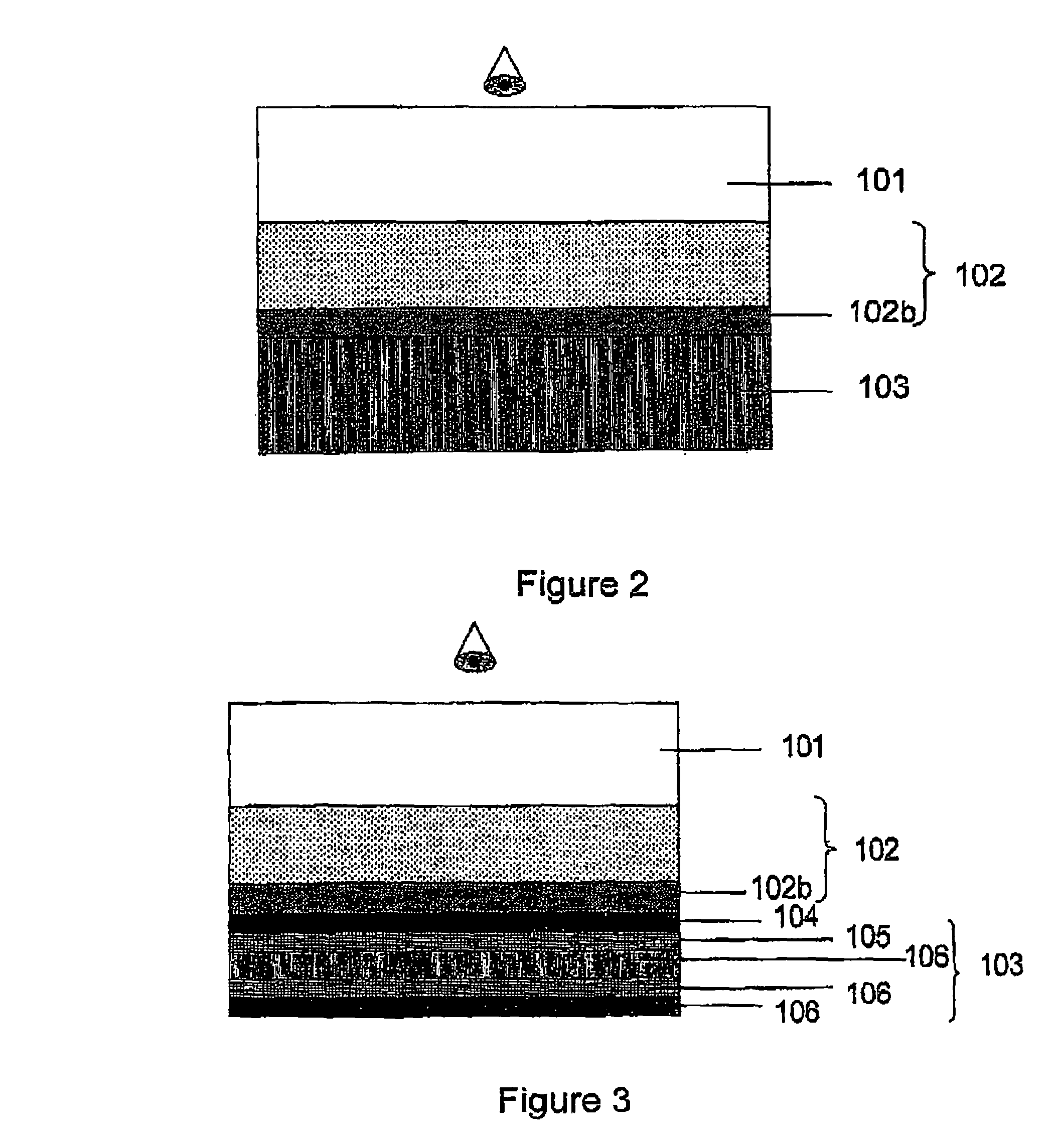

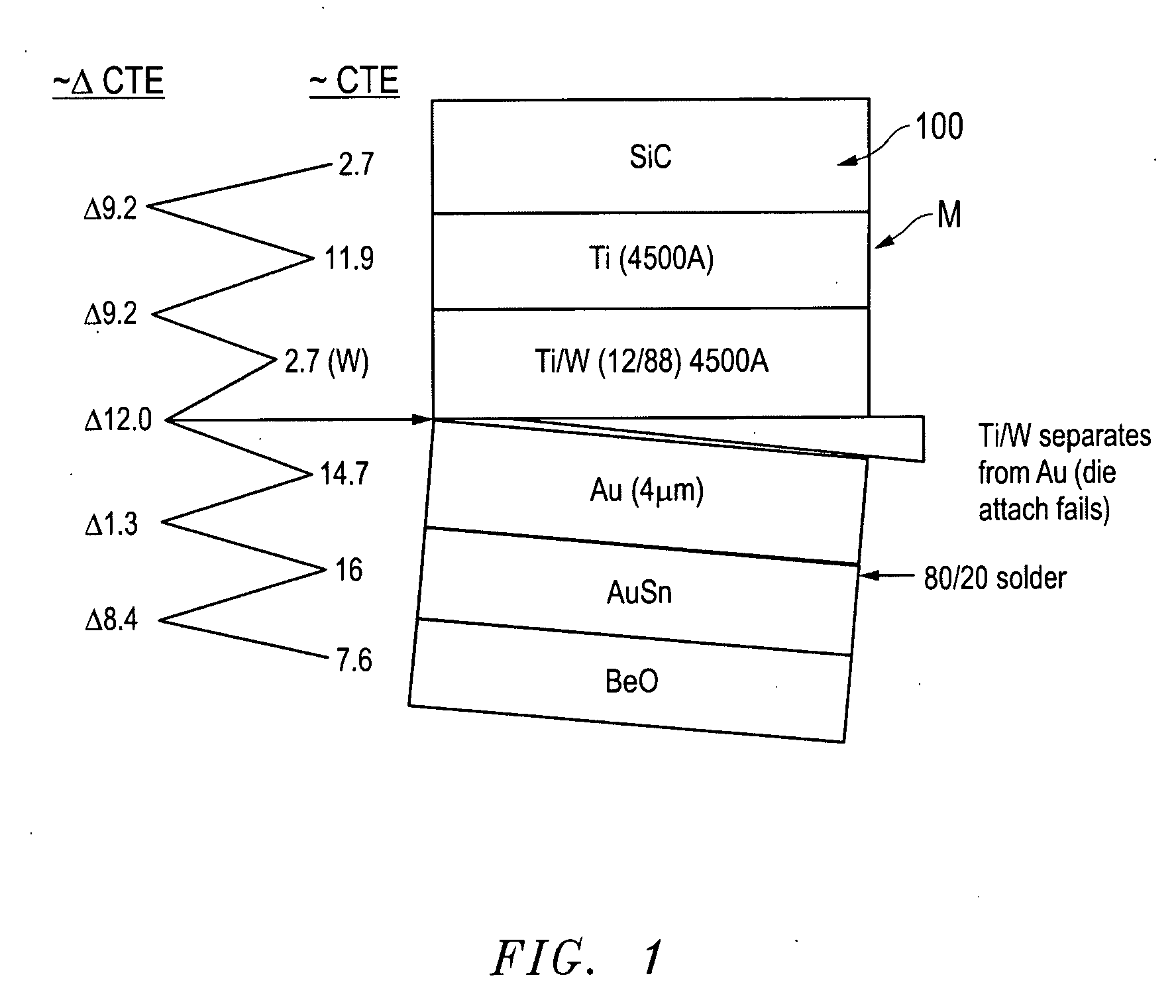

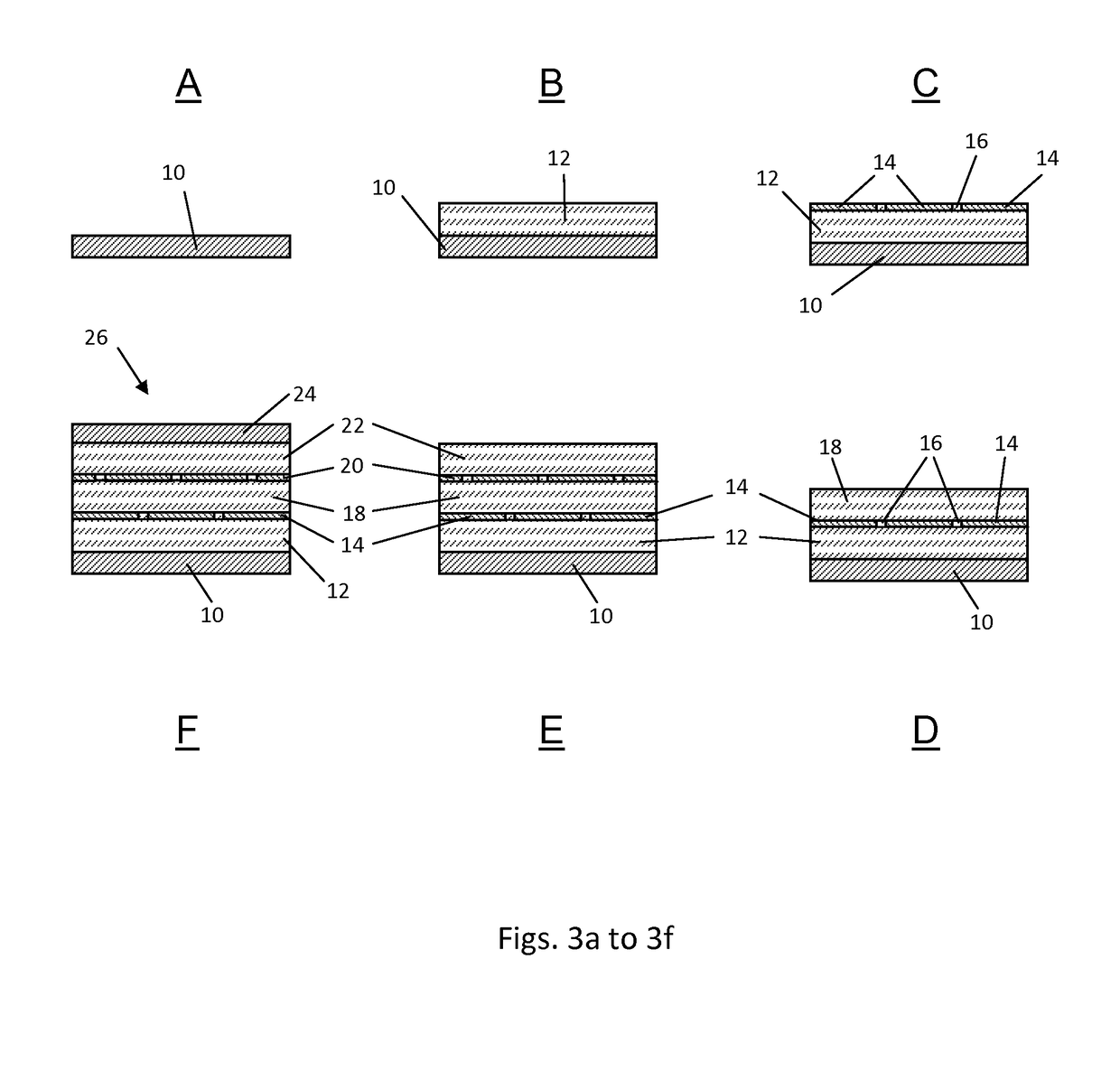

Solder and material designs to improve resistance to cycling fatigue in laser diode stacks

InactiveUS6424667B1Improve resistance to cycling fatigueReduce mechanical strainOptical wave guidanceSemiconductor laser arrangementsMaterial DesignThermal expansion

Laser modules that are operated intermittently are prone to stop operating after only a few thousand cycles or less. The laser modules sometimes experience a significant increase in operating temperature before they stop operating and, in some cases, manifest an opening of the electrical circuit that connects the laser diodes in the stack of laser subassemblies. In extreme cases, the laser module disintegrates into component subassemblies. These problems arise from structural failures in affixing agents like solder that are used to affix component parts to each other. The structural failures are caused by cyclical thermal expansion and contraction of component parts that exceed the elastic limit of the solder. Resistance to global plastic deformation (creep) and to local plastic deformation (fatigue) is improved by selecting materials to reduce mechanical strain and increase resistance to creep and fatigue, by altering the structural design of the laser module to reduce mechanical strain induced into the affixing agents, and by altering operational practices to reduce the range of temperatures imposed on laser module components. One design method improves resistance to creep and fatigue by controlling the thickness of the affixing agents used to affix component parts to each other.

