Barium strontium titanate based aluminum oxide composite ceramic with high energy storage density and preparation method of barium strontium titanate based aluminum oxide composite ceramic

A technology with high energy storage density and barium strontium titanate, which is applied in the field of dielectric materials for energy storage capacitors, can solve the problems of reduced polarization, low energy storage density, and improved breakdown strength, so as to achieve increased energy storage density and improved dielectric strength. Effect of improving electrical breakdown strength and dielectric breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

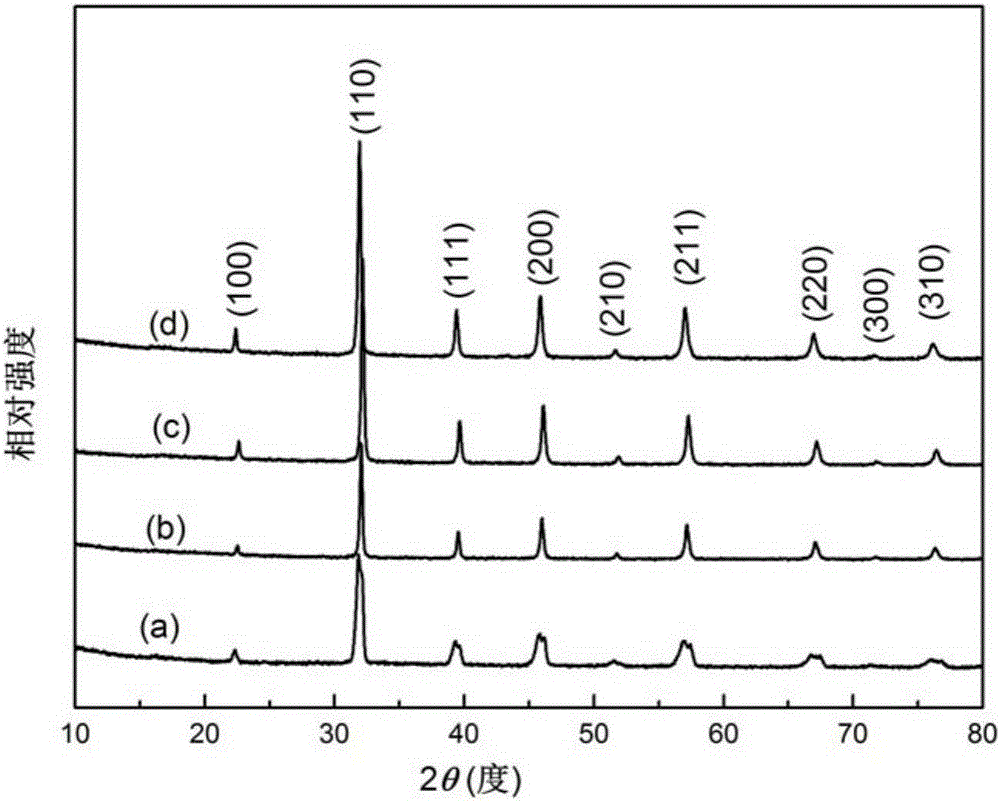

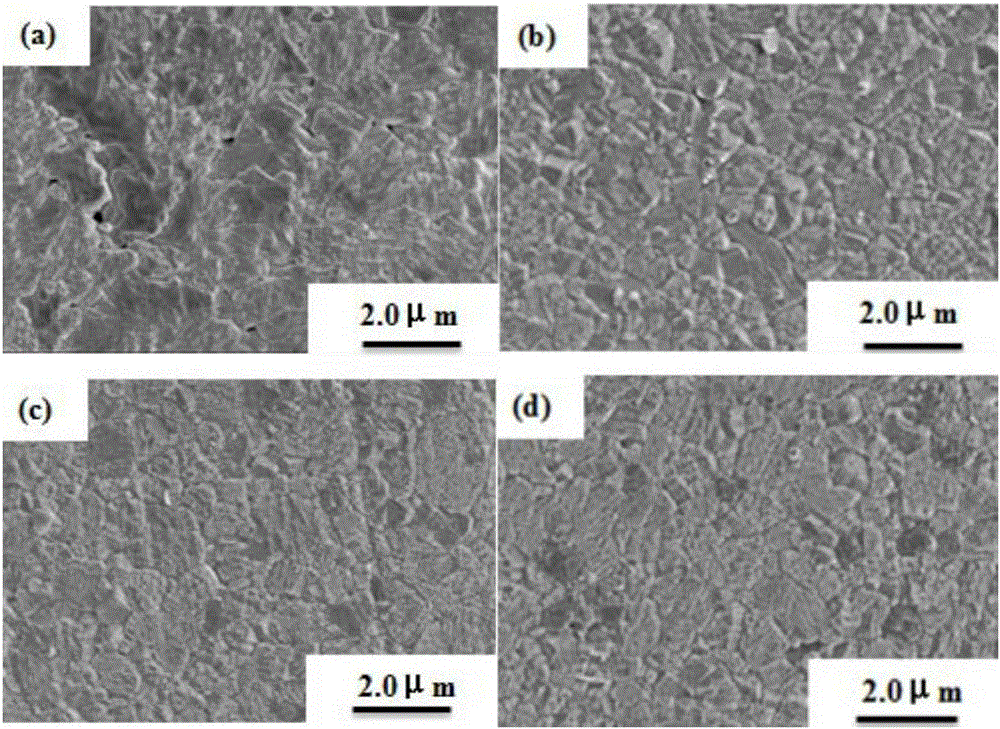

Embodiment 1

[0023] (1) The raw material BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.4 Sr 0.6 TiO 3 Chemical formula ingredients, grind to a particle size of 100nm-500nm, dry and sieve;

[0024] (2) After calcining the powder prepared in step (1) at 1150°C for 3 hours, sieve to obtain Ba 0.4 Sr 0.6 TiO 3 Powder;

[0025] (3) Ba obtained from step (2) 0.4 Sr 0.6 TiO 3 Powder and Al 2 o 3 The powder is batched according to the mass ratio of 100:1, dried after grinding, and sieved to obtain ceramic powder;

