Feeding mechanism of blender

A mixing machine and material feeding technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of poor versatility of the feeding machine, achieve the effect of simple structure, avoid repeated start and stop, and reduce mechanical strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

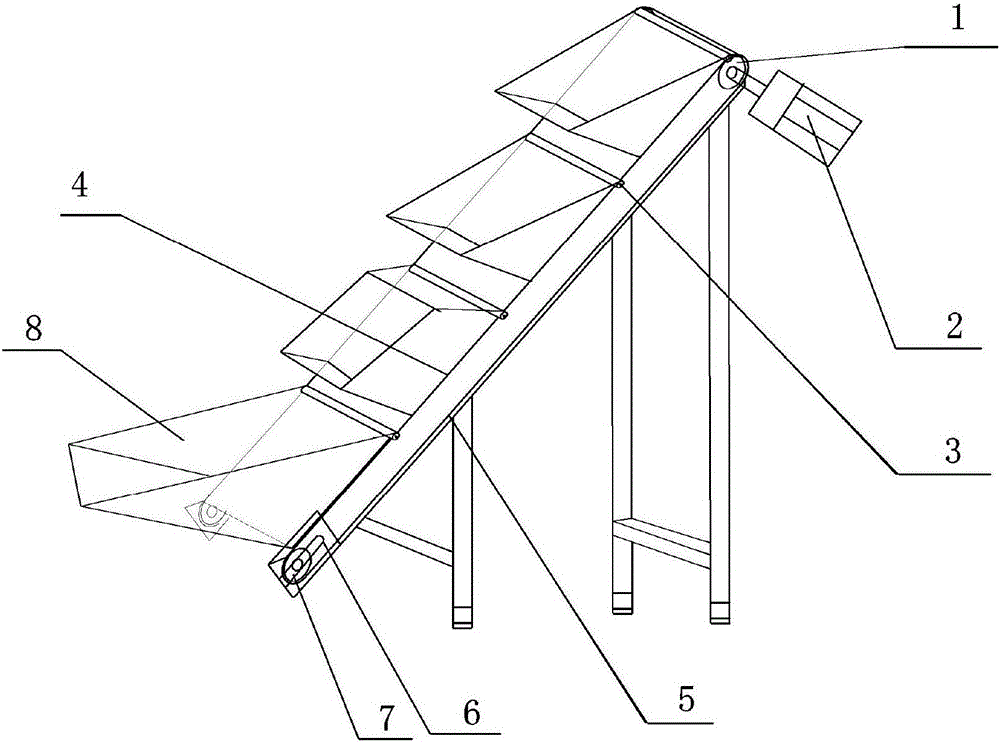

[0011] A feeding mechanism for a mixer, comprising a motor 2, a bracket 5, a conveyor belt 4 and a hopper 8, the conveyor belt 4 is an endless conveyor belt, and the conveyor belt 4 is fixedly installed with a horizontal shaft 3 at fixed intervals, and the horizontal shaft 3 is provided with A bushing that can rotate around the horizontal axis 3, each bushing is connected to a hopper 8, the conveyor belt 4 is installed on the bracket 5, and the driving roller 1 is set on the upper top of the bracket 5, and the tensioning roller is set on the lower end of the bracket 5 7. The conveyor belt 4 is set outside the driving drum 1 and the tensioning drum 7, and the driving drum 1 is connected with the motor 2.

[0012] The tensioning roller 7 is installed on the tensioning device 6 arranged at the bottom of the bracket 5 .

[0013] The hopper 8 may be a triangular hopper with triangular sides, or a square hopper with quadrilateral sides.

[0014] When feeding and stirring, different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com