Owner:JDS UNIPHASE CORP

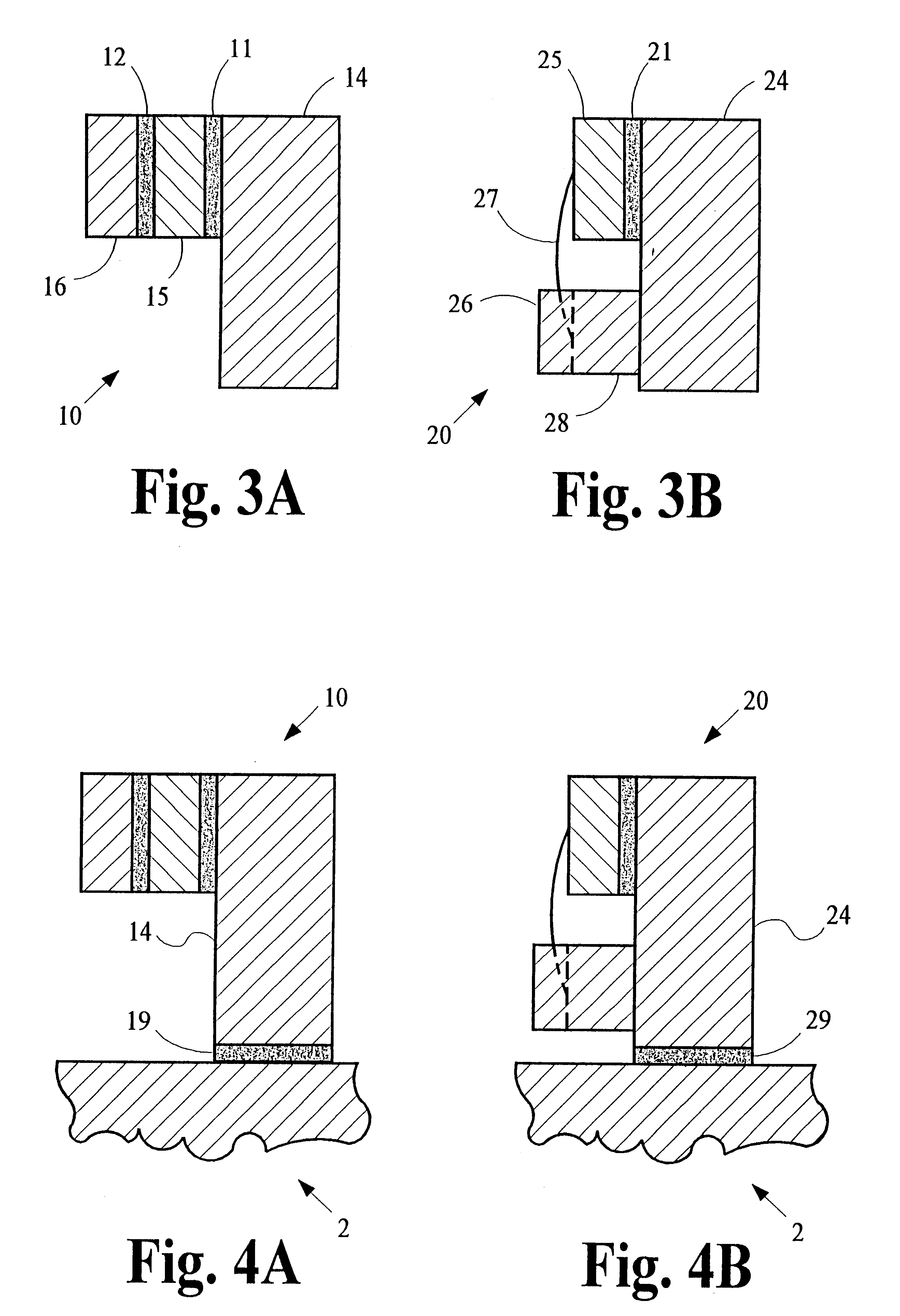

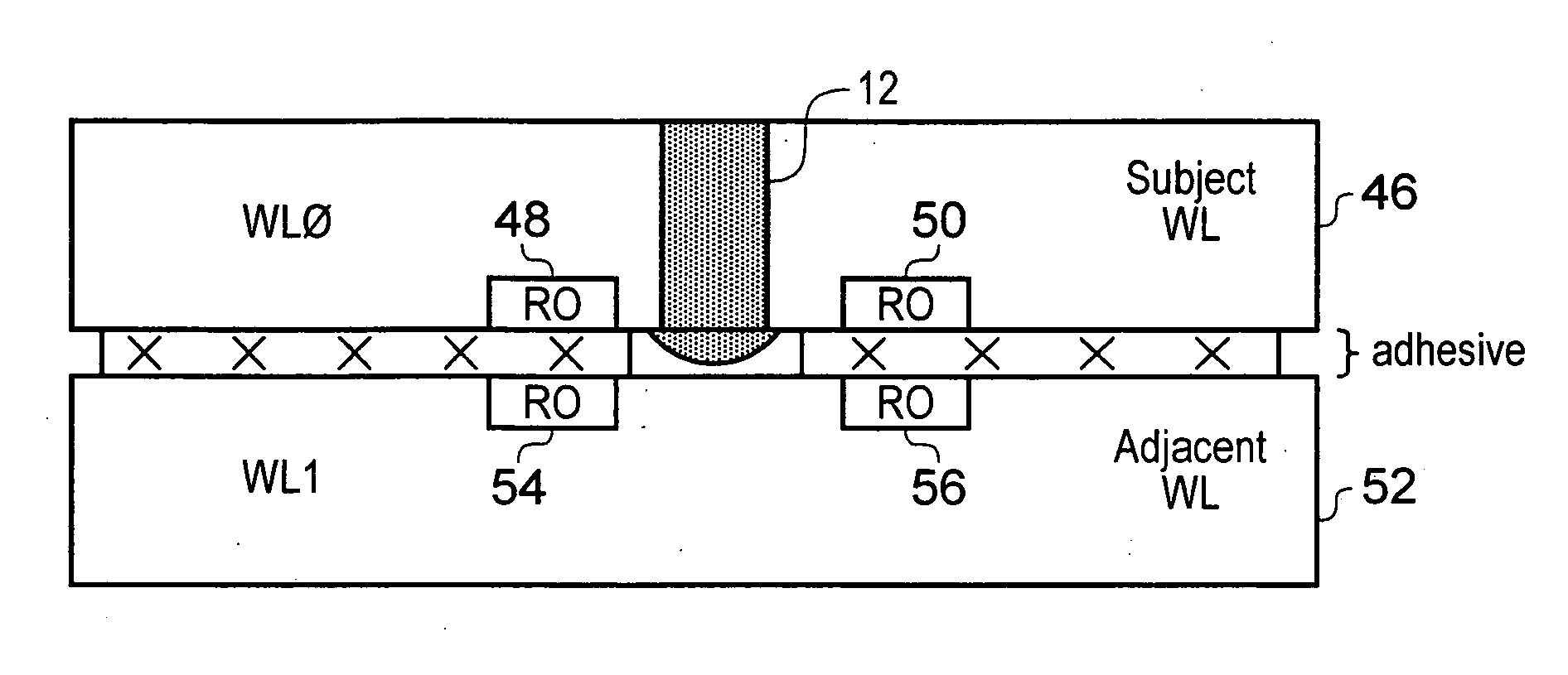

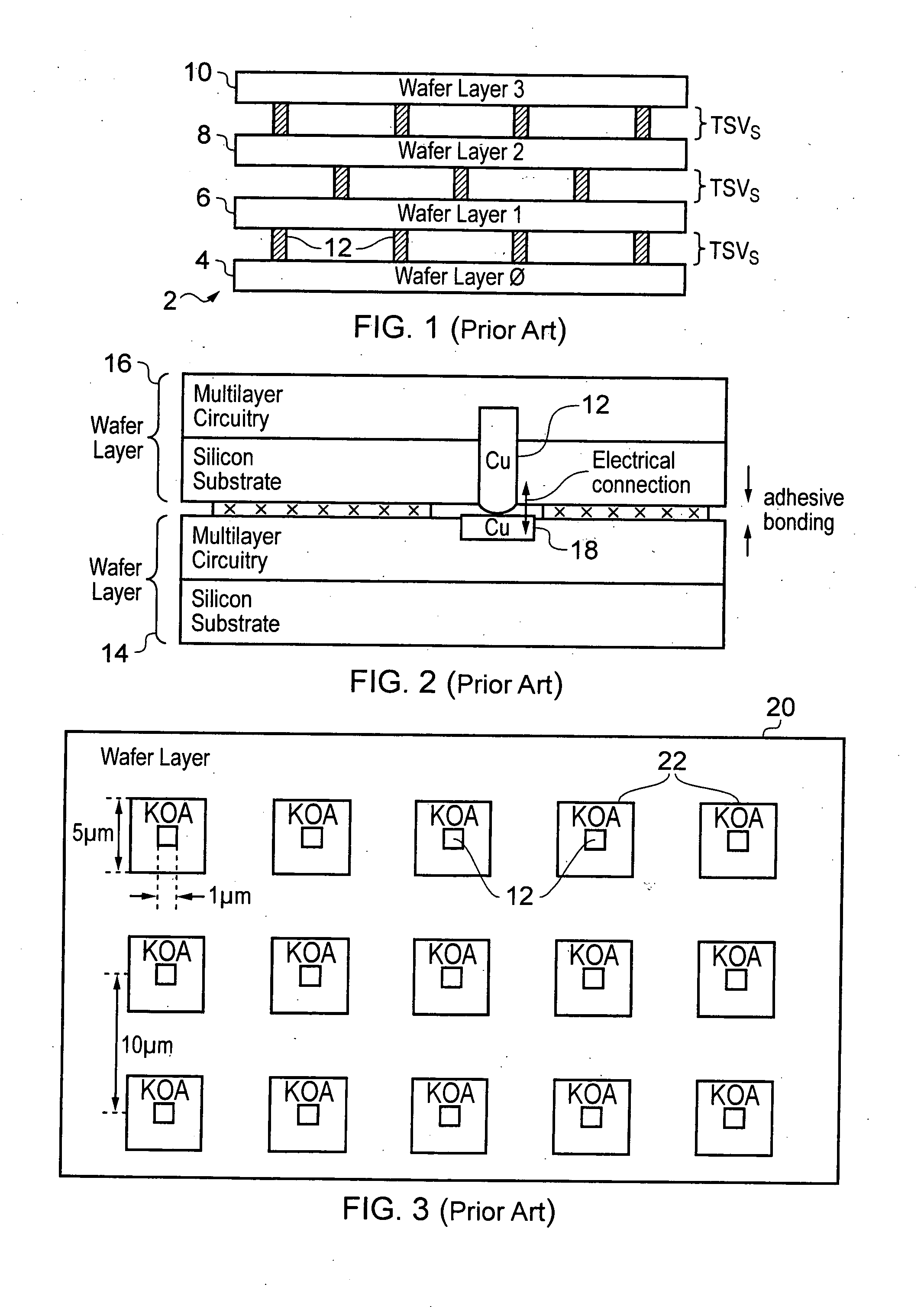

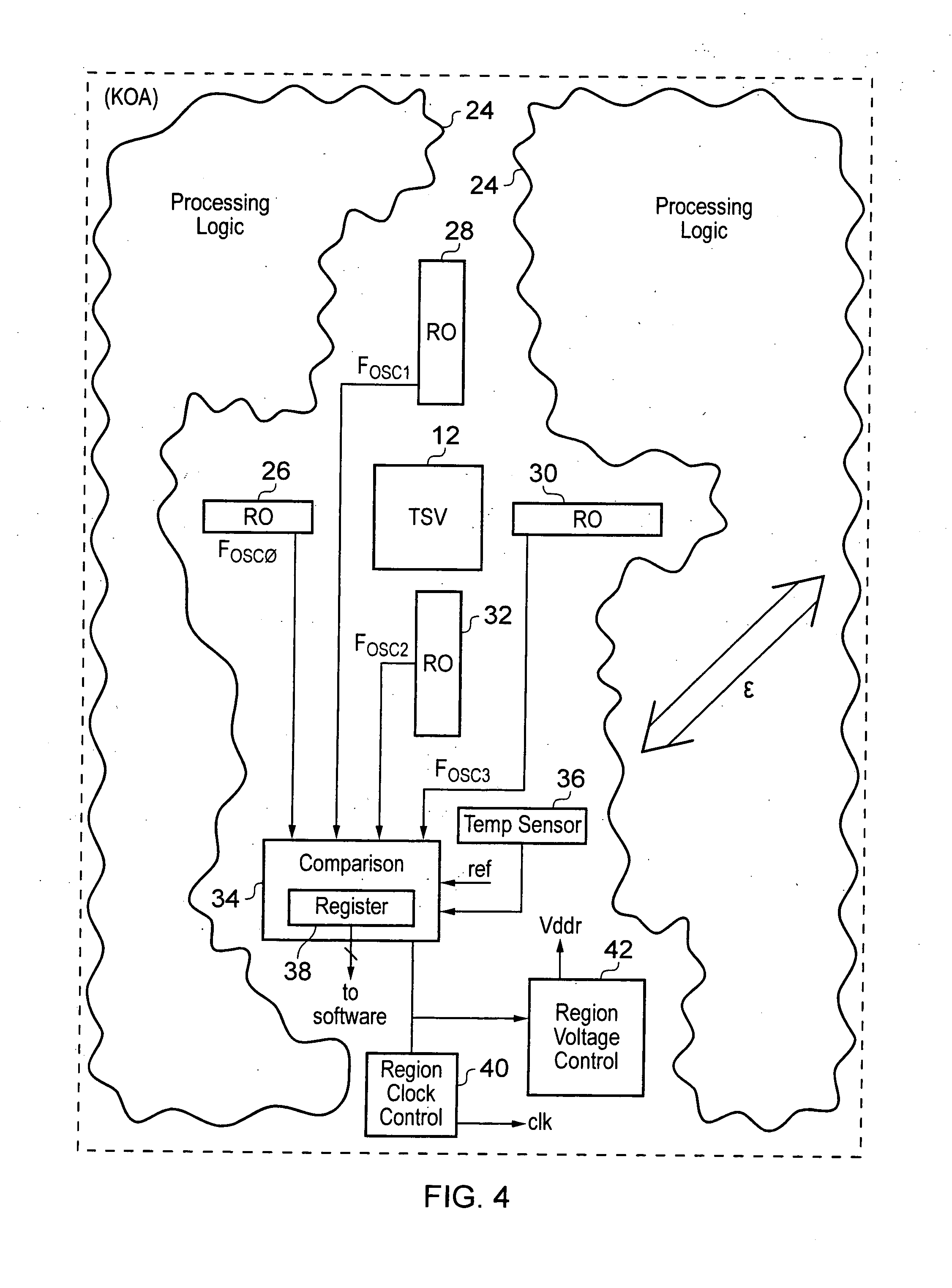

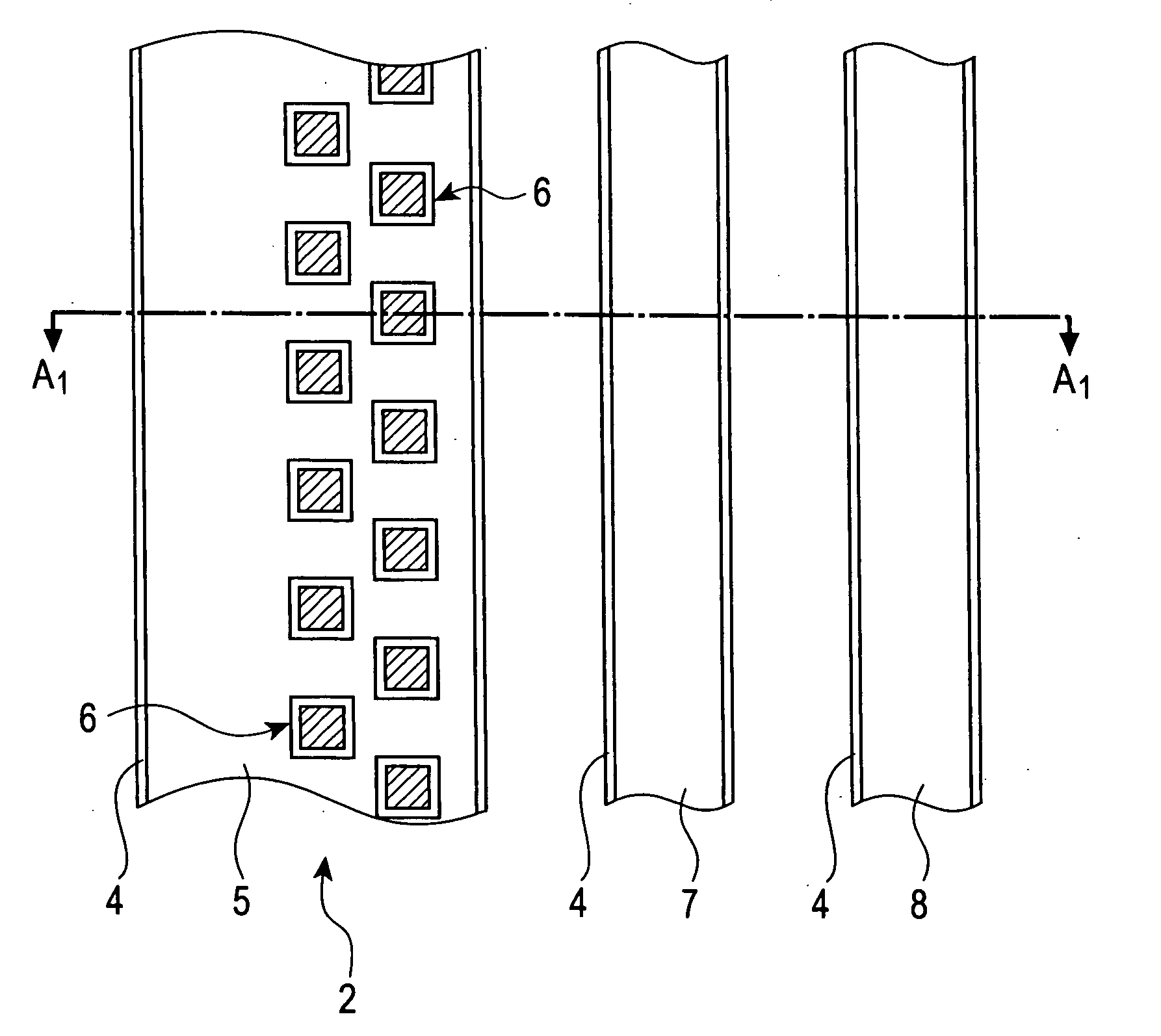

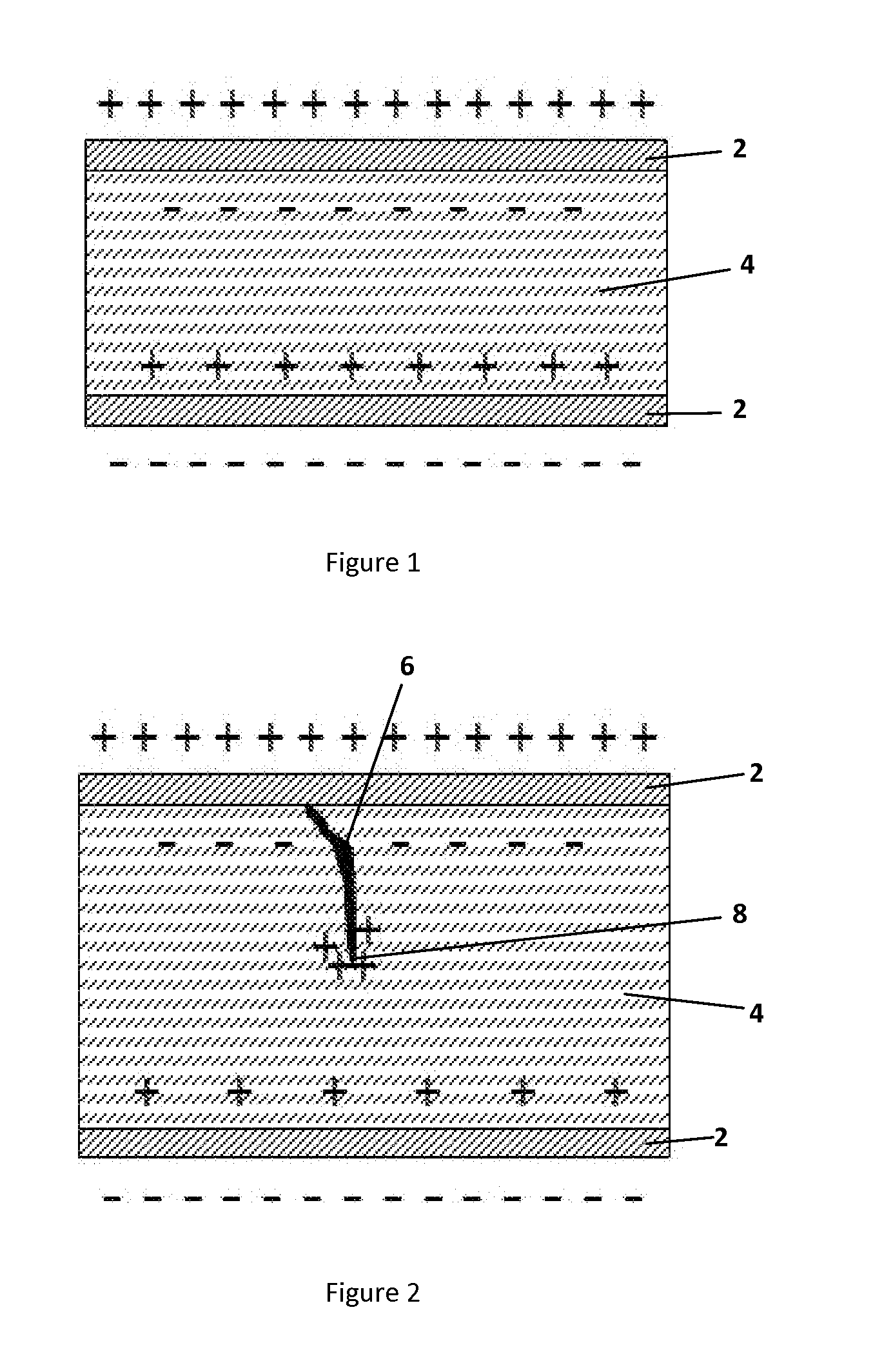

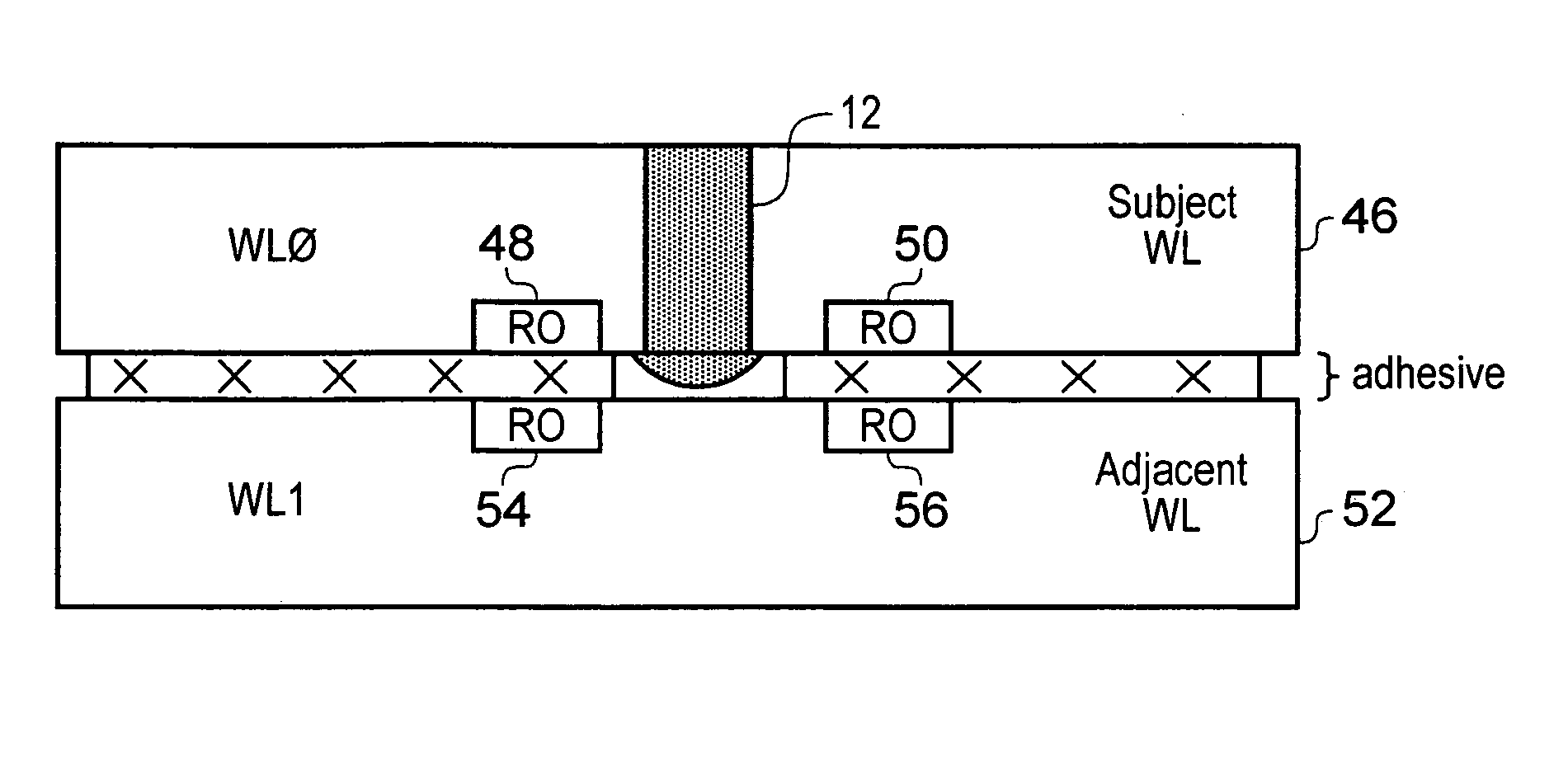

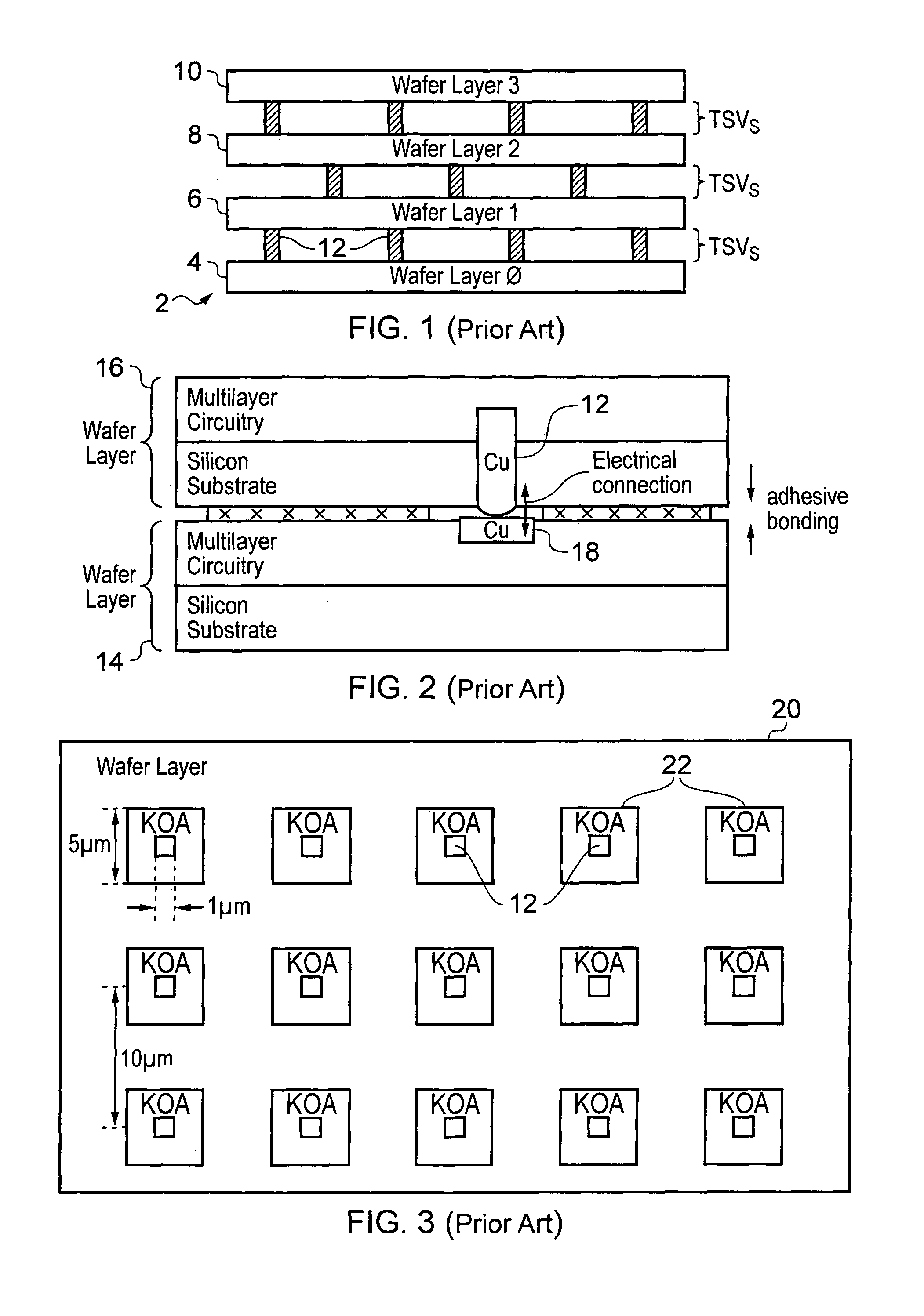

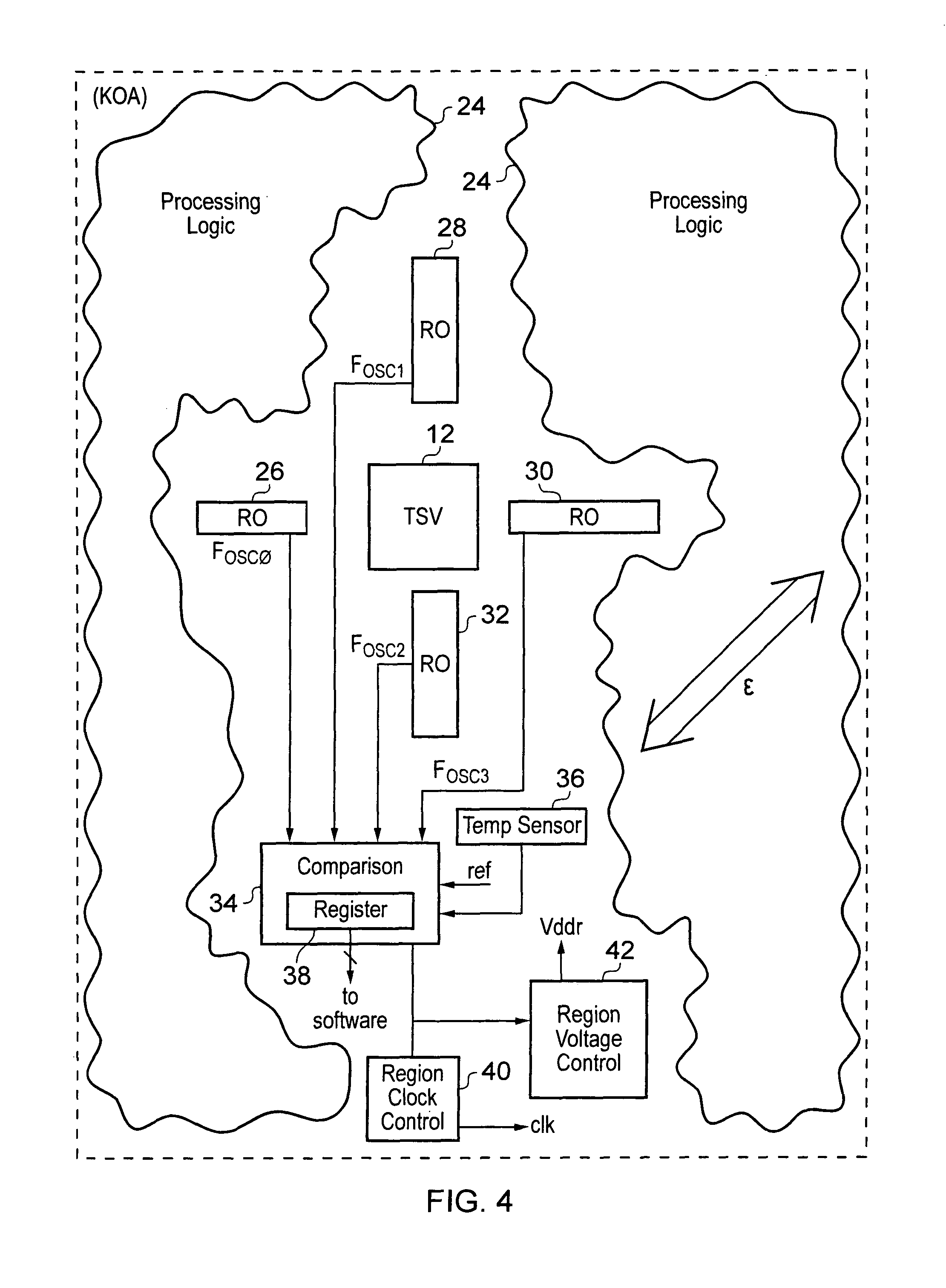

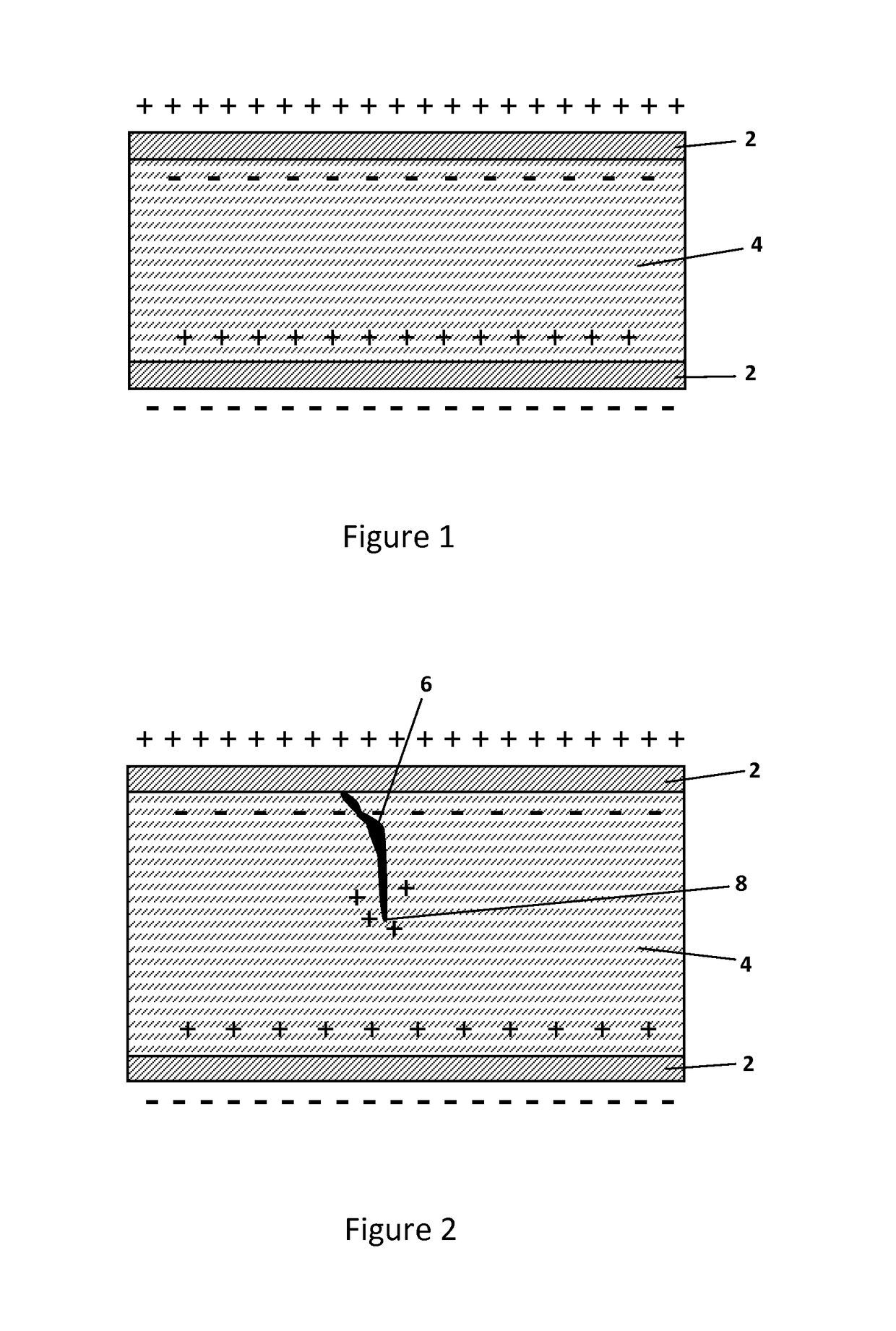

Stress detection within an integrated circuit having through silicon vias

ActiveUS20120006122A1Efficient managementReliable functionTesting/calibration apparatusSemiconductor/solid-state device testing/measurementClock rateStrain sensor

An integrated circuit 2 is formed of multiple wafer layers 4, 6, 8, 10 arranged in a stack and connected with through silicon vias 12. Mechanical strain sensors 26, 28, 30, 32 in the form of ring oscillators are provided proximal to the through silicon vias 12 and detect mechanical strain associated with the through silicon via 12. The measured mechanical strain may be used to dynamically adjust operating parameters of the integrated circuit either as a whole or in regions where the mechanical strain is detected. The operating parameters adjusted can include clock frequency, operating voltage and heat generation.

Owner:ARM LTD

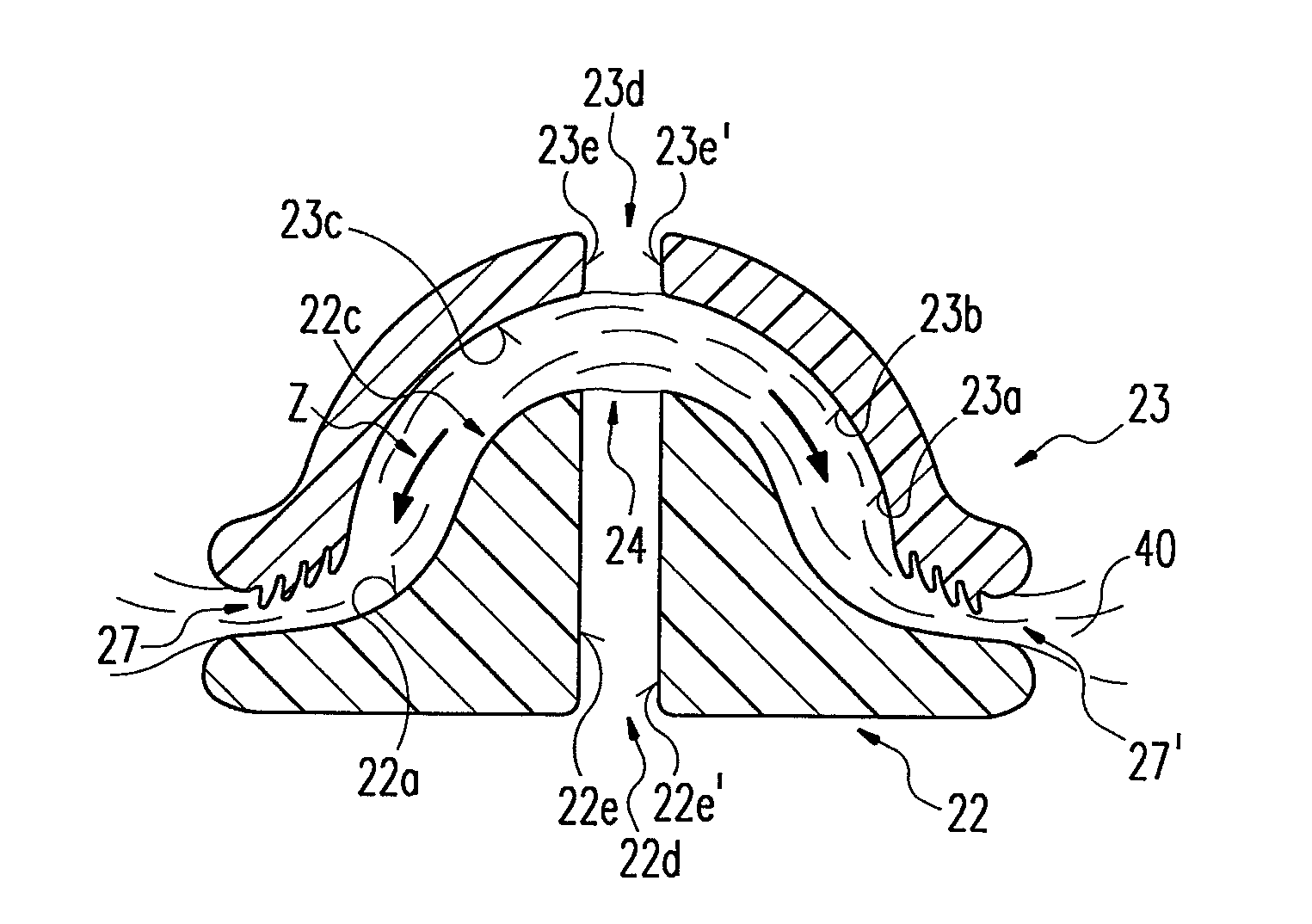

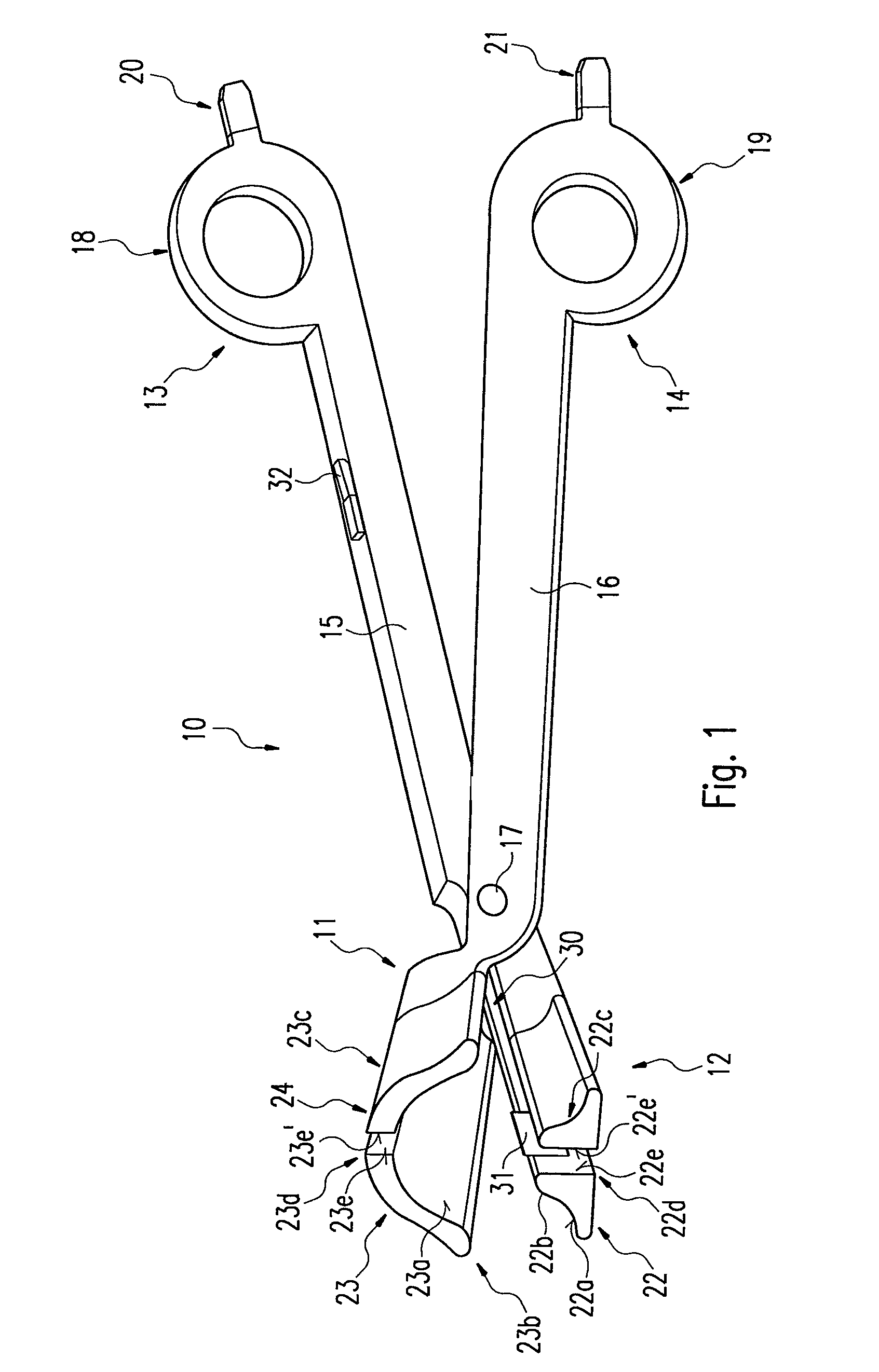

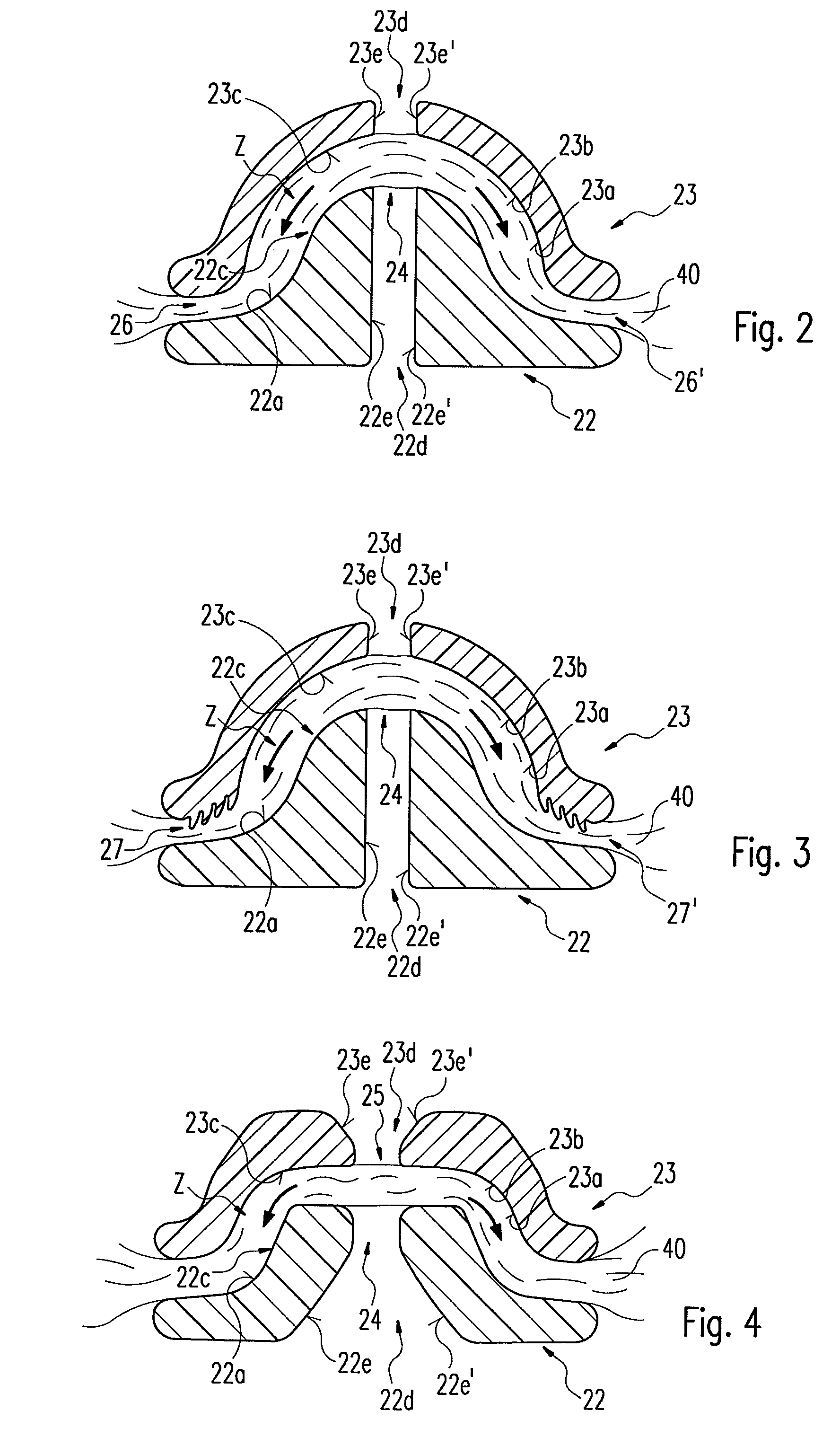

Electrosurgical instrument with opposing jaws, central knife, and barbs for maintaining clamping tension on tissue even after opening jaws

ActiveUS7972331B2Reduce mechanical strainSurgical instruments for heatingSurgical forcepsPower flowBiomedical engineering

The invention concerns an electrosurgical instrument comprising two articulated limbs, which can be actuated in the manner of a cutting or a clamping tool. The instrument further comprises opposing electrode parts with coagulating surfaces at the distal ends of the limbs for grasping a vessel or tissue and for conducting a coagulating current through the vessel or tissue in order to cause it to coagulate, as well as current-supplying devices for supplying the coagulating current to the electrode parts from a HF generator. In addition, the electrode parts each have at least one clamping region, such that clamped tissue is pretensioned between the electrode parts in order that a cutting procedure can be carried out on the pretensioned tissue by means of a cutting instrument.