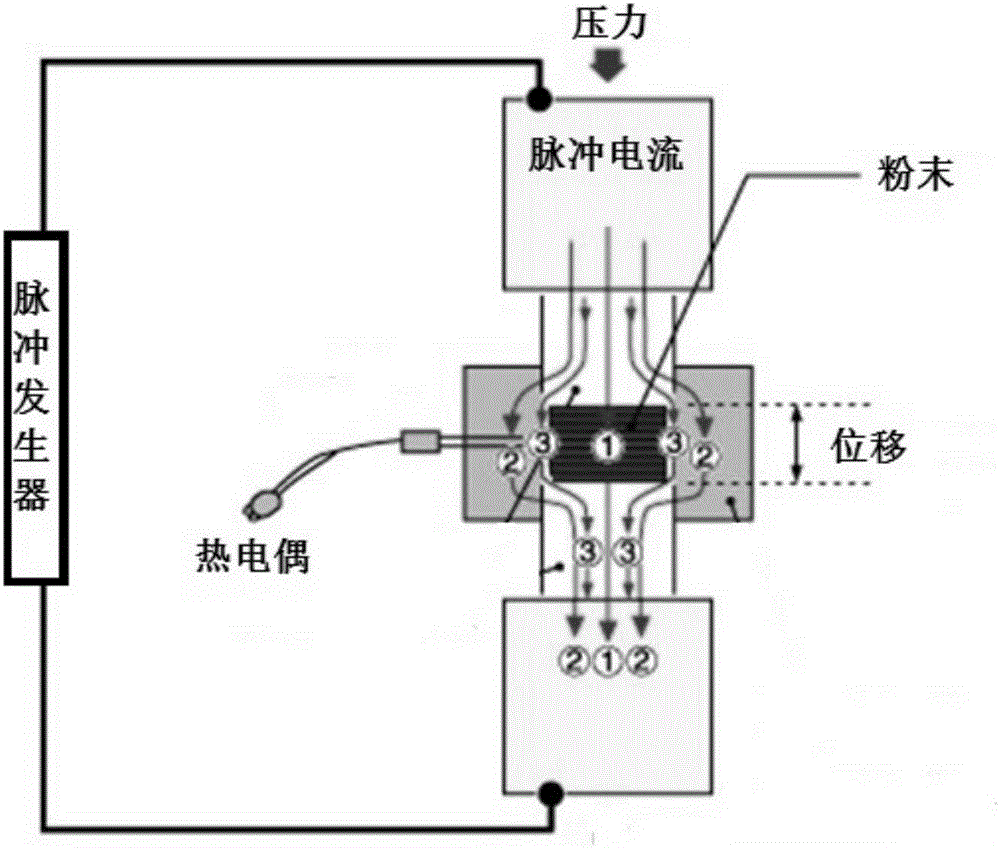

[0026] (4) Load the ceramic powder prepared in step (3) into a mold, and sinter in a vacuum environment at 1000° C. by using a spark plasma sintering system to obtain a ceramic sintered body;

[0027] (5) Under the air atmosphere, the ceramic sintered body prepared in step (4) was heat-treated at 1100° C. for 3 hours to obtain a high energy storage density of 98wt.% Ba 0.4 Sr 0.6 TiO 3 –1wt.%Al 2 o 3 Composite ceramics.

[0028] The principle of SPS sintering is: SPS uses DC ...

Embodiment 2

[0030] (1) The raw material BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.4 Sr 0.6 TiO 3 Chemical formula ingredients, grind to a particle size of 100nm-500nm, dry and sieve;

[0031] (2) After calcining the powder prepared in step (1) at 1150°C for 3 hours, sieve to obtain Ba 0.4 Sr 0.6 TiO 3 Powder;

[0032] (3) Ba obtained from step (2) 0.4 Sr 0.6 TiO 3 Powder and Al 2 o 3 The powder is batched according to the mass ratio of 100:2, dried after grinding, and sieved to obtain ceramic powder;

[0033] (4) Load the ceramic powder prepared in step (3) into a mold, and sinter in a vacuum environment at 1000° C. by using a spark plasma sintering system to obtain a ceramic sintered body;

[0034] (5) Under the air atmosphere, the ceramic sintered body prepared in step (4) was heat-treated at 1100° C. for 3 hours to obtain a high energy storage density of 98wt.% Ba 0.4 Sr 0.6 TiO 3 –2wt.%Al 2 o 3 Composite ceramics.

Embodiment 3

[0036] (1) The raw material BaCO 3 , SrCO 3 and TiO 2 Press Ba 0.4 Sr 0.6 TiO 3 Chemical formula ingredients, grind to a particle size of 100nm-500nm, dry and sieve;

[0037] (2) After calcining the powder prepared in step (1) at 1150°C for 3 hours, sieve to obtain Ba 0.4 Sr 0.6 TiO 3 Powder;

[0038] (3) Ba obtained from step (2) 0.4 Sr 0.6 TiO 3 Powder and Al 2 o 3 The powder is batched according to the mass ratio of 100:5, dried after grinding, and sieved to obtain ceramic powder;

[0039] (4) Load the ceramic powder prepared in step (3) into a mold, and sinter in a vacuum environment at 1000° C. by using a spark plasma sintering system to obtain a ceramic sintered body;

[0040] (5) Under the air atmosphere, the ceramic sintered body prepared in step (4) was heat-treated at 1100° C. for 3 hours to obtain a high energy storage density of 98wt.% Ba 0.4 Sr 0.6 TiO 3 –5wt.%Al 2 o 3 Composite ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com