Polypropylene-based high-voltage direct-current cable material and preparation method thereof

A high-voltage DC, polypropylene-based technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of limited use, high brittleness, poor low-temperature impact performance, etc., to improve impact performance, easy recycling, Good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

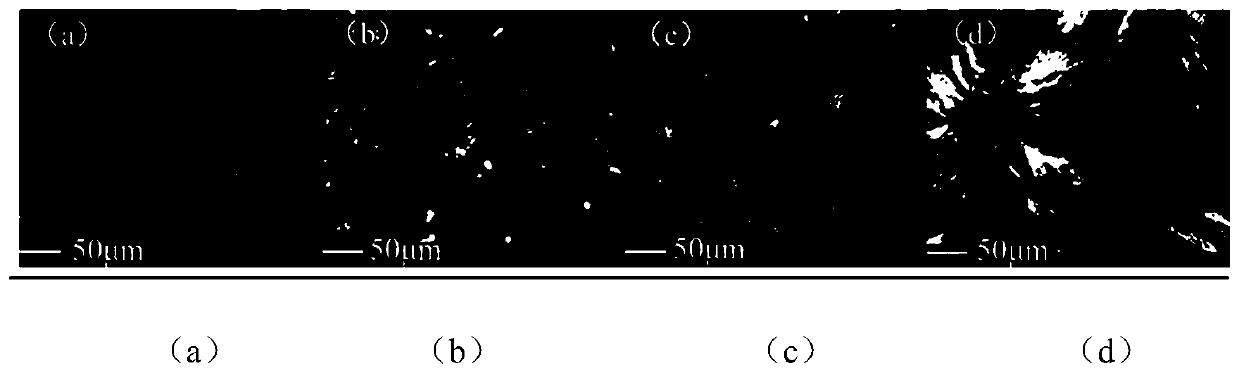

Image

Examples

preparation example Construction

[0031] The preparation method of the polypropylene-based high-voltage DC cable material of the present invention, in order to ensure that the nucleating agent is uniformly and stably dispersed in the polypropylene, adopts the masterbatch method and the step-by-step formula to prepare the finished material, specifically comprising the following steps:

[0032] 1) Preparation of polypropylene masterbatch containing β-nucleating agent: add isotactic polypropylene (iPP) and nucleating agent in proportion to the micro-twin-screw mixer for melt blending, and set the temperature of each zone of the screw to (195 ~ between 200°C), feed port speed (8-12rpm), screw speed (150-200rpm), after twin-screw mixing and extrusion to obtain a polypropylene masterbatch containing 5% 10% beta nucleating agent.

[0033] 2) Preparation of semi-finished materials: Add polypropylene masterbatch and polypropylene containing 5% to 10% β-nucleating agent in proportion to melt blending in a micro-twin-scre...

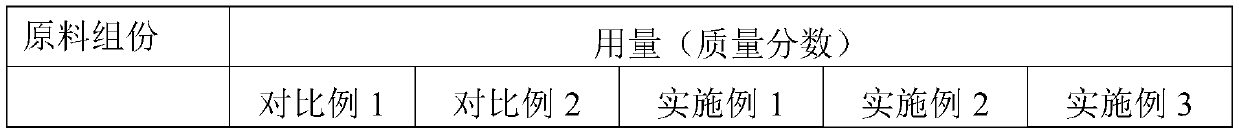

Embodiment 1

[0042] Example 1: In terms of parts by mass, 70 parts of ethylene-propylene block copolymerized polypropylene, 30 parts of isotactic polypropylene, and 300 parts of antioxidant were added.

Embodiment 2

[0043] Embodiment 2: In terms of parts by mass, 60 parts of ethylene-propylene block copolymerized polypropylenes, 40 parts of isotactic polypropylenes, 0.12 parts of rare earth nucleating agents, and addition of antioxidant 1010 (tetra[beta-(3,5 -di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester), antioxidant 168 (tris(2.4-di-tert-butylphenyl) phosphite), antioxidant 300 (4,4'- Thiobis(6-tert-butyl-3-methylphenol)) were 0.1, 0.2, 0.1 parts respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com