Owner:ERBE ELEKTROMEDIZIN GMBH

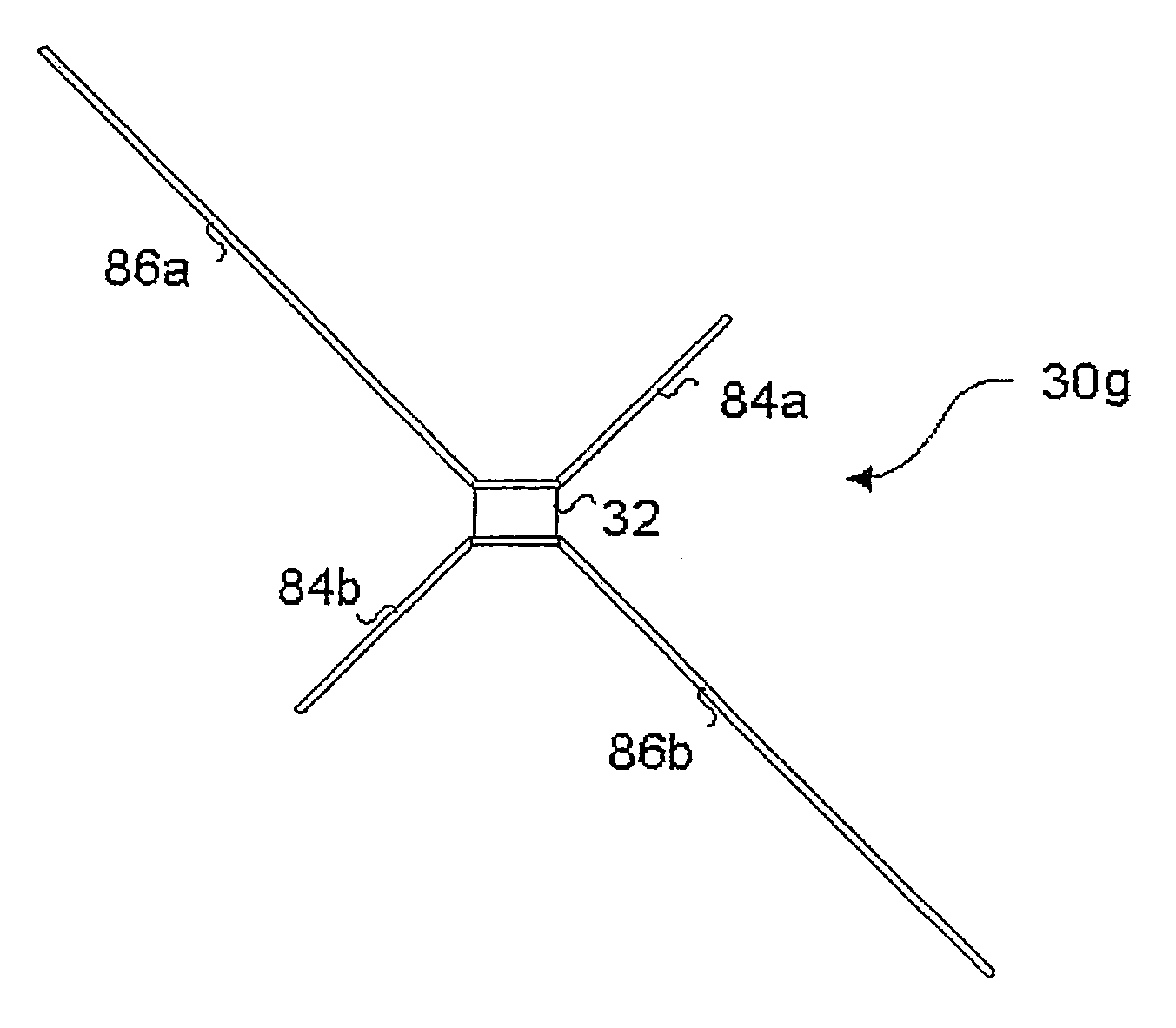

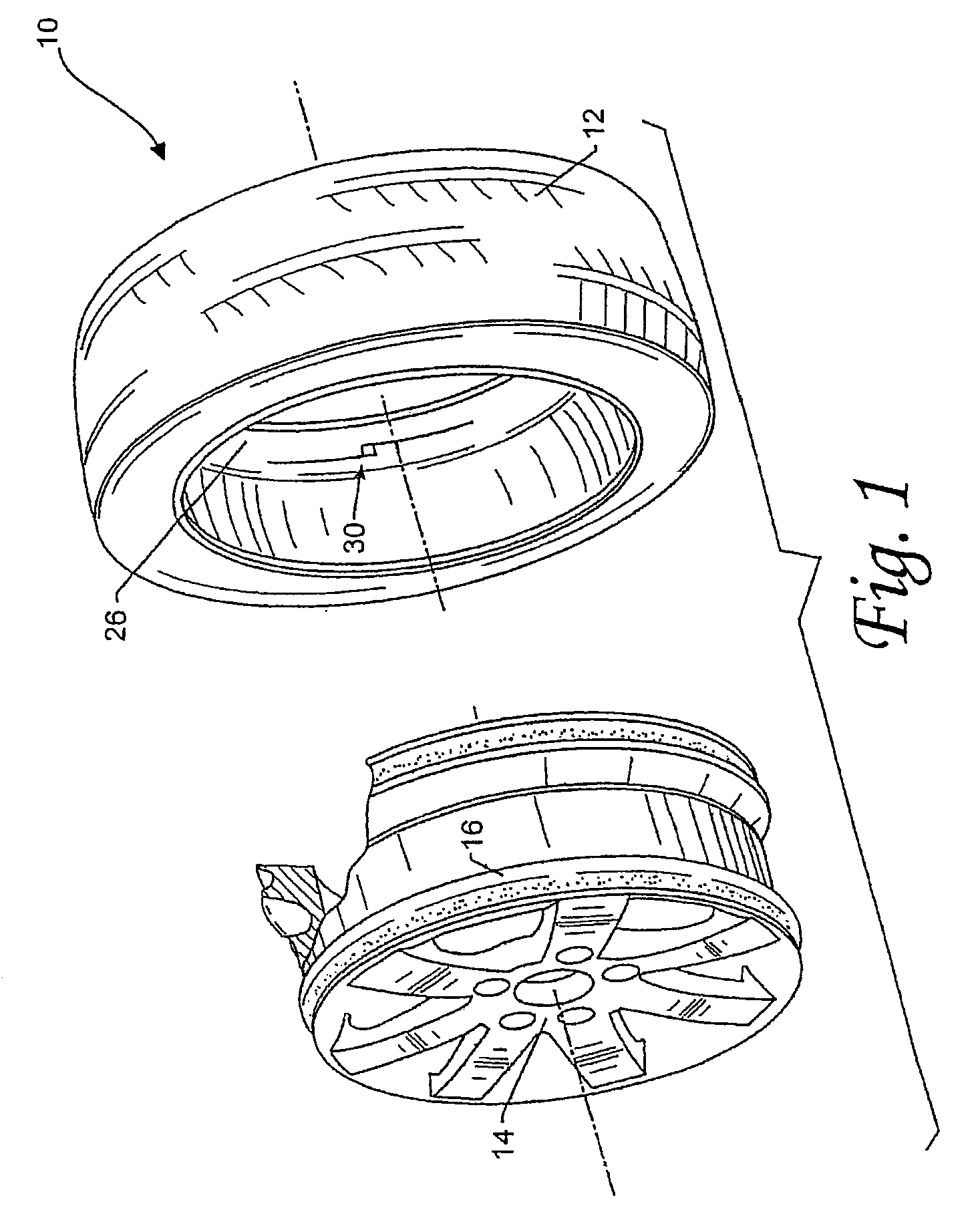

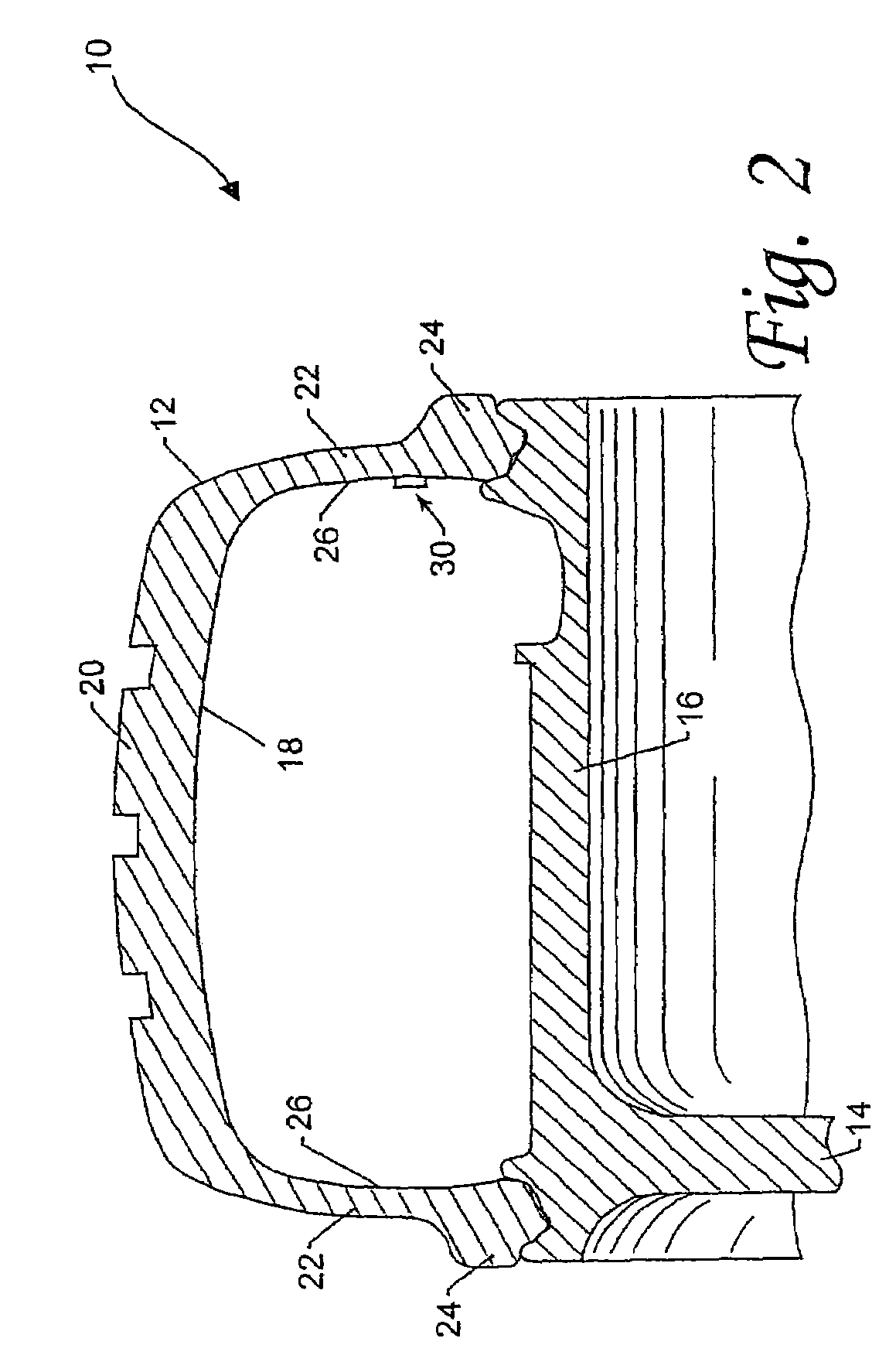

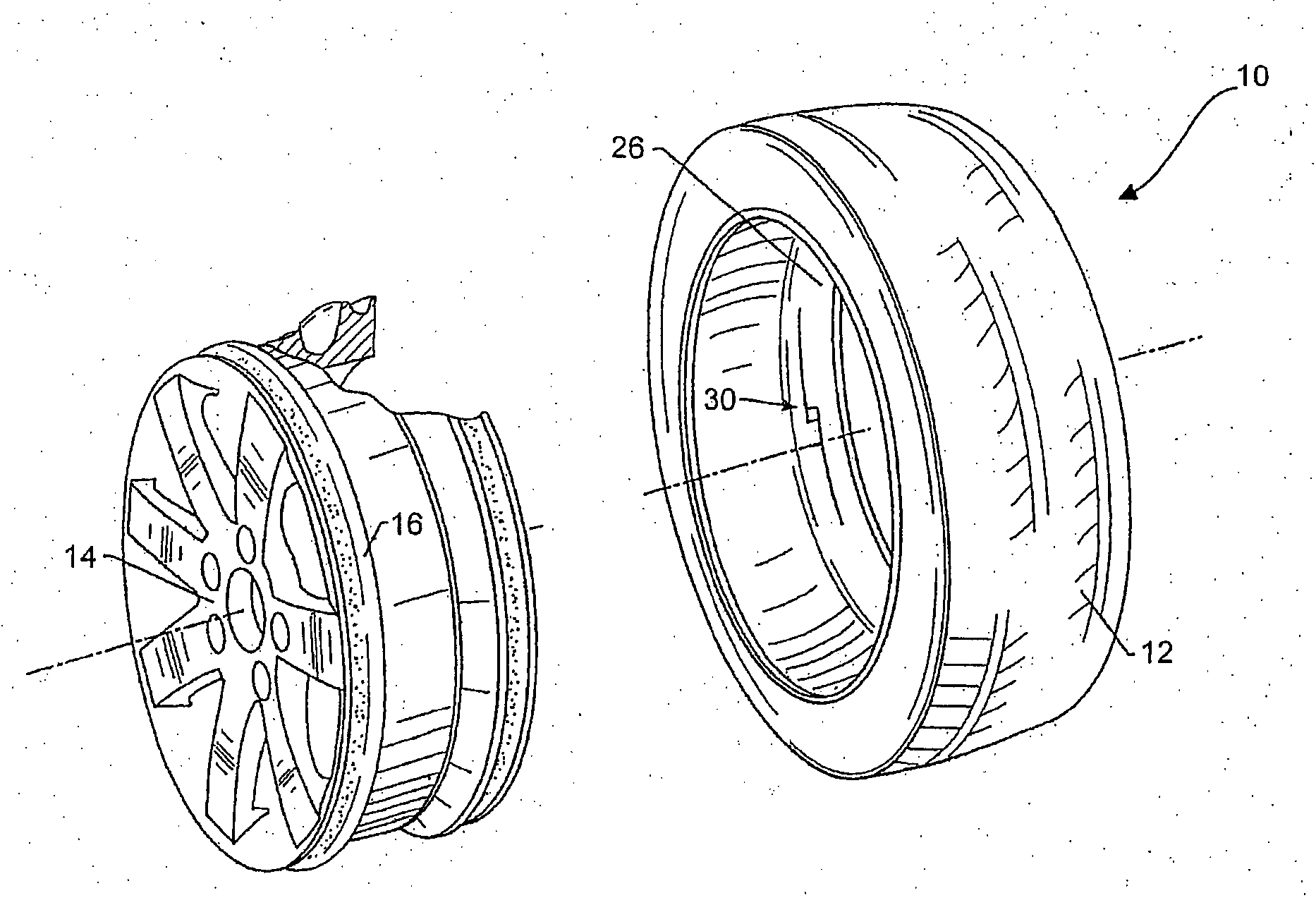

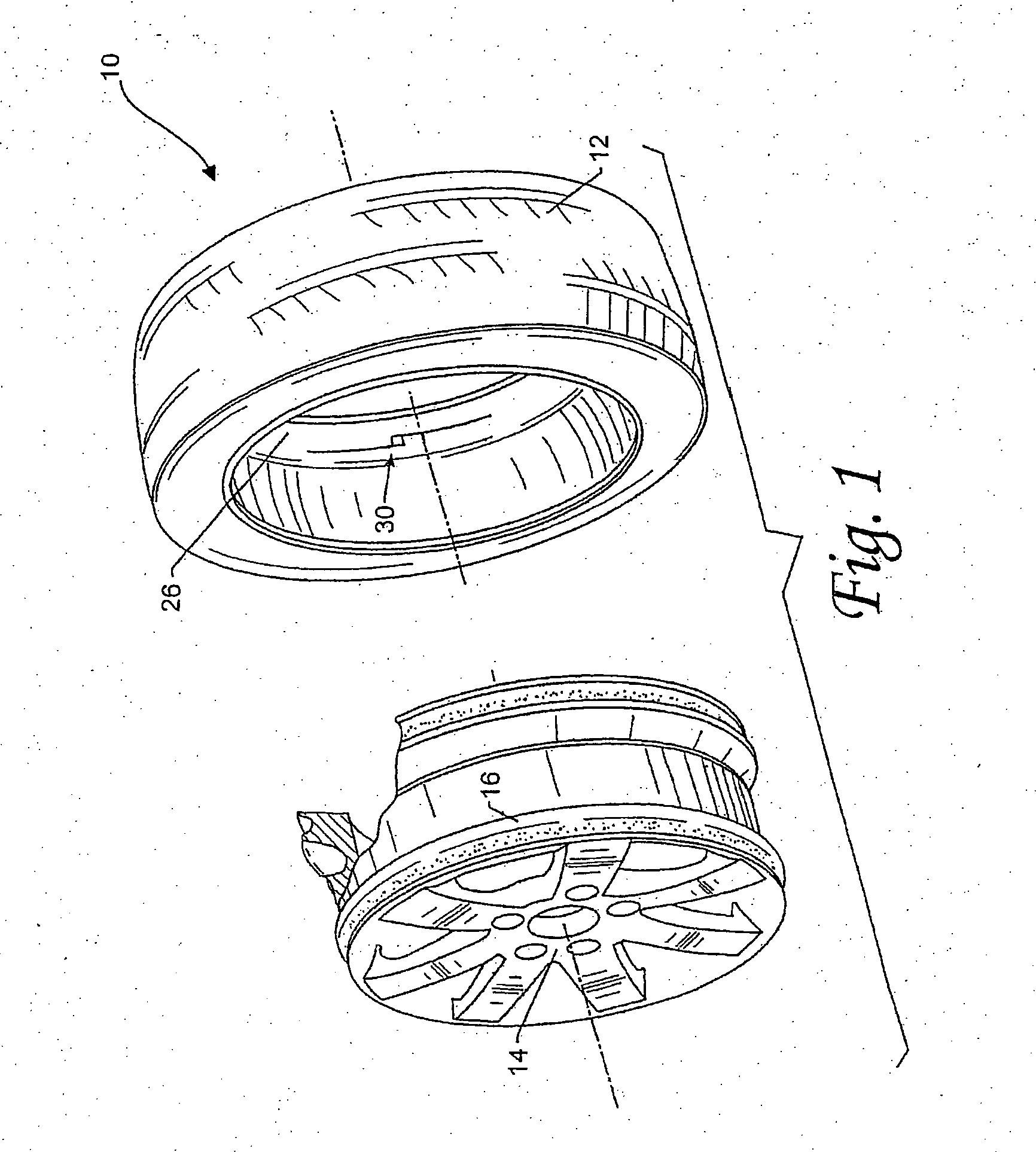

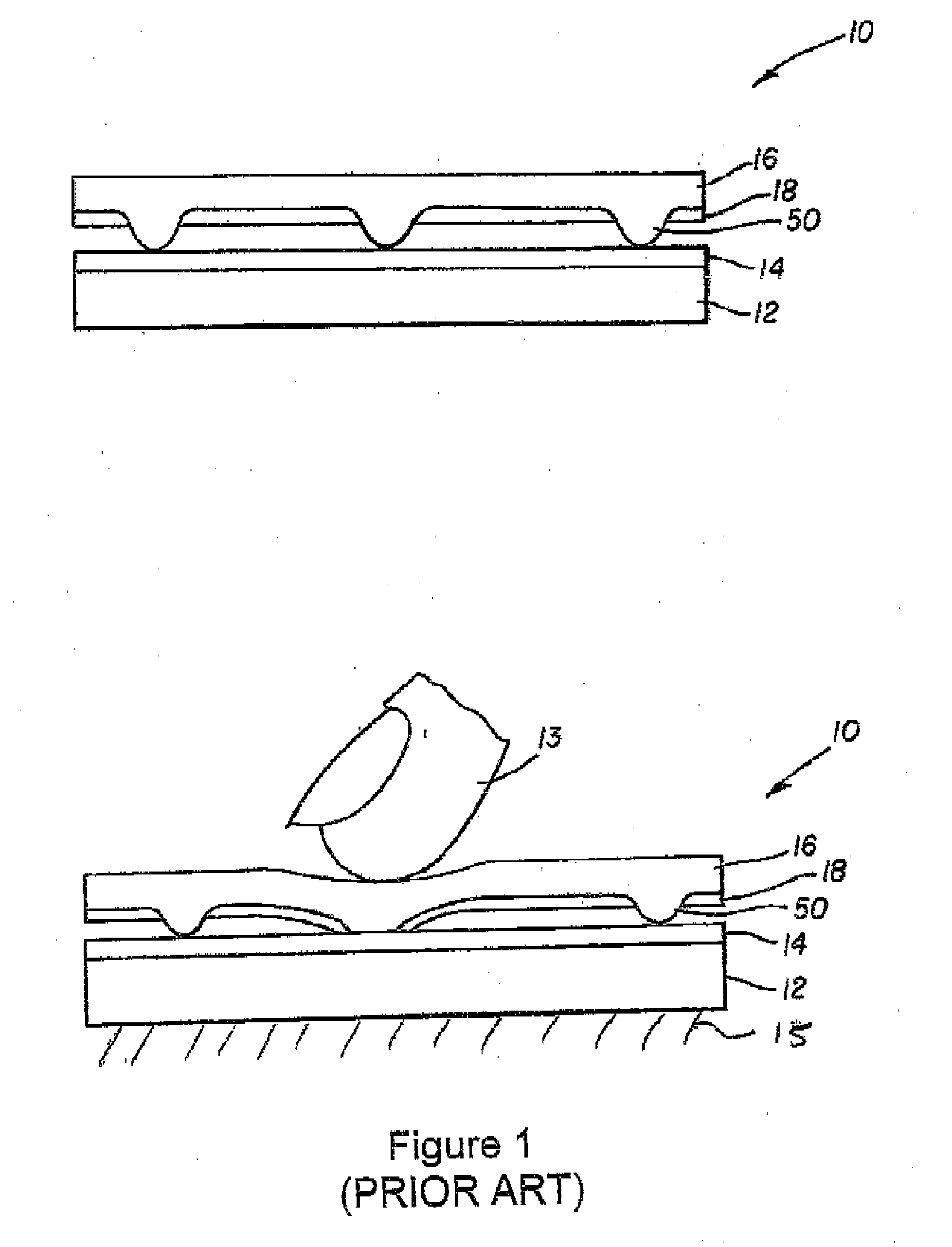

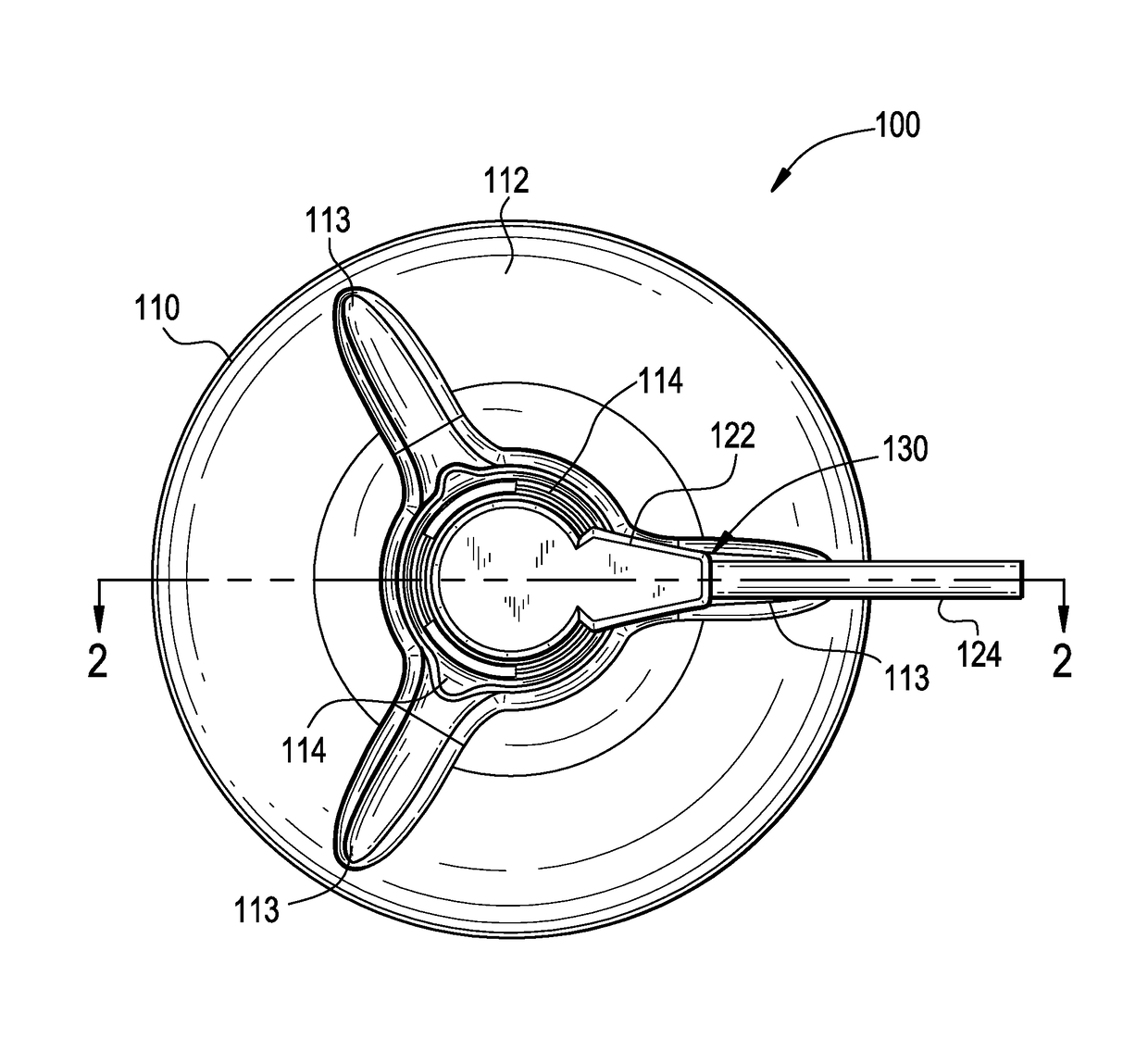

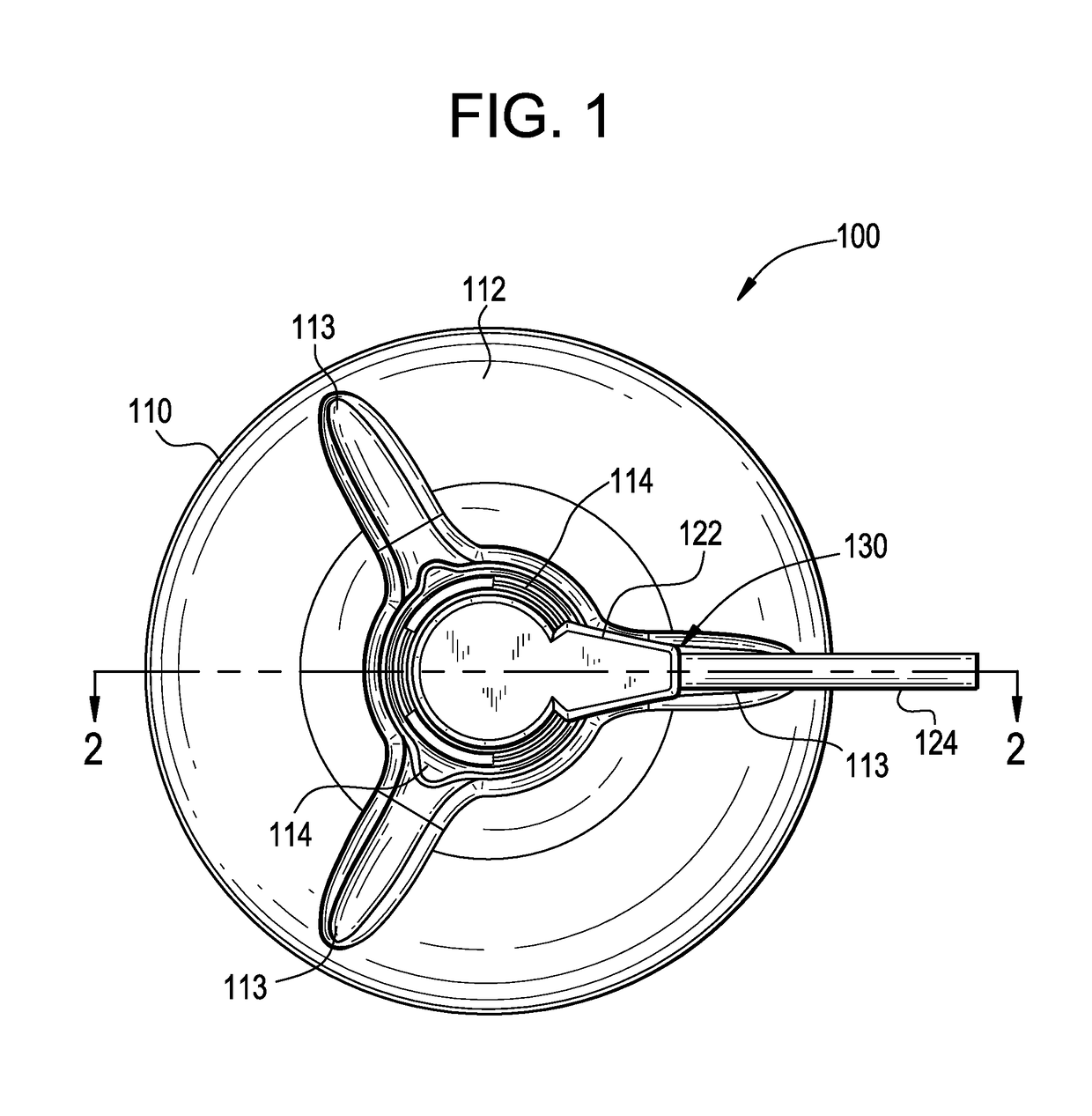

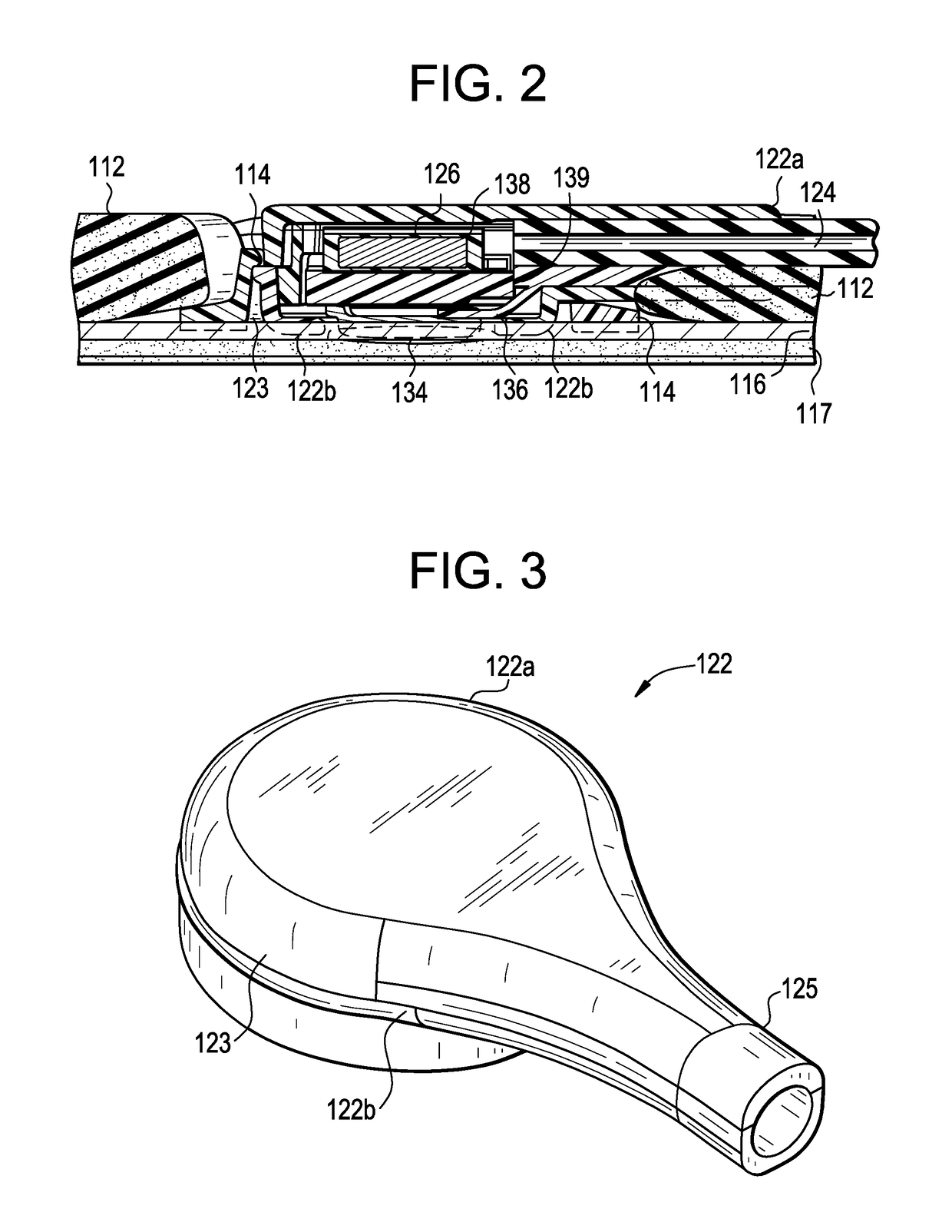

Tire electronics assembly having a multi-frequency antenna

ActiveUS7091841B2Easy to manufactureHigh mechanical strengthSimultaneous aerial operationsAntenna supports/mountingsIntegrated electronicsEngineering

A tire assembly with integrated electronic components includes a tire structure and an integrated electronics assembly, which preferably includes at least a radio frequency (RF) device and a multi-frequency antenna that enables wireless communication in at least first and second resonant frequency bands. Such multi-frequency antenna further comprises at least first and second antenna wires connected to the RF device, thus facilitating the transmission of RF signals which may include information such as tire identification information or measured condition information such as tire temperature, pressure, and other characteristics. The first and second antenna wires preferably function together as at least two dipole antennas, for example, two half-wave dipole antennas, or one half-wave dipole antenna and one three-half-wave dipole antenna. A two-wire configuration may be more readily implemented and also designed to reduce strains concentrated at the connection point(s) between the RF device and the antenna wires.

Owner:MICHELIN RECH & TECH SA

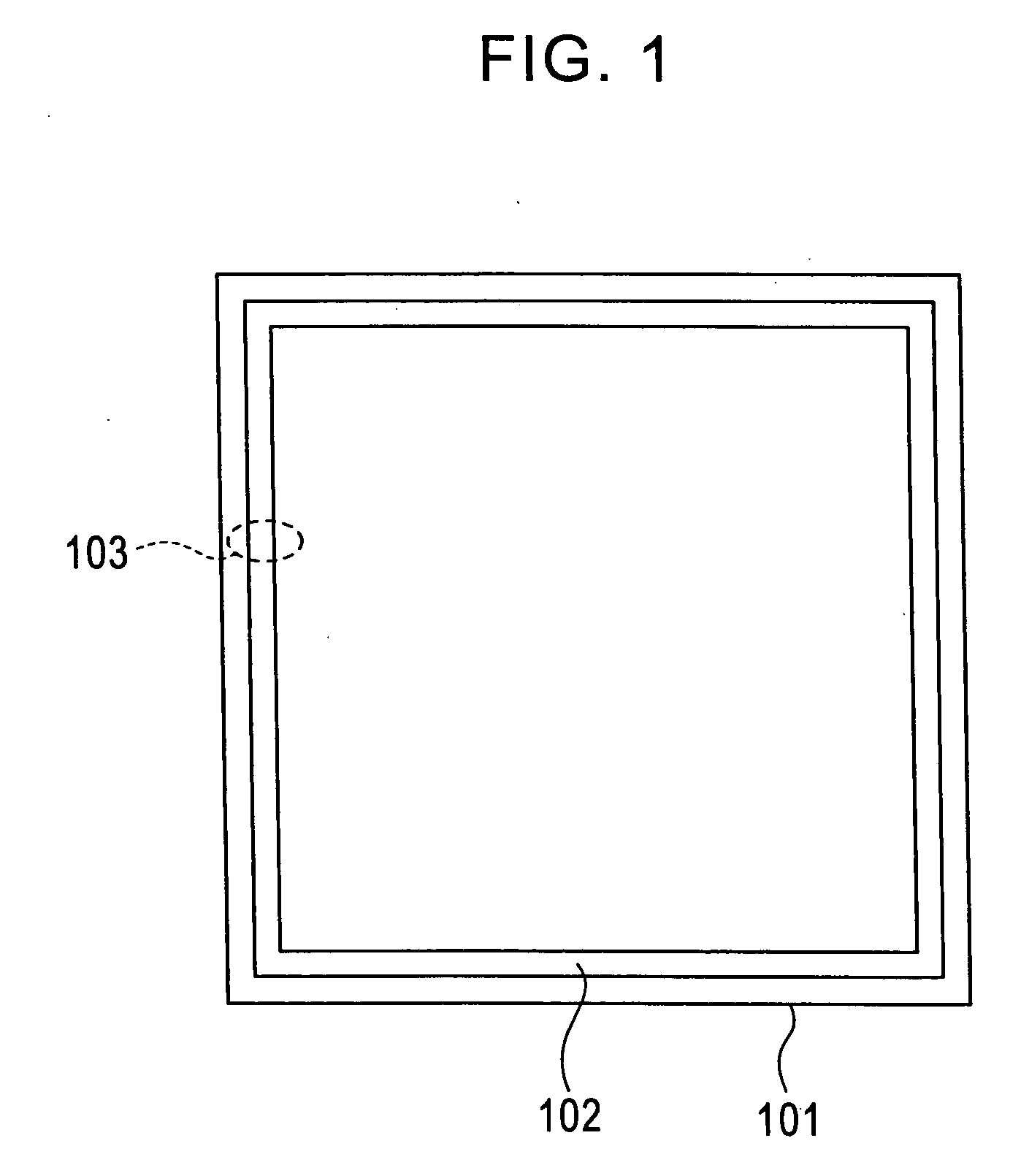

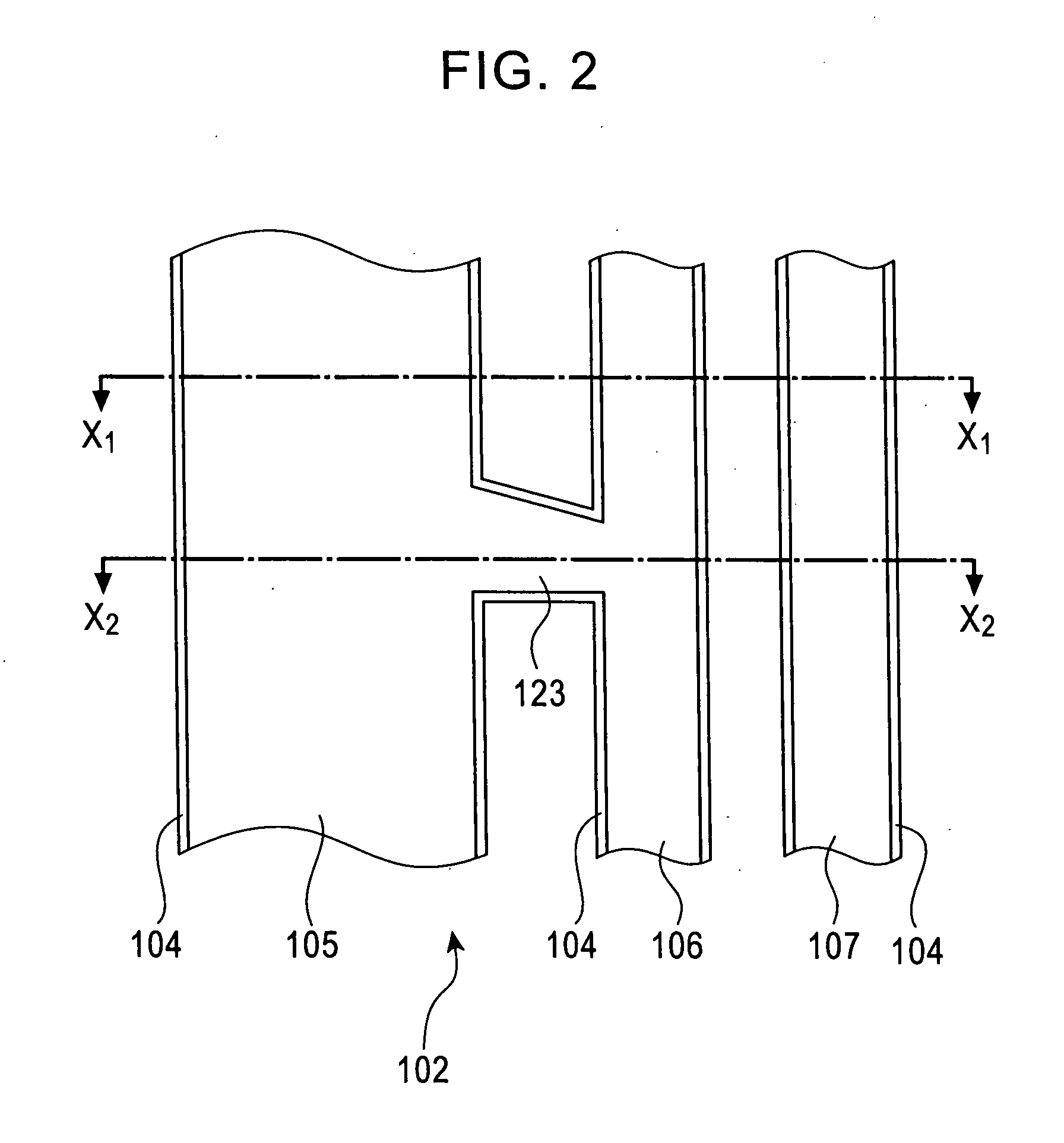

Semiconductor device

ActiveUS20060001165A1Avoid crackingReduce mechanical strainSemiconductor/solid-state device detailsSolid-state devicesDevice materialMicrometer

A semiconductor device with a damascene wiring structure which can prevent short-circuits between a seal ring and a wiring line or electrode pad. The upper layer barrier layer made from a conductive barrier material film is formed on the interlayer insulating film groove sidewall of the semiconductor device, an upper layer seal ring wiring line with the thickness of approximately 10 micrometers for instance made from a wiring material film is embedded in a groove, and a plurality of isolated pockets of insulators are formed to be disbursed in the upper layer seal ring wiring line. These isolated pockets of insulators formed using the interlayer insulating film which forms the aforementioned damascene wiring line. Furthermore, a first upper layer groove wiring line and a second upper layer groove wiring line are formed in the element forming region, and an upper layer barrier layer is formed on the outside perimeter. The upper layer seal ring wiring line and both upper layer wiring lines all have (dual) damascene wiring structures.

Owner:LAPIS SEMICON CO LTD

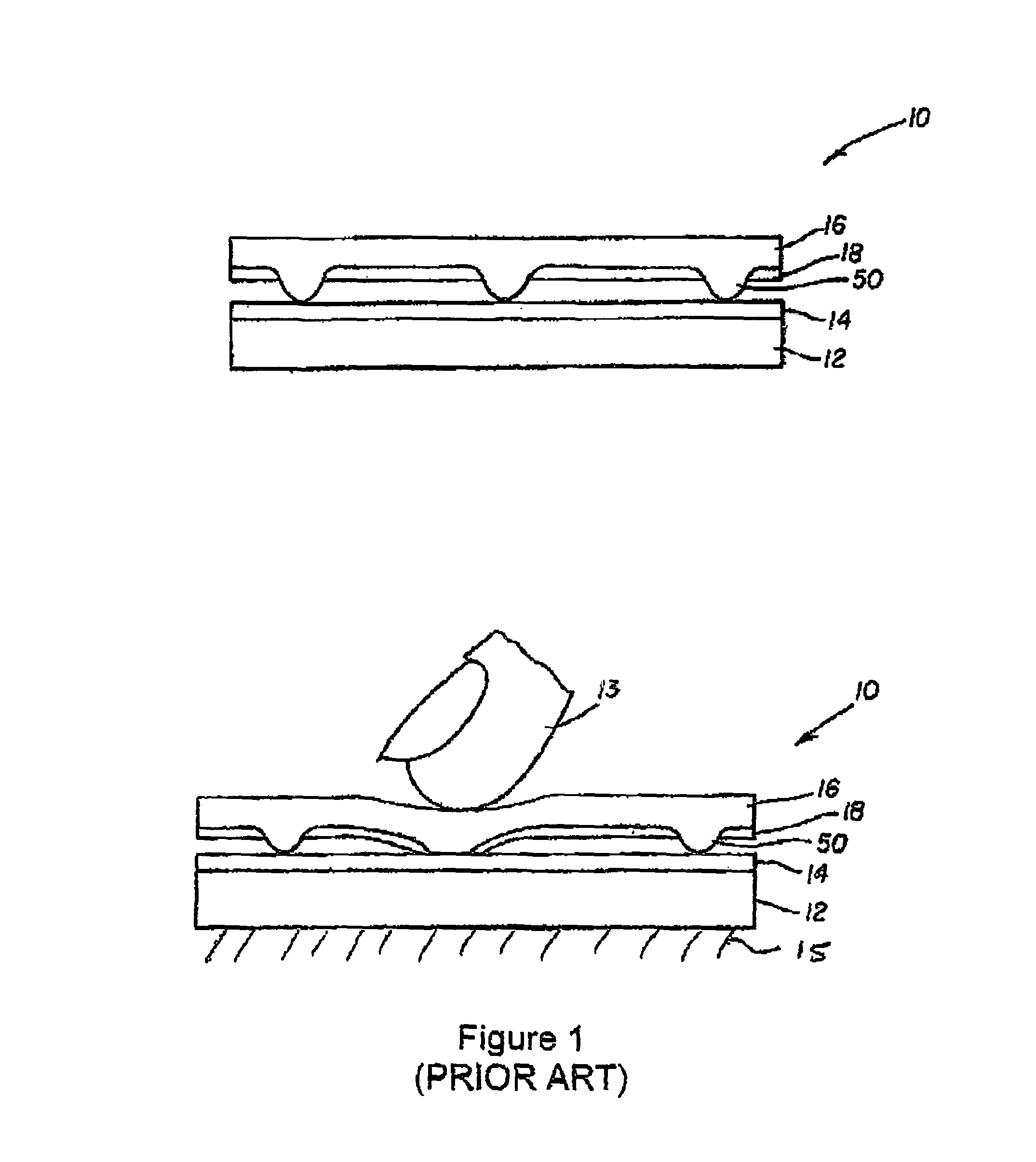

Tire electronics assembly having a multi-frequency antenna

ActiveUS20050275518A1Easy to manufactureHigh mechanical strengthSimultaneous aerial operationsAntenna supports/mountingsIntegrated electronicsElectronic component

A tire assembly with integrated electronic components includes a tire structure and an integrated electronics assembly, which preferably includes at least a radio frequency (RF) device and a multi-frequency antenna that enables wireless communication in at least first and second resonant frequency bands. Such multi-frequency antenna further comprises at least first and second antenna wires connected to the RF device, thus facilitating the transmission of RF signals which may include information such as tire identification information or measured condition information such as tire temperature, pressure, and other characteristics. The first and second antenna wires preferably function together as at least two dipole antennas, for example, two half-wave dipole antennas, or one half-wave dipole antenna and one three-half-wave dipole antenna. A two-wire configuration may be more readily implemented and also designed to reduce strains concentrated at the connection point(s) between the RF device and the antenna wires.

Owner:MICHELIN RECH & TECH SA

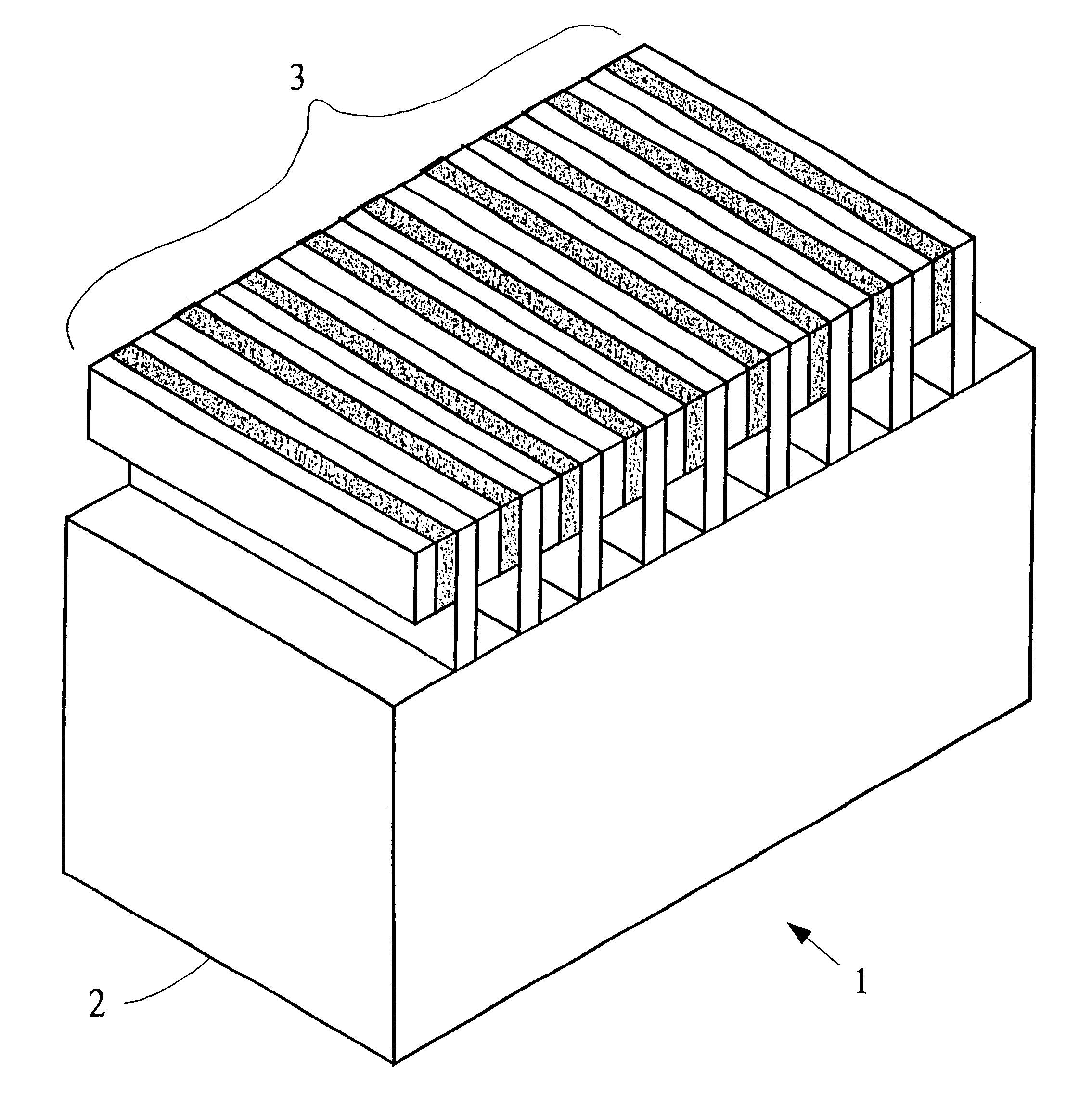

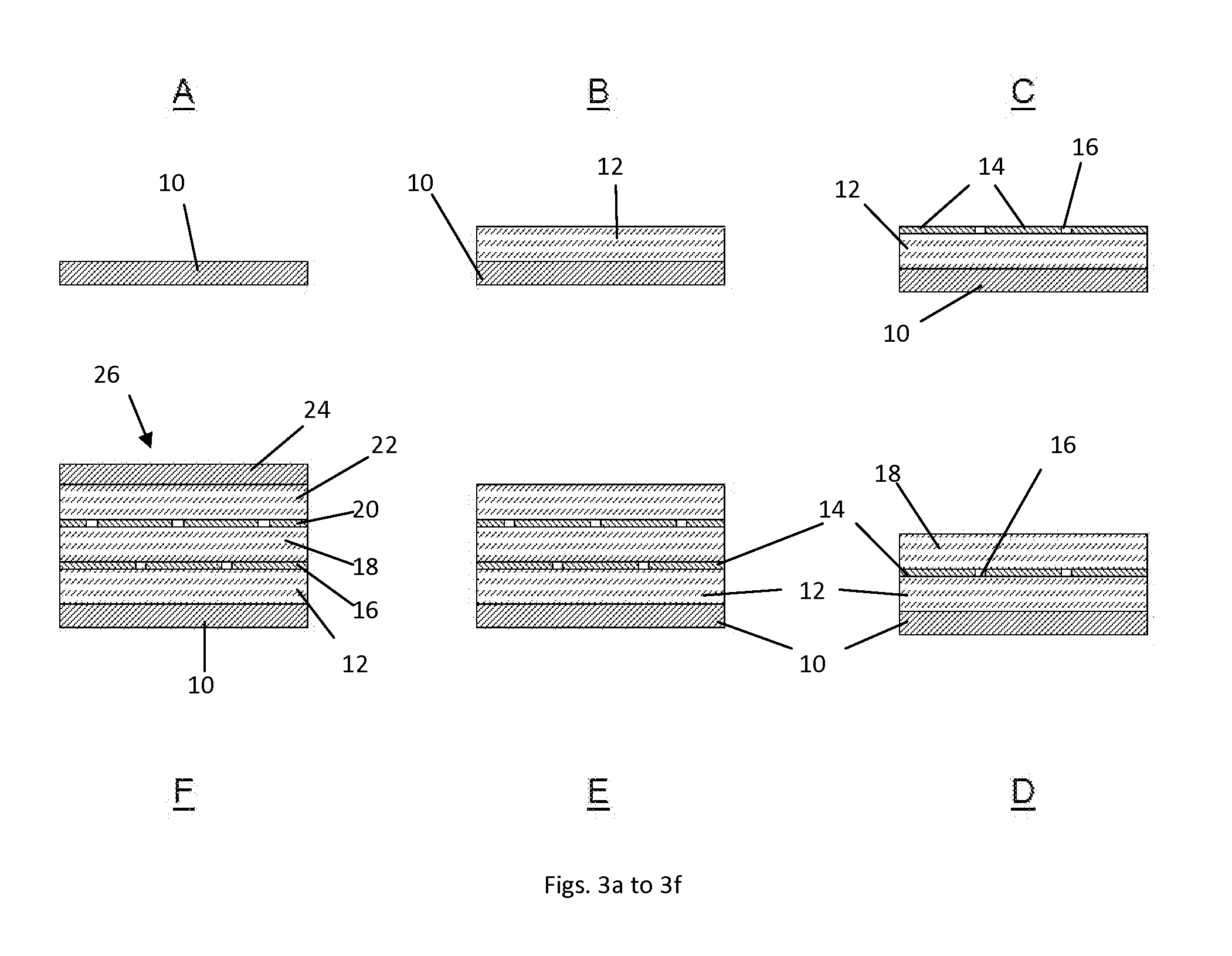

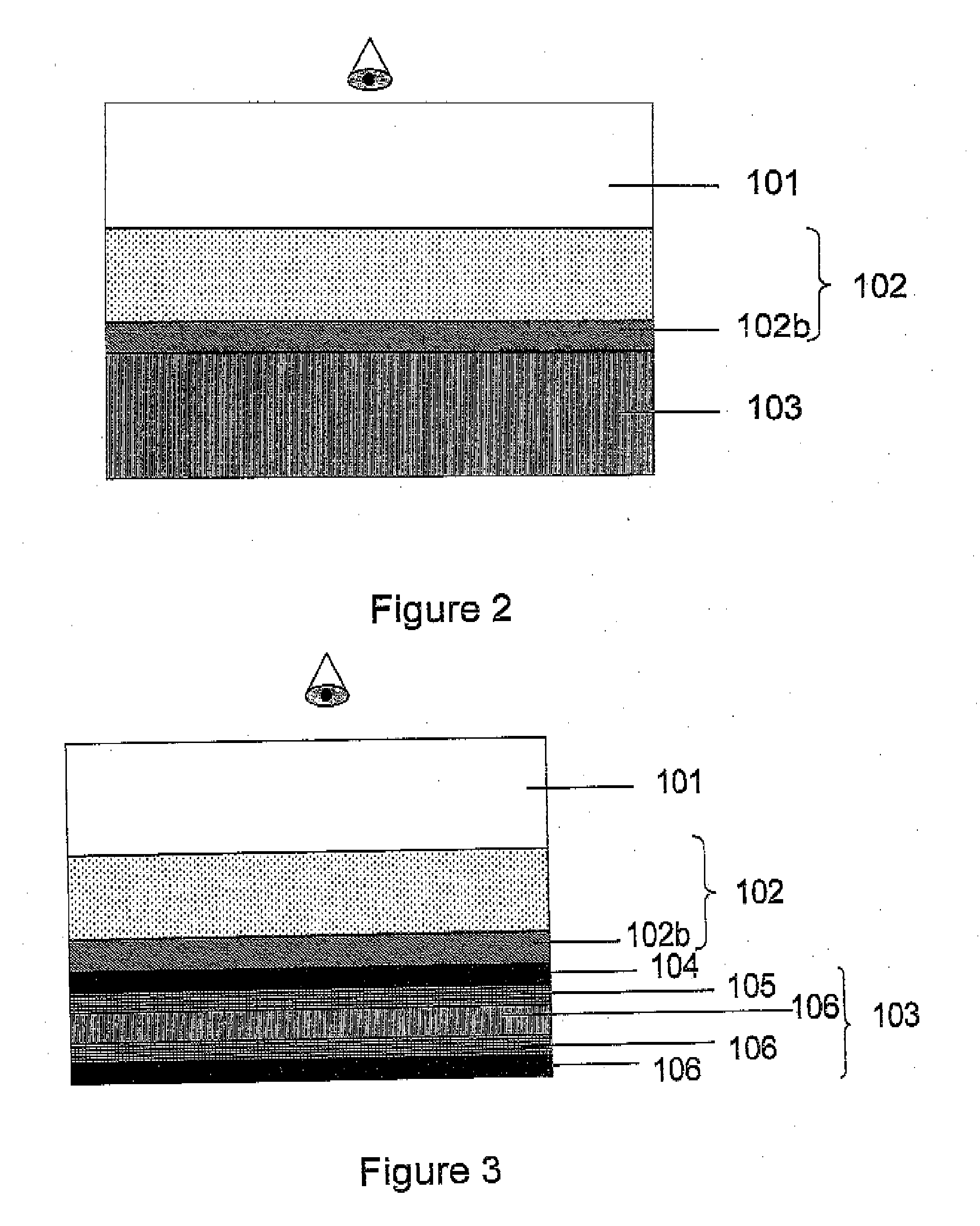

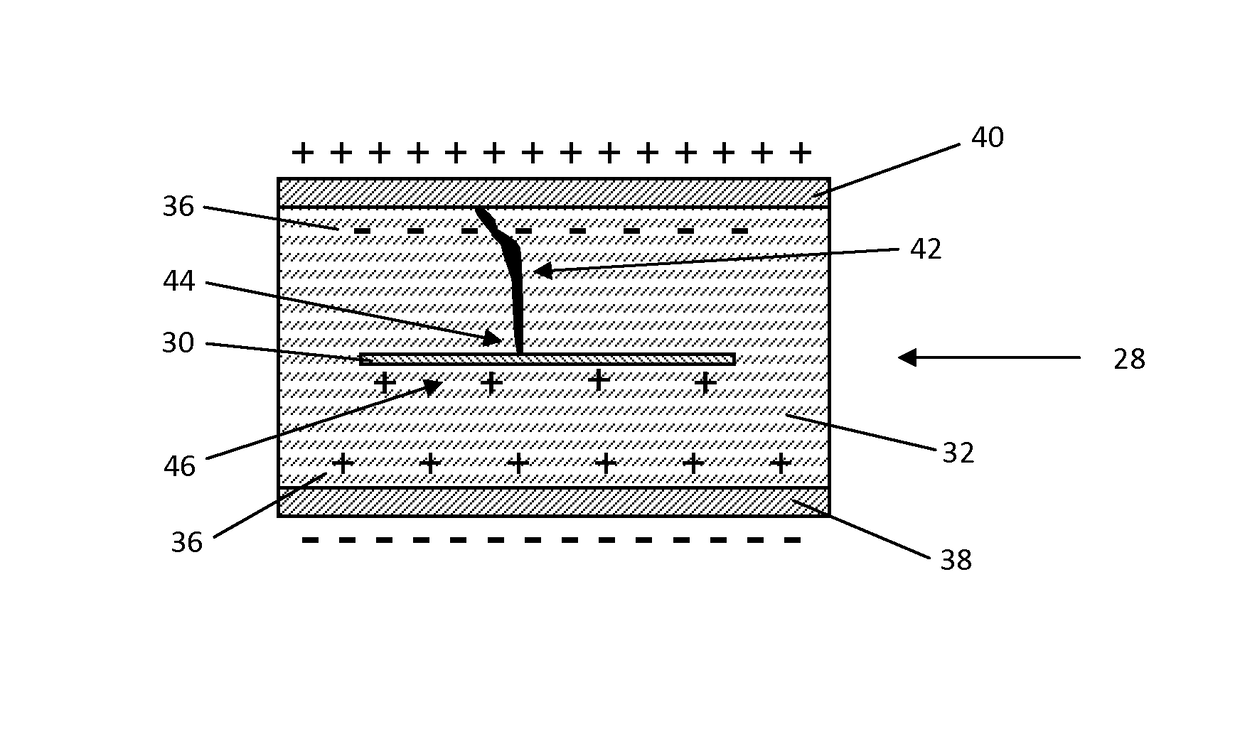

Method of making dielectric capacitors with increased dielectric breakdown strength

ActiveUS20130335882A1Minimize impactBlock and slow down growthFixed capacitor electrodesFixed capacitor dielectricBreakdown strengthMicro fracture

The invention is directed to a process for making a dielectric ceramic film capacitor and the ceramic dielectric laminated capacitor formed therefrom, the dielectric ceramic film capacitors having increased dielectric breakdown strength. The invention increases breakdown strength by embedding a conductive oxide layer between electrode layers within the dielectric layer of the capacitors. The conductive oxide layer redistributes and dissipates charge, thus mitigating charge concentration and micro fractures formed within the dielectric by electric fields.

Owner:UCHICAGO ARGONNE LLC

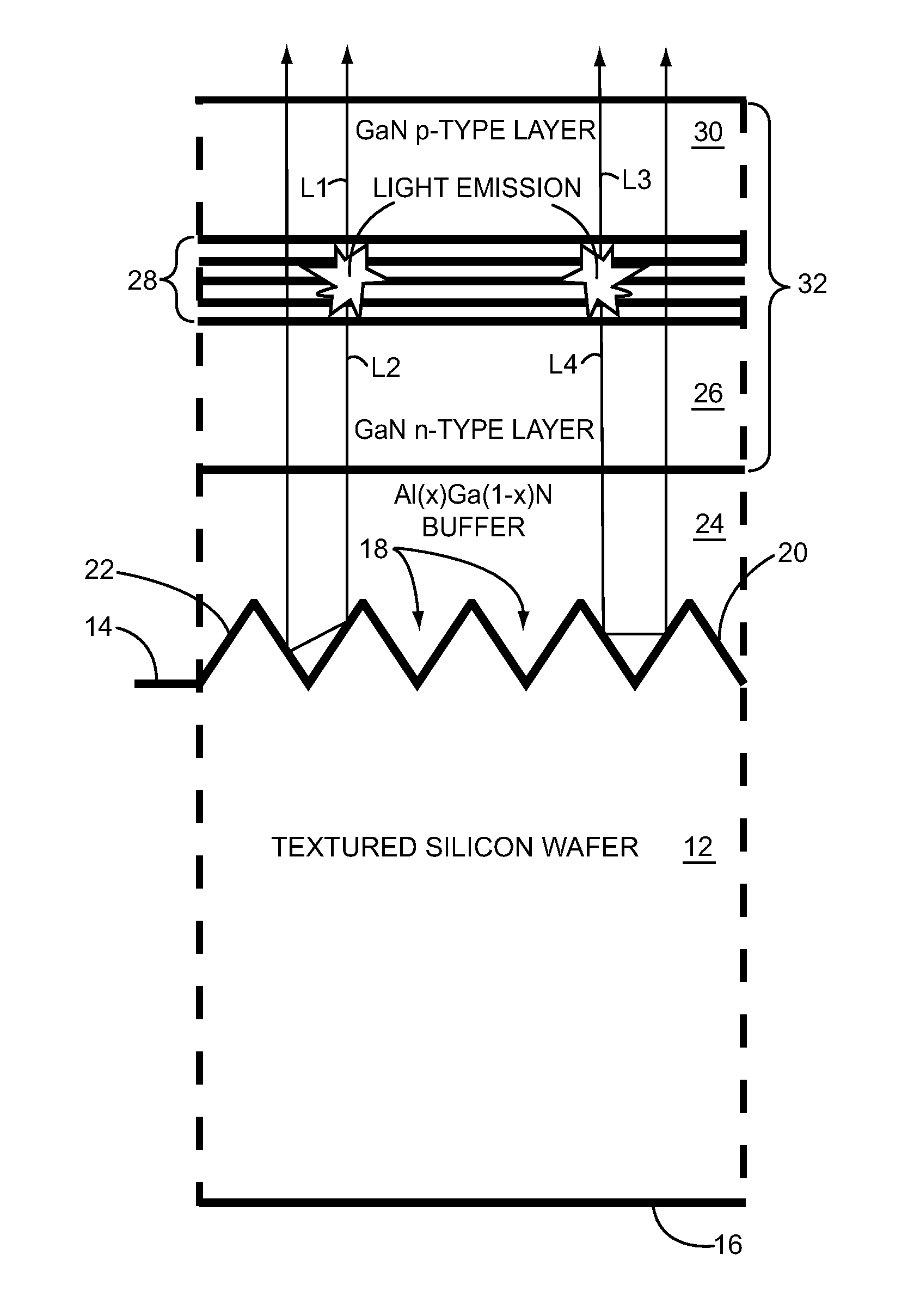

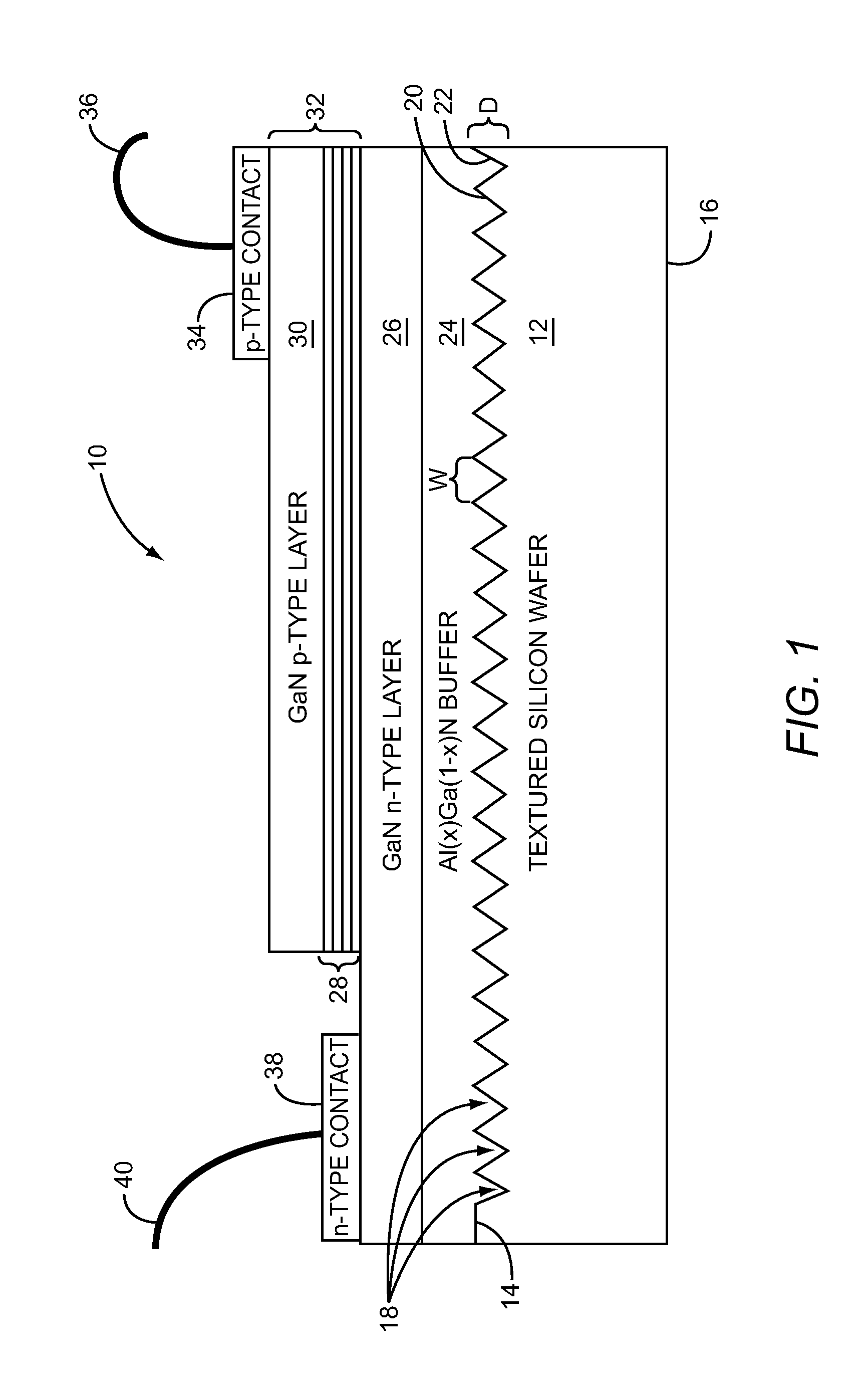

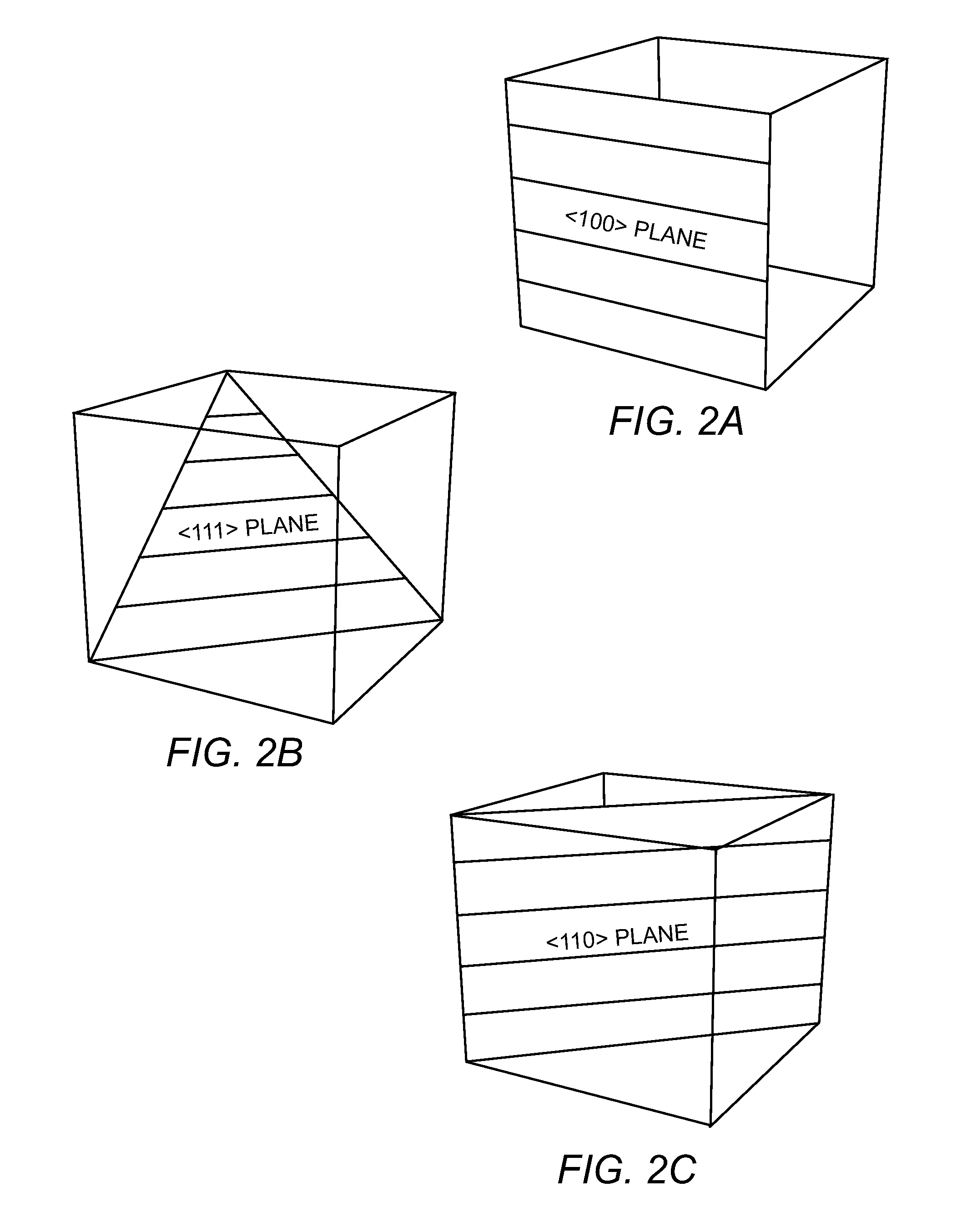

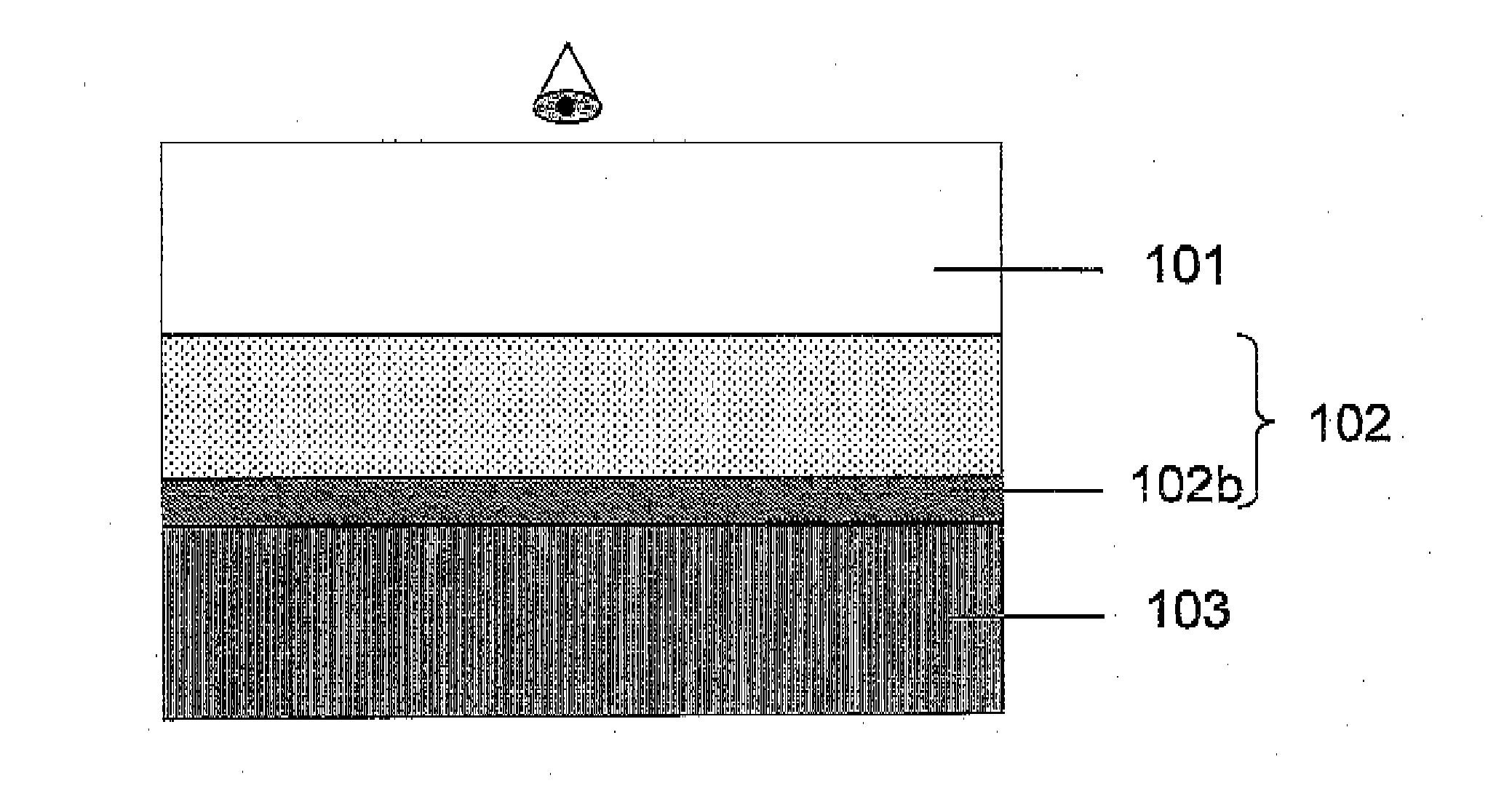

Reflecting light emitting structure and method of manufacture thereof

ActiveUS20110101300A1Uniform surfaceEffective dispersionSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodePhysics

A reflecting light emitting structure includes a substrate having a plurality of grooves formed in a first face of the substrate is disclosed. The first face is in a first crystallographic plane. Each of the plurality of grooves includes a first sidewall that is coplanar with a second crystallographic plane and a second sidewall that is coplanar with a third crystallographic plane. A buffer layer is provided on the substrate to reduce mechanical strain between the substrate and a light emitting diode (LED) fabricated on the buffer layer.

Owner:QORVO US INC

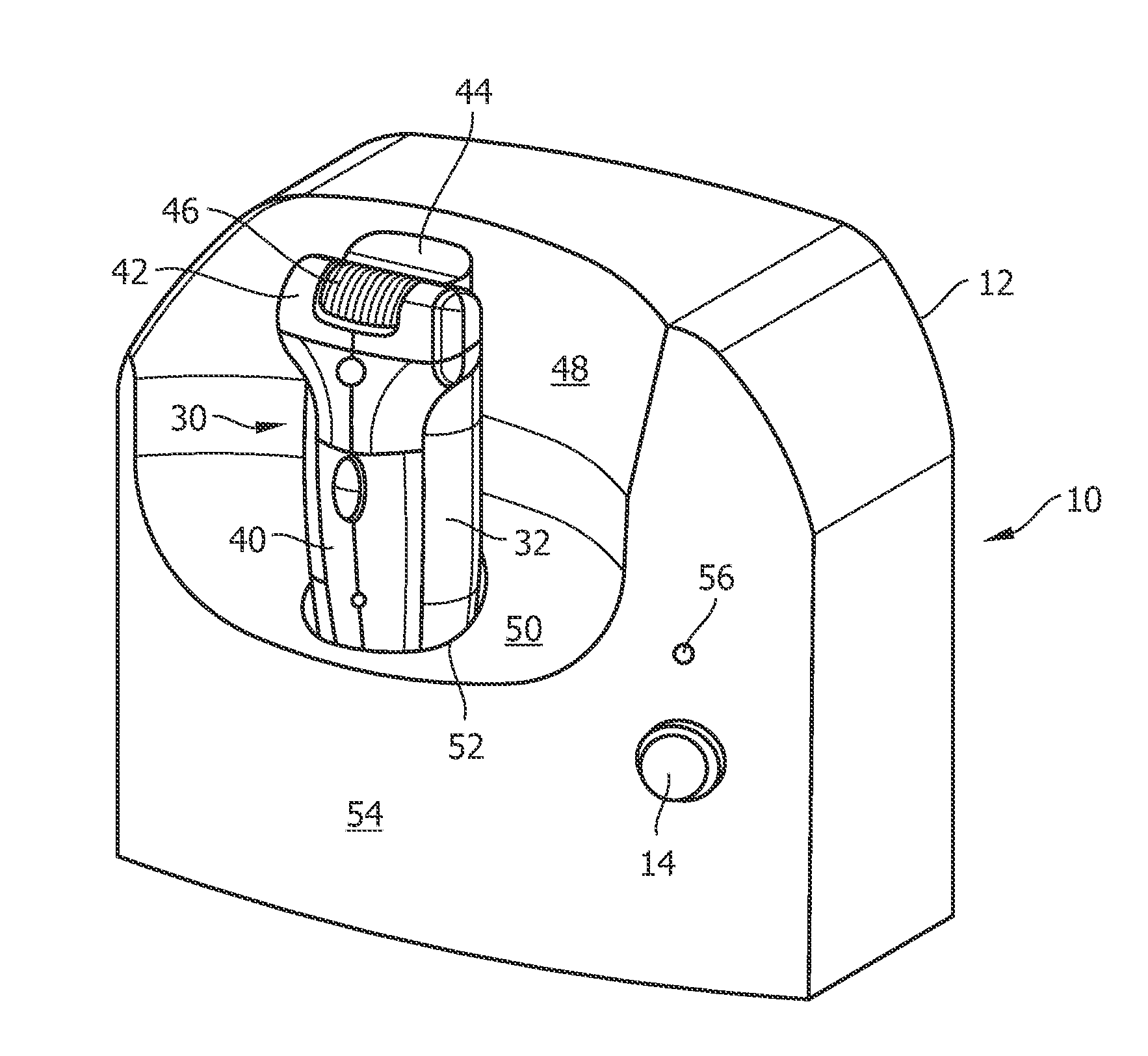

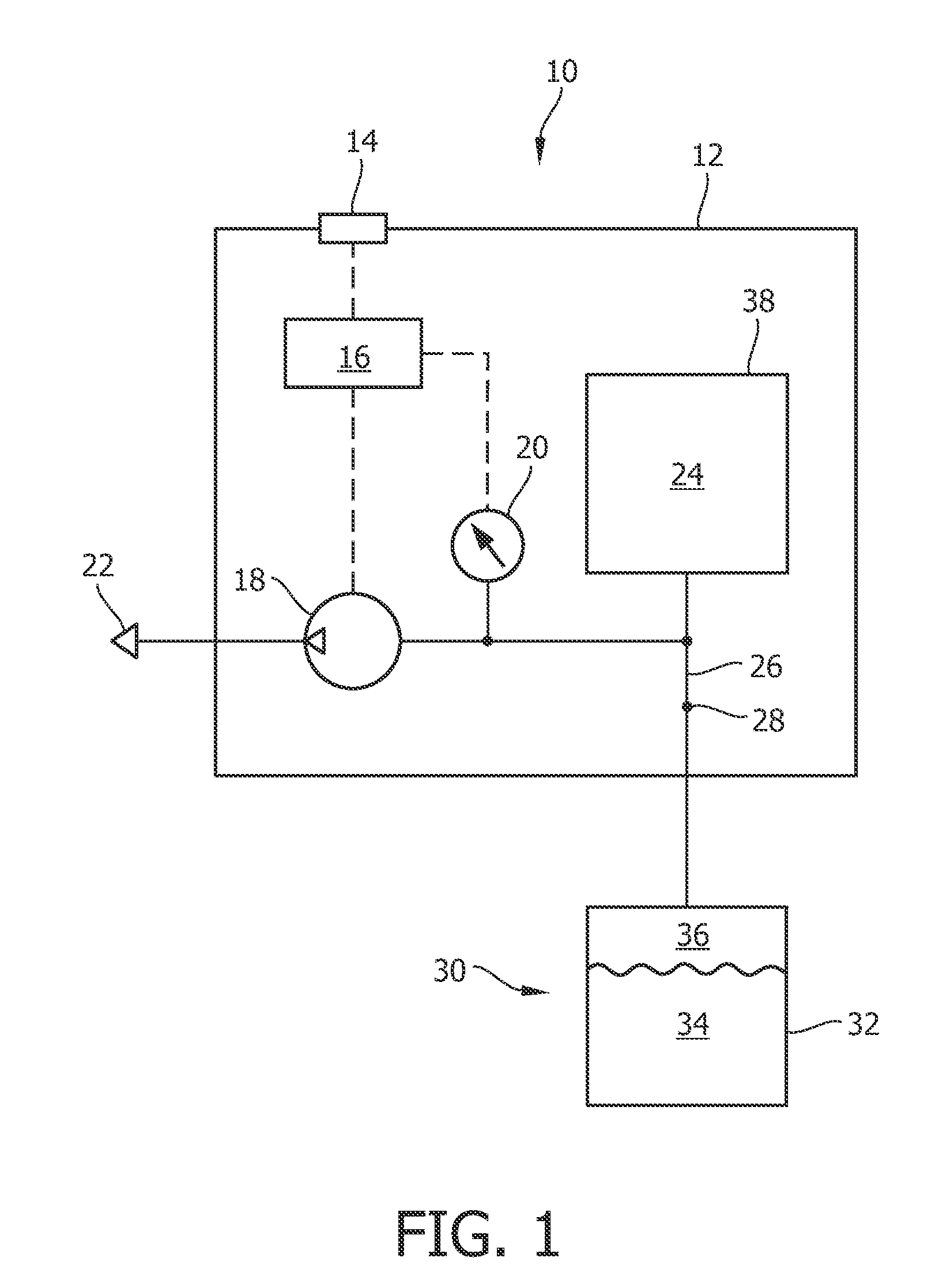

Docking station for a skin treatment device having a cooling member

InactiveUS20110015652A1Easy to takeAdvantageously employedHair-singeingSurgeryDocking stationSkin treatments

The invention relates to a docking station (10) for a skin treatment device (30) having a cooling member (32). According to the invention, the docking station comprises: an evacuator (18) for lowering a pressure inside the cooling member, and means (28) for connecting an interior of the cooling member to a sorbent (24). The sorbent preferably comprises a zeolite. The invention further relates to a skin treatment device (30), particularly an epilator, comprising a cooling member (32) for containing a cooling agent (34, 36). According to the invention, the skin treatment device comprises means (28) for connecting the cooling member to a docking station (10) as mentioned above. The cooling agent is preferably water or an aqueous solution.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

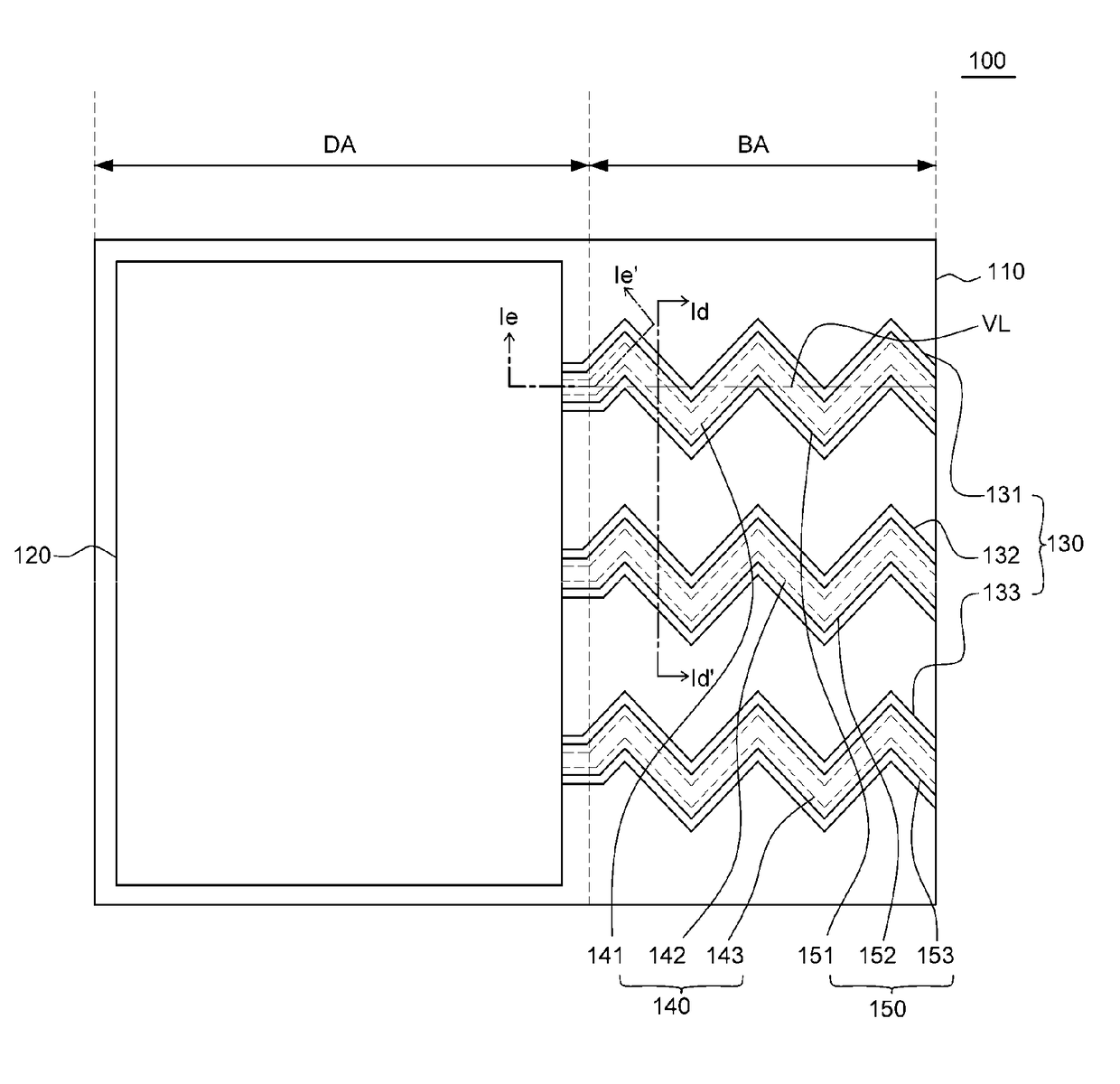

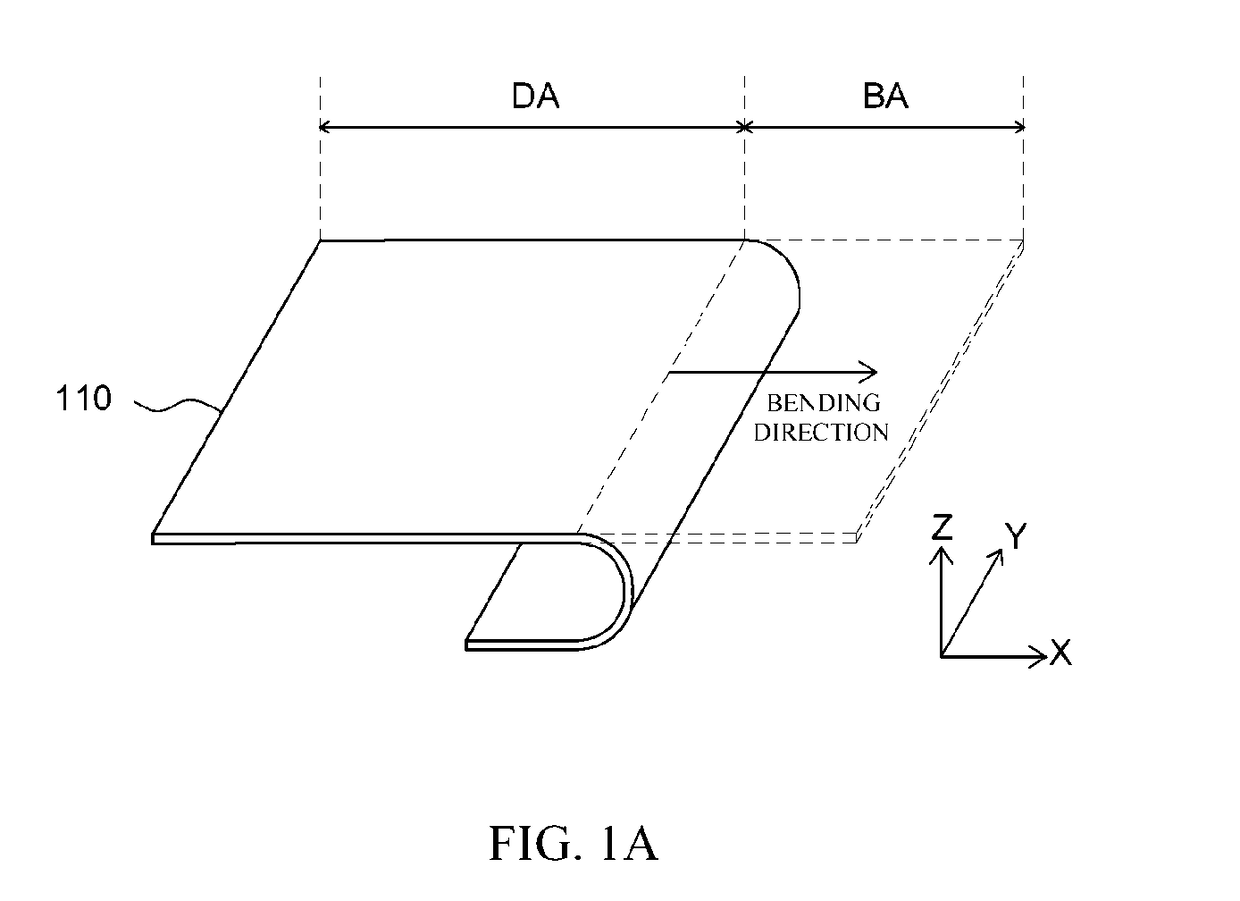

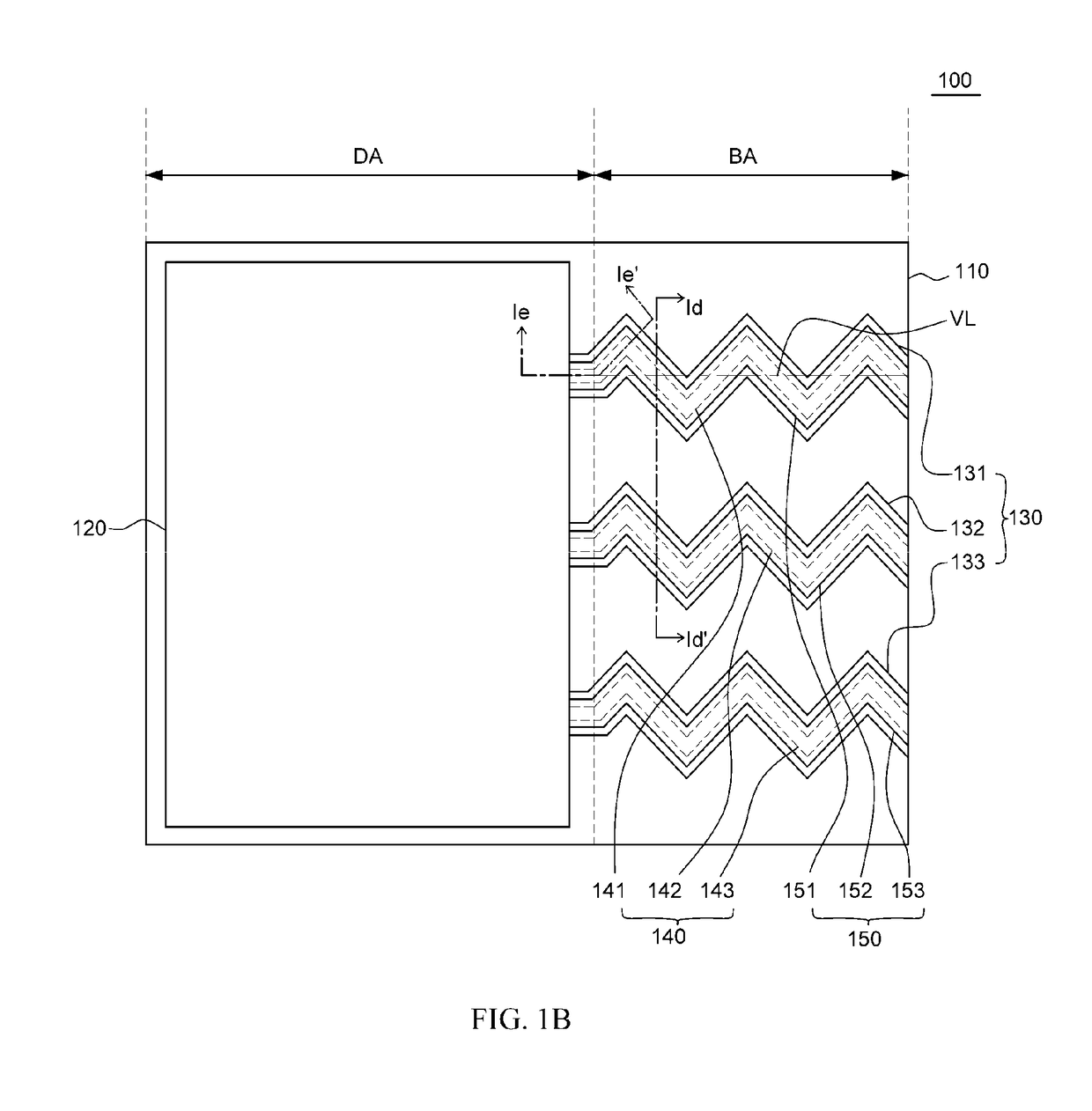

Flexible organic light emitting display device and method for manufacturing the same

ActiveUS9740035B2Reduce generationIncrease flexibilityFinal product manufactureElectroluminescent light sourcesDisplay deviceFlexible display

There is provided a flexible display having a new wire structure and a new insulating layer structure. A flexible display includes a flexible substrate having a first area and a second area. The second area is curved in a non-zero angle relative to the plane of the first area. The flexible display further includes a plurality of wires that extend over from the first area to the second area of the flexible substrate. Each of the wires is covered by an upper insulating pattern, which is separated from other upper insulating pattern. Each upper insulating pattern covering the wire has substantially the same trace pattern shape of the corresponding wire thereunder. Accordingly, by adopting the above-described wire structure and upper insulating layer structure, crack generation and propagation in the wires and the insulating layers from bending of the flexible display can be minimized.

Owner:LG DISPLAY CO LTD

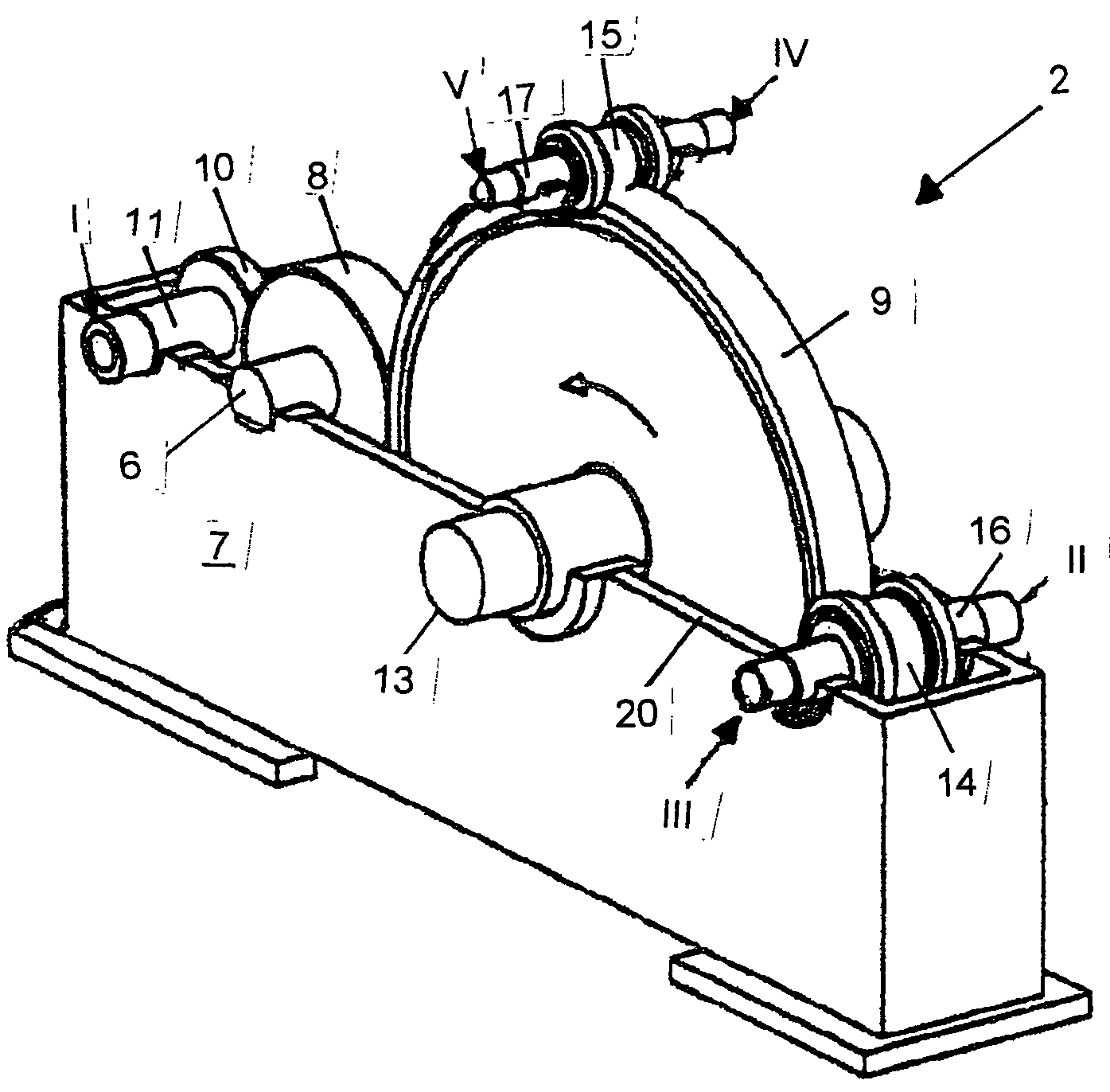

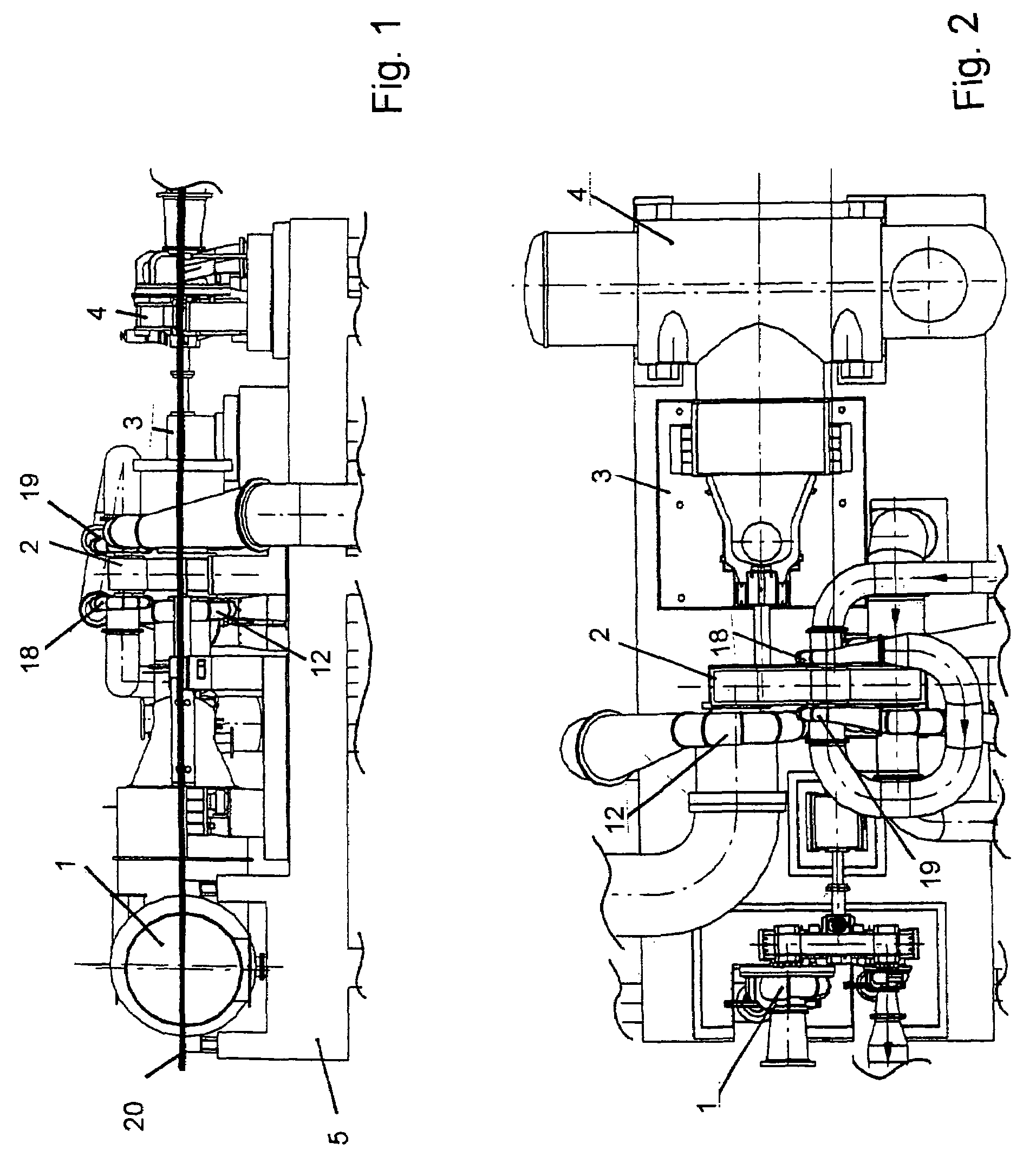

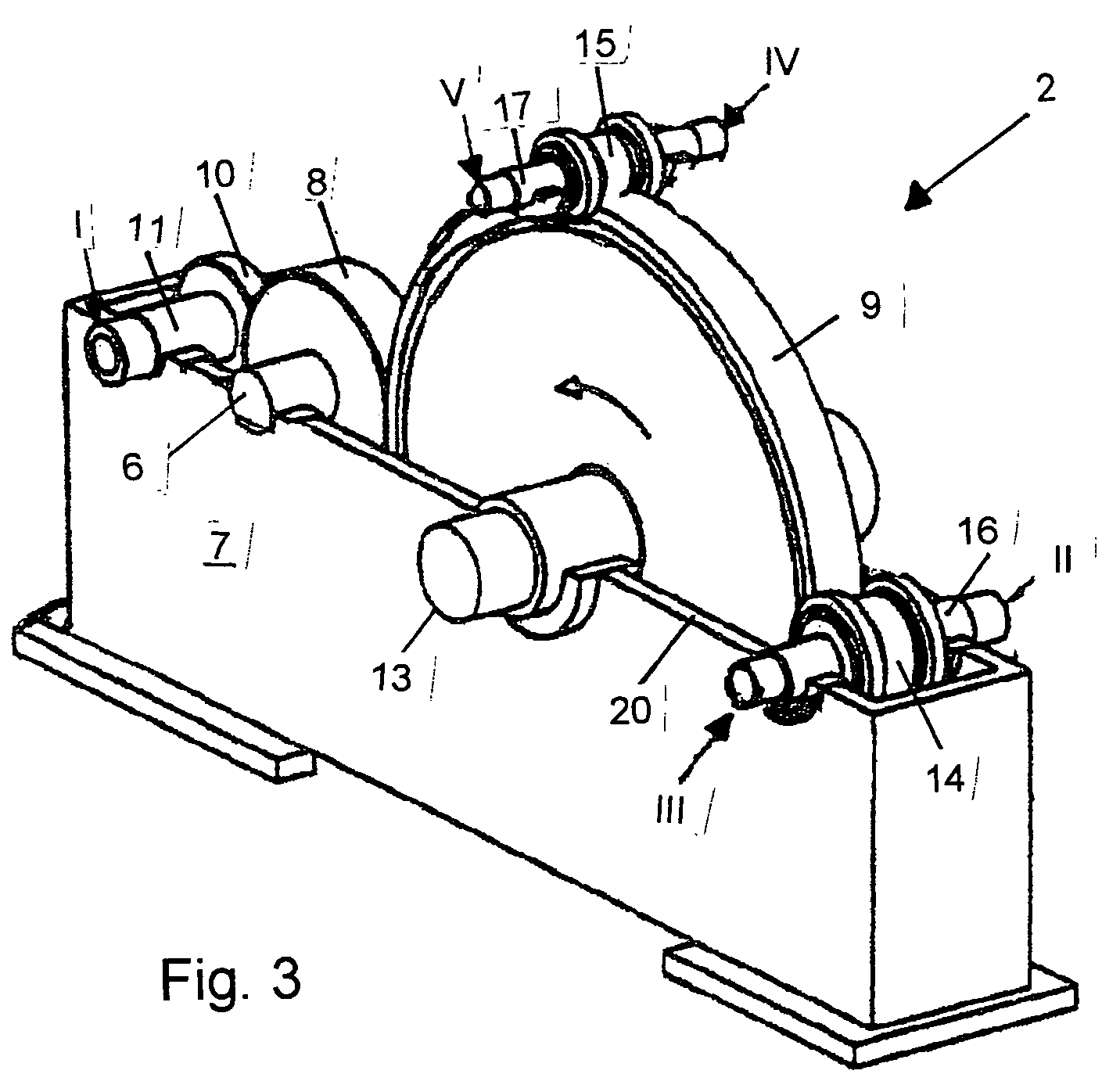

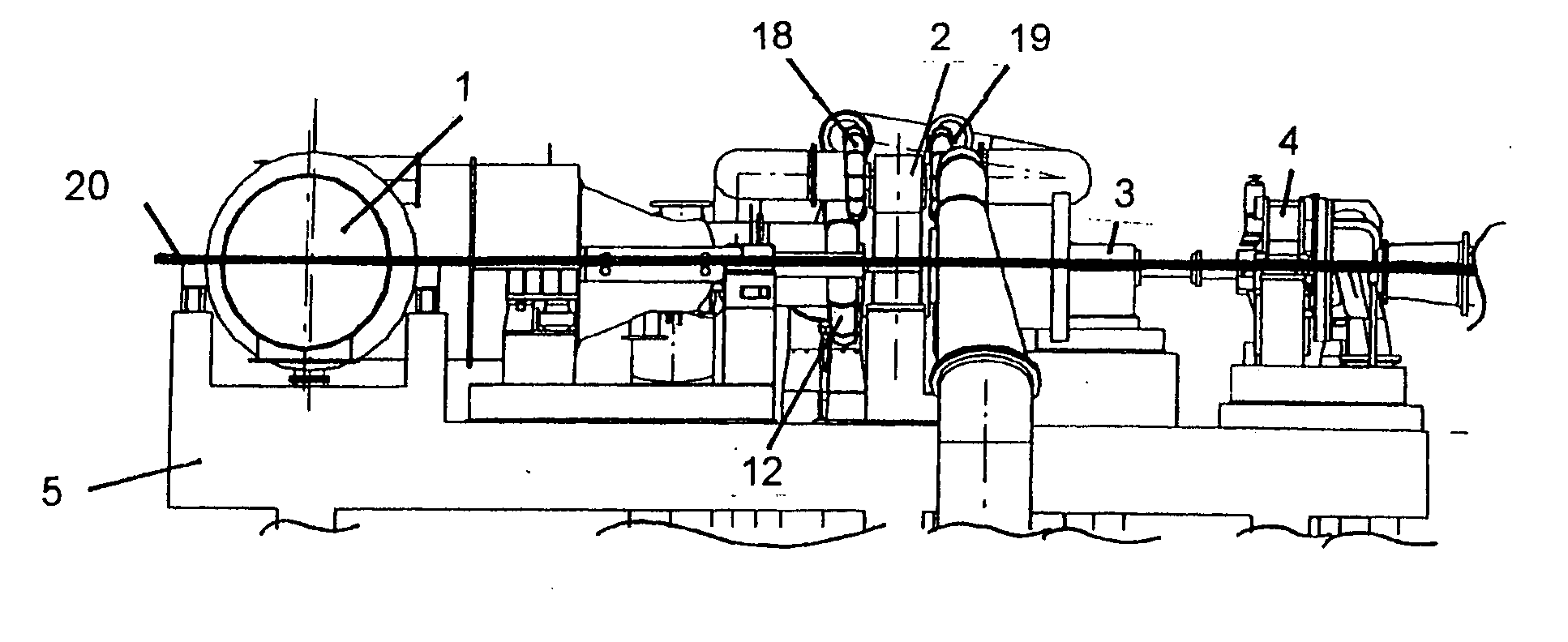

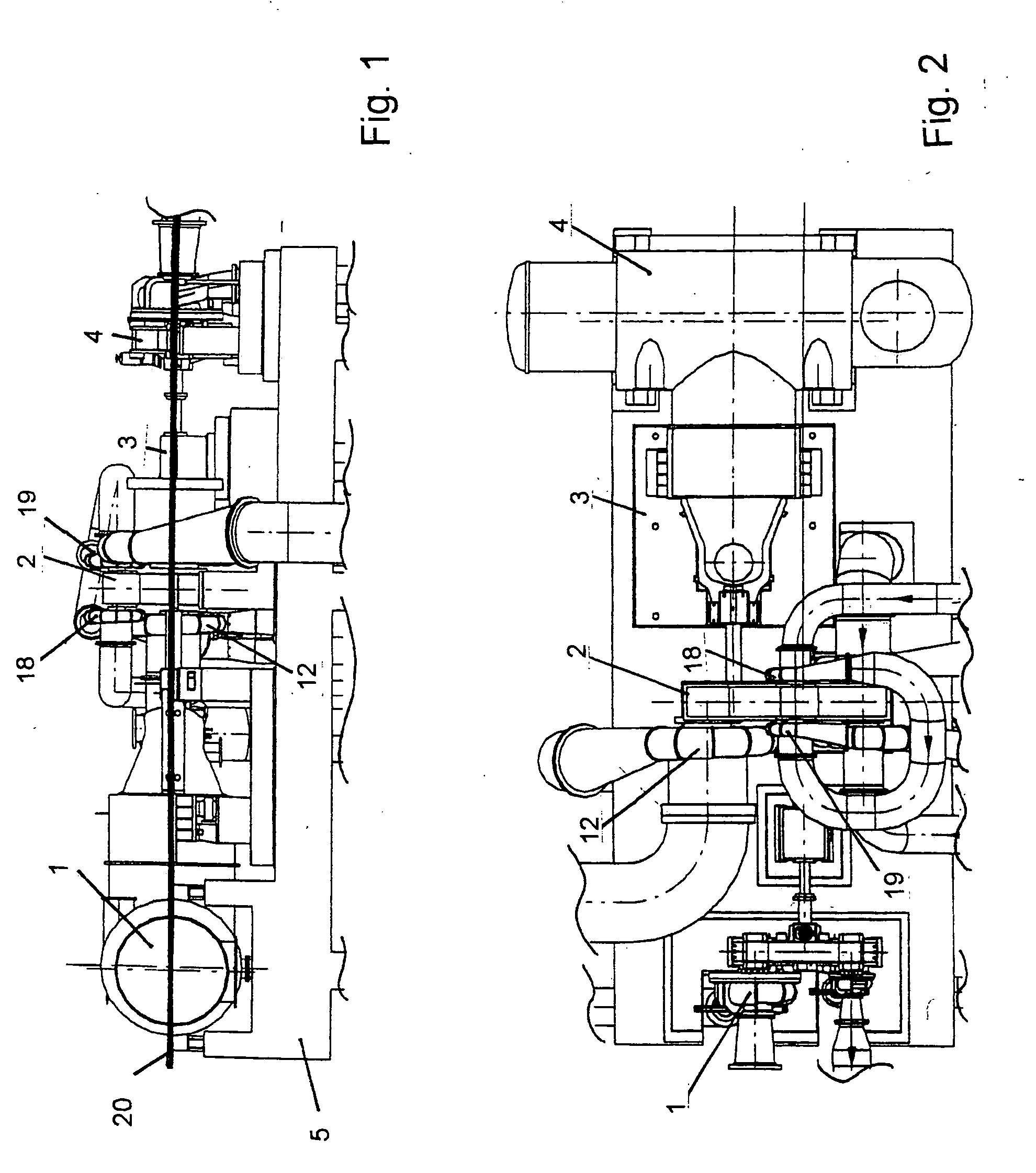

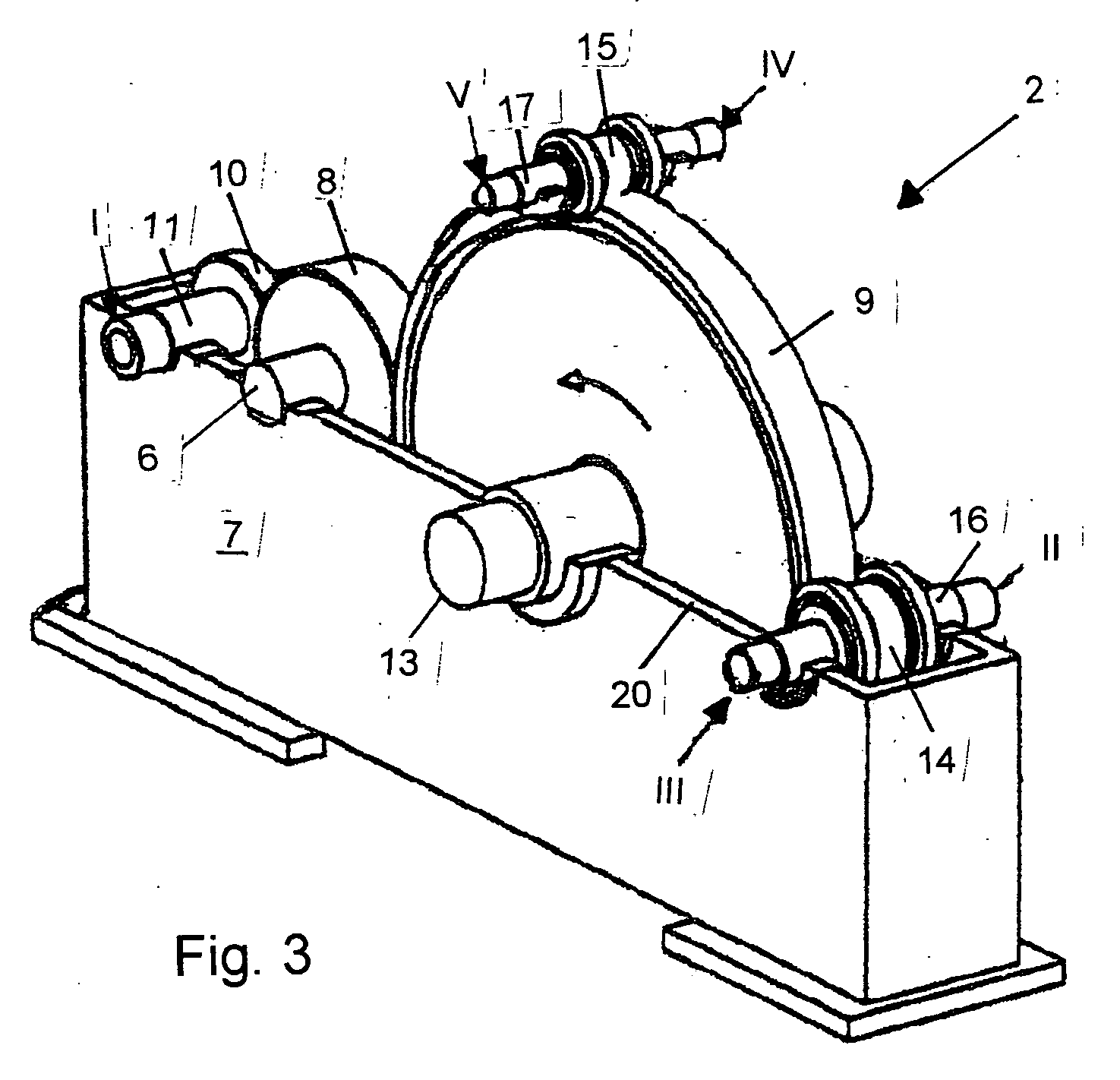

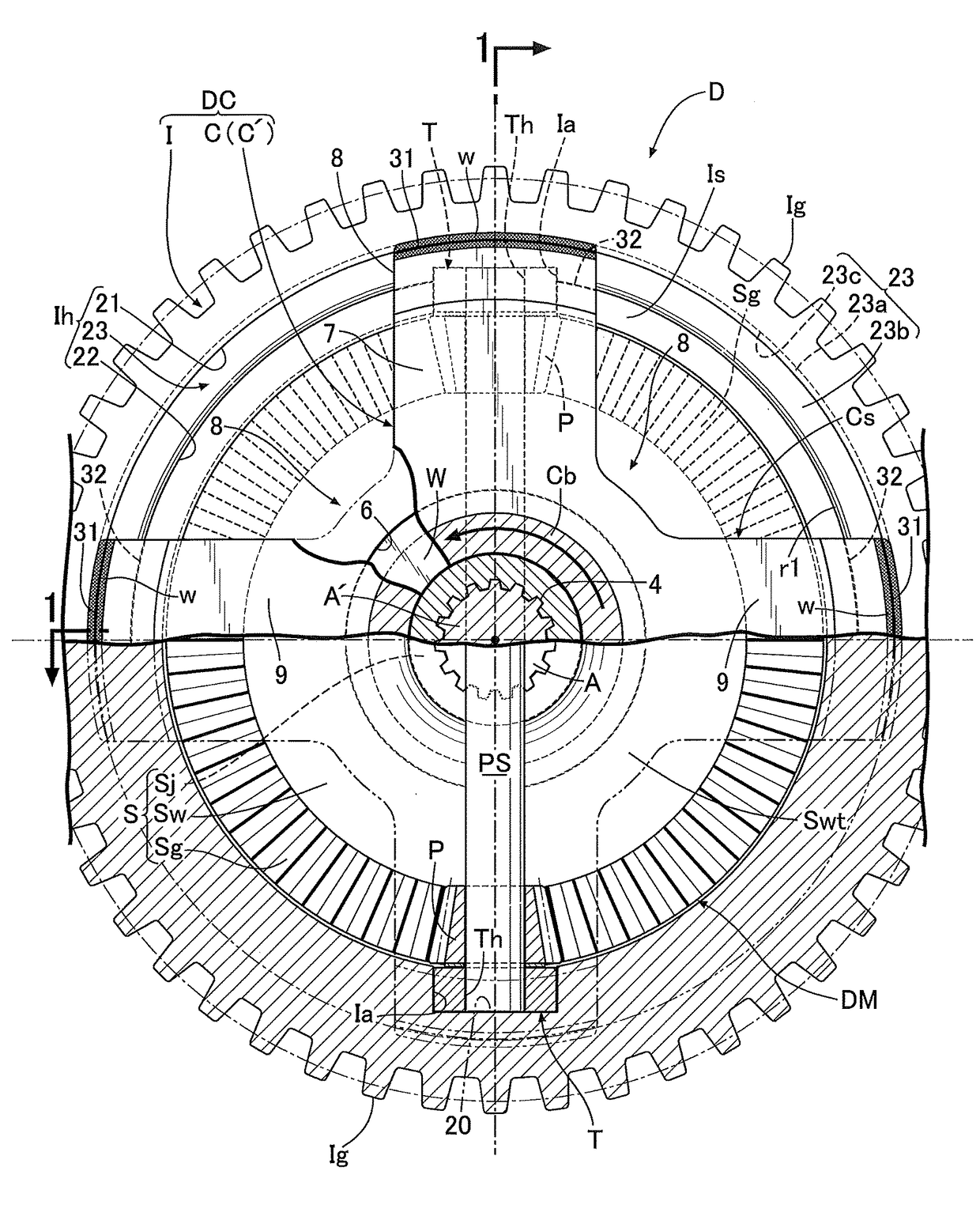

Multistage turbocompressor

ActiveUS7559200B2Closely arrangedEasy maintenanceCombustion enginesPump installationsImpellerGear drive

A multistage turbocompressor, designed as a geared compressor with an integrated gear, contains a central greater wheel (9) that meshes with a plurality of pinions (14, 15), wherein each pinion (14, 15) is mounted, in a manner adapted to rotate in unison, on a pinion shaft (16, 17). A bladed wheel of a compressor stage (II, III, IV, V) is arranged on the ends of each of the pinion shafts. The greater wheel (9) meshes with a driving pinion (8), which is mounted, in a manner adapted to rotate in unison, on a driving shaft 6 connected to a drive unit (1). The axis of the driving pinion (8) is arranged, with the axis of the greater wheel (9), in the same horizontal plane (20), and the driving pinion (8) meshes with a pinion (10) of a first compressor stage (I) mounted, in a manner adapted to rotate in unison, on a pinion shaft (11).

Owner:MAN ENERGY SOLUTIONS SA

Flexible touch screen display

InactiveUS20130265280A1No impairment of optical clarityEasy to useInput/output processes for data processingActive matrixDisplay device

A touch sensitive active matrix display device is provided. The device includes a display fabricated on a first flexible substrate, said display having a viewing surface. The device further includes a touch sensitive sensor including a second flexible substrate, under said display. The touch sensor is operated by touching said viewing surface of said display, and said combined display and touch sensitive sensor is flexible.

Owner:FLEXENABLE LTD

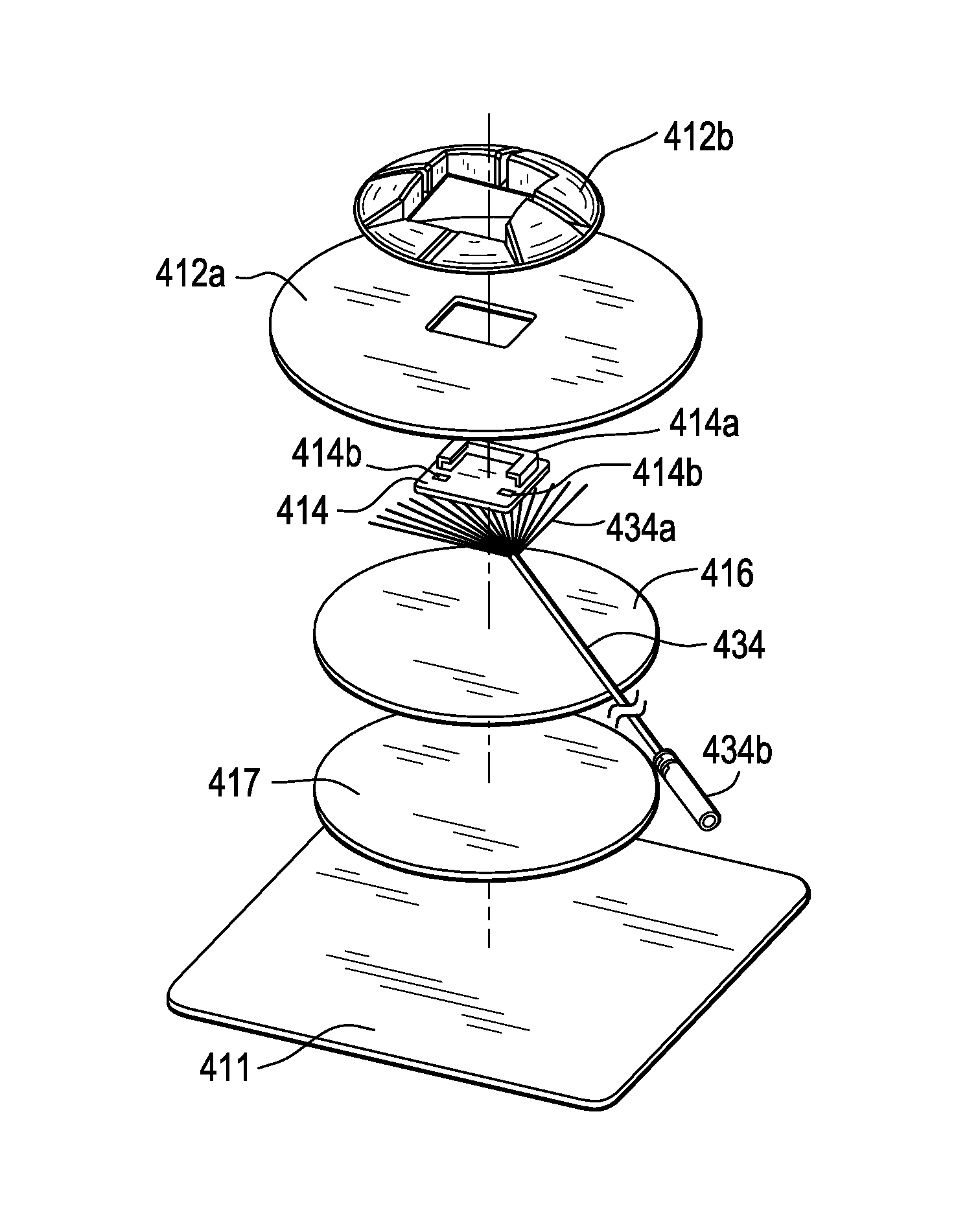

Disposable patch and reusable sensor assembly for use in medical device localization and mapping systems

ActiveUS9014778B2Reduce mechanical strainDiagnostic recording/measuringMagnetic field sensorsAdhesiveElectrophysiology

An patch and sensor assembly for use in an EP mapping system has two portions: a reusable portion and a disposable portion. The reusable portion houses the biosensors used in magnetic based location and mapping systems and the electrical lead necessary to communicate between the biosensor and the mapping system. The reusable portion may also contain a portion of the electrode necessary to receive electrical signals from the body of the patient. The disposable portion of the patch and sensor assembly contains an adhesive covered flexible patch having at least a portion of the electrode used to receive electrical signals form the body of the patient and may contain the electrical lead necessary to communicate such an electrical signal to the mapping system. The disposable portion contains a receptacle adapted to receive and mechanically secure the reusable portion to the disposable portion of the assembly. Such a patch and sensor assembly is useful in hybrid magnetic and impedance based location and mapping systems such as those used in electrophysiology.

Owner:BIOSENSE WEBSTER INC

Cathode composition

InactiveUS20140017394A1Reduce formationImprove utilizationNon-metal conductorsConductive materialSulfurLithium sulfur

Owner:ROBERT BOSCH GMBH

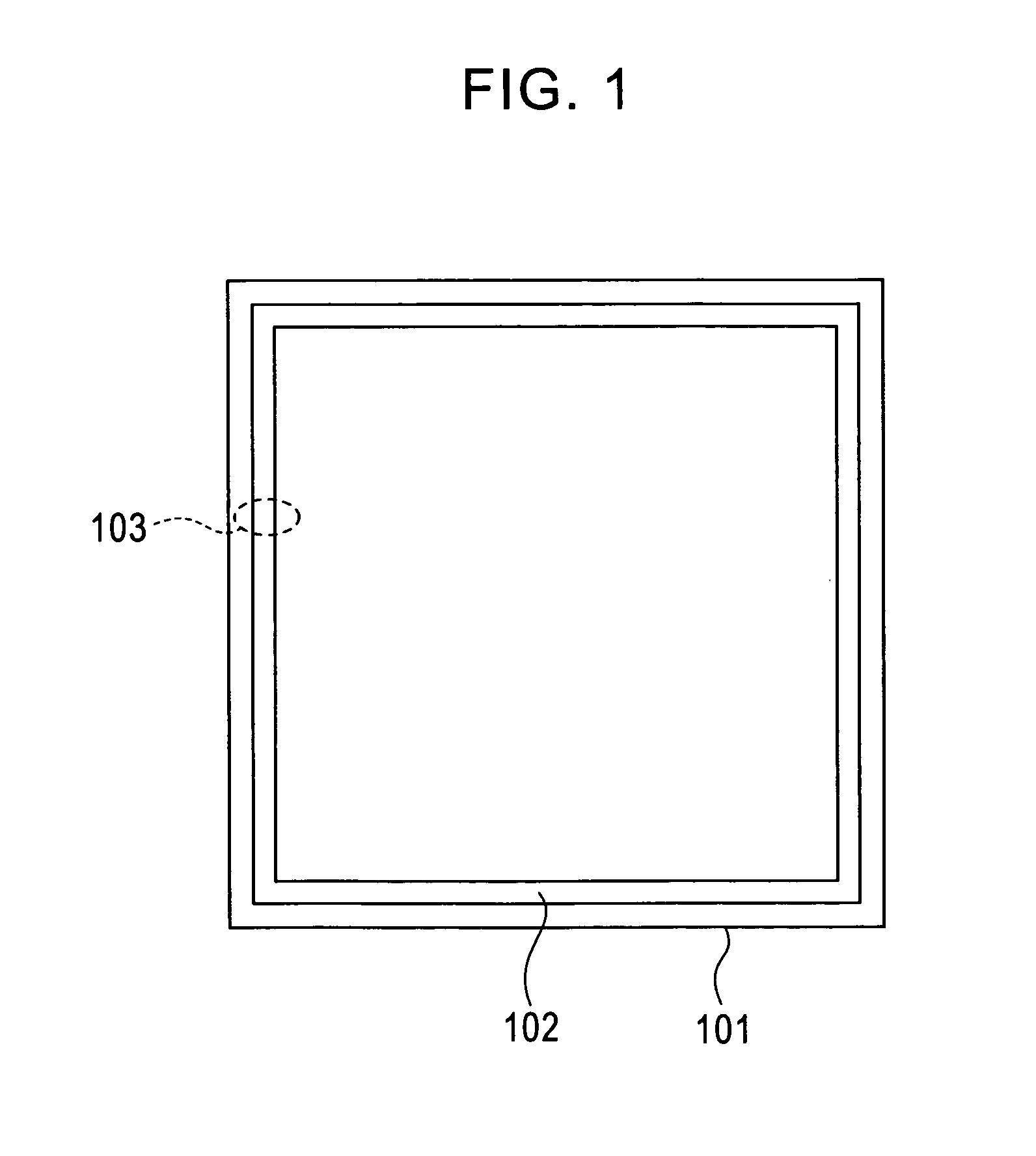

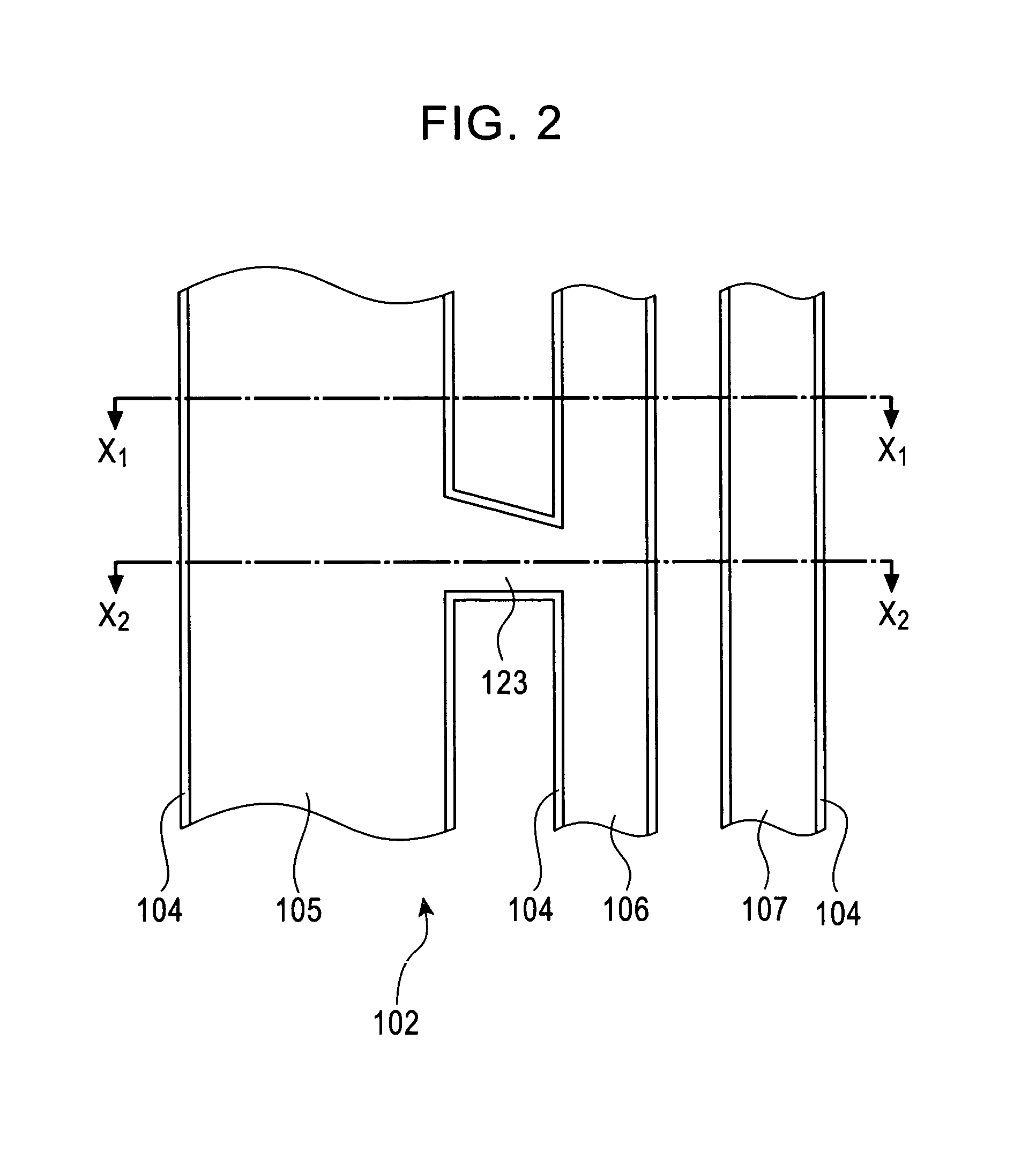

Semiconductor device having isolated pockets of insulation in conductive seal ring

ActiveUS7675175B2Avoid crackingReduce mechanical strainSemiconductor/solid-state device detailsSolid-state devicesMicrometerEngineering

A semiconductor device with a damascene wiring structure which can prevent short-circuits between a seal ring and a wiring line or electrode pad. An upper layer barrier layer made from a conductive barrier material film is formed on an interlayer insulating film groove sidewall of the semiconductor device. Embedded in the groove is an upper layer seal ring wiring line with thickness of approximately 10 micrometers for instance, in which a plurality of isolated pockets of insulators are disbursed. These isolated pockets of insulators are formed using the interlayer insulating film which forms the damascene wiring line. Additionally, a first upper layer groove wiring line and a second upper layer groove wiring line are formed in an element forming region, and an upper layer barrier layer is formed on the outside perimeter. The upper layer seal ring wiring line and both upper layer wiring lines all have damascene wiring structures.

Owner:LAPIS SEMICON CO LTD

Flexible touch screen display

ActiveUS8451249B2Reduce thicknessEliminate needStatic indicating devicesInput/output processes for data processingActive matrixDisplay device

A touch sensitive active matrix display device is provided. The device includes a display fabricated on a first flexible substrate, said display having a viewing surface. The device further includes a touch sensitive sensor including a second flexible substrate, under said display. The touch sensor is operated by touching said viewing surface of said display, and said combined display and touch sensitive sensor is flexible.

Owner:FLEHKSENEHBL LTD

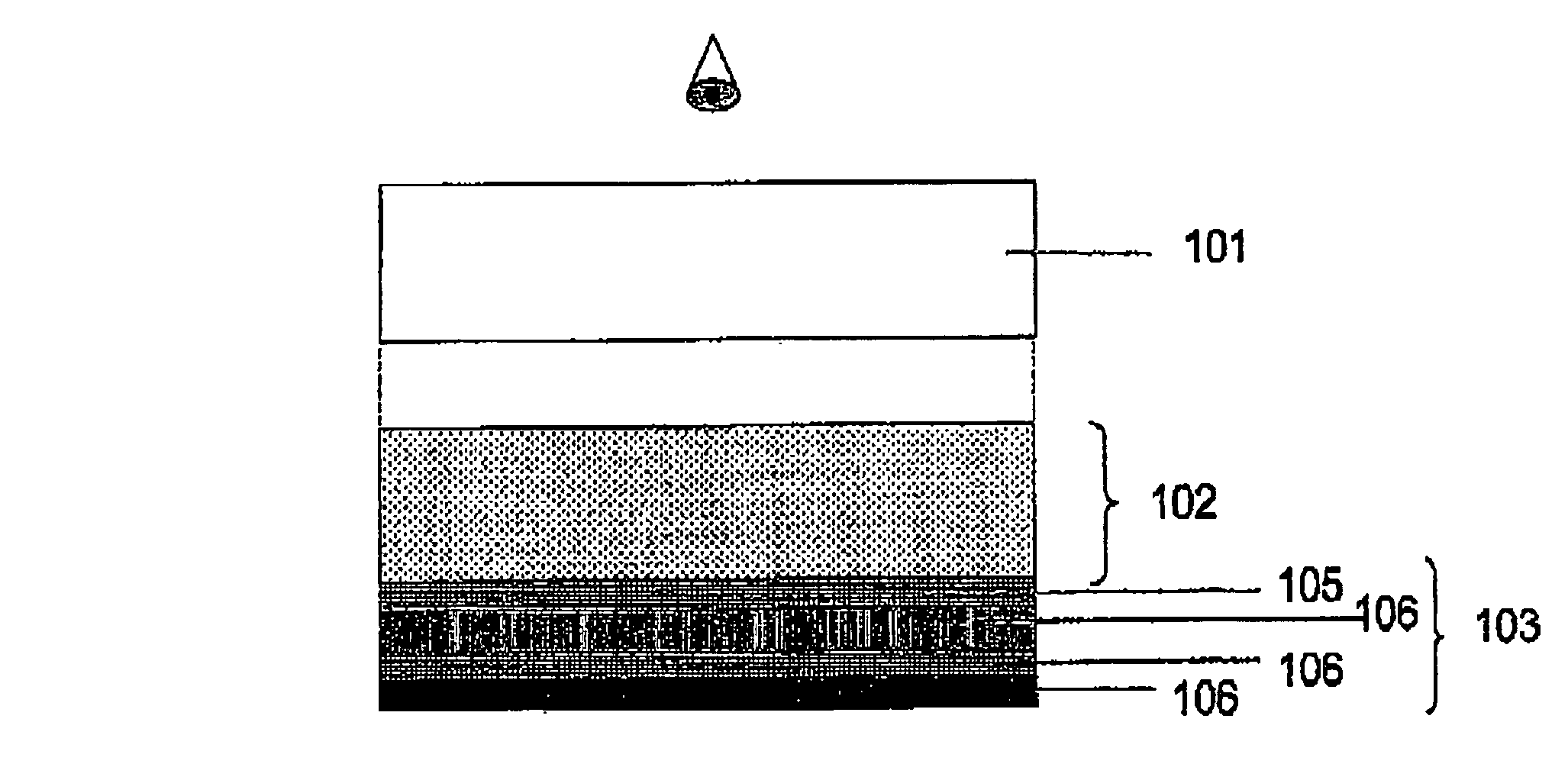

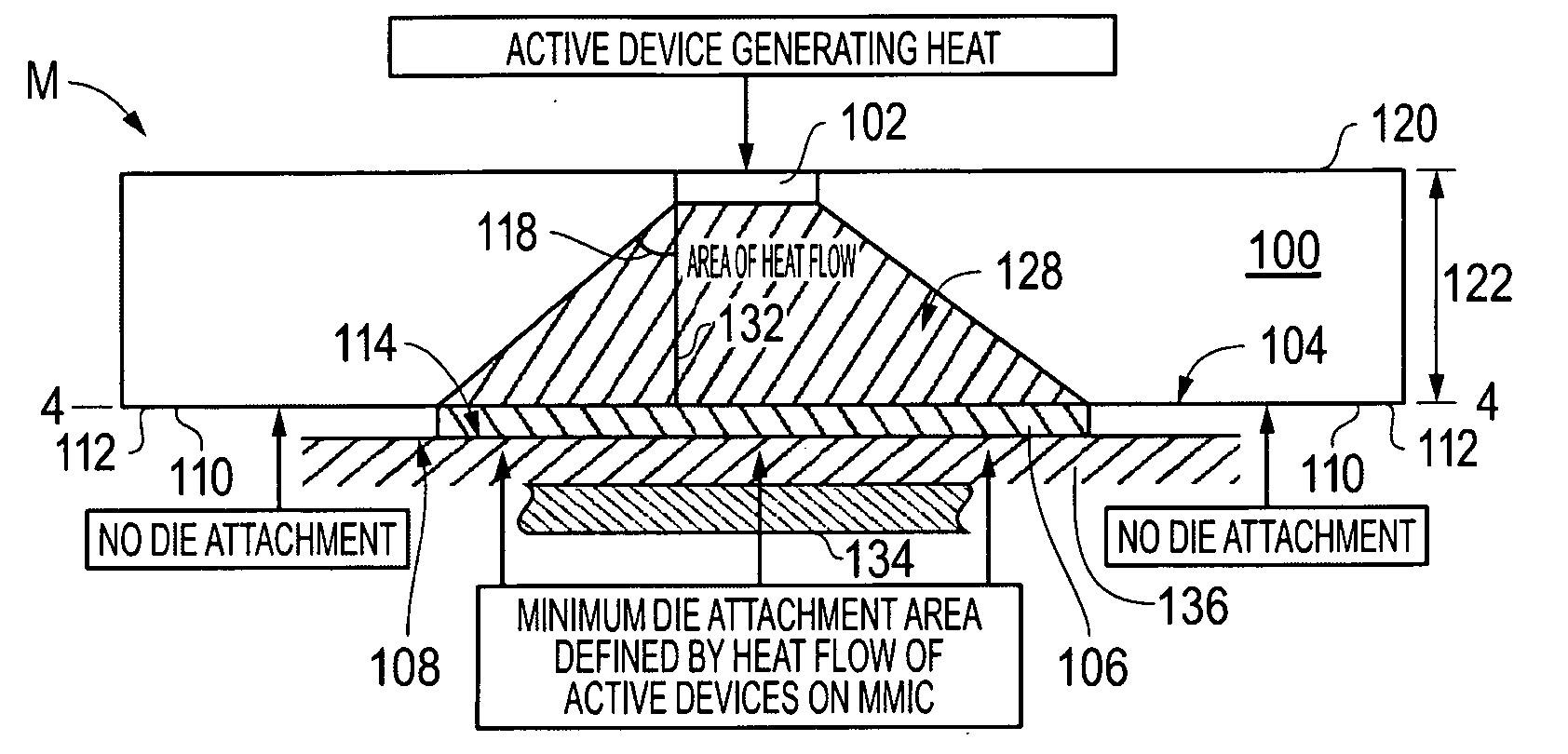

Reliability improvement in a compound semiconductor mmic

InactiveUS20090250808A1Prolong lifeReduce mechanical strainSemiconductor/solid-state device detailsSolid-state devicesBackplaneEngineering

A semiconductor package (M) includes a semiconductor substrate layer (100) having a first side or upper surface (120) and a second side or lower surface or backplane (104) opposite the first side (120). A heat producing active area (102) is formed associated with the first side (120) of the semiconductor substrate layer (100). A die attachment member (106) is formed in contact with the second side (104) of the semiconductor substrate layer (100) and extends over less than all of the second side (104) of the semiconductor substrate layer (100). The die attachment material (106) is essentially uniformly disposed opposite of the heat producing area (102) with relation to the semiconductor substrate layer (100).

Owner:NORTHROP GRUMMAN SYST CORP

Multistage turbocompressor

ActiveUS20060156728A1Closely arrangedEasy maintenanceCombustion enginesSteam engine plantsImpellerGear drive

A multistage turbocompressor, designed as a geared compressor with an integrated gear, contains a central greater wheel (9) that meshes with a plurality of pinions (14, 15), wherein each pinion (14, 15) is mounted, in a manner adapted to rotate in unison, on a pinion shaft (16, 17). A bladed wheel of a compressor stage (II, III, IV, V) is arranged on the ends of each of the pinion shafts. The greater wheel (9) meshes with a driving pinion (8), which is mounted, in a manner adapted to rotate in unison, on a driving shaft 6 connected to a drive unit (1). The axis of the driving pinion (8) is arranged, with the axis of the greater wheel (9), in the same horizontal plane (20), and the driving pinion (8) meshes with a pinion (10) of a first compressor stage (I) mounted, in a manner adapted to rotate in unison, on a pinion shaft (11).

Owner:MAN ENERGY SOLUTIONS SA

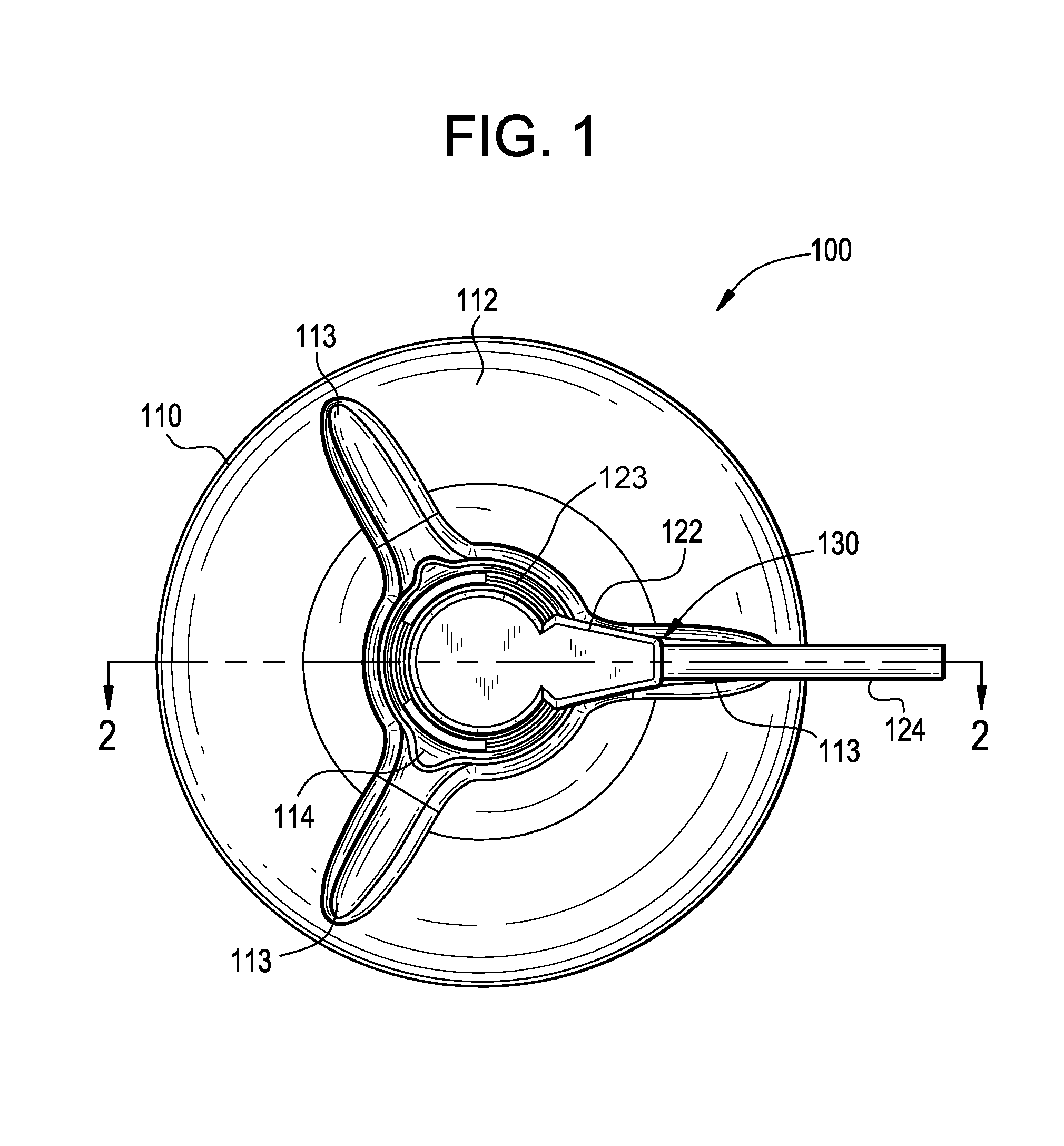

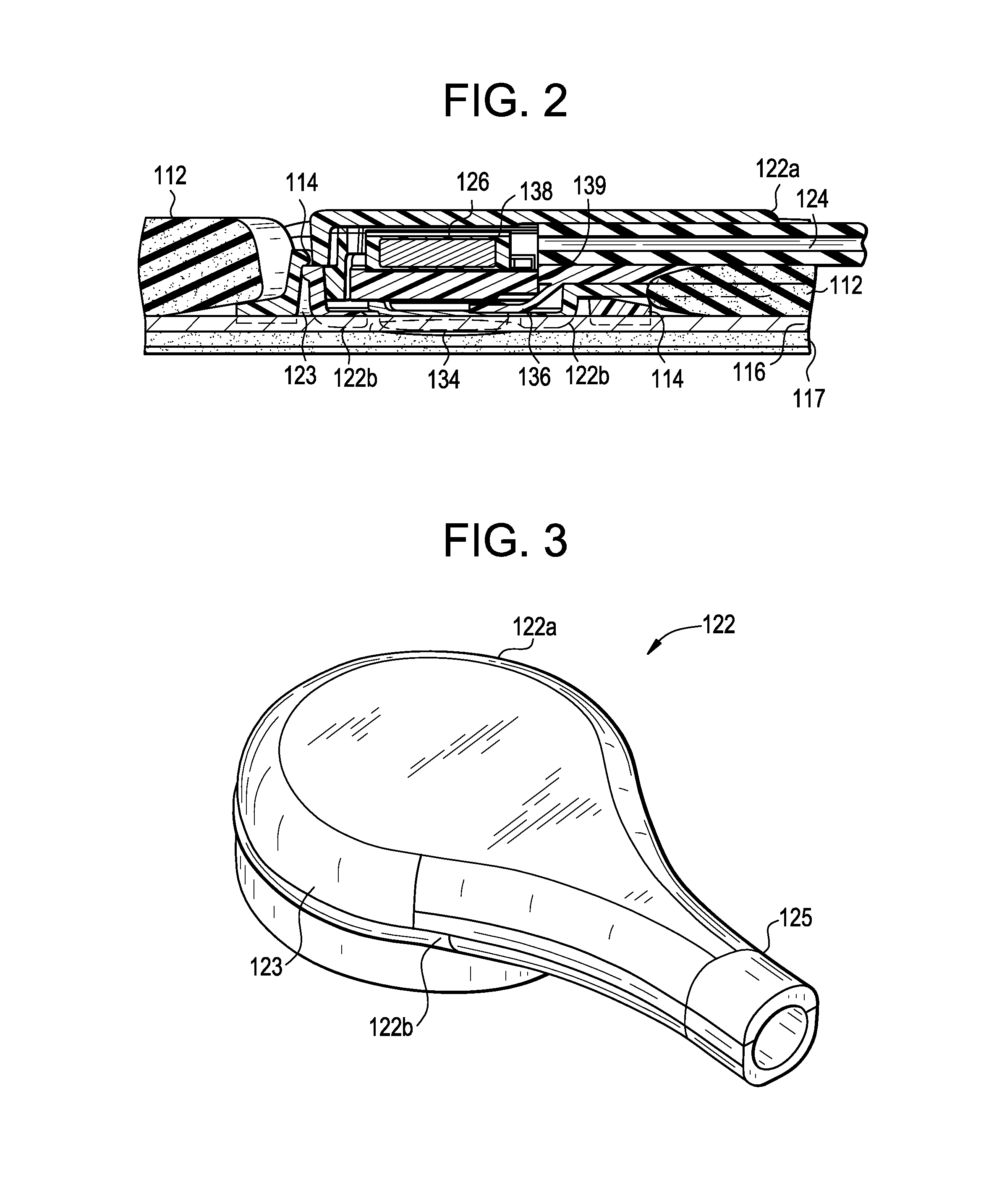

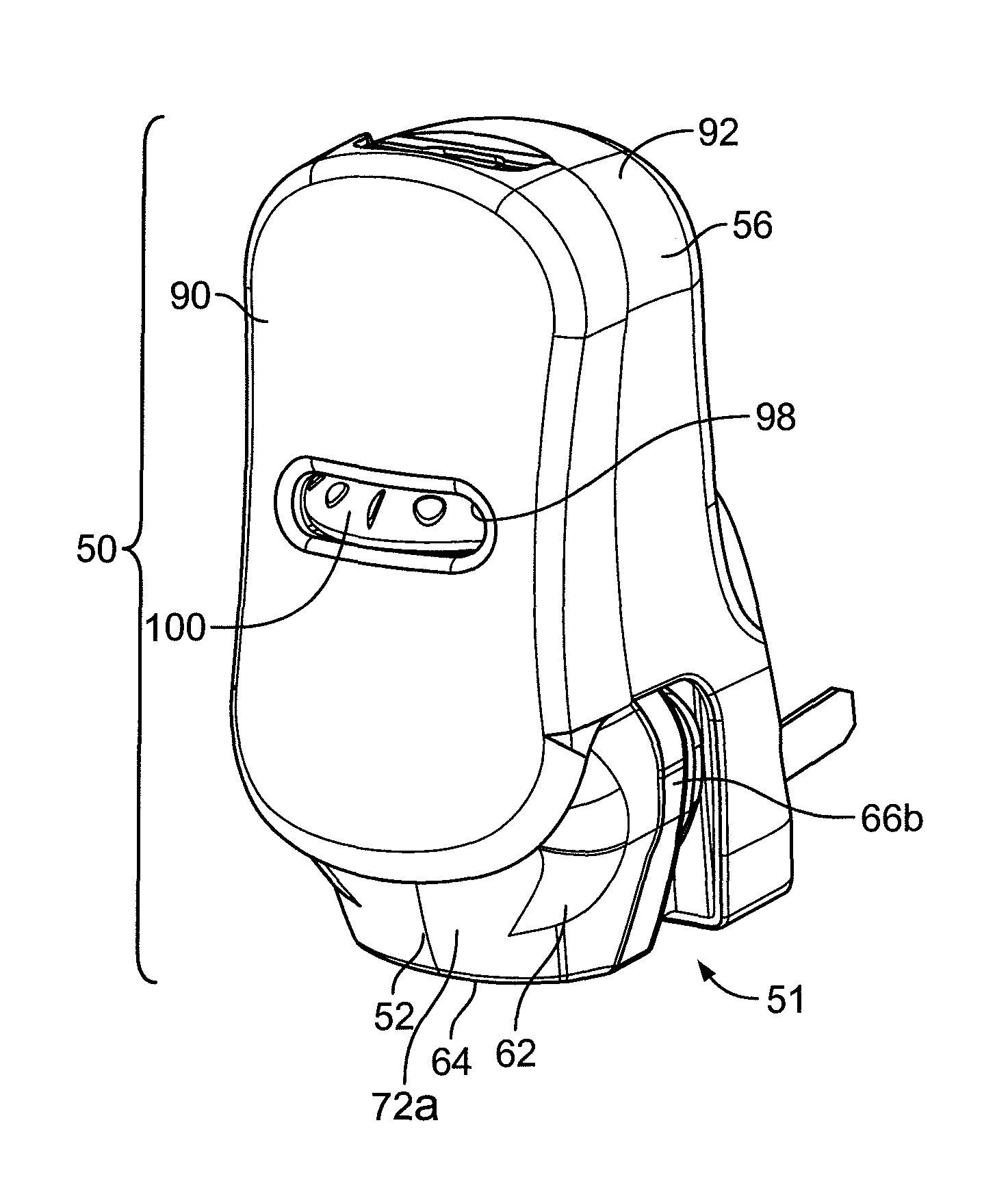

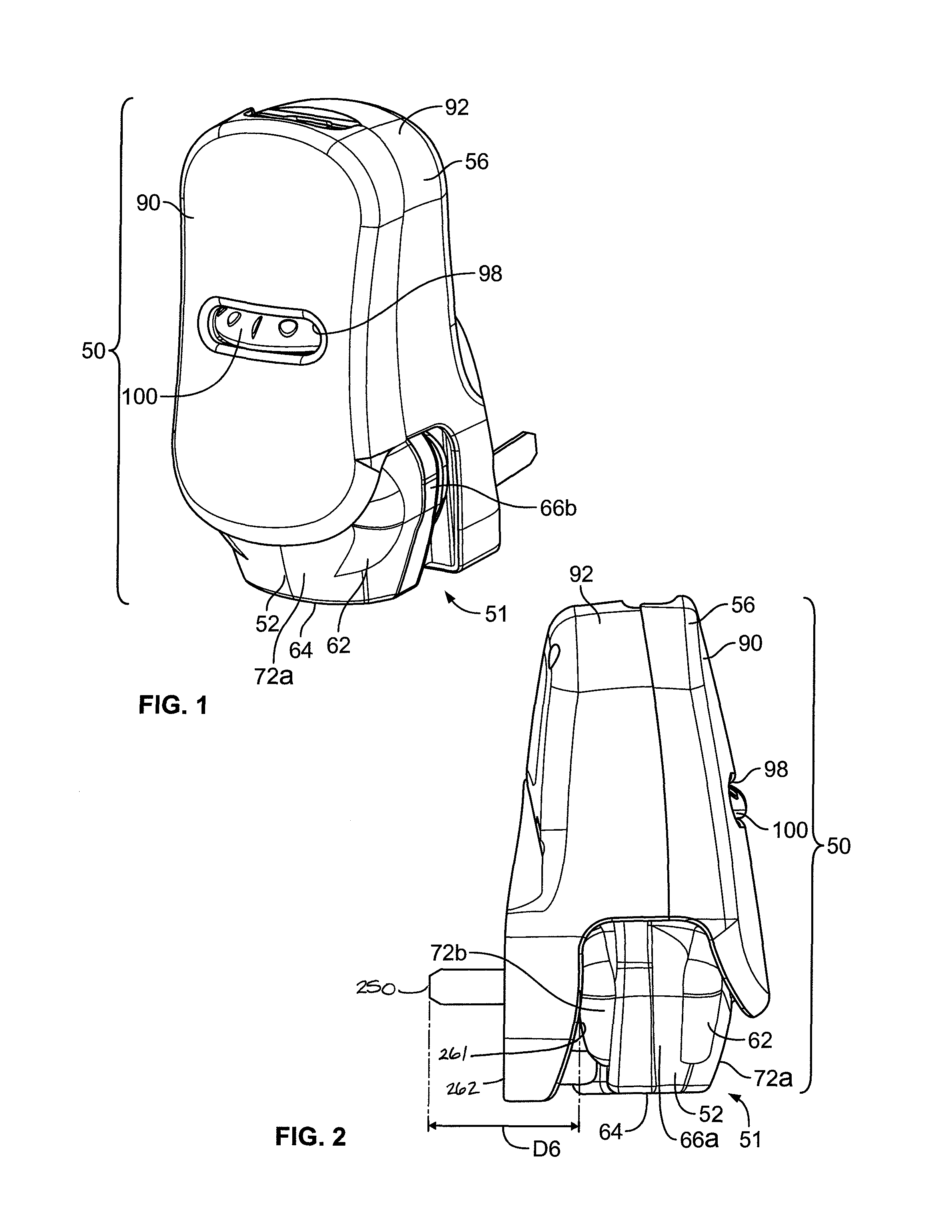

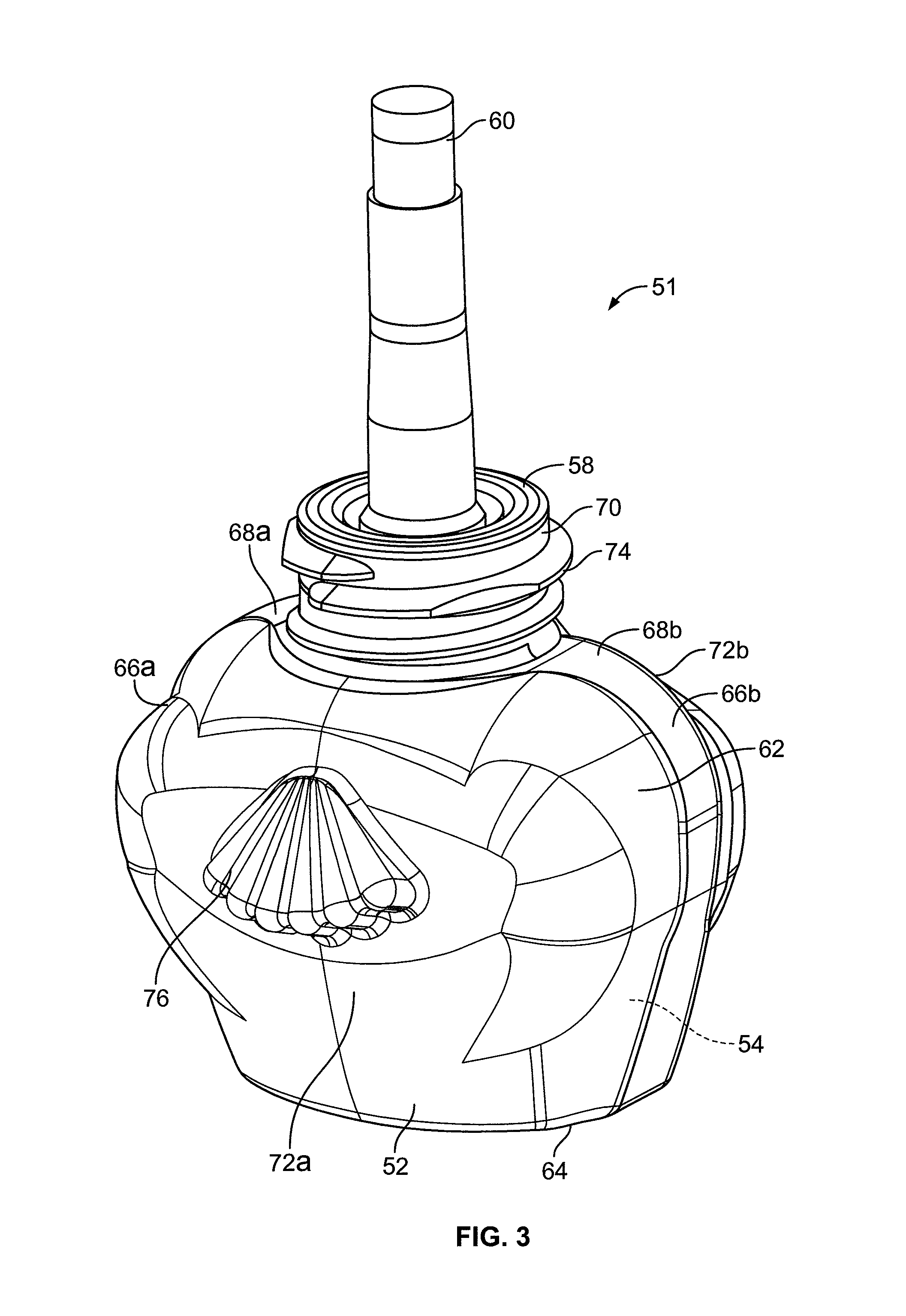

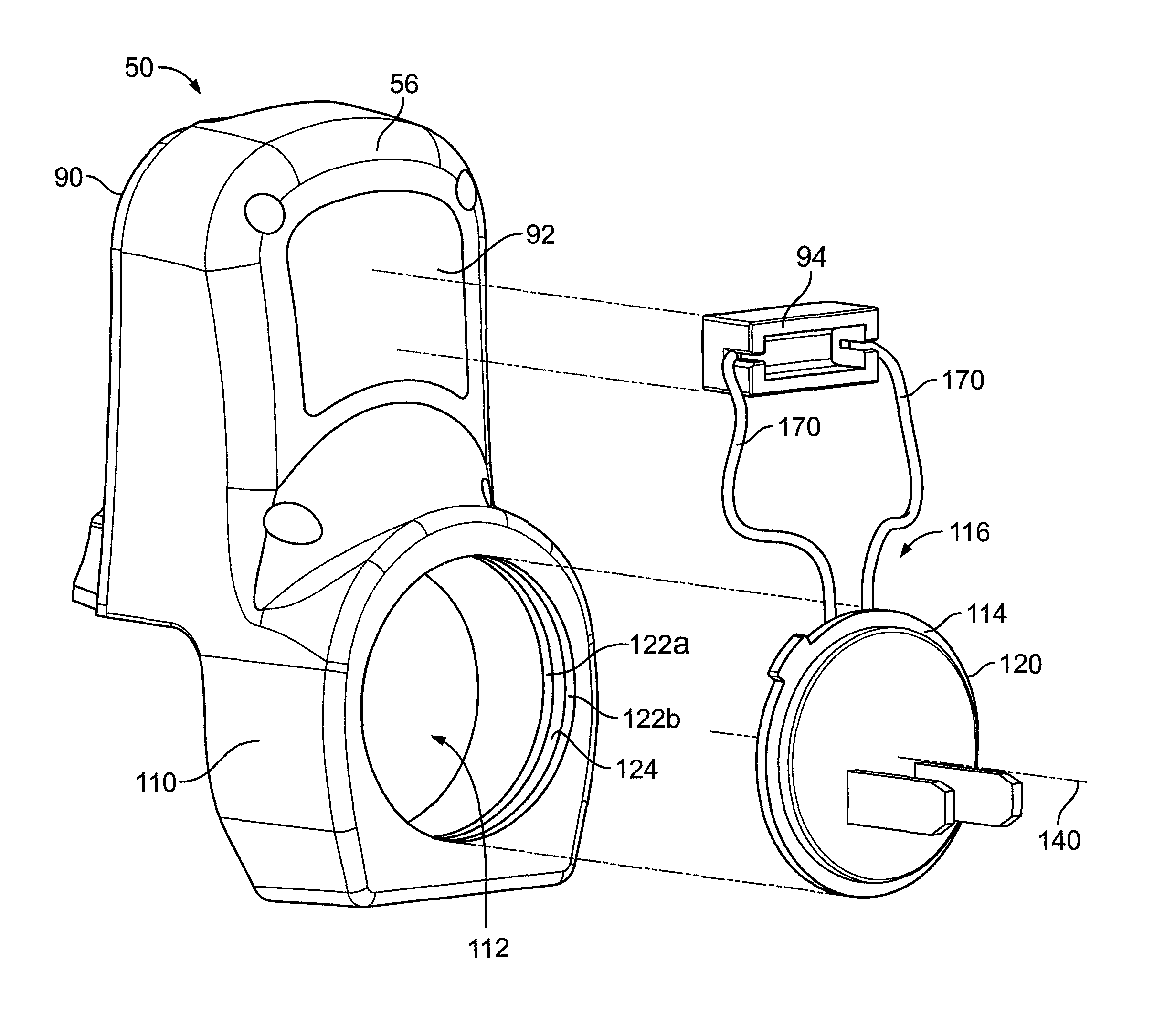

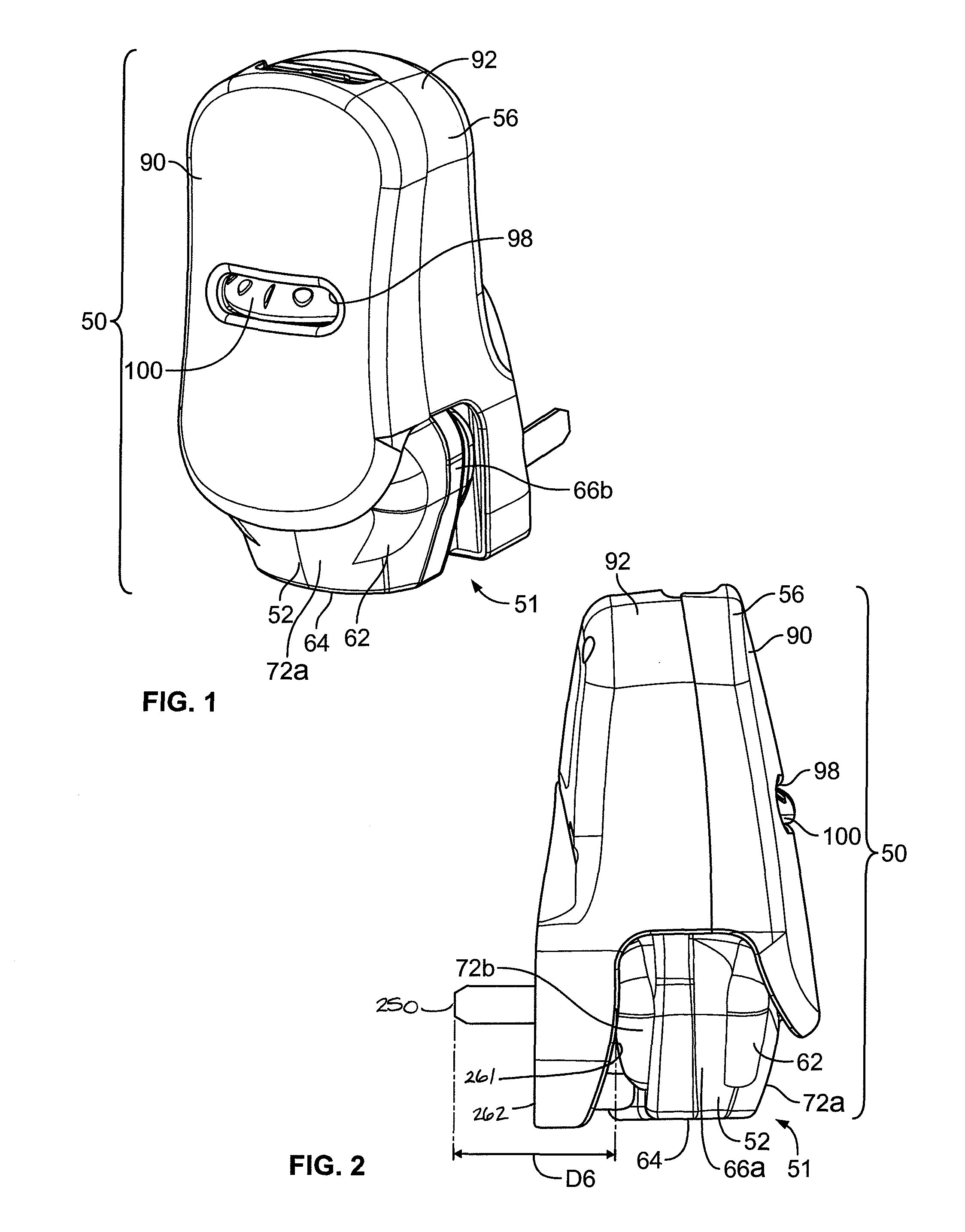

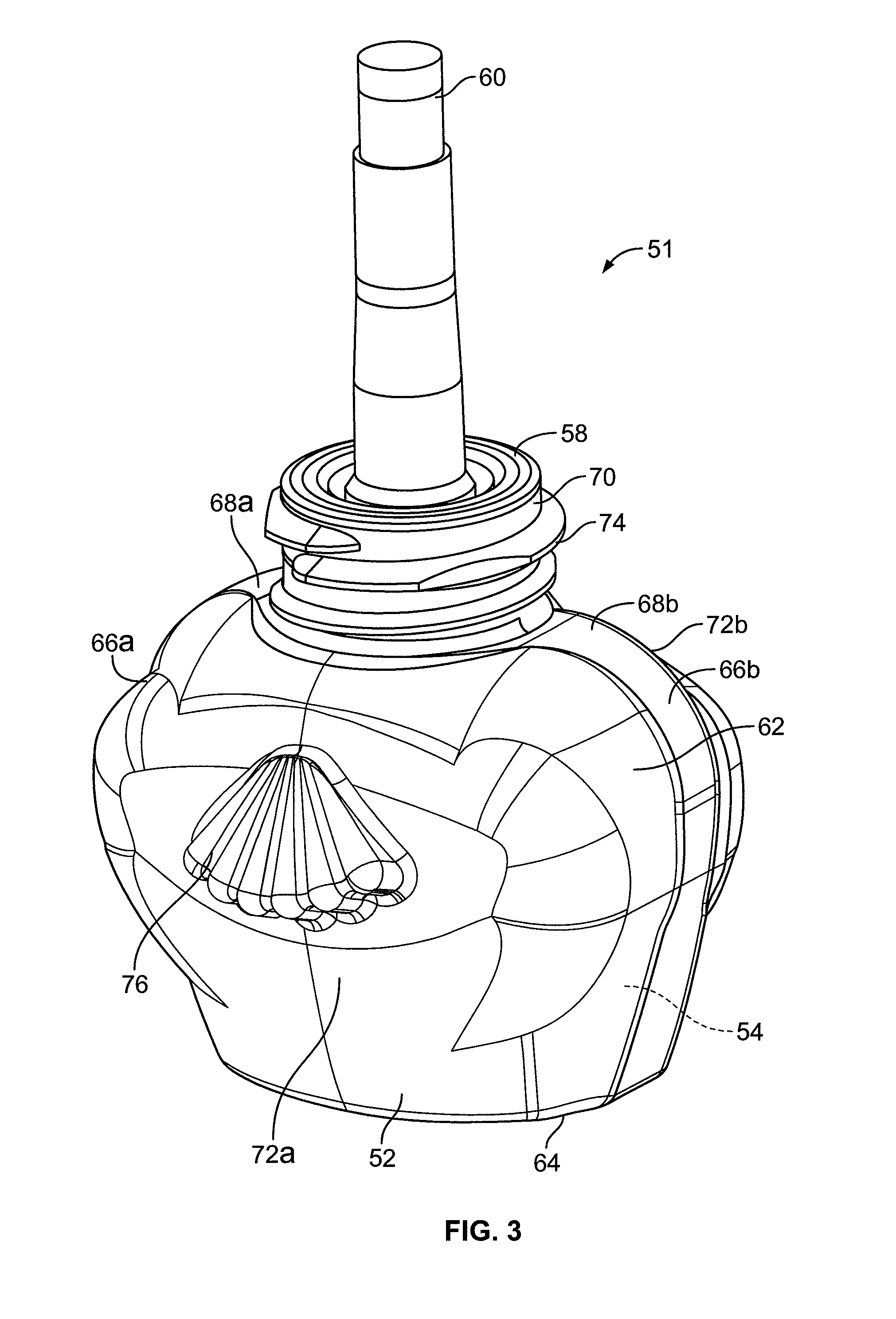

Rotatable plug assembly and housing for a volatile material dispenser

ActiveUS8821171B2Reduce mechanical strainLow profileCoupling device connectionsGaseous substancesEngineeringMechanical engineering

A rotatable electrical plug assembly for a volatile material dispenser includes a support block including a base having a base member and a wall extending from the base member and forming a cavity with the base member. The plug assembly further includes a cover disposed within the cavity and electrical plug pins extending through apertures in the base and including contacts that extend at an angle of about 90 degrees with respect to the plug pins, wherein the contacts are disposed between the base member and the cover. A ratio of an overall plug assembly thickness over a plug pin thickness is less than about 1.5.

Owner:SC JOHNSON & SON INC

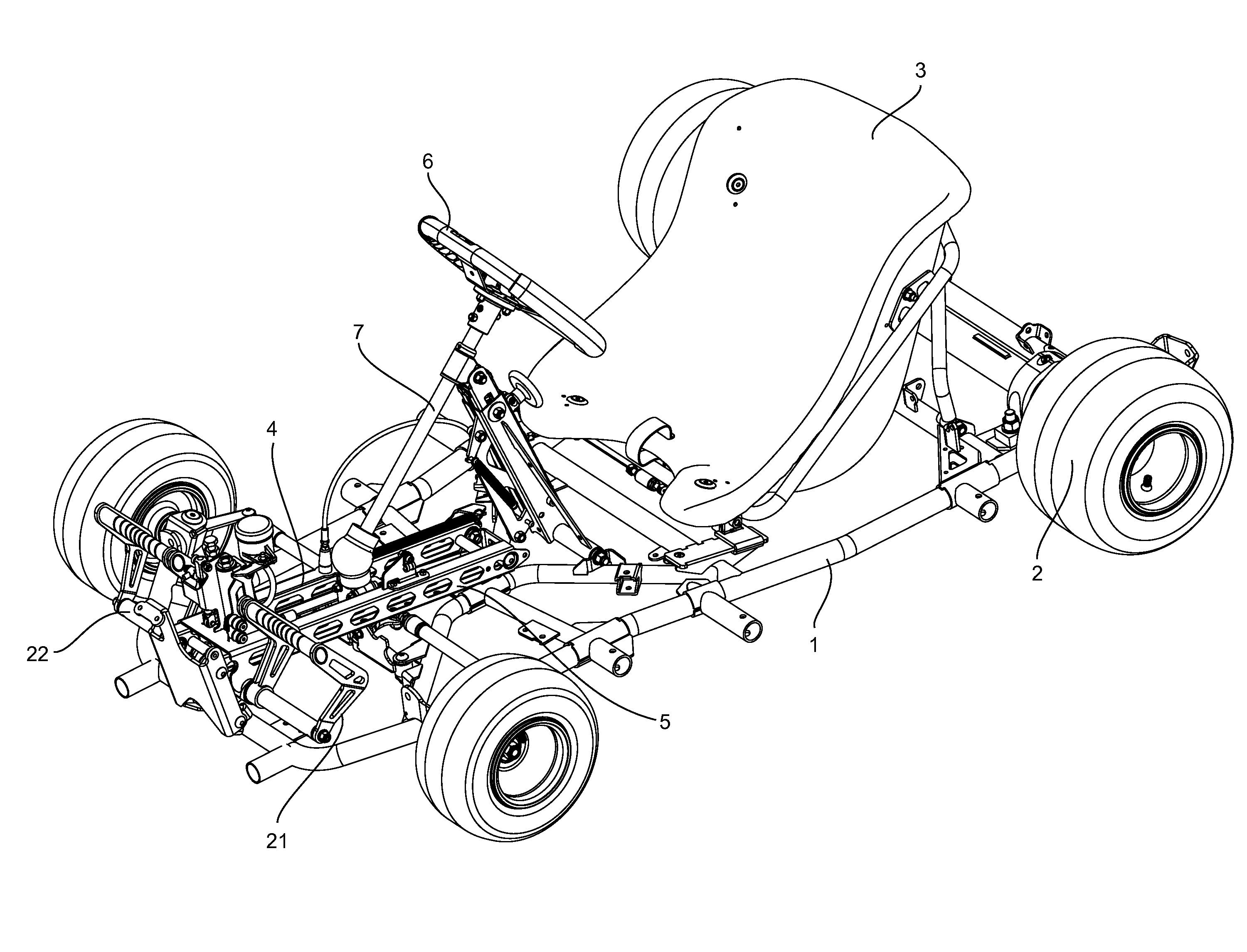

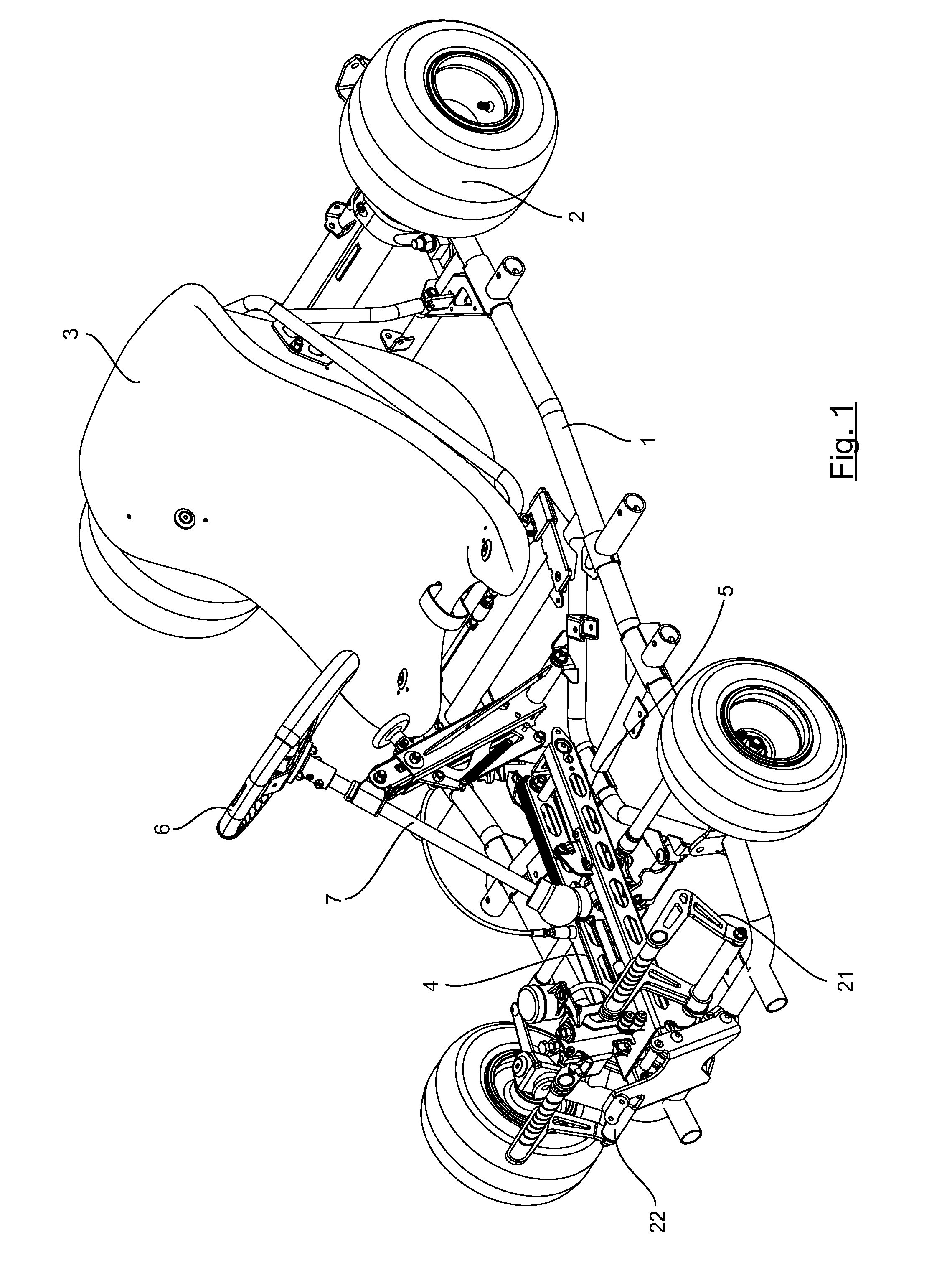

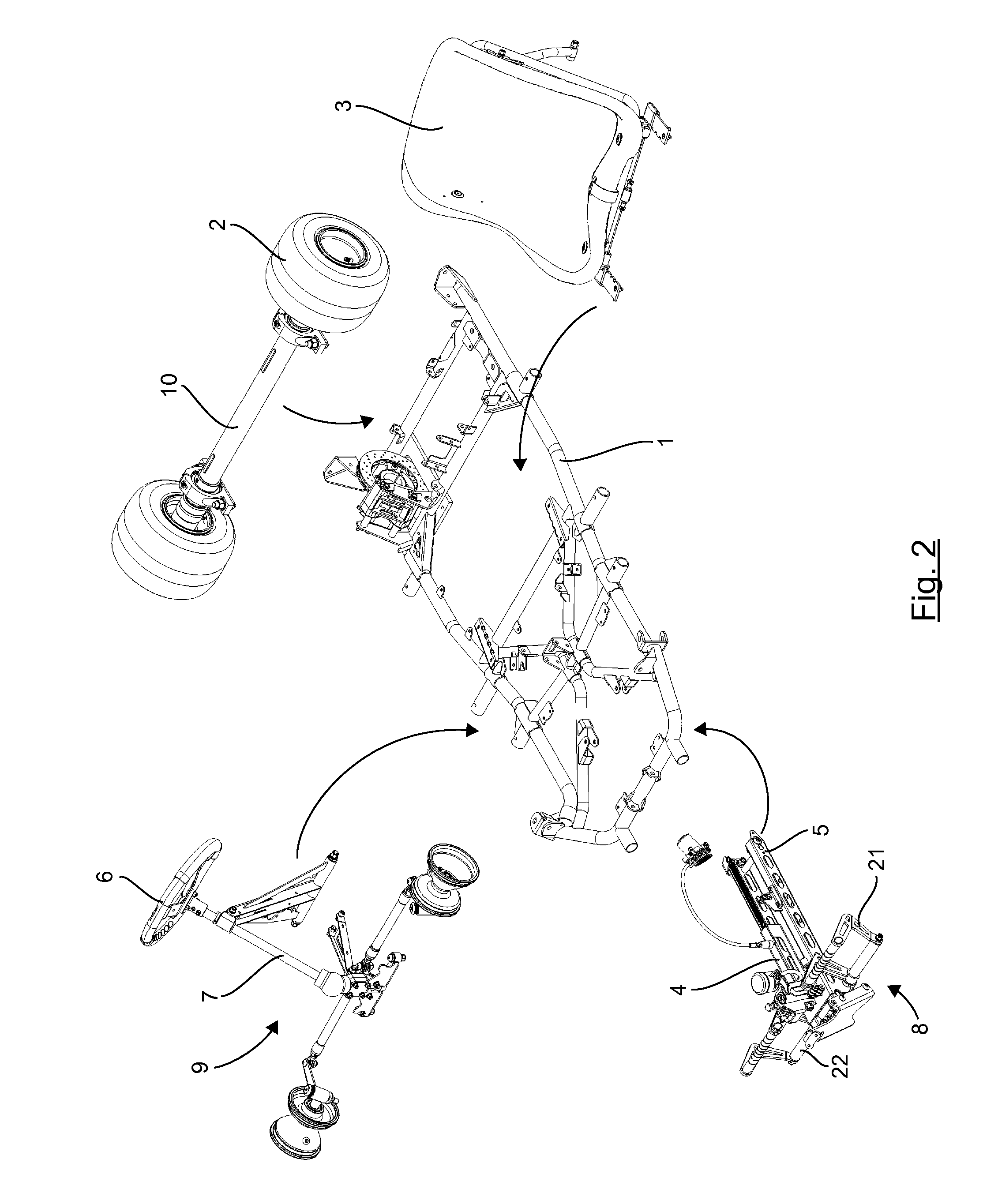

Kart Chassis with Increased Impact Resistance, and Corresponding Kart

ActiveUS20160059896A1Improve stress conditionReduce mechanical strainVehicle seatsRace vehiclesStraight tubeEngineering

A kart includes a chassis having a pair of substantially parallel tubular rails extending longitudinally and connected to one another at each end by at least one transverse tubular element. The kart chassis includes, in the front portion thereof, at least two substantially flared-U-shaped tubes positioned facing one another and assembled in the middle portion such as to form an X-shaped structure between the tubular rails, and at least two substantially rectilinear tubes disposed on each side of the X-shaped structure and each having a first end solidly connected to one of the tubular rails and another end solidly connected to a central portion of the X-shaped structure.

Owner:SODIKART

Stress detection within an integrated circuit having through silicon vias

ActiveUS8347728B2The result is accurateReduce mechanical strainTesting/calibration apparatusSemiconductor/solid-state device testing/measurementClock rateEngineering

An integrated circuit 2 is formed of multiple wafer layers 4, 6, 8, 10 arranged in a stack and connected with through silicon vias 12. Mechanical strain sensors 26, 28, 30, 32 in the form of ring oscillators are provided proximal to the through silicon vias 12 and detect mechanical strain associated with the through silicon via 12. The measured mechanical strain may be used to dynamically adjust operating parameters of the integrated circuit either as a whole or in regions where the mechanical strain is detected. The operating parameters adjusted can include clock frequency, operating voltage and heat generation.

Owner:ARM LTD

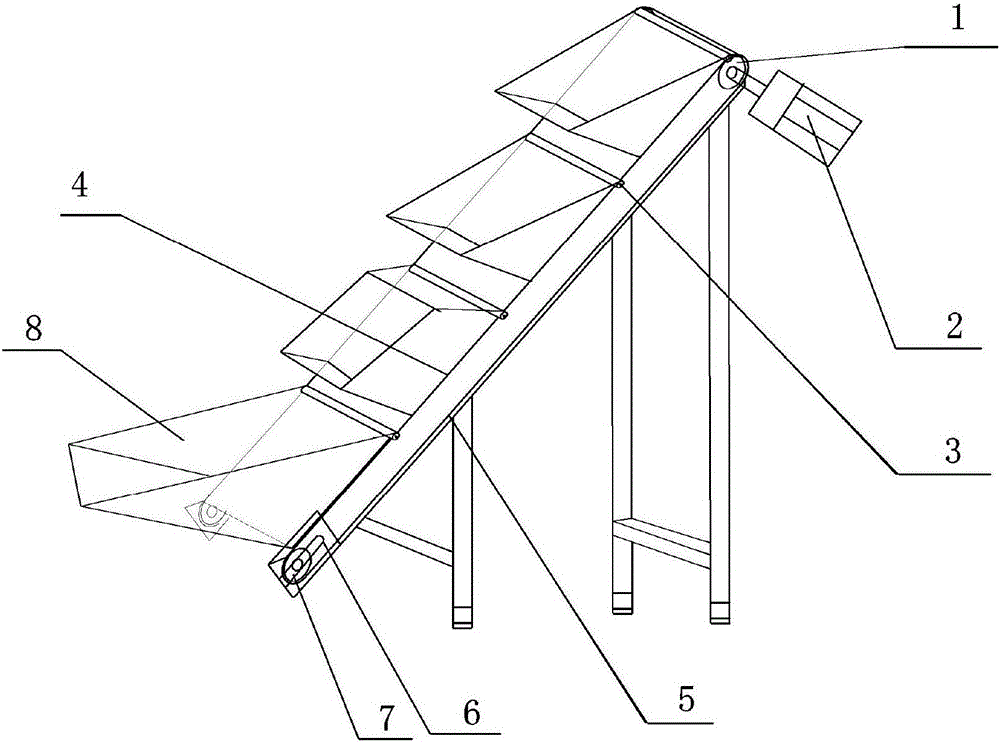

Feeding mechanism of blender

InactiveCN106516566ASimple structureAvoid repeated startup and shutdownConveyorsEngineeringMechanical engineering

Owner:TIANJIN BAOXINGWEI TECH

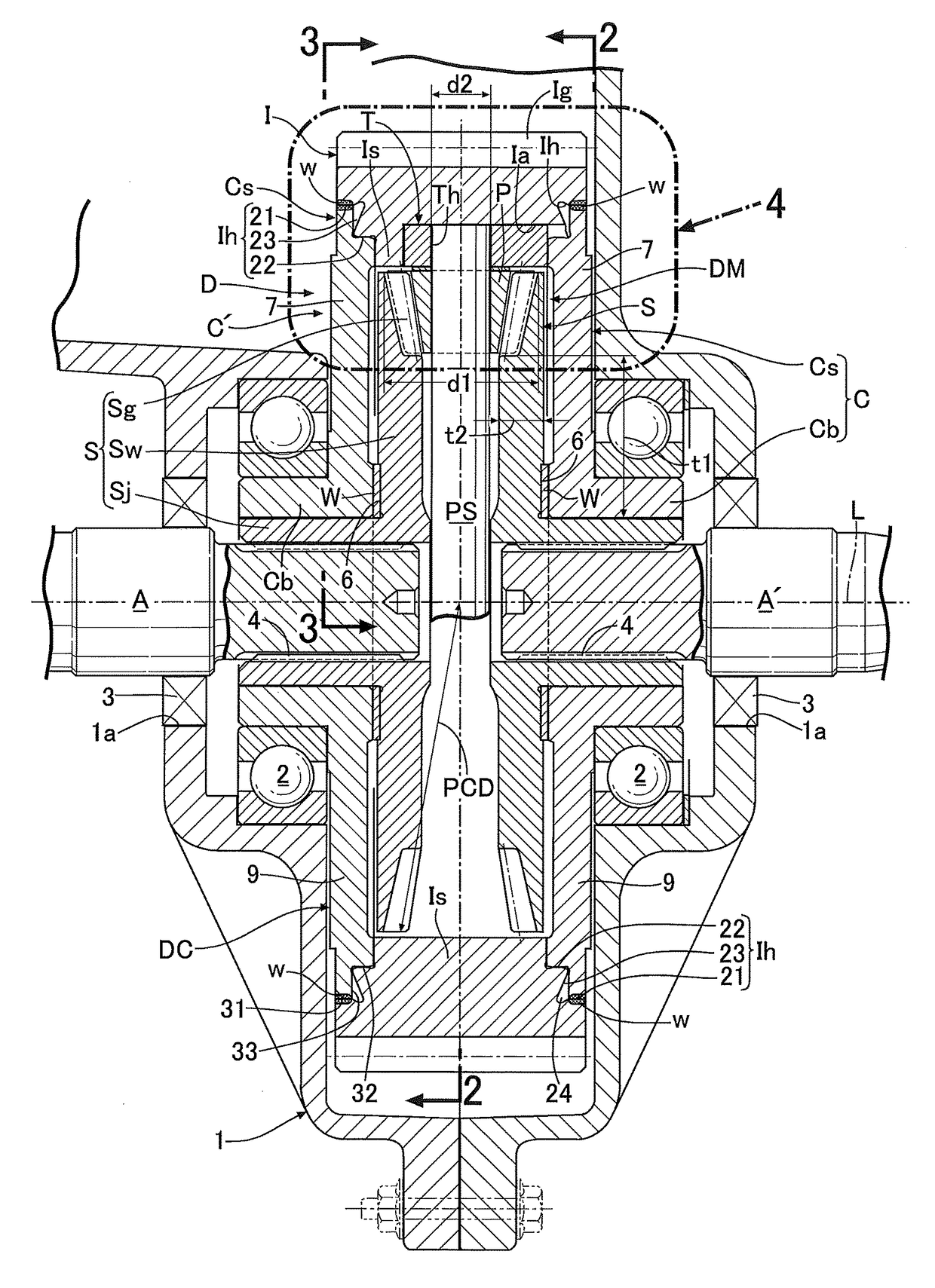

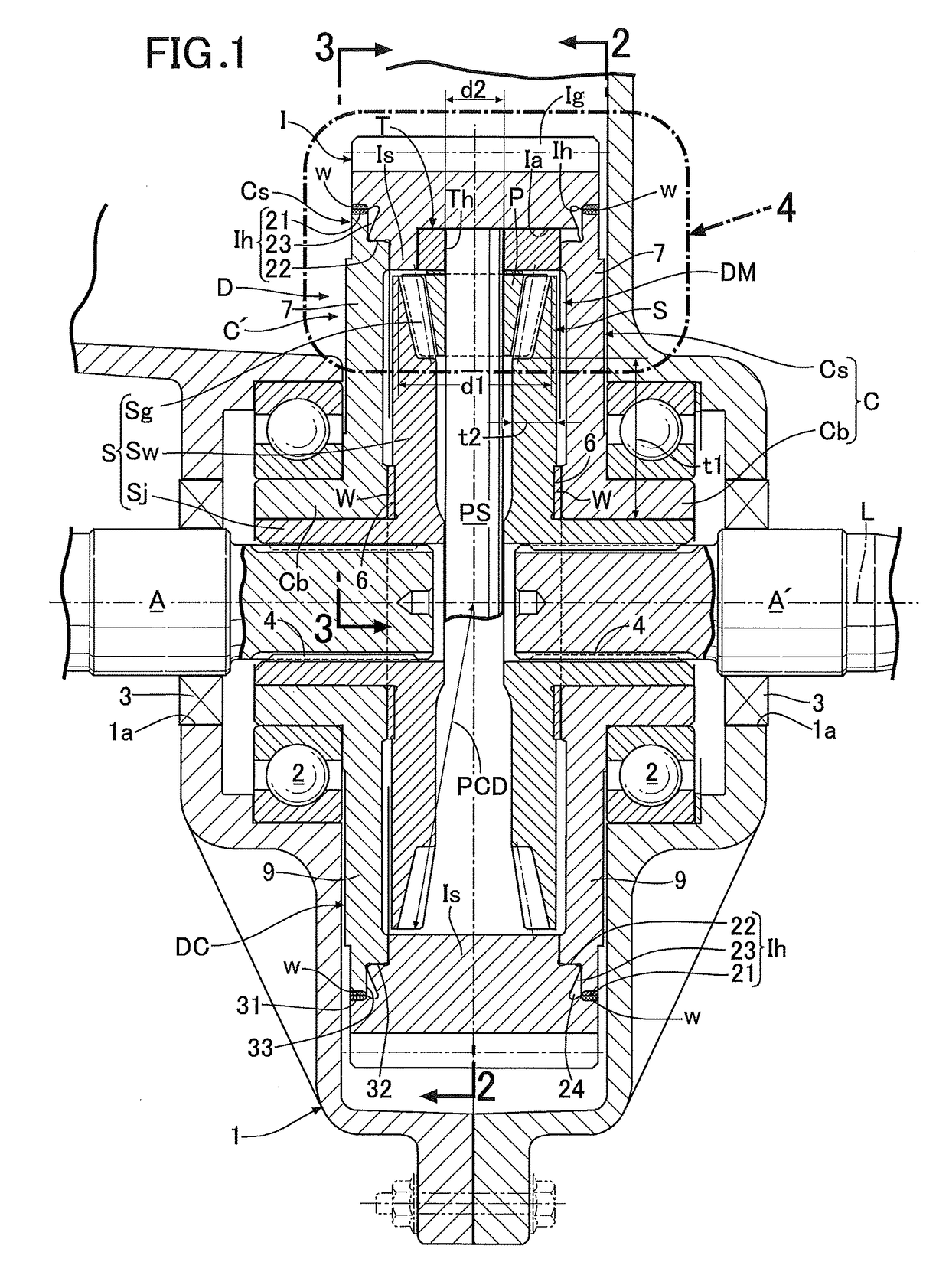

Differential device

In a differential device distributing rotational force acting on a differential case to a pair of output shafts, the differential case including an input member and a cover portion, assembling precision of the differential device is enhanced by suppressing strain due to welding and press-fitting. The input member includes: a welded portion fitting the cover portion in axial direction and joined by welding; a press-fitted portion located inward of the welded portion in radial direction and axial direction and press-fitted to the cover portion; and a connecting surface connecting the welded portion and the press-fitted portion and forming a space between the connecting surface and the cover portion, the space allowing deformation of the press-fitted portion during press-fitting. The connecting surface includes one end portion continuous to the welded portion and extending outward from the welded portion in radial direction.

Owner:MUSA PRECISION IND CO LTD

Method of making dielectric capacitors with increased dielectric breakdown strength

ActiveUS9646766B2Increase energy densityReduce mechanical strainFixed capacitor electrodesFixed capacitor dielectricBreakdown strengthMicro fracture

The invention is directed to a process for making a dielectric ceramic film capacitor and the ceramic dielectric laminated capacitor formed therefrom, the dielectric ceramic film capacitors having increased dielectric breakdown strength. The invention increases breakdown strength by embedding a conductive oxide layer between electrode layers within the dielectric layer of the capacitors. The conductive oxide layer redistributes and dissipates charge, thus mitigating charge concentration and micro fractures formed within the dielectric by electric fields.

Owner:UCHICAGO ARGONNE LLC

Rotatable plug assembly and housing for a volatile material dispenser

ActiveUS20130078834A1Reduce mechanical strainLow profileCoupling device connectionsDisinfectionEngineeringMechanical engineering

A rotatable electrical plug assembly for a volatile material dispenser includes a support block including a base having a base member and a wall extending from the base member and forming a cavity with the base member. The plug assembly further includes a cover disposed within the cavity and electrical plug pins extending through apertures in the base and including contacts that extend at an angle of about 90 degrees with respect to the plug pins, wherein the contacts are disposed between the base member and the cover. A ratio of an overall plug assembly thickness over a plug pin thickness is less than about 1.5.

Owner:SC JOHNSON & SON INC

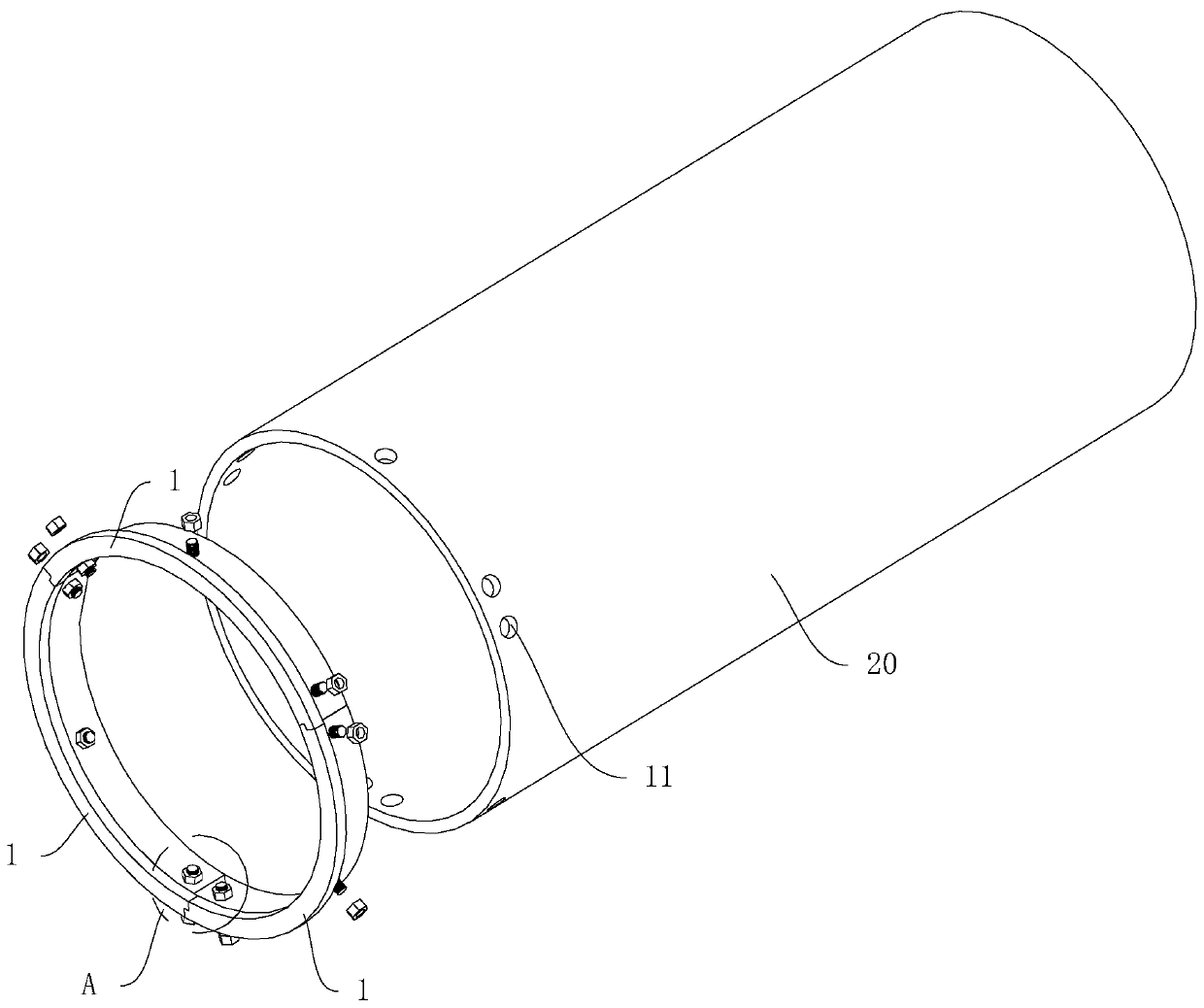

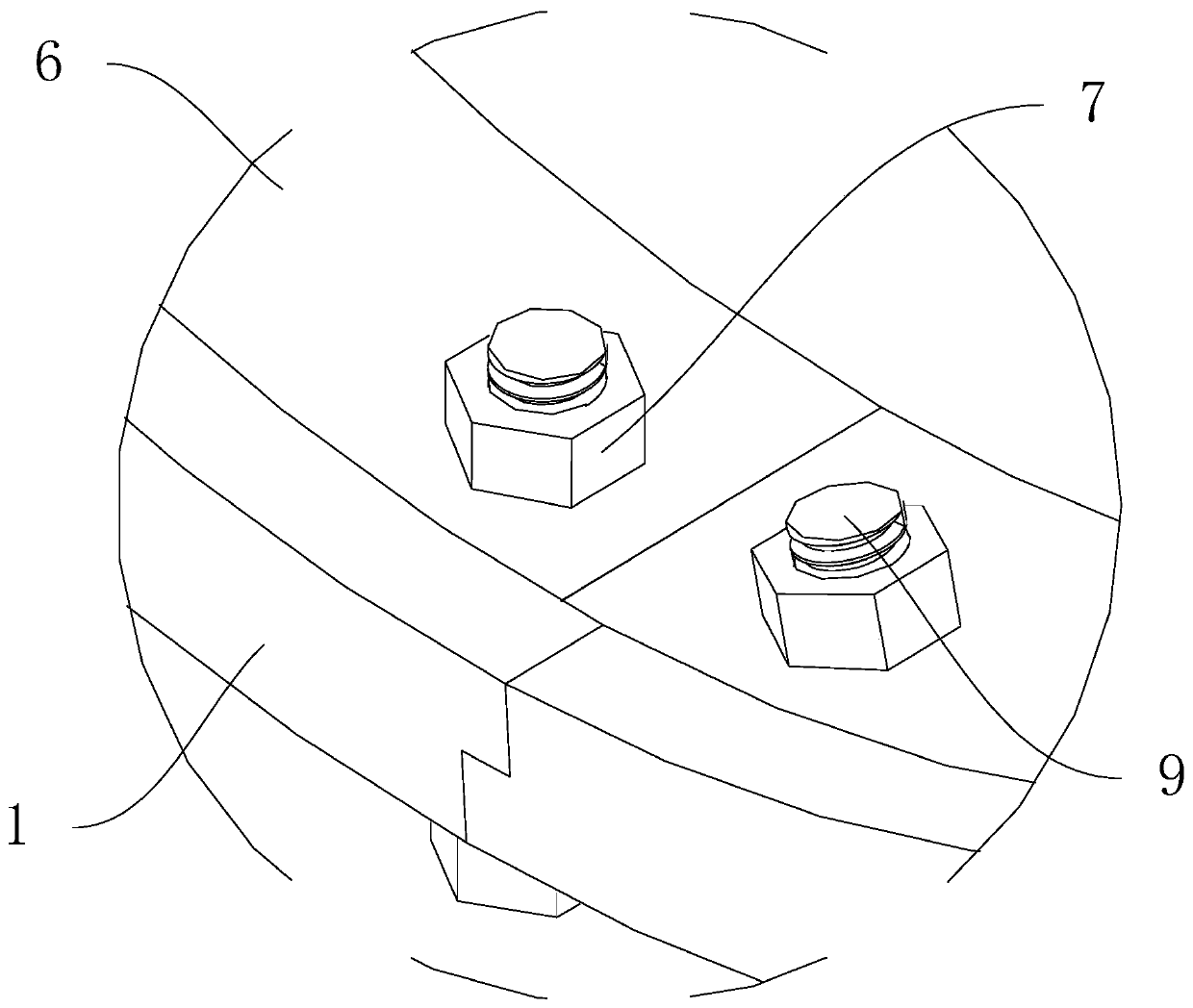

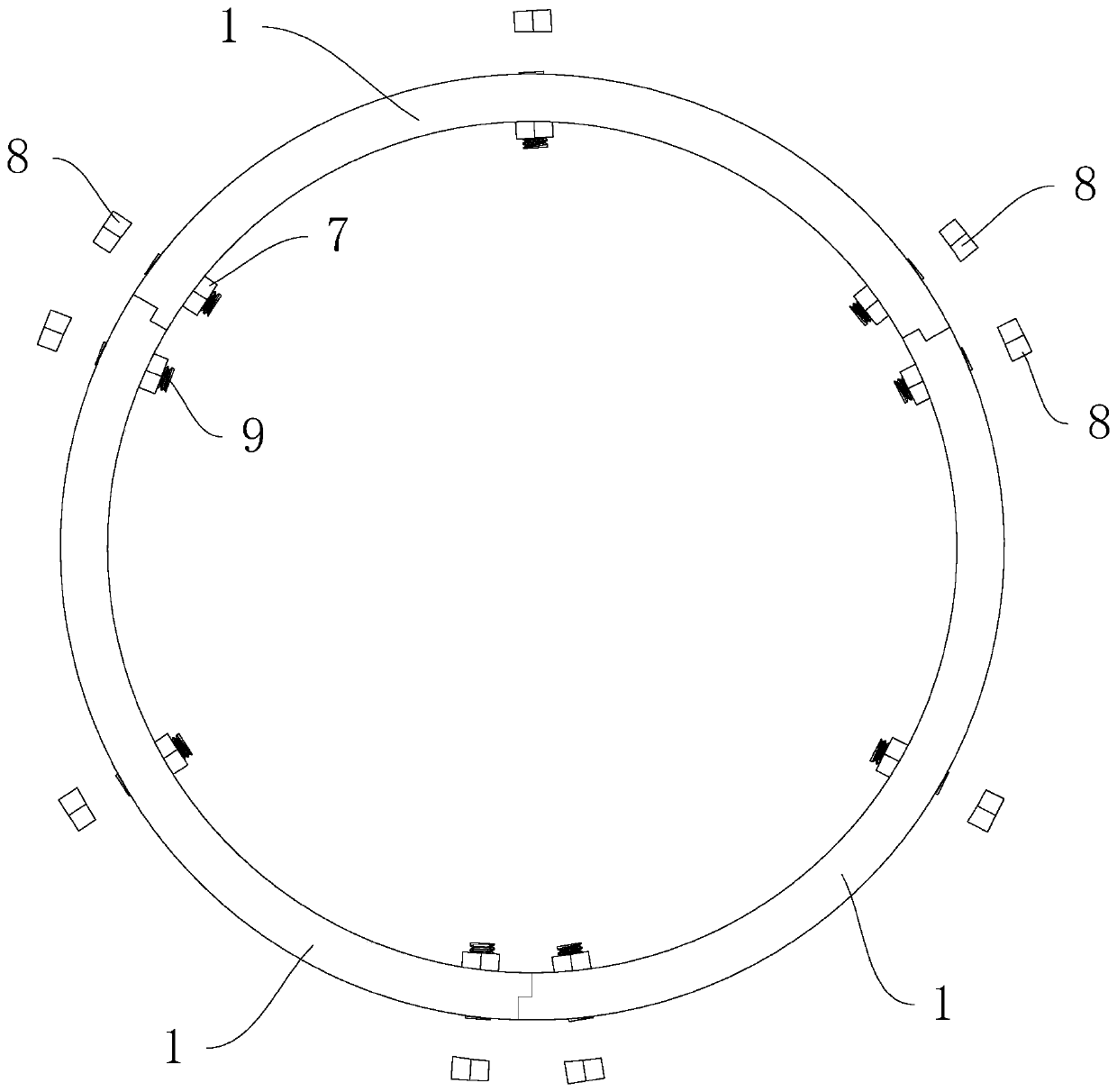

Heat preservation cylinder clamping groove device for sintering furnace

ActiveCN111043857AReduce mechanical strainAvoid scourCharge treatment typeHeat conservationEngineering

The invention belongs to the technical field of sintering furnace parts and relates to a heat preservation cylinder clamping groove device for a sintering furnace. The device comprises a plurality ofend face clamping strips which can be spliced with one another; all the end face clamping strips can be spliced into an annular support coaxial with a heat preservation cylinder; the inner diameter ofthe annular support is smaller than that of the heat preservation cylinder; one side face of each end face clamping strip can be tightly attached to the end face of the heat preservation cylinder, wherein the side face of each end face clamping strip a sealing face; the sealing faces of the end face clamping strips are provided with flow-resisting blocking edges extending in the axial direction of the heat preservation cylinder; the flow-resisting blocking edges can be spliced with one another to form a flow-resisting ring which is coaxial with the annular support and is attached to the innersurface of the end part of the heat preservation cylinder; the flow-resisting blocking edges are curved strips; the inner arc surface of each of the flow-resisting blocking edges can be closely adhere to the inner wall surface of the heat preservation cylinder through a locking mechanism. According to the heat preservation cylinder clamping groove device for the sintering furnace of the invention, the use damage of the heat preservation cylinder can be decreased, and therefore, the stability of the heat preservation cylinder can be improved, and the service life of the heat preservation cylinder can be prolonged.

Owner:ZHUZHOU RUIDEER METALLURGICAL EQUIP MFG CO LTD

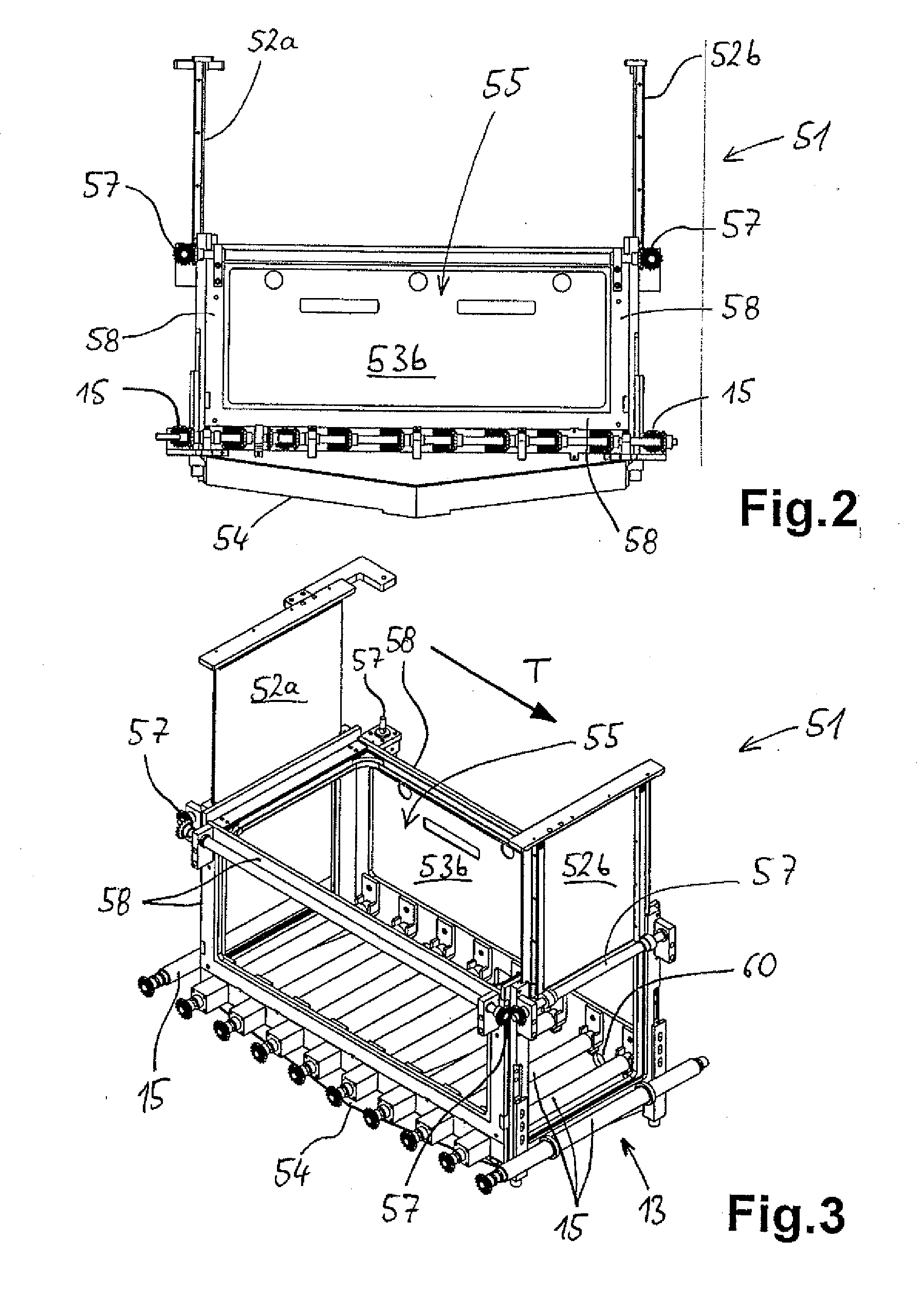

Method for detaching wafers from a wafer carrier and device for this purpose

InactiveUS20110209324A1Reduce mechanical strainPrevent fallingAdhesive processes with adhesive heatingSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

In a method for detaching wafers from a carrier unit, the wafers being formed by sawing a wafer block fastened to the carrier unit by gluing, and the wafers themselves still being glued on one side, the carrier unit with the wafers is introduced into an ungluing unit along a uniform movement plane. It remains therein and is enclosed in an ungluing basin by movable wall parts. Solvent for ungluing is applied into the ungluing basin and onto the wafers after the formation and closing of the ungluing basin to dissolve the glued bond and subsequently detach the wafers from the carrier unit.

Owner:GEBR SCHMID GMBH & CO

Patch and sensor assembly for use in medical device localization and mapping systems

An patch and sensor assembly for use in an EP mapping system has two portions: a reusable portion and a disposable portion. The reusable portion houses the biosensors used in magnetic based location and mapping systems and the electrical lead necessary to communicate between the biosensor and the mapping system. The reusable portion may also contain a portion of the electrode necessary to receive electrical signals from the body of the patient. The disposable portion of the patch and sensor assembly contains an adhesive covered flexible patch having at least a portion of the electrode used to receive electrical signals form the body of the patient and may contain the electrical lead necessary to communicate such an electrical signal to the mapping system. The disposable portion contains a receptacle adapted to receive and mechanically secure the reusable portion to the disposable portion of the assembly. Such a patch and sensor assembly is useful in hybrid magnetic and impedance based location and mapping systems such as those used in electrophysiology.

Owner:BIOSENSE WEBSTER INC

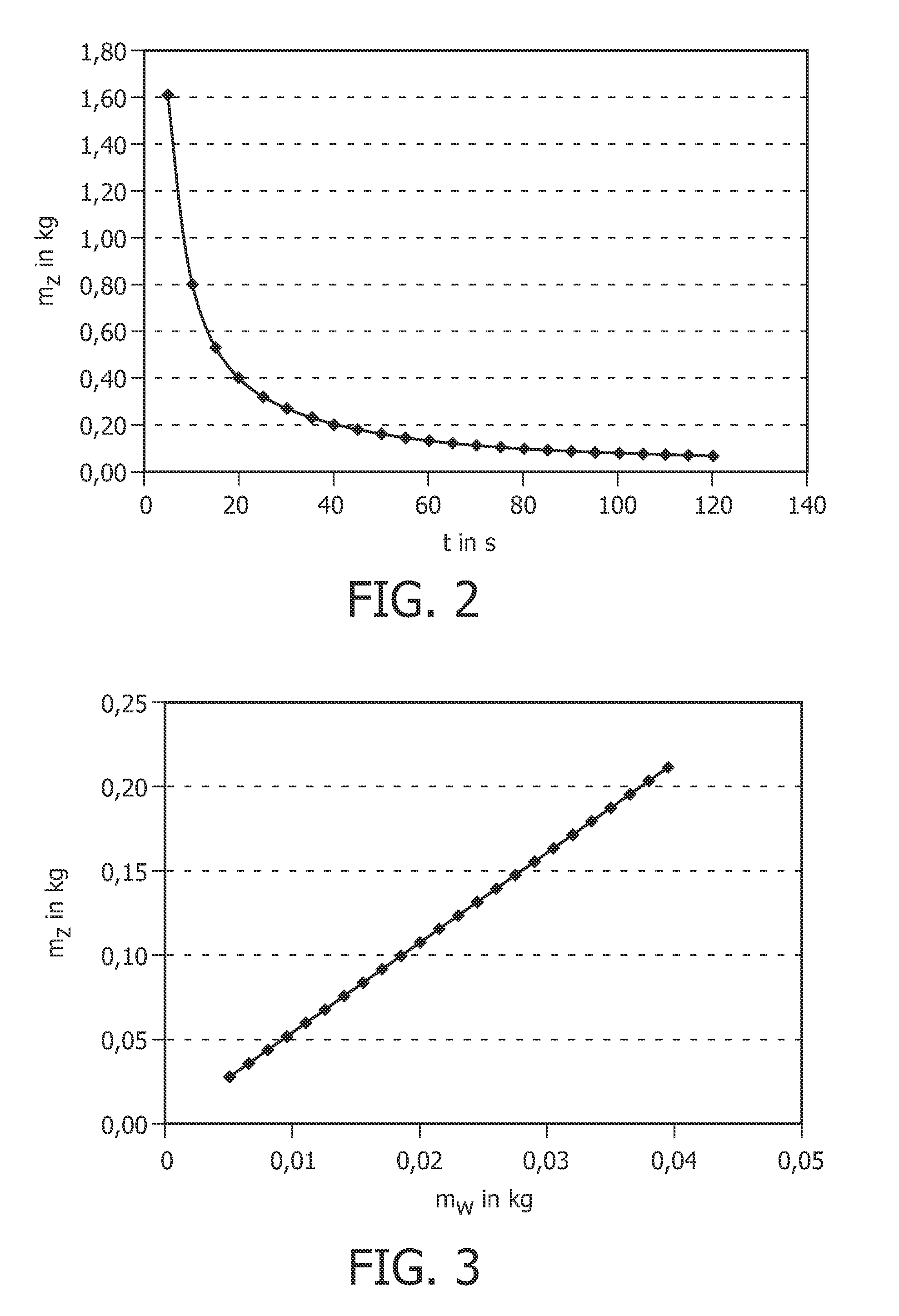

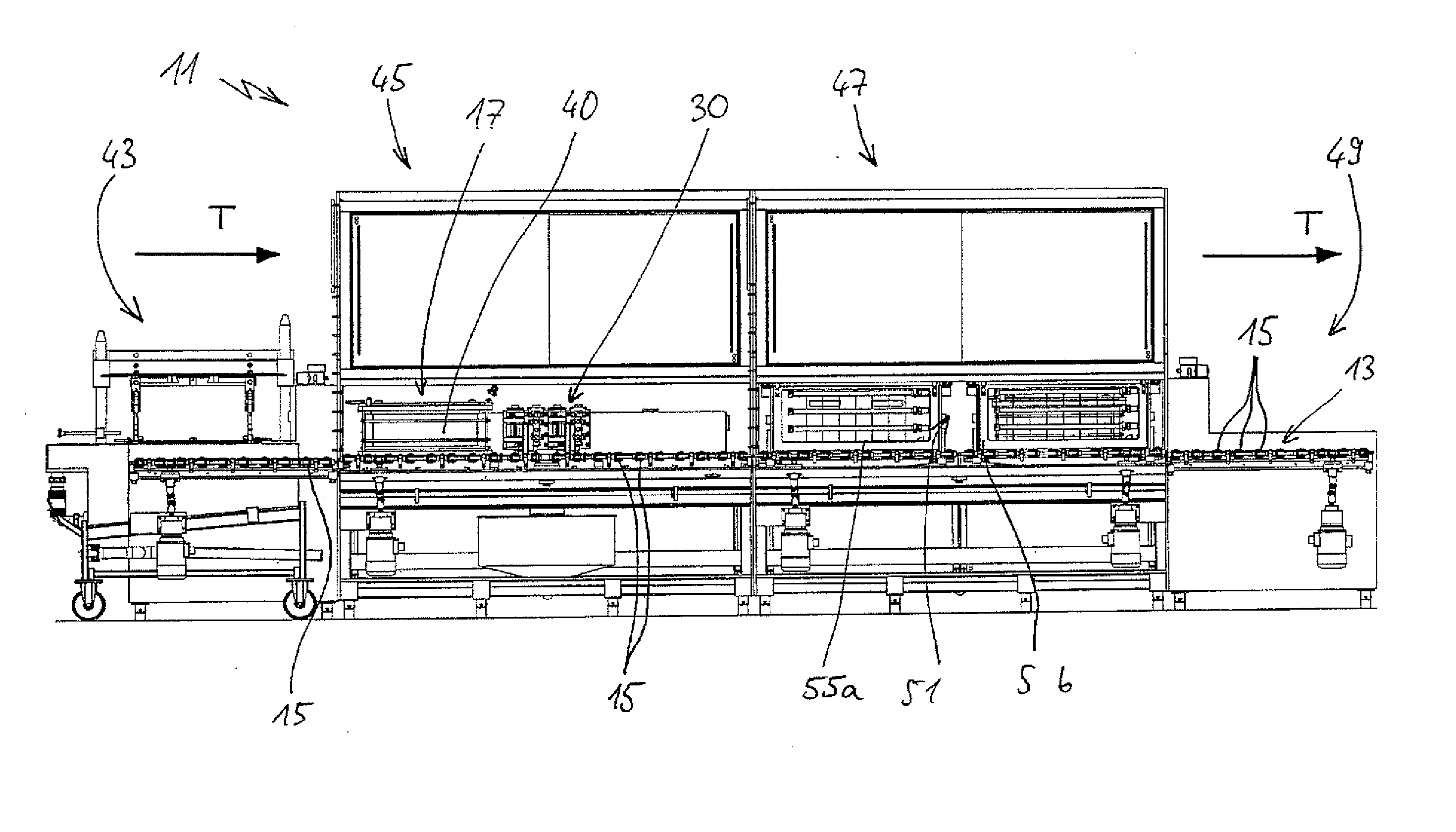

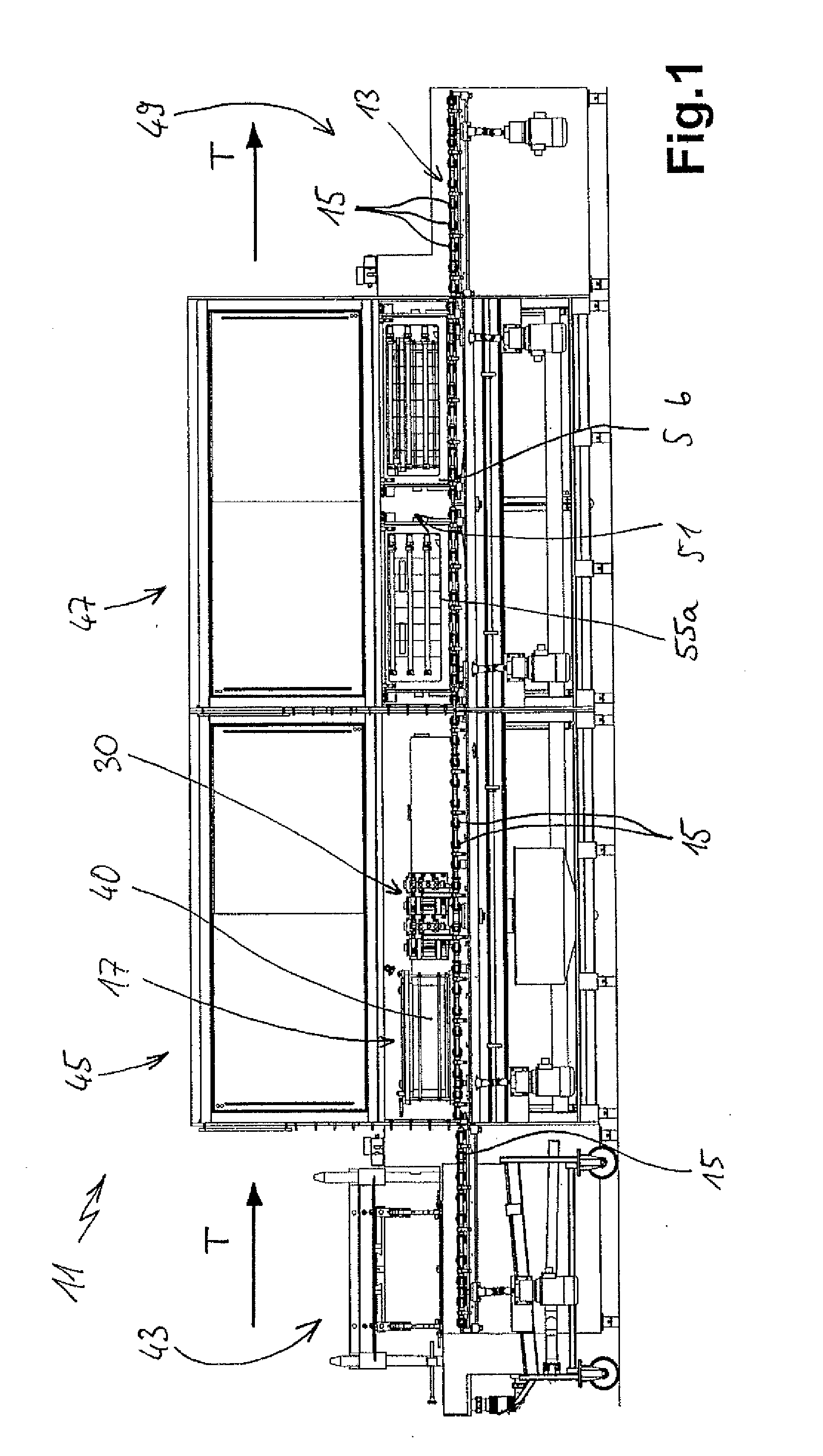

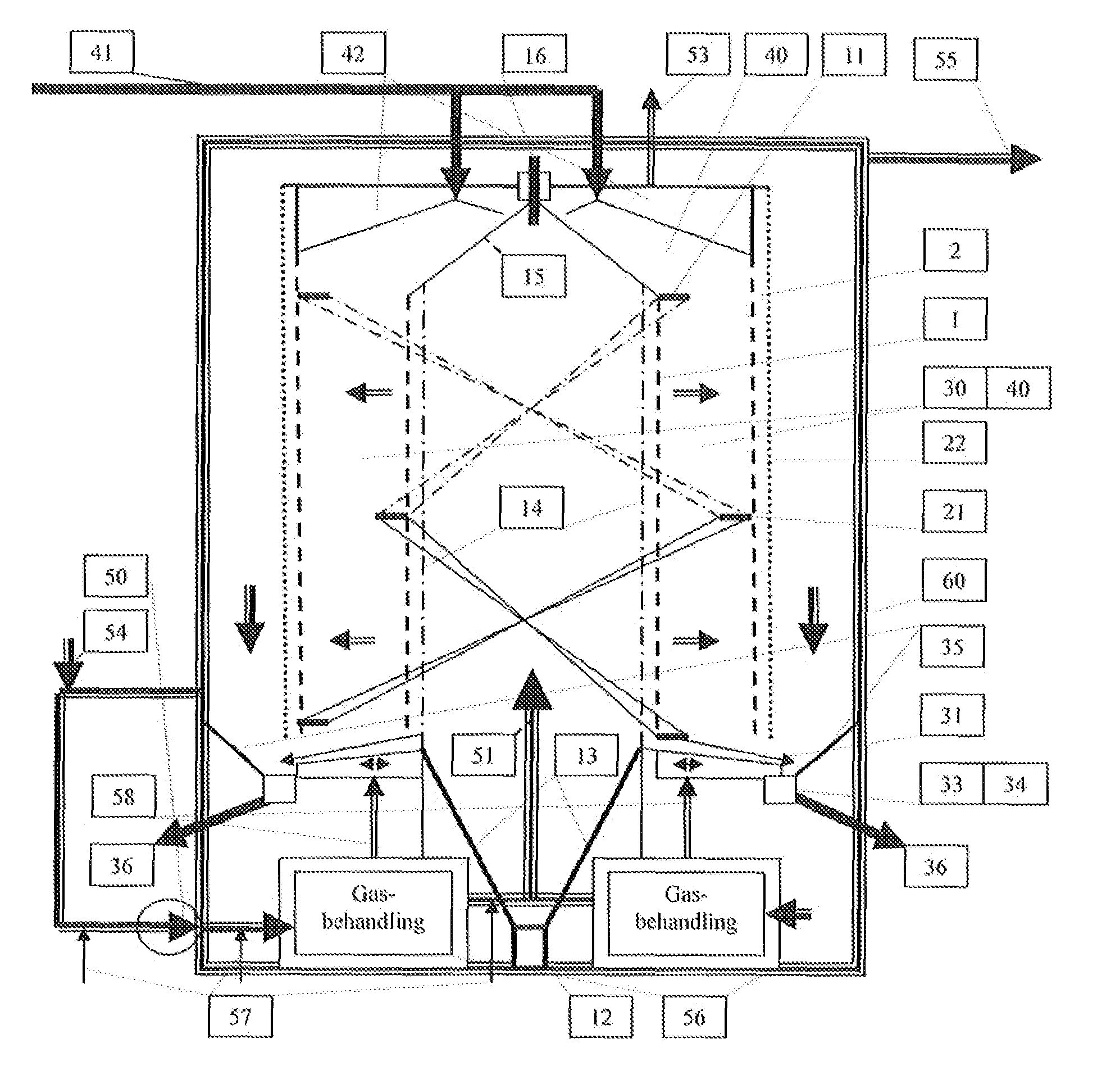

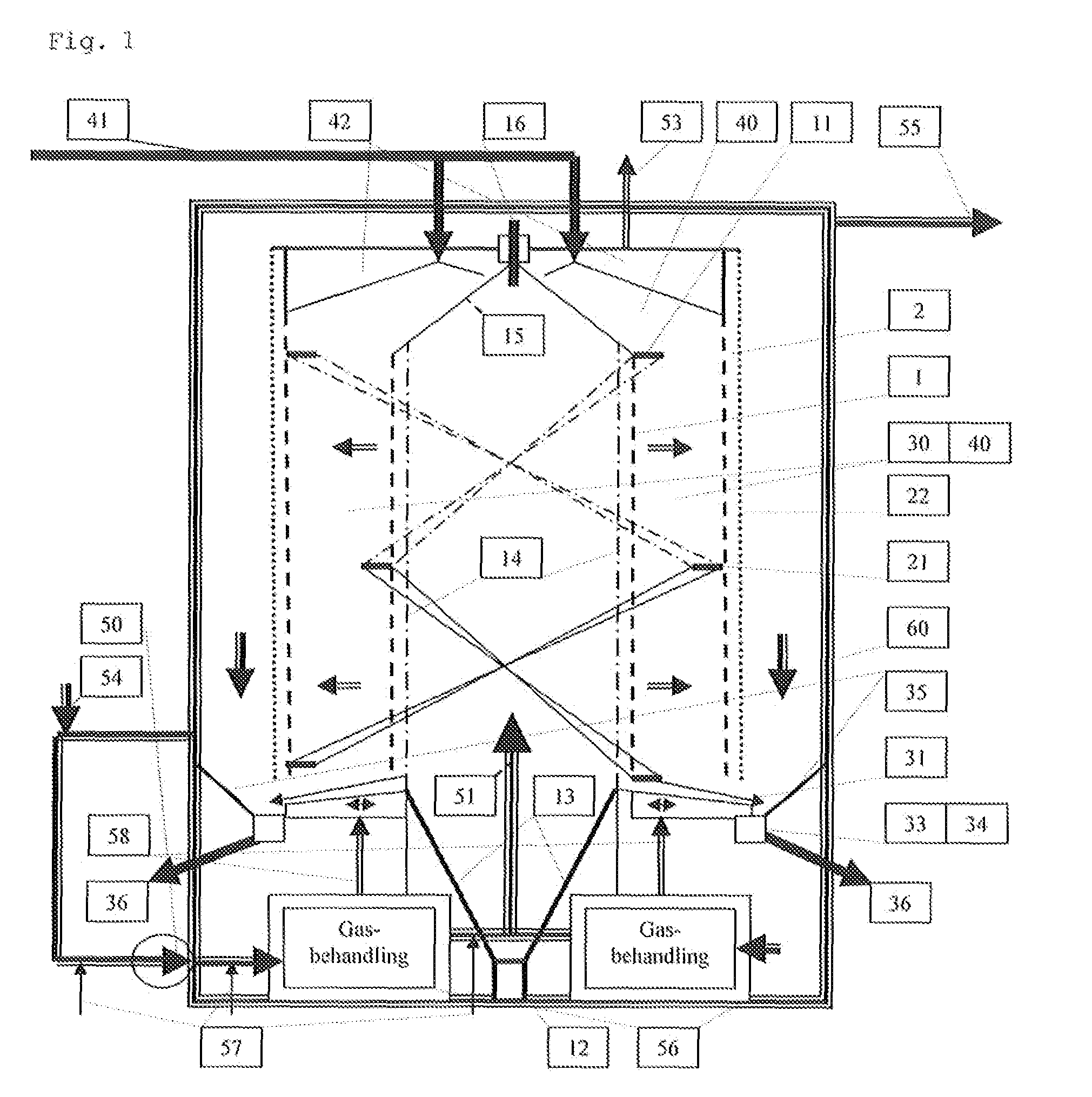

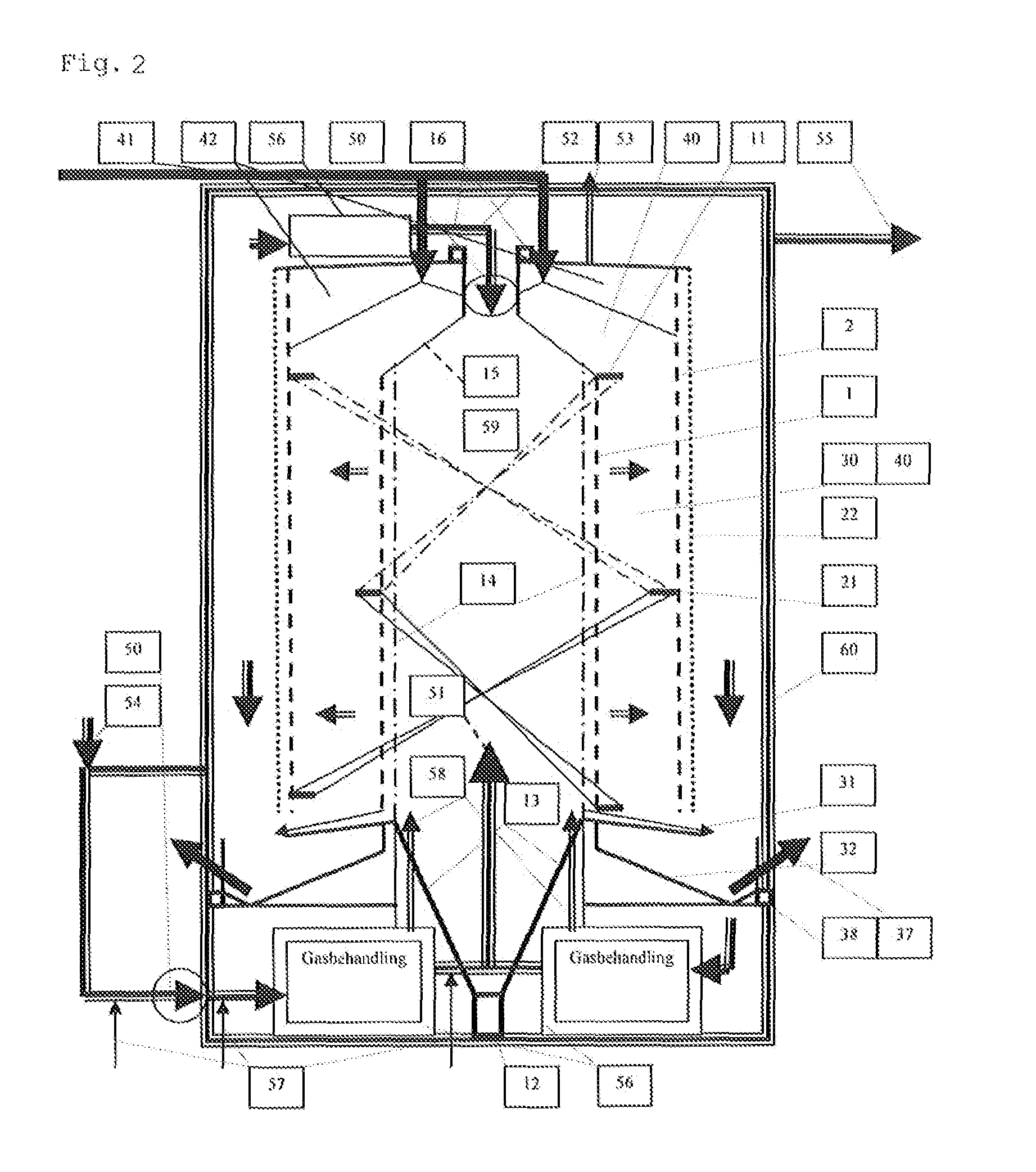

Means for drying of a particulate material with a gas

InactiveUS20120036731A1Reduce mechanical strainDrying machines with progressive movementsPorosityParticulates

A device to bring a gas into contact with a particulate solid bulk material, comprising a first and a second tubular, radially gas-permeable element (1, 2) having different diameters and which each define a central axis, wherein one of the elements is essentially coaxially placed in the second element, wherein the elements (1, 2) internally define a ring-shaped shaft (30) for a material (40) that is to be contacted by the gas, wherein the elements have essentially vertically oriented axes, a ventilation device (50) for compelling the gas radially through the shaft and the material, a first device (41) for addition of the material to an upper end of the shaft (30) and a second device (31-36) for output of dried material from the lower end of the shaft. Driving means (12) are provided for internal displacement of the elements (1, 2). At least one of the walls is provided with at least one screw line ramp which maintains a high porosity and a controlled feeding of the material.

Owner:ANG BYHAMMAR TOMAